Title Page

-

Performed by

- Marcos cruz

- Roman Gomez

- Juan Carlos Ramirez

- Mario Macias

- Juan Macias

- Carlos Montijo

- Juan Vega

- Mario Moran

- Alex Rodriguez

- Eliseo Bombela

- Flor Valenzuela

- Cortez Johnson

-

Date/Time performed:

Hegla 3 Galactic Cutter PM - ONCE PER SHIFT

-

Change cutter wheel and axle.

-

Cutting Oil Level : Minimum 1/2 Full

-

Verify that cutting oil is minimum 1/2 full.

-

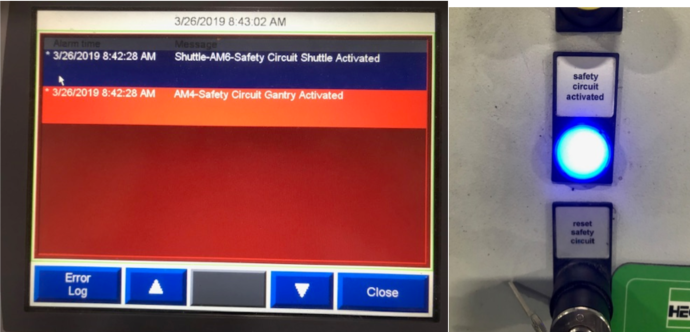

Verify all Safety Features (e.g. barriers, warning signals, etc.) are functioning

-

Verify that all safety features are functioning.

