Commercial Manufacturing

-

Policyholder:

-

Policynumber:

-

Status of account:

-

Site Contact number:

-

Broker:

-

Broker Contact number:

-

Broker Email:

-

Insurer:

-

Date of Survey:

-

Location:

-

Surveyor name:

-

Survey s m L:

-

Google street view:

-

Total km minus first 50km:

-

Tolls:

-

Completed for and on behalf of:

-

Contact point email:

Business Details

-

Date Established:

-

Period Owned by current owner:

-

Business description:

-

Website URL if any:

-

Trading hours:

-

General site description:

-

Aerial overview link:

-

Risk address correct:

Occupation and Fire Risk Classification:

-

Underwriter please note the below occupation and risk classification is based on the provided

data received from your office. We include this in our report as a value add to your internal

underwriters, for ease of reference and upon your request after our communication (where

applicable). We highly suggest that this occupation and risk classification description is internally

verified and confirmed to avoid any rating errors

(high/medium/low/accommodation/referral/decline), reinsurance treaty capacity limitations or

exclusions based on the occupancy types or any other factors material to this risk. It is warranted

that should any changes to your internal occupancy and fire risk classification methodology or

rating program be made, it remains the responsibility of the underwriter to provide such

information, changes or amendments to Occusurv in writing to avoid any discrepancies with the

risk classification code on this report in relation to your internal document(s). Please refer to our

liability disclaimer at the top of this report. -

Applicable underwriter of the risk:

-

Low Risk - (L, L1, L2)

Medium Risk - (M, M1,M2)

High Risk - (H, H1, H2, H3)

Accommodation - (AC)

Refer - (R)

Declined - (D) -

Applicable fire risk classification:

- L

- L1

- L2

- M

- M1

- M2

- H

- H1

- H2

- H2

- H3

- AC

- R

- D

-

Occupancy or operation consistent with the underwriters

Operational and Safety Overview:

-

Risk management measures:

- Operational(day to day) controls

- Preventative maintenance

- Scheduled maintenance

-

Staff training:

- Inhouse training

- Outsourced

-

Supervision:

- Hands on day to day management

- Close supervisory roles in place

- Team leaders

-

Site plan:

-

Rational design (where applicable):

-

Occupancy certificate:

-

Contractor services acquired:

-

contractors qualified:

-

Liability insurance confirmed:

-

Hotworks permit enforced:

Buildings:

-

Building 1

-

Building name and usage:

-

Approx floor area (sqm):

-

Age:

-

Proximity to nearest insured building:

-

Sans10400 Occupancy Classification:

- B1

- B2

- B3

- D1

- D2

- D3

- D4

- J1

- J2

- J3

- E1

- E2

- E3

- E4

- J4

- B4

- F1

- F2

- F3

- F4

- A1

- A2

- A3

- A4

- H1

- H2

- H3

- H4

- C1

- C2

-

J1 storage >100sqm within any other occupancy type:

