Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Authorised by

-

QA

-

Location

GENERAL

-

PURPOSE: This procedure outlines the steps and methods that are required to be followed by the staff in processing areas while performing the cleaning functions to ensure the desired result is achieved.

In order to ensure safe food production, minimise the risk of cross-contamination and avoid recalls and reputation damage to the business, it is essential to follow the instructions detailed in this manual -

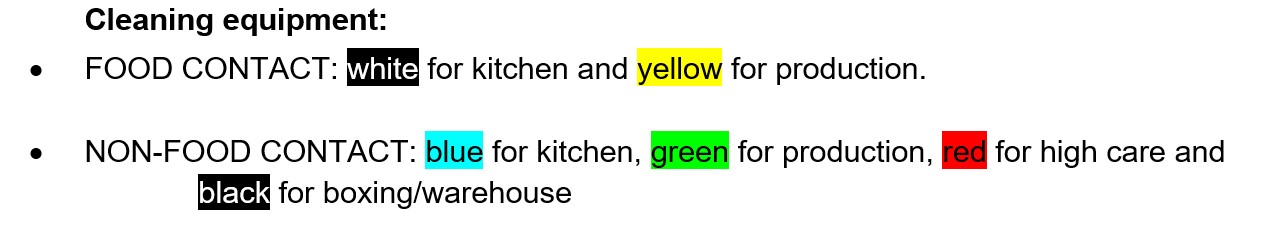

Cleaning equipment

-

PPEs required: Hairnets, beard snoods, shoe covers, blue single use aprons, gloves, safety glasses

-

Chemicals used, dilution and contact times:

-

Note:

• All cleaning solution should be diluted as per the above table unless dispensed from the dosing stations.

• All cleaning equipment like brushes, sponges, squeezers and mops need to be cleaned with detergents and sanitized to reduce microbiological load and hung to dry.

1. PASTA MIXERS & SHUTTLE

A. Mixers

-

a. Ensure the mixers are empty as much as possible.

-

b. Open protection gates and manually remove any remaining dough.

-

c. Using a scrapper remove any dough that is attached to the paddles. Then use the brush to clean off remaining dough and discard to waste. Repeat until all dough is removed from all surfaces.

-

d. Using bucket, fill with GP Liquid from dosing station, moisten sponge and scrub all the paddles and inside of the mixers, leave it for 15 mins.

-

e. Wipe down external areas with GP liquid to ensure there is no food residue.

-

f. Moisten a clean cloth with clean water (in a bucket), wipe down all the surfaces until all the GP Liquid is completely removed. Visually inspect to ensure all surfaces are clean.