-

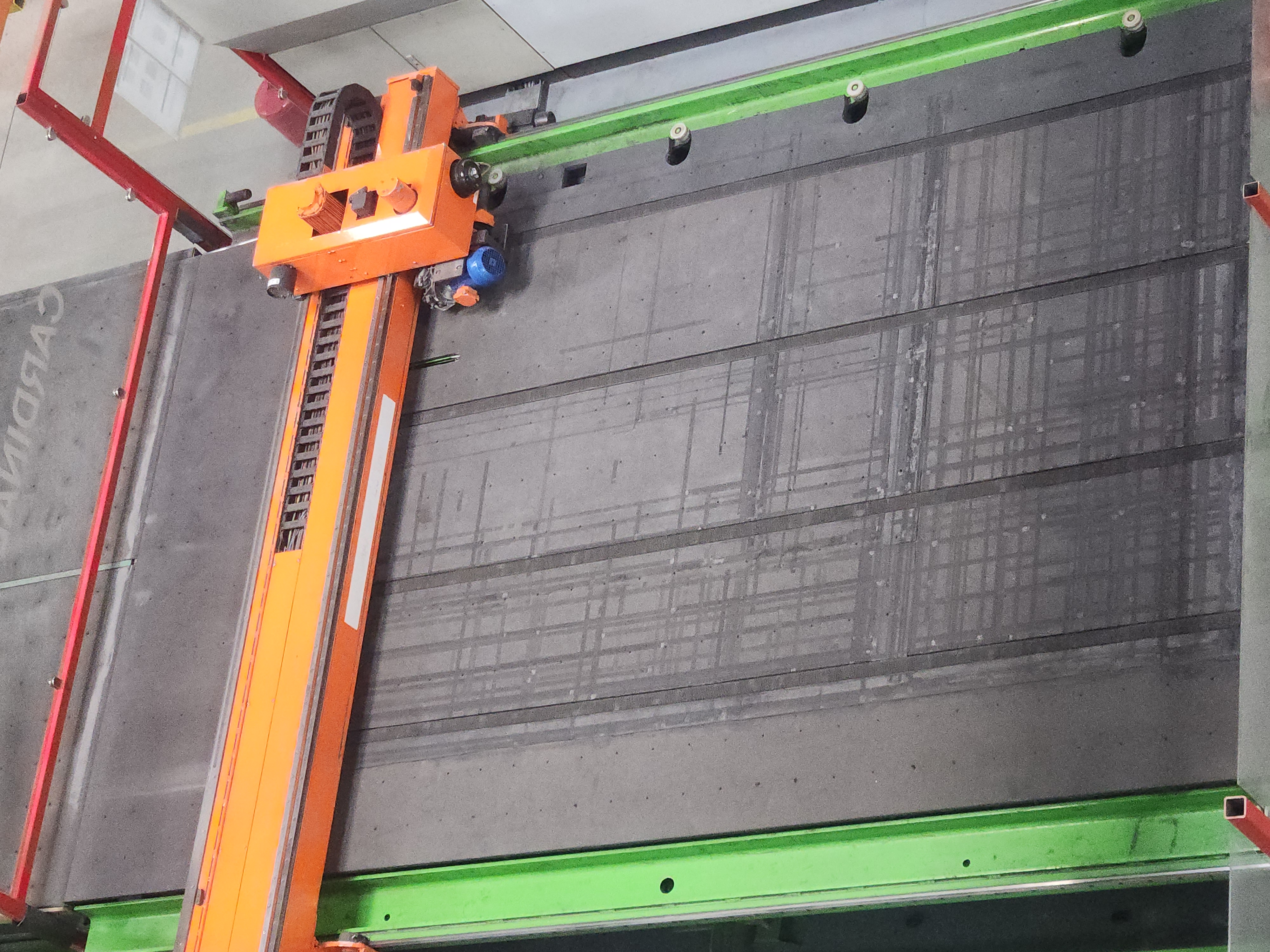

Blow off cutting table/breakout table felts thoroughly prior to shift start

-

Blow off cutting table/breakout table felts thoroughly prior to shift start.