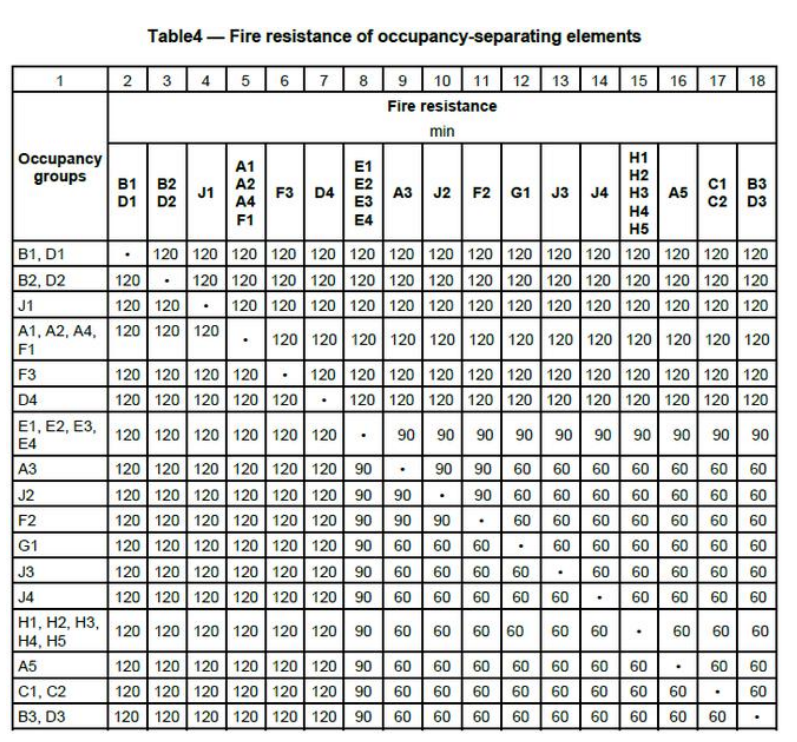

Table 4

-

-

Occupancy Separation:

-

Tenancy Separation

-

Fire doors

Construction

-

Walls:

- Brick

- Concrete

- IBR SHEETING

-

Finishing:

- Plastered one side

- Plastered both sides

- Not Plastered

-

Combustible cladding fixed to walls or used as walls:

-

Height:

- Single storey

- Double storey

-

Floor:

-

Combustible flooring:

-

Roof

-

Green roof:

-

Roof shape:

-

Internal or external use of insulated panels:

General:

-

Emergency exits, obstructions and signage:

- Exits appear to be sufficient

- Exits clear from obstructions

- All exits and pathways marked

-

Maintenance level:

-

Handrails secured:

-

Raw Material(s)

-

Workshop(s) and storage rooms:

-

Describe:

-

Kitchen(s)

-

Laundry:

- General stuff kitchenette with basic appliances

-

Watermarks on ceilings/windows frames/walls:

-

Geysers internal or external to building(s):

-

Drip trays and overflow piping:

-

Possible extent of geyser burst resultant damages:

Fire Detection:

-

Year of occupancy of last building alteration:

-

Building>30m in height or >5000sqm:

-

Auto FD system required. In place

-

Occupancy include A1/A2/C1/C2/(F1<500sqm):

-

Occupancy include F1>500sqm:

-

Occupancy include H1/H2/E2/E3/E4:

SPRINKLER SYSTEMS

-

Table 3: Max division limits

-

Sprinkler system requirement based on SANS10400 4.4 Table 3:

- Yes - it appears that the site may require a sprinkler system

- No - it appears that the site may not require a sprinkler system

-

Photos

-

Sprinkler installed:

-

Access available to ICV and/or pump room:

-

Supply:

-

Type of system:

-

Static pressure on gauge:

-

Incoming pressure on gauge:

-

Valid block plan:

-

Storage compliant with block plan:

- Unknown - block plan not available to establish storage limitations

- Storage compliant with block plan

- Storage Not compliant with block plan

-

Latest system test records available:

-

Visibly loose hanger clamps:

-

Visible rust and corrosion:

Stacking Heights:

-

SANS10287 stacking heights / product CAT:

-

Products stacking in blocks or racks:

-

Product(s) stacked:

Product Categories:

-

Category classification of product(s)(height):

-

Stacking methods:

-

Stacking heights on site compliant with Sans10287:

-

Underwriter please note that stacking heights are in excess of SANS10287 limitations and/or

non-compliant with the sprinkler block plan where applicable.

Determination if stacking heights are acceptable based on this underwriters acceptance limits: -

Survey conducted for and on behalf of :

-

Stacking heights on site acceptable to this underwriter:

-

Photo Library (Building External)

-

Photo Library (Building External 1)

-

General External photos

-

Photo Library (Building Internal)

-

Photo Library (Building Internal)1

-

General Internal photos of office area

Housekeeping:

-

Gutters, downpipes and drains:

- Generally acceptable,maintained, free flowing and clear

-

Overhead trees, wiring or hazards identified:

-

Evidence of smoking:

-

Waste removal management:

-

Waste buildup:

-

Waste area distance to buldings:

- Waste stored between 5m - 10m from the building(s)

-

Combustibles against buildings:

-

Combustibles close to lighting/electrical/heat sources

-

Congestion:

-

General housekeeping rating 1 (very poor) to 10 (excellent):

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Utilities:

-

Main supply

-

Electrical COC:

-

Electrical hazards noted:

-

Cables, wiring and sockets:

-

Overuse of sockets or multiplugs:

-

Power Surge Protection:

-

Generators:

-

Total:

-

Purpose of units:

-

KVA?

