Title Page

-

Houston

-

-

-

-

Daily Dust Audit

-

Document No.

-

Conducted on

-

Prepared by James Daye

-

Accompanied by

Sawmill

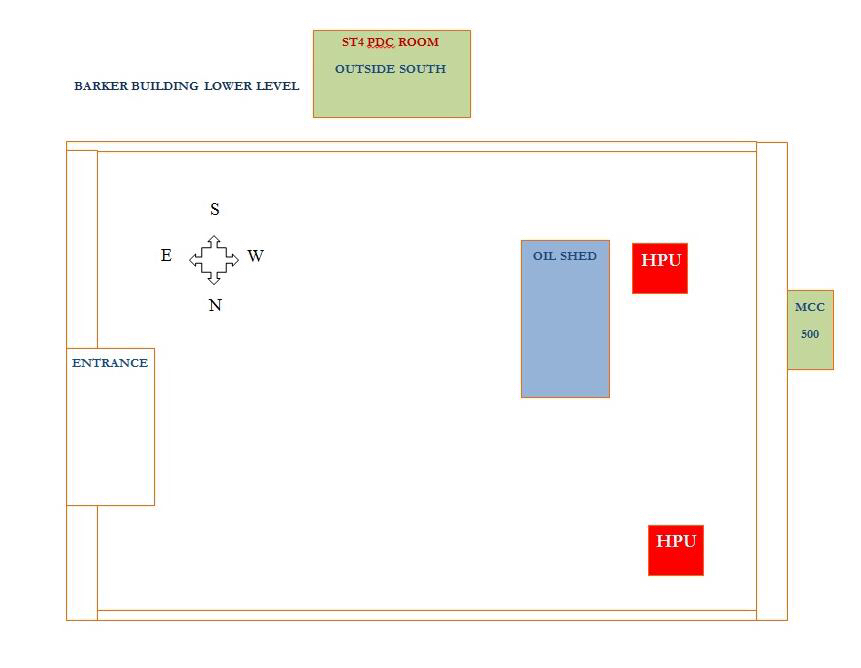

Zone 1 Barker Building Lower Level

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

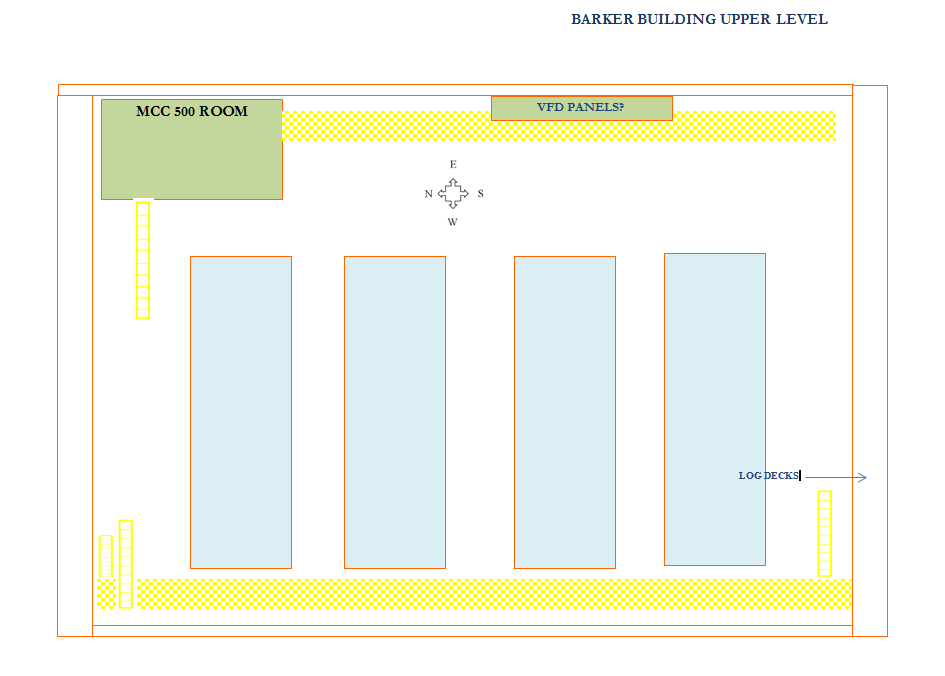

Zone 2 Barker Building Upper Level

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

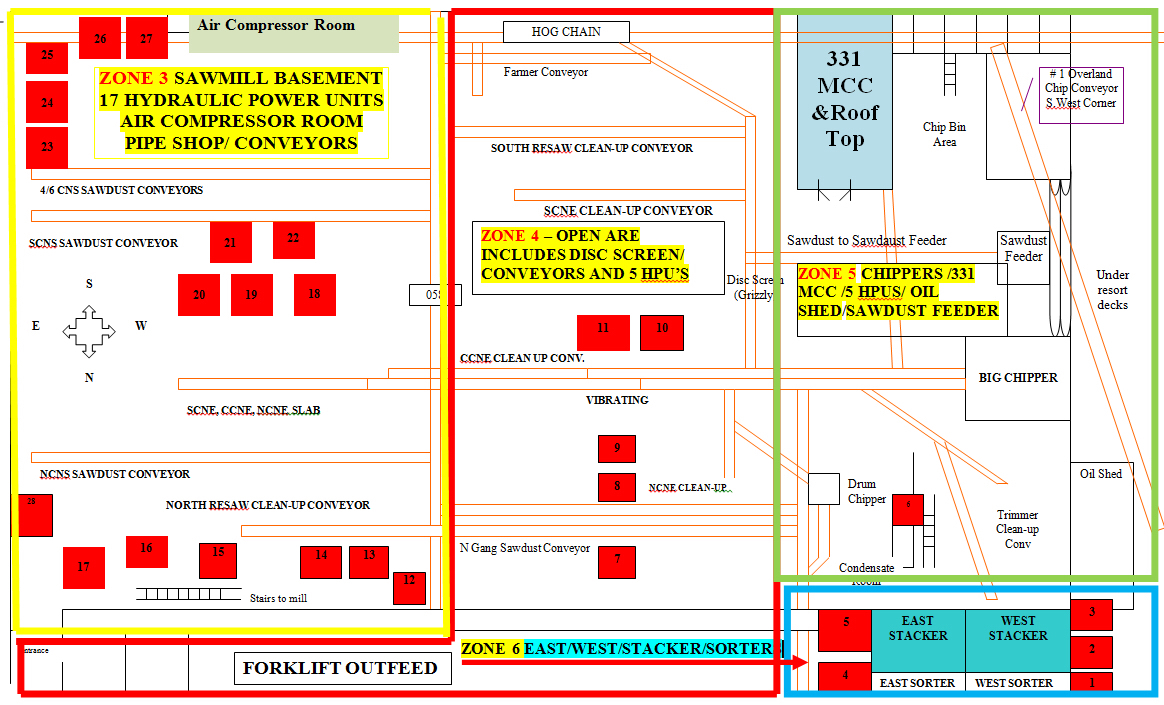

Zone 3 CNS/resaw/Air Compressor Room/Pipe shop/Conveyors Basement

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 4 Disc Screen Conveyor/Hog Chain/Edgers/Gangs Basement

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 5 Chippers/Oil shed/331MCC/Sawdust Feeder

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 6 Sorters/Stackers

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if you did not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 7 CNS/Canter/Offices/Lunchroom

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 8 Upper Chip Bins/Trimmers/Edgers

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 11 Filing Room

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 13 Reman/Cyclones/MCC 332

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Mobile Shop and Stores

Zone 9 Fabrication Shop/Welding Shop/Stores

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 10 Mobile Shop

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Planer

Zone 12 Planer Motor Storage/Maintenance Area/334 MCC/Chipper Room

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 14 Tilt Hoists/Strips/Lunchroom/Office/Planer Room/Slowdown Belts

-

Is there opportunity for 5s?

-

Are the HPUs in good condition?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if you did not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 15 Trimmers/Sorters

-

Is there opportunity for 5s?

-

Are the HPUs in good condition?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Zone 16 Stackers/Bander/Paper Wrap

-

Is there opportunity for 5s?

-

Are the HPUs in good condition?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