-

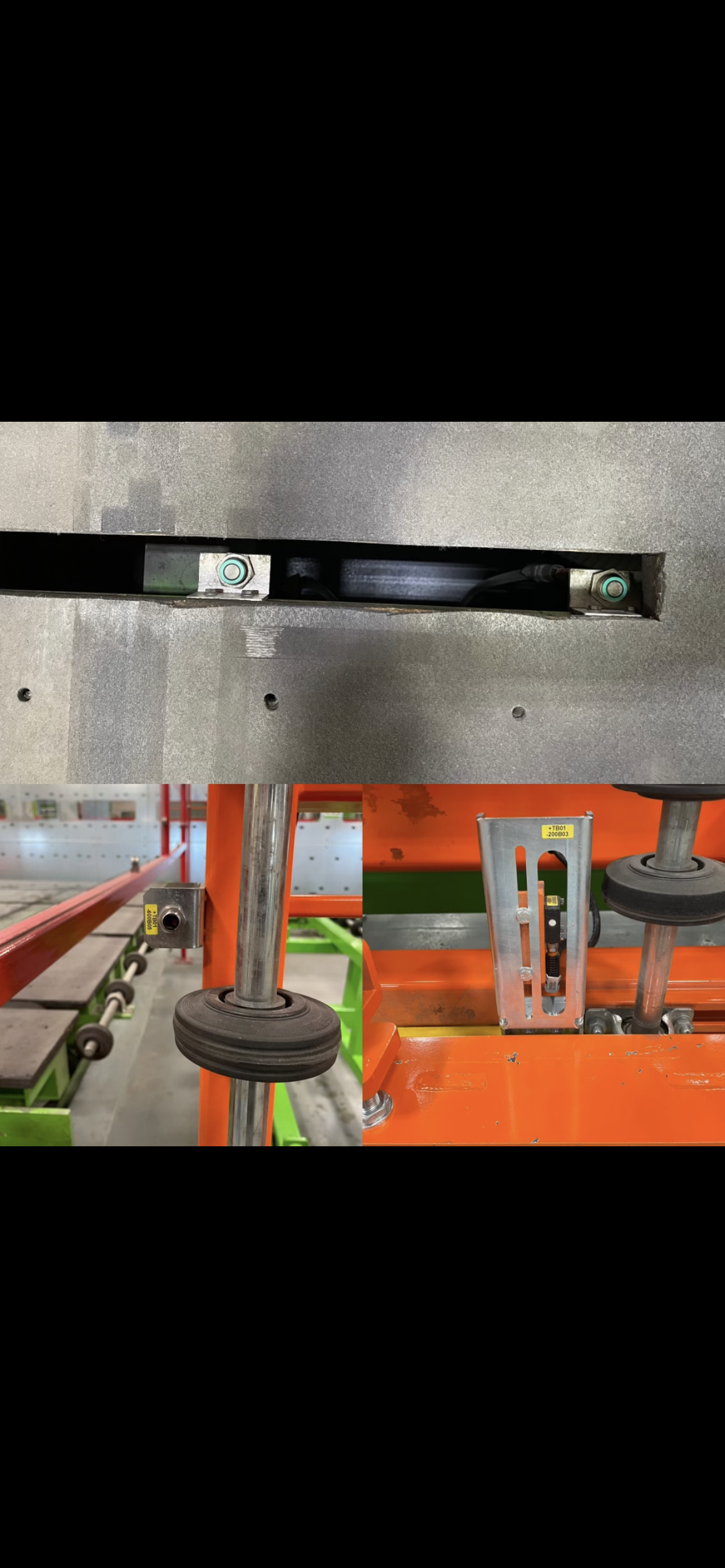

Clean all sensors with a lint free cloth. (Do not damage or shift sensors.)

-

Clean all sensors with a lint free cloth.

-

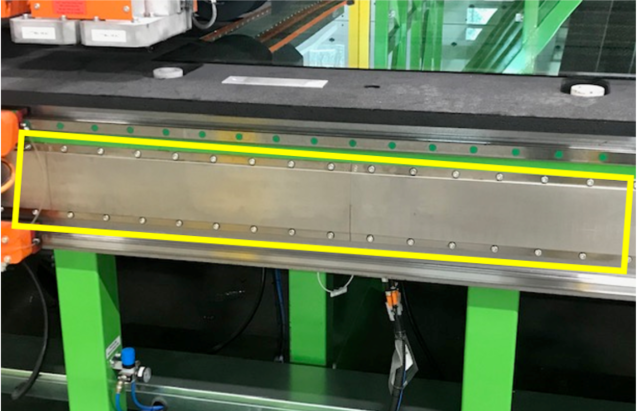

Clean and keep permanent magnets free of contamination. Use no more than glass cleaner as a cleaning agent and keep credit cards, phones, flash drives, etc. away from magnets as this will cause failure. These items should be placed in container hanging on glass wall before entering.

-

Clean magnets using no more than glass cleaner as cleaning agent.

-

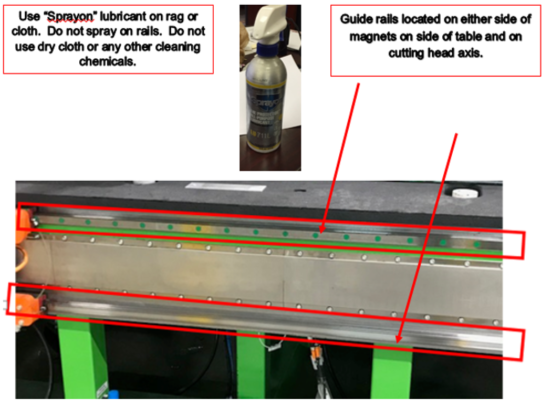

Clean guide rail and check for wear and debris.

-

Clean guide rail and check for ear and debris.

-

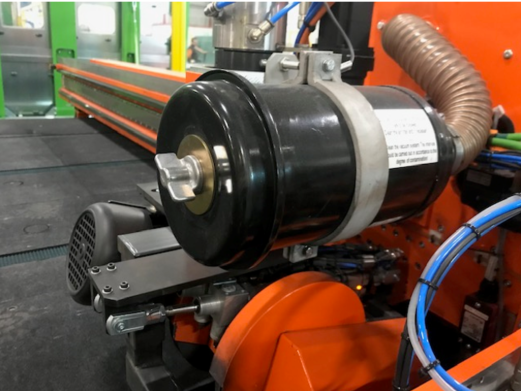

Check filter cartridge at the grinding head. Inform maintenance personnel if it needs changed.

-

Check filter cartridge at the grinding head. Inform maintenance personnel if it needs changed.

-

Check Auto Oiler Levels. Notify Maintenance if collar is at or near minimum level.

-

Check Auto Oiler Levels. Notify Mainteance if collar is at our near minimum level.

-

Clean the transport belts with a damp cloth.

-

Clean the transport belts with a damp cloth.

-

Inspect the stops on cutting table for wear and damage.

-

Inspect the stops on cutting table for wear and damage.