Title Page

-

Project / Site

-

Lead Contractor

-

Conducted on

-

Prepared by

-

This audit is an assessment of the conditions and activities on the worksite(s) at the time of the visit. The assessment points are assessed against agreed expectations between PCBU’s, legislative and regulatory requirements and/or industry best practice.

…

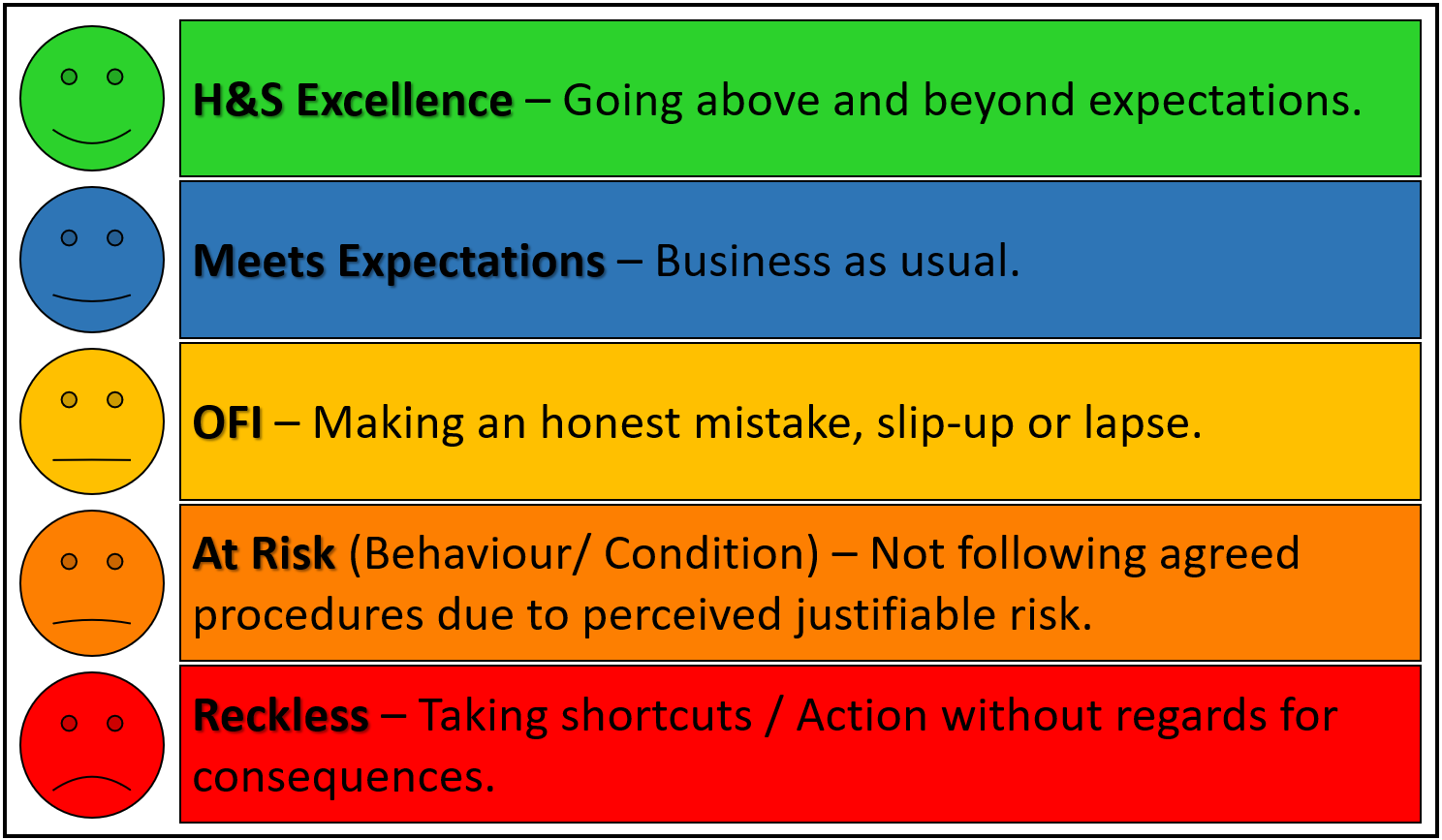

Assessment Criteria:

…

Meets Expectations (ME) = The assessed condition or activity meets current expectations.

...

Opportunity For Improvement (OFI) = The assessed condition or activity does not fully meet current expectations.

...

At Risk (AR) = The assessed condition or activity does not fully meet current expectations and as a result there is an intolerable level of risk of harm to people, the environment and/or the business.

...

Not Checked (NC) = The condition or activity was not checked.

...

Not Applicable (NA) = The condition or activity was not present.

Critical Risk Activities

-

Select the Critical Risk Activity you are reviewing?

- Working at Heights

- Heavy Machinery and Excavations

- Lifting Operations/ Cranage

- Working around Live Services

Working At Heights - General

-

Is there a Task Risk Assessment in place for Working at Heights activities (proof of regular review and communicated to all workers involved)?