-

g. Using clean dry towel, wipe down all surfaces

-

h. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

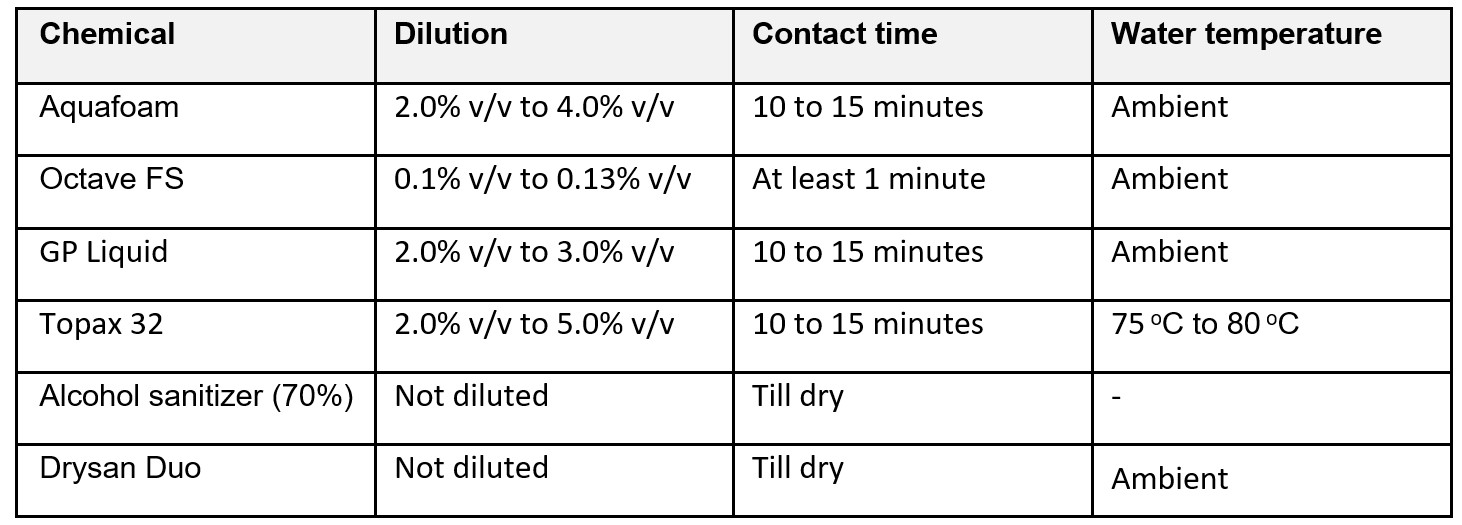

Turbo

-

-

a. Take off the flour chamber, remove semolina with shovel tool and discard.

-

b. Open turbo head, take the blade out. Remove all pasta from the blade and discard.

-

c. Soak blade with water in the washroom sink.

-

d. Moisten the sponge with GP Liquid and scrub all the paddles/blades and leave for 15 minutes.

-

e. Rinse with clean water and allow to air dry.

-

f. Use the food contact brush, clean inside of inside the turbo to remove dough residue and discard. Repeat until dough residue has been removed.

-

g. Soak the brush with GP Liquid from dosing station and brush inside the turbo (leave it for 15 minutes).

-

h. Wipe the external surfaces with GP Liquid, using sponge, to remove any food residue.

-

i. Moisten the clean cloth with water, wipe down all the food contact surface until all the GP Liquid removed from the surface.

-

j. Wipe down inside the turbo with a clean dry cloth and visually inspect to ensure it is clean.

-

k. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

B. Pasta Shuttle

-

-

a. Stop the shuttle, open the sliding door, and remove all pasta.

-

b. Rinse with water on the surface of the roller.

-

c. Use the brush to clean off remaining dough and discard to waste. Repeat until all dough is removed from all surfaces.

-

d. Moisten the sponge with GP Liquid and scrub the chamber and plastic door. Repeat this step until all the remaining pasta is removed from the surface. (leave it for 15 minutes).

-

e. Moisten a clean cloth with water, wipe down all the food contact surface until all the GP Liquid is completely removed from the surface.

-

f. Wipe all surfaces with clean dry cloth and visually inspect to ensure it is clean.

-

g. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

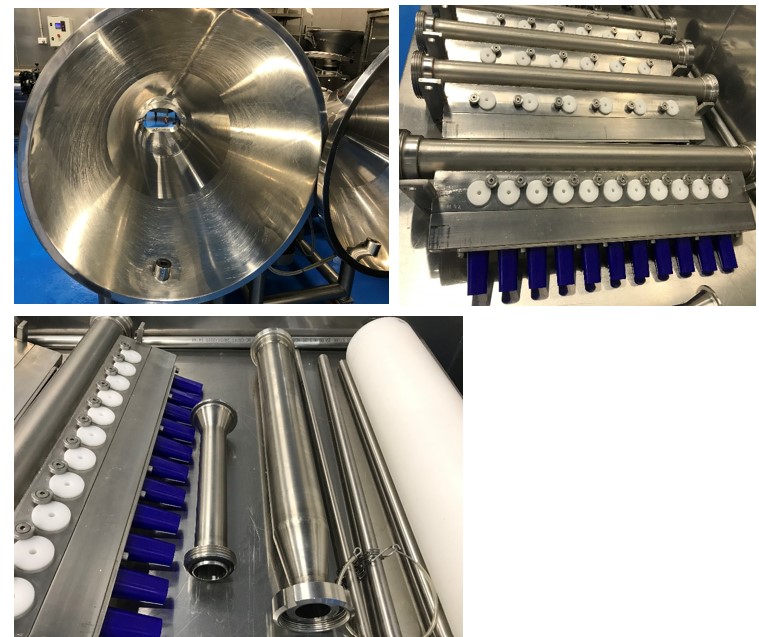

C. Egg Vat/Veg Vat

-

a. Empty contents and discard.