-

Supply:

-

Fuel:

-

Built-in-tanks or stand alone flow-bin

-

Tank capacity:

-

Fuel storage(if not contained in built-in-tanks):

-

Max volume stored:

-

Generator location:

-

Ventilation:

-

Switch over:

-

Solar Panels:

Water:

-

Water Supply:

Transformers and substations:

-

Transformers and substations:

Carparks:

-

Parking defined and marked:

-

Car park surface:

-

Surface condition:

-

Car park drainage:

-

Condition of structures or shade nets:

-

Photos of carpark:

Local risk:

-

Occupation and distance to TP building (left):

-

Occupation and distance to TP building (right):

-

Occupation and distance to TP building (rear):

-

Occupation and distance to TP building (front):

-

Immediate surrounds posing threat of fire spread or explosion:

- No specific and visible risk noticed at the time of survey

-

Type of location:

- Freestanding on own plot in industrial area

-

Crime:

-

Immediate third parties with late trading hours:

-

Surrounding graffiti, high pedestrian traffic or waste build-up:

-

Surrounding taxi rank or township:

-

Other know hazardous/explosives in immediate area:

Security:

-

Buildings key access:

-

Visitor access control:

- Site access: Security post with sign-in process at entrance gate

- Building access: Free access during office hours

-

Building and site entry points:

- Site entry points: 1

- Site entry points:2

- Site entry points:3

- Site entry points:4

- Site entry points:5

- Building entry points:1

- Building entry points:+2

- Building entry points:+4

-

Doors and security gates:

- Aluminum frame doors - some fitted with security gates

- Roller Shutters

-

Windows and burglar bars:

- Aluminum frame - fully fitted with burglar bars

- Steel frame - fully fitted with

-

Perimeter fence:

- Fence/wall only no electrical wiring

- Fence/wall with electrical wiring

- No wall

-

Ram raid prevention:

-

Alarm system:

- SAIDSA approved linked alarm with armed response

-

Other physical security:

-

Security lighting:

-

Security guards:

-

Guards PSIRA registered:

-

Guards armed:

-

Cash on site:

-

Are there any ATM'S installed on site?

-

General security rating 1 (very poor) to 10 (excellent):

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Glass:

-

Retail trading or storefront exposure:

Public Liability:

-

Spread of fire to TP property:

-

Open air trade risk:

-

Visible liability disclaimer:

-

Loose overhead fixture or fittings:

-

General flooring/walkways/stairs conditions:

- Acceptable with no adverse exposure noted

-

Hazardous/gas/chemical/pollution/explosion exposures:

-

Above/below ground flammable tanks:

-

Bodies of water on site:

Fire risk innternal:

-

Extinguishers:

-

Extinguishers secured to walls:

-

Pressure gauges:

-

Service expiry:

-

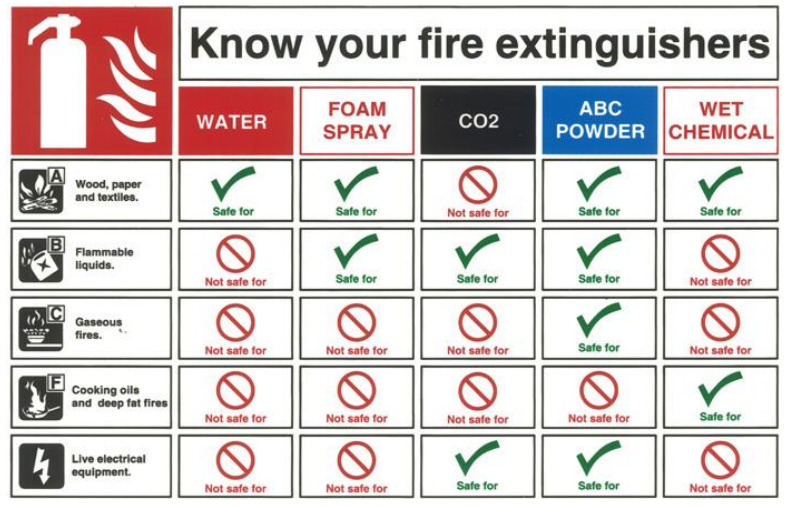

Class A Fires - Combustible Material: paper/wood/cloth/textiles/plastic/soft furnishing