-

Activity Pre-Start completed?

-

Workers use safe means of access e.g. ladder, EWP, scaffold etc.

-

Is there risk of falling to a lower level?

-

Ladders of commercial grade and used correctly?

-

Exclusion zones implemented for overhead work activities?

-

Safety harness worn and used correctly where required? i.e appropriate lanyard lengths, hook on points.

Scaffold

-

Is there any scaffold on site?

-

Scaffold inspected by a competent person (competency of scaffold inspector verified)?

-

Has a handover certificate been issued for the scaffold?

-

Is the scaffold tagged and has it been inspected within the last 7 days?

-

Are scaffold jacks sitting squarely on the sole boards?

-

Is the access point gated and is it self-closing?

-

Are there any scaffold components missing e.g. braces, hand rails, mid rails, toe boards etc.

-

Housekeeping maintained on scaffold platforms / landings (safe access and egress)?

-

Are scaffold planks secured / tied down?

-

Scaffold planks in good condition (pitting, excessive rust, splitting / saw cuts in timber planks etc.)?

-

Gaps between scaffold platform and work face do not exceed 300 mm?

-

Gaps between the planks/ bays do not exceed 50 mm?

-

Mobile scaffold's erected as per manufacturer's instructions?

Safety Nets

-

Are there any safety nets installed or safety harnesses in use on site?

-

Safety nets installed where required and to standard?

-

Safety nets certificate available for inspection?

-

Safety nets in a good condition (visible signs of damage to the safety net system)?

-

Have the nets been installed as close as is reasonably practicable to the underside of<br>the work platform?

-

Are all gaps between net and structure less than 100 mm?

-

Is the net clear of debris?

Elevated Work Platforms

-

Are there any EWP's on site?

-

EWP operator certified to operate equipment?

-

EWP inspected prior to use?

-

EWP used in accordance with manufacturers guidelines?

-

EWP maintenance intervals maintained (6-monthly)?

Lifting Operations

-

Is there a Task Risk Assessment in place for Lifting Operations/ Cranage (proof of regular review and communicated to all workers involved)?

-

Activity Pre-Start completed?

-

Crane certs in place and dates valid?

-

Crane operator licensed / certified to operate crane (HiAb US 16617 and Cranes US 3730)?

-

Rigger / Dogman certified and competent to conduct crane lifts (US 30072)?

-

Is there a lift plan in place & has it been communicated all workers involved?

-

Rigging and lifting gear in good condition with current tags / certificates?

-

Exclusion zones established?

-

Crane established on firm solid ground, outriggers fully extended and outrigger pads in place?

-

Tag lines used to control the load (where required e.g. wind conditions)?

-

No overhead lifting?

-

Is there evidence of overriding the crane safety system (e.g. disabling the anti-two block or crane safety system)?

Heavy Mchinery

-

Is there a Task Risk Assessment in place for Heavy Machinery (proof of regular review and communicated to all workers involved)?

-

Activity Pre-Start completed?

-

Exclusion zones implemented and maintained, where appropriate?

-

Equipment servicing up to date?

-

Equipment operators licensed to operate machinery?

-

Equipment inspected prior to use, faults identified & reported?

-

Spotters used during heavy machine operation?

-

Before U Dig plans obtained and check for live services conducted?

-

Are there any notifiable excavations or trenches on the worksite?

-

Is there a Task Risk Assessment in place for Excavations/ Trenches (proof of regular review and communicated to all workers involved)?

-

Activity Pre-Start completed?

-

Edge protection around open excavations or where there is a risk of fall onto a lower level?

-

Excavations shored and braced/ benched/ battered where required?

-

Safe access and egress provided into the excavation?

-

Is there a risk of a dangerous atmosphere (Confined Space scenario)?

-

Is there a Task Risk Assessment in place for Confined Spaces (proof of regular review and communicated to all workers involved)?

-

Does the Emergency Response Plan cover Confined Space rescue?

-

Are Confined Space activities correctly managed and meeting Confined Space requirements (i.e. permits, competency requirements etc.)?

Working Around Live Services

-

Is there a Task Risk Assessment in place for Working around Live Services (proof of review, communicated to and understood by all workers involved)?

-

Is there an Activity/ Daily Pre-Start conducted?

-

Before U Dig plans obtained (no older than 28 days from request date)?

-

Supporting evidence of service locations provided (as-builds, site mark up plans, GPR location etc.)?

-

Minimum Approach Distance (M.A.D) Permit obtained and adhered to (where required)?

-

Services de-energised/isolated where required?

-

Services marked and physically located/ verified (hand dug trial holes)?

-

Controls in place to prevent contact / damage? i.e. spotter, stand-over, mud bucket etc.

Observations

-

Any observations for items not covered in the critical risk criteria?

-

-

What was your Observation?

Click on the "+ button" over here ---->--->

Observation

-

What was your Worksite Observation?<br>(Select one of the following)