-

b. Remove egg/veg vat tube and place in sink to soak in water.

-

c. Rinse insides of the vat with clean water, empty contents and discard it.

-

d. Soak the brush with GP Liquid from dosing station and scrub internal surfaces (leave it for 15 minutes).

-

e. Rinse well with clean water several times until all the GP Liquid is completely removed. Allow to air dry

-

f. Wipe down external surfaces with clean dry towel

-

g. Spray internal surfaces with alcohol sanitiser and allow to air dry.

-

Done by

-

QA checked by

D. Production Pasta Mixer Platform

-

-

a. Broom the platform and stairs.

-

b. Wash the platform and stairs with GP Liquid. Use disposable mop.

-

c. Repeat step ‘b’ twice.

-

d. Wipe all areas with moistened, clean mop to remove GP liquid residue.

-

e. Allow to air dry.

-

Done by

-

QA checked by

2. PRODUCTION LINE

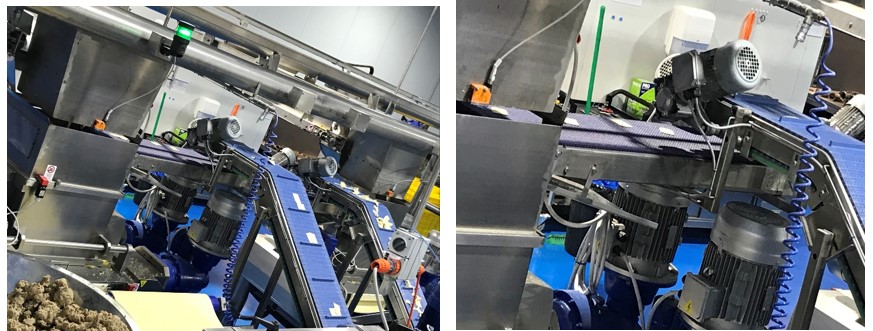

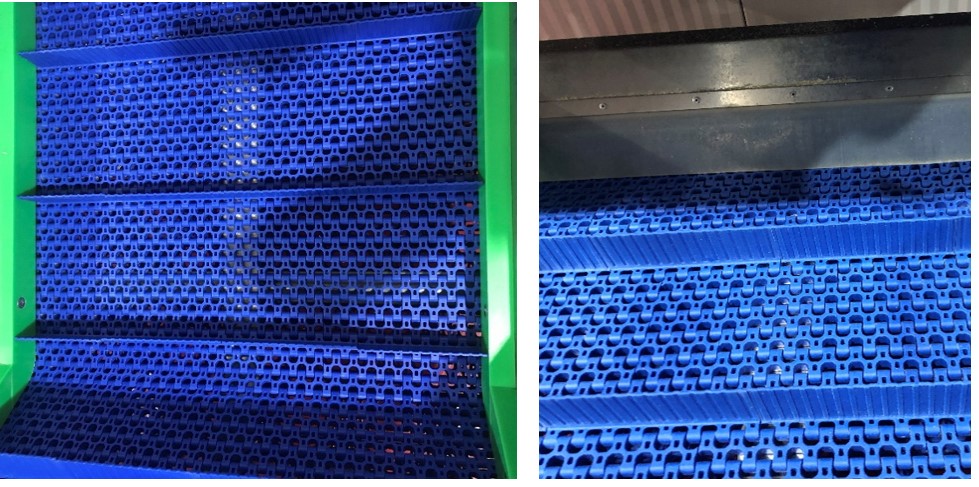

A. Pasta Feed Belts above the Laminator Machine

-

-

a. Clean/remove excess pasta particles, using brush

-

b. Pre-rinse with water, using clean cloth.

-

c. Applying GP Liquid on the belt, using spray bottles (leave it for 15 minutes).

-

d. Wipe it down with clean dry cloth until all the GP Liquid is completely removed from the surface.

-

e. Rinse the belt with water, using clean damp cloth

-

f. Use clean dry cloth and wipe to dry.