Class B Fires - Flammable Liquids: flammable liquids/paint/petrol/diesels/solvents/oil/tar

Class C Fires - Flammable Gases: propane/butane/methane

Class D Fires - Flammable Metals: aluminum/potassium/lithium) and Electrical Fires -

computers/generators/chargers)

Class F Fires - Deep fat fryers/cooking oil/chip pans -

Extinguisher class correct:

-

SANS10400 Table 11: 1/400sqm - A4/A5/B3/D4/H3/J3/J4 1/200sqm - A1/A2/A3/B2/C1/C2/D3/E1/E2/E3/E4/F1/F2/F3/G1/H1/H2 1/100sqm - B1/D1/D2/H5/J1/J2

-

Number of FEA sufficient:

Hose reels requirements: 2+ storeys or 1 storey > 250sqm floor area at 1x per 500sqm. H3 require reels where no independent escape access to ground level is available.

-

Hose reels:

Number of hose reels sufficient:

-

Hydrants:

Buildings (excl H4) > 12m or 1000m2 floor area required: -

Hydrants:

-

Other water supplies:

-

Hydrants and Reels missing parts:

Sprinklers:

-

Sprinklers: independent- serviced, cleared, stacking compliant:

-

Sprinklers: independent-non complied with one or various requirements:

-

Sprinklers: council supplied- serviced, cleared, stacking:

Compliant:

-

Sprinklers: council supplied- non compliant with one or various requirements:

-

Sprinklers: none:

Separation:

-

Appears to have full separation: brick walls to roof with fire doors:

-

Appears to have full separation: brick walls to roof with no fire doors:

-

Appears that no fire rated separation: fully communicating:

Detection:

-

Fire detection: Automatic - serviced and operational:

-

Fire detection: Automatic - not serviced or operational:

-

Fire detection: Manual - serviced and operational :

-

Fire detection: Manual - not serviced or operational:

-

Fire detection: none:

-

Nearest Fire Station:

-

Fire Brigade access:

- Site access appears to be sufficient

-

Obstructions blocking FEA:

-

Fire fighting equipment signposted:

-

Fire escape plan fitted:

-

Fire drills:

-

Staff trained fire fighters:

-

Fire fighting capacity:

- Both active and passive fire fighting measures

-

Smoke control:

- Both natural and mechanical ventilation

-

Electrical heaters used:

-

Inception hazard:

-

Spread Hazard:

-

Fire load:

-

Smoke:

-

Arson risk:

-

Fire Classes Sum Insured (inclusive of BI):

Perils exposure:

-

Fire

-

Wind

-

Explosion

-

Lightning

-

Lightning informative: Groundflash density areas in excess of 7ng:

Barberton / Belfast / Benoni / Bethal / Boksburg / Brakpan / Brits / Carletonville / Colenso /

Donnybrook / Doornfontein / Dundee / Ermelo / Evander / Germiston / Harrismith / Heidelberg

(WC)/ Irene / Johannesburg / Kempton Park / Klerksdorp / Krugersdorp / Ladybrand / Ladysmith

(KZN) / Machadodorp / Modimole / Pietermaritzburg / Piet Retief (very high) / Potch / PTA /

Richmond (KZN) / Rustenburg / Springs / Standerton / Utrecht / Vereeniging / Vryheid /

Warmbaths / Witbank -

Flood (Coastal areas)

-

Dams / rivers in close proximity or elevated position:

-

Earthquake:

-

Dolomite/limestone:

-

Known dolomite area include:

Barberton / Bo-Karoo / Burgersfort / Origstad / Bushbuckridge / Carltonville Daniëlskuil / Delmas