Energy Plant Area

Zone 18 Hog Building

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

Zone 19 Wet Fuel Bin

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

Zone 20 Energy Plant

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

Zone 21 Chip Tower

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.

-

Are observed employee work practices within the zone consistent with the program (ie. Use of compressed air, hot work practices)?

-

Did you test employees knowledge of combustible dust and its associated hazards? Choose N/A if not.

-

Ask employee each of the following questions and check if answered correctly (Answer is included)

-

Can you tell me the difference between primary and secondary dust? A. Primary dust is found at the dust source and is larger with higher moisture contents than secondary dust that has spread throughout the area on raised surfaces.

-

What is considered an unacceptable level of secondary dust? A. 1/8" over 5% of the work area.

-

What are your responsibilities with regards to mitigation of combustible dust? A. Understand the risk mitigation matrix for my area, understand the divisional dust control plan, recognize, control and report unsafe conditions.

-

Describe the requirements for use of compressed air? A. Fill out a compressed air pre-work card, do not create a dust plume, compressed air is only to be used as a last resort.

Kilns

Zone 17 Kiln Control Rooms/Transformer Room/Walkway

-

Is there opportunity for 5s?

-

Are primary dust levels acceptable, have they been removed from possible ignition sources such as heaters, electricity, hot work or friction?

-

Are secondary dust levels acceptable, are they at less than 1/8" over 5% of the work area?

-

Is it free of risk due to an upset condition?

-

Does the divisional clean-up schedule show that the area will be cleaned shortly?

-

Is the current clean-up schedule adequate?

-

Could the secondary dust have been better controlled at the source? If yes, please comment as to how by pressing the (...) buttons to the right.