-

g. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

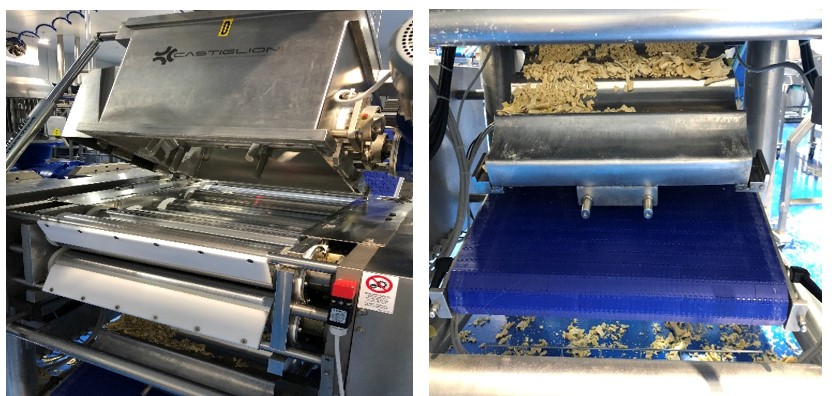

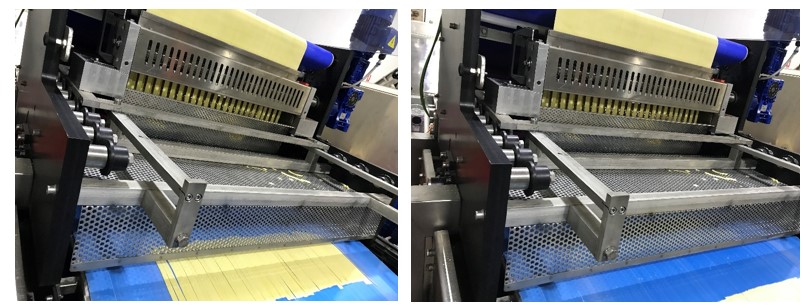

B. Laminator Machine

-

-

a. Clean/remove excess pasta from laminator rolls/nesting machine and discard.

-

b. Moisten sponge/brush with GP Liquid in bucket from dosing station and scrub all the paddles (leave it for 15 minutes).

-

c. Soak the clean cloth with water, wipe down all the food contact surface until all the GP Liquid is completely removed from the surface.

-

d. Rinse the belt with water, using clean damp cloth and inspect to ensure it is clean.

-

e. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

C. Filling Hopper (Vat) with pipes and fill pistons

-

-

a. Remove all the remaining fillings from vat and pipes and discard to waste.

-

b. Remove pipes and fill pistons and place in sink for washing and soak in water.

-

c. Rinse all the equipment with water., using clean damp cloth.

-

d. Moisten the sponge and brush with GP Liquid from dosing station and scrub the equipment (leave it for 15 minutes).

-

e. Rinse well with water until all the GP Liquid is completely removed.

-

f. Blow inside pipes to remove excess water, then allow to air dry.

-

g. Inspect to ensure all equipment is clean.

-

h. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

i. Wipe external surfaces of vats with cloth and GP liquid from spray bottles

-

j. Rinse with clean damp cloth and allow to air dry.

-

Done by

-

QA checked by

D. Forming Machine dies and pistons

-

-

a. Remove all remaining fillings from the dies and pistons and discard to waste

-

b. Rinse all parts with water in the wash bay.

-

c. Soak and wash pistons with GP Liquid in the washroom sink. Use brushes/sponges to assist in removal of food remains – being careful not to cause damages to die and pistons. Leave it for 15 minutes.

-

d. Rinse well with water until all the GP Liquid is completely removed and inspect to ensure they are clean.

-

e. Blow inside the pistons to remove excess water.