/ Diamondfields / East-Rand / Ellisras / Elukwatini / Ganyesa / Griekwastad / Groblersdal /

Hoedspruit / Hopetown / Johannesburg / Kathu / Kgalagadi / Klerksdorp/ Krugersdorp / Kuruman

/ Lebowakgomo / Lichtenburg / Mafikeng / Marble Hall /Meyerton / Mogwase / Nylstroom / Parys

/ Pietersburg / Pomfret / Postmasburg / Potchefstroom / Potgietersrus / Pretoria / Prieska /

Randfontein / Reivilo / Sabie / Sasolburg / Sterkfontein / Thabazimbi / Tzaneen / Ventersdorp

Vereeniging / Vryburg / Warmbaths / Westonaria / Zeerust -

Slope:

Hotworks:

-

Hotworks conducted:

Spraying operations:

-

Spraying operations:

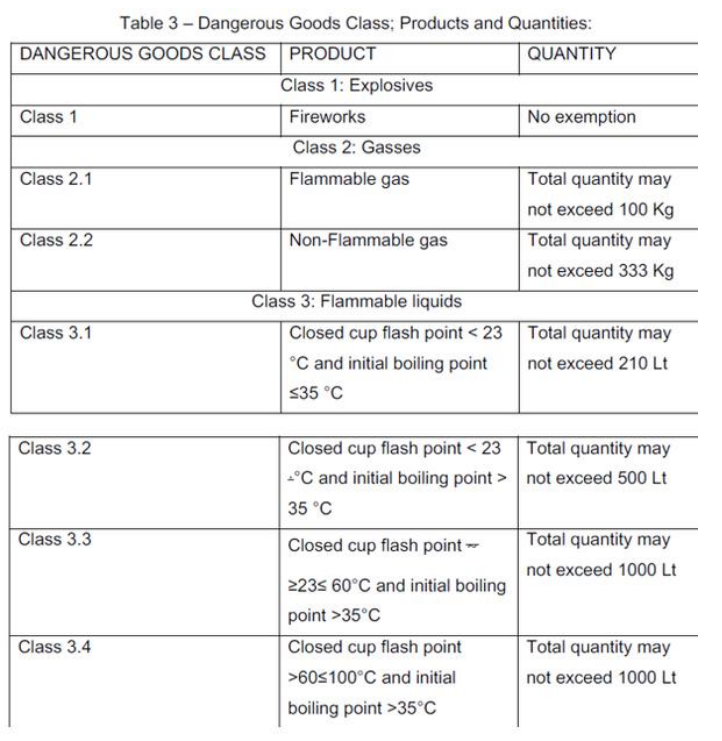

Flammable/combustible material, storage and tanks:

-

Usage or storage of flammable/combustible material:

-

Type of flammables:

Flammable Liquids:

-

Type | Volume | Category of liquids:

Various flammable inks -

Storage location of liquids:

-

Flammables stored in approved containers and tanks:

-

Excessive flammables on production floor(s):

-

Bulk drums grounded and bonded to containers during<br>dispensing:

-

Lighting and ventilation of storage room(s):

-

No smoking and flammables signage:

-

Spill kits maintained:

-

Ventilation of under/aboveground storage tanks:

-

Sufficient bunding (110%):

-

Fire fighting equipment nearby:

-

Flammable liquid storage:

Flammable Gas:

-

Type | Volume of gas: LP Gas Bulk Tank

-

Storage location of gas:

-

Excessive gas on production floor(s):

-

Ventilation of gas storage area:

-

Cylinders secured in locked caged:

-

Stored away from<br>heat/combustibles/corrosives/drains/cellars/dry<br>grass/weeds/paper/waste and cooking appliances:

-

Cylinders > 5m from DBs/electrical motors and > 2m from<br>drains:

-

Cylinders (2+ adjacent to each other) > 3m away from<br>boundary walls (unless boundary has firewall):

-

Emergency shut-off valve(s):

-

Serviced DCP nearby:

-

LPG and other compressed gas stored > 3m apart:

-

Notice boards instruction for emergencies:

-

Valve protectors in use:

-

Cylinders hydro dates maintained:

-

In-service cylinders supported:

-

SANS10087 COC:

-

Dumpies refilling on site:

-

Gas storage:

Fire Clearance Requirements:

-

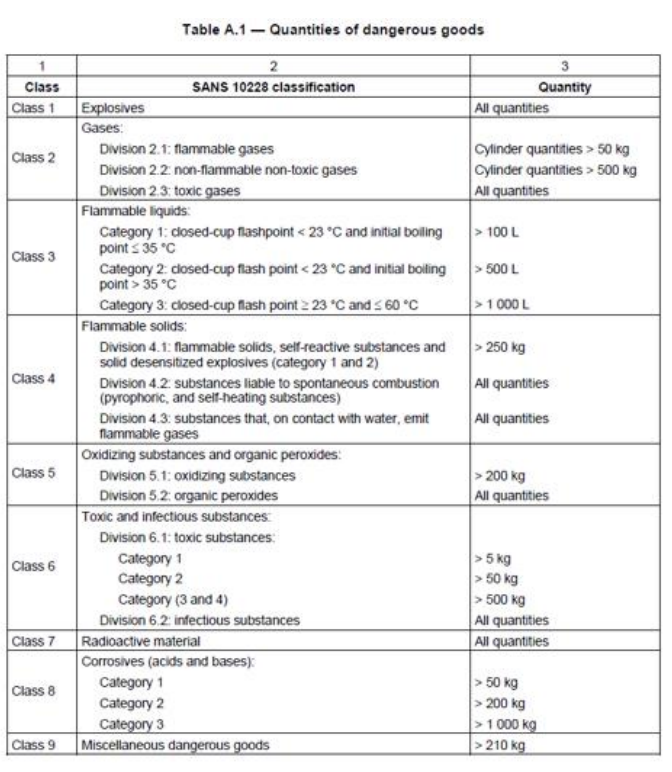

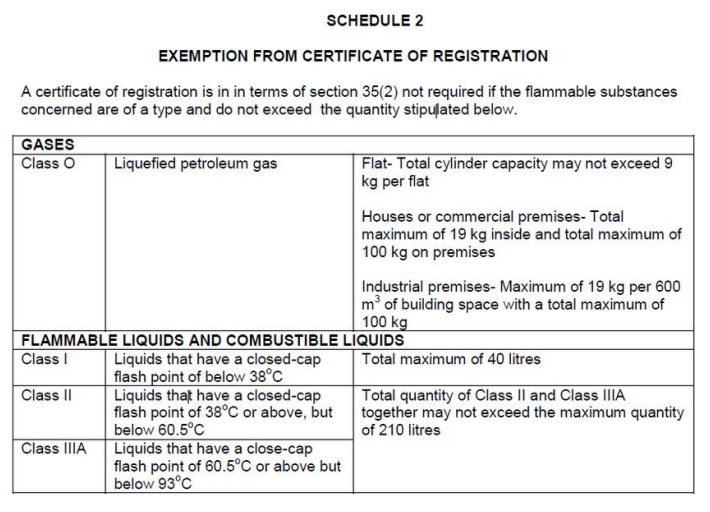

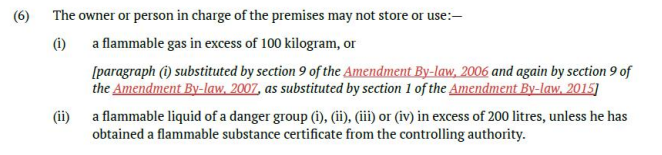

SANS10288 Table A.1 City of Johannesburg Flammables Bylaws:

-

City of Cape Town Flammables Bylaws:

-

-

Ethekwini Flammables Bylaws:

-

Fire clearance required:

-

Valid fire clearance on file for liquids:

-

Storage volume of liquids compliant with fire clearance:

-

Flammable room installed:

-

General construction specs of flammable liquid/solid storeroom include (but are not limited to) as

per the General Safety Regulations of 1986, section 4 (in addition to the Emergency By-laws Part

6): -

1.The floor of the flammable store must consist of concrete.