-

f. Sanitize with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

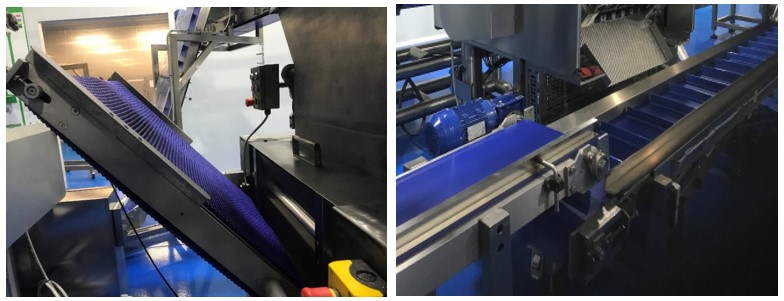

E. Conveyor Belts (including Z inclining belts)

-

-

a. Blow down all the remaining pasta from the belt.

-

b. Moisten the sponge/brush with GP Liquid from dosing station and wipe/brush the belts thoroughly to remove any remaining particles stuck to it.

-

c. Rinse well with water, using cloth, until all the GP Liquid is completely removed.

-

d. Inspect to ensure the belts are clean.

-

e. Sanitize with alcohol (70%) sanitiser and allow to air dry

-

Done by

-

QA checked by

F. PASTEURIZER & DRIER

a) Pasteurizer Unit

-

a) Pasteurizer Unit

-

a. Turn on the power to the pasteurizer and raise the canopy.

-

b. Run the belts and blow down the belts with air while they are running until all the remaining pasta is removed from the belt.

-

c. Turn on the foaming unit to dispense Aquafoam (foaming detergent; concentration is set at 2.4% v/v).

-

d. The foaming unit is connected to the pasteurisers and will dispense the detergent at the set concentration. Do not change any setting on the unit.

-

e. Run it for 15 minutes and use the brushes to scrub the belt, while it is running. This step includes the pre-rinse, foaming and rinse.

-

f. Moisten the sponge with GP Liquid from the dosing station, clean all the rollers and the platform under the belt, do it carefully to avoid cross contamination from the leftover food to the belt (leave it for 15 minutes).

-

g. If step ‘e’ is not removing all the leftover food particles, use high pressure water as the final rinse.

-

h. Rinse well with water until all the detergent is completely removed.

-

i. Sanitise the belts with alcohol (70%) sanitiser and allow to air dry, no rinse required.

-

j. Ensure the blue plastic flaps are wiped, cleaned and sanitized.

-

Done by

-

QA checked by

b) Drier Unit

-

a. Run the drier belts and blow down with air to remove all remaining food particles. Ensure to check the shooter at the end of drier to remove any debris that could not be visible otherwise. Perform this task simultaneously with the pasteurizer belts.

-

b. Remove any products on the floor of the unit with a wet mop. Check the corners while doing so to ensure all the leftover particles are completely removed.

-

c. Wipe the walls and doors with GP Liquid on a sponge (leave it for 15 minutes).

-

d. Rinse all the external areas with water and wipe down with a clean dry cloth.

-

e. Allow to air dry.

-

f. Sanitise the belts with alcohol (70%) sanitiser and leave to dry, no rinse required.

-

g. Leave doors open allow to air dry.

-

Done by

-

QA checked by

3. HIGH CARE

A. Z Style Incline Conveyor

-

-

a. Blow down the conveyor belts with air to remove any pasta remnants and dust. Ensure to blow underneath the belt as well. Perform this task with the belts running.

-

b. Reduce the speed of the belt.

-

c. Moisten the sponge/brush with GP Liquid and scrub it.

-

d. Scrub the sides of the belts as well as the flaps (leave it for 15 minutes).

-

e. Rinse well with clean water several times until all the GP Liquid is completely removed.

-

f. Inspect the belts to ensure they are clean.

-

g. Sanitise with Drysan Duo using fogger machine.

-

h. Allow to air dry.

-

Done by

-

QA checked by

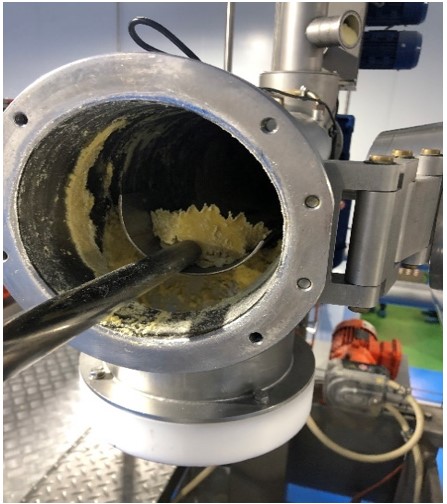

B. Chiller

-

-

a. Blow down the conveyor belts with air to remove any pasta remnants and dust.

-

b. Fill the foaming machine with GP Liquid from the chemical dispensing station in high care.

-

c. Open the front door, foam the belts with GP Liquid from the foaming machine and use the brushes to brush the belts as they are running. Leave it for 15 mins.

-

d. Rinse the belts with hot water leaving only front door open. When belts are clean, open the doors on one side and lightly rinse. Repeat the process with the doors on the other side open.

-

e. Repeat step ‘d’ till the all the detergent is removed completely.

-

f. Scrub the front and rear plastic flaps on chiller. Ensure to clean both sides (inside and outside) of the flaps.

-

g. Wipe the walls, doors with GP Liquid on a sponge, including the sealing strips (leave it for 15 minutes).

-

h. Rinse all the areas with water and wipe down with a clean dry cloth.

-

i. Allow to air dry.

-

j. Inspect all areas to ensure they are clean.

-

k. Fill the fogger machine with Drysan Duo from the chemical dispensing station in high care.

-

l. Sanitize the belts with Drysan Duo using fogger machine and allow to air dry.

-

Done by

-

QA checked by

C. Unfilled Pasta Cutting Machine & Belts

-

-

a. Blow down all the remaining pasta from the machine and the belts with air.

-

b. Using GP Liquid on a sponge/brush scrub machine parts to remove any materials struck on to it (leave it for 15 minutes).

-

c. Rinse thoroughly with water until all the detergent is completely removed.

-

d. Wipe down with clean dry cloth.

-

e. Inspect to ensure all items are clean

-

f. Sanitise all areas with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

D. Bucket Elevator

-

-

a. Turn on the bucket elevator.

-

b. Blow down every bucket with air while running. Check the corners and edges to ensure no pasta is stuck anywhere.

-

c. Moisten a clean cloth with GP Liquid and wipe all the buckets, inside and out (including under the buckets).

-

d. Run the elevator to ensure all buckets are cleaned.

-

e. Moisten a clean cloth with water and wipe all the buckets.

-

f. Allow the buckets to air dry, while elevator is running.

-

g. After drying and with the elevator still turned on, spray the buckets with alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

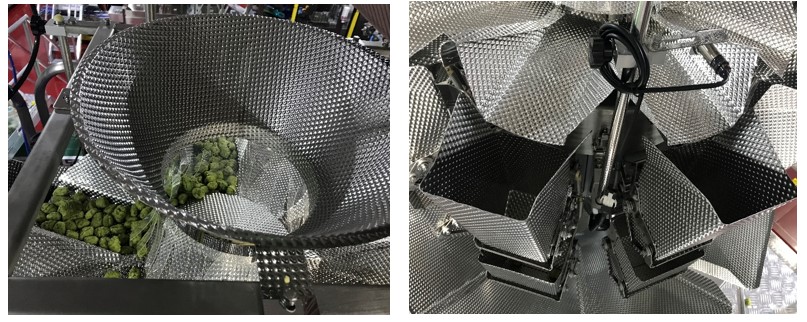

E. Multihead Weighers

-

-

a. Ensure the ladder is fixed and secured to the platform before access.

-

b. Blow down the multi-head weighers and buckets with air to remove any pasta remnants and dust.

-

c. Ensure this is done from top to bottom.

-

d. Check the shutters and make sure no product is captured at the edge.

-

e. Wipe arms, rams and sensors using a clean dry microfibre cloth.

-

f. Inspect to ensure all surface areas are clean.

-

g. Spray alcohol (70%) sanitiser on the multihead weighers and buckets and allow to air dry.

-

Note: The ladder is used for access to the multiheaded weighing platform, only. It is not to be used to access other areas

-

Done by

-

QA checked by

F. Bag Machine and Z Incline Conveyor Belt

-

-

a. Blow down the bag machine including the hoppers / formers and the conveyor belt thoroughly with air.

-

b. Wipe the hopper and bag former with GP Liquid on a clean cloth (leave it for 15 minutes)

-

c. Wipe with clean cloth and water until GP Liquid is completely removed.

-

d. Wipe the belts with a clean dry cloth, no chemical required. Use a brush to get into any corners, where pasta dust may collect.

-

e. Run the conveyor to ensure all the belt is cleaned.

-

f. Inspect to ensure all areas are clean

-

g. Spray all areas with alcohol (70%) sanitiser and allow to air dry

-

Done by

-

QA checked by

G. Packaging Machine Covers (including baggers), belts and metal detectors, etc.

-

-

a. Take off the covers on all the machines.

-

b. Cover the bottom film on the roller with a bag.

-

c. Blowdown the covers as well the connected conveyor belts thoroughly with air.

-

d. Inspect to ensure all areas are clean.

-

e. Spray alcohol (70%) sanitiser and allow to air dry.

-

Done by

-

QA checked by

H. Packing Multihead Platform

-

a. Broom the platform and stairs.

-

b. Mop the platform and stairs with GP Liquid. Use disposable mop.

-

c. Repeat step ‘b’ twice.

-

d. Wipe all areas with moistened, clean mop to remove GP liquid residue.

-

e. Inspect to ensure the platform is clean

-

f. Allow to air dry

-

Done by

-

QA checked by

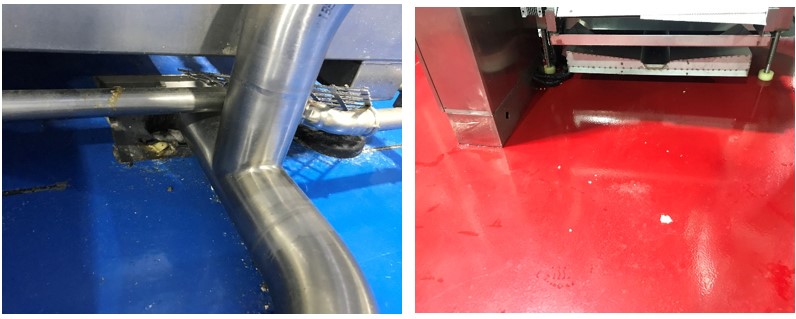

4. GENERAL AREA

A. Floor

-

-

a. Sweep the floor to remove the food particles and excess water that are remaining after cleaning the processing equipment.

-

b. Fill up floor cleaning machine with GP Liquid and move over all production and packing area floors.

-

c. Hard to reach areas, such as the corners and places around where the equipment is bolted onto the floor, need to be swept and mopped to remove all the accumulated debris.

-

d. Don’t step over cleaned floor and allow to air dry.

-

Done by

-

QA checked by

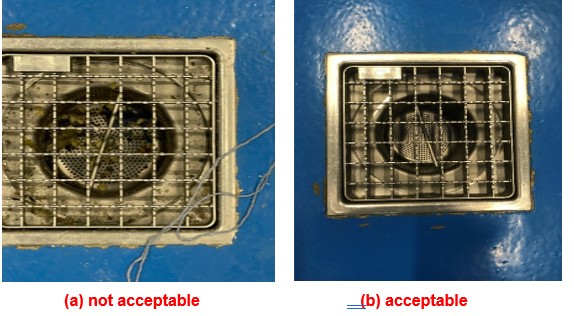

B. Drain

-

-

a. Remove the drain cover

-

b. Clean the debris around the area

-

c. Apply Aquafoam

-

d. Allow to stay 10-15 for minutes

-

e. Use brush to scrub inside of drain

-

f. Rinse with water

-

g. Apply Drysan Duo to the surface and allow to air dry.

-

Prior to starting production in Diseb Group-

-

• After the weekly cleaning is conducted on Saturday by the cleaning company (VAC), all the disassembled parts of the equipment & machines are reassembled by the production staff.

-

• The production Manager shall supervise the reassembly and sanitation

-

• All the equipment and machine parts are checked for cleanliness and sanitization by QA personnel.

-

• The food contact and non-food contact surface areas (as required) are then sanitized with 70% alcohol sanitizer.

-

• The sanitizer is allowed to air dry.

-

• The routine swabs are then conducted by the QA personnel for validation. ATP / Protein swabs are recorded.

-

Done by

-

QA checked by