2.The flammable store walls must be constructed of a material that has a fire resistance of at

least 120 minutes.

3.The storeroom roof needs to consist of reinforced concrete with a fire resistance of at least 120

minutes or any other non-combustible material if the flammable store is not situated within 5

meters of any structure.

4.The flammable store must be sunken or must have a bund wall to prevent spills from leaking

out of this room. This installation must be able to contain at least 110% capacity, to a maximum

height of 450mm of the total quantity of flammables stored within.

5.The entrance must have a fire door and locks/s installed as per South African National

Standards, with all appropriate signage displayed on the outside.

6.Any flammable store with a length of 4m or more, must have two approved fire doors installed

as far as practical from each other.

7.Any flammable store door must be capable of being easily opened from the inside of the store,

without the use of a key.

8.A certificate of registration for the flammable store must be easily visible on the outside of an

entrance door and must be placed within a weatherproof container.

9.All window frames must be manufactured of steel and must be fitted with wire glass which

must be a minimum thickness of 8mm. The window panel cannot exceed 450mmx450mm and

may not be capable of opening.

10.The Fire door must remain closed whenever the room is not in use.

11.There must be adequate air ventilation within the flammable store. This may include natural or

mechanical ventilation, which must comply with the South African National Standards. The fumes

must be released into the open air at a place/s where the fumes are not likely to come into

contact with any source of ignition.

12. All electrical wiring, lighting, etc installed within the flammable store must be intrinsically safe.

There must be no electrical plug points within the flammable store and all electrical installations

are to comply with the South African National Standards and are required to be installed by an

accredited electrician with an updated electrical COC that must be forwarded to the insurers -

Flammable room compliant:

Boilers:

-

Boilers on site:

Forklifts:

-

Operational forklifts:

-

Type(s):

-

Valid operator's licenses:

-

Forklift overhead guards:

-

Operating in areas where flammable gas, combustible dust,<br>or ignitable fibers may be present in the atmosphere?

Commercial Kitchens:

-

Commercial Kitchen Operations:

Cold rooms warehousing/storage:

-

Cold rooms warehousing/storage:

Woodwork:

-

Operations involve woodwork:

Plastic manufacturing, processing or related risk:

-

Plastic manufacturing, moulding, extrusion, fabricating or<br>other plastic related operations:

PML (MPL) / EML:

-

Definitions

Probable Maximum Loss

The maximum loss that could occur when the most unfavourable circumstances combine, and

when, as a consequence, the fire is not fought against at all, or not satisfactorily fought against,

and is therefore only stopped by impassable obstacles or by lack of physical property.

Estimated Maximum Loss

The extent of the fire likely to occur in the normal course of events based on the activity,

occupancy, and fire protection of the range of buildings concerned. Unusual circumstances

(accidental or extraordinary) likely to modify the circumstances of the risk are not taken into

consideration. -

Existing interruption control plan/system (if any):

Simplicity of obtaining/replacing/repairing plant and machinery and stock after a loss:

-

Some machinery is imported with most bought from local competitors.

Stock can be manufactured, but it will take time to replace machinery if local suppliers haven't got stock of

equipment and must be imported.

Target and/or subdivision risk in fire areas:

-

The inspected factory and storage area is the target area and communicated internally throughout.

Distribution of values:

-

Building :

-

Plant and equipment

-

Stock

-

BI

-

PML (MPL) Fire Calculation:

-

EML Fire Calculation:

-

EML:

Claims:

-

Any specific claims, notes or requests made by the<br>underwriter to provide information on?

Notes

-

Surveyor notes on risk:

-

Summarized finding(s) or concern(s):<br>

-

Level of risk and acceptance:

-

Other:

Requirements, Recommendations and Executive summary:

-

Requirements: 1

-

Implication of non-compliance with requirement:

-

Priority:

-

Requirements: 2

-

Implication of non-compliance with requirement:

-

Priority:

-

Requirements: 3

-

Implication of non-compliance with requirement:

-

Priority:

Executive Summary:

-

Requirements:

-

Resurvey timeframe recommendation:

-

RQ brackets ")" check:

Completion:

-

Name of surveyor

-

Flagged items checked: