Information

-

EHS Audit

-

OSHA Safety audit with corrective action recommendations

-

Document No.

-

Audit Title

-

Company or Organization Name / Site contact name

-

Location

-

Choose Type of Facility Or Organization

- Manufacturing

- Warehouse

- Lab

- University

- Transportation

- Resturant

- Hotel

- Chemical Plant

- Printing Facility

1-General & Mgr Support

-

Audit completed on:

-

Auditor

- Mitch Paris

-

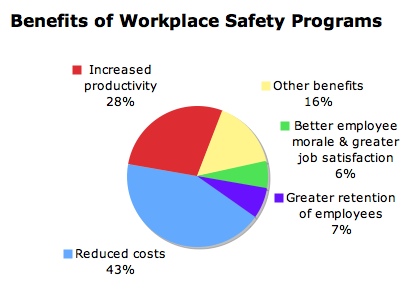

Recommended ways to improve your Safety Program and Eliminate Accidents! Multiple Choice:

- Improve Engineering Controls

- Improve Worker Awareness

- Improve PPE Policies

- Improve managers knowledge

- Lead By Example

- Improve Employee Discipline

- Improve Training Program

- Improve Policies & Procedures

- Improve management oversight

- Improve Hazard Recognition

- Improve Worker Incentive Program

- Increase inspection Frequancy

- Investigate Accidents for Root Cause

- Track Trends With KPIs

- Improve Record-keeping

- Conduct Testing

- Improve Housekeeping

- Make Safety A core value

-

Auditors Comments

-

Auditors summary

1.0 Previous Inspection

-

Was there a previous Audit complete at this location?

-

Items from previous audit have been corrected

-

Items from previous audit were observed and have NOT been fully corrected

-

ATTENTION: Items observed on this audit were repeat observances or uncorrected issues. It is imperative that all items be corrected to insure the safety of your staff and reduce risk of accidents or violation. If you need assistance or would like to discuss any item please call 877-354-5434.

-

This facility scored a low risk of injuries, accidents or safety violations based on the observations at the time of this audit

-

This facility scored a moderate risk of accidents, injuries or violations based on the observations at the time of the audit.

-

This facility scored an above average risk of accidents, injuries or violations based on the observations at the time of this audit. Any serious items should be corrected immediately.

-

ATTENTION: The facility scored an extremely high risk score which will likely result in accidents, injuries or violations based on the observations at the time of this audit. Any serious items should be corrected immediately.

Manager Safety Awareness

-

Manager - Supervisor - Worker safety awareness and involvement.

-

Overall Safety Culture in facility - Based on observations and worker feedback

-

Overall Safety Awareness of the management and workers.

-

Overall Readiness for an OSHA Inspectiion

-

Overall management understanding of OSHA regulations and requirments.

-

Supervisors assist in worksite hazard analysis, ensure physical protections, reinforce training, enforce discipline, and can explain work procedures based on the training provided to them?

-

Managers verify employees are applying their safety training and following procedures?

-

Management follows the rules and usually addresses the safety behavior of others?

-

Employees feel they have a positive impact on identifying and resolving safety and health issues?

-

Visitors, contractors and vendors are provided safety rules and procedures while on site.

General Duty Safety

-

OSHA general duty clause hazards observed

-

General hazards observed that could cause injury

-

General hazards observed that could cause injury

-

General hazards observed that could cause injury

-

General hazards observed that could cause injury

-

General hazards observed that could cause injury

2-Chemical Safety

Chemical compliance

-

Chemical Hazards Were Observed by the Auditor (You Must Correct Severe Issues immediately)

-

Are secondary bottles labeled to meet compliance? Do they contain information or pictograms to indicate hazards along with first aid and specific hazard warning instructions.

-

Is there an updated chemical inventory available with maximum quantity on hand and location?

-

Is there an COSHH binder available where chemicals are used and has it been updated in the last 12 months?

-

Person responsible.

-

Date for action to be close out

-

Auditor comments

Chemical Handling and Storage

-

Chemical hazards observed

-

Are open drums and containers stored on spill containment pallets or pans?

-

Are quantities of more than 5 litres of flammable liquid stored in an approved flammable cabinet?

-

Are metal flammable storage drums grounded properly to prevent sparks and fire?

-

Are approved secondary containers utilized, are they labeled properly and are they compatible with its contents?

-

Are any chemicals stored or being handled in an unsafe manner?

-

Person responsible.

-

Date for action to be closed out.

-

Auditor comments

Compressed Gasses

-

Do you have compressed gas cylinders stored or used onsite?

-

Are compressed gas cylinders capped with a metal protective cover when not in use?

-

Do empty cylinders have their valves closed?

-

Are compressed gas cylinders stored to prevent tipping or falling?

-

Person responsible

-

Date for action to be closed out

-

Auditor comment

3-Confined Space

Confined Space

-

Do you have confined spaces that have potentially hazardous conditions? Confined Space (Has limited or restricted means of entry or exit (Tanks, vessels, silos, storage bins, hoppers, vaults, pits, and space with limited means of entry)

-

Are only trained personnel permitted to enter confined spaces? Do they have the appropriate equipment to enter the space safely?

-

Do you have permit required or non permit required confined space posted properly?

-

Safe Entry procedures are established for permit required or non permit required confined space for employees and contractors?

-

Emergency and protective equipment and materials provided and available?

-

Person responsible

-

Date for action to be closed out.

-

Auditor comments

4-Electrical Safety

Electrical Safety

-

Electrical hazards observed

-

Do electrical panels and disconnects have 36" radial clearance for emergency access?

-

Are there any electrical cords that are supplying equipment not considered temporary that should be hard wired?

-

Were there excessive extension cords, surge protectors or overloaded circuits observed?

-

Are electrical panels, disconnects and breakers labeled as to what they control?

-

Observed electrical panels and disconnects or junction boxes with open slots, uncapped conduit holes, discontinued circuits or uncovered wiring.

-

Are electrical panels and disconnects labeled with amperage and voltage?

-

Person responsible

-

Date for action to be closed out.

-

Auditor comments

5-Emergency & Fire

Emergency Equipment

-

Emergency equipment issues

-

Spill kits available where required, inspected and adequate for amount and type of chemicals on site?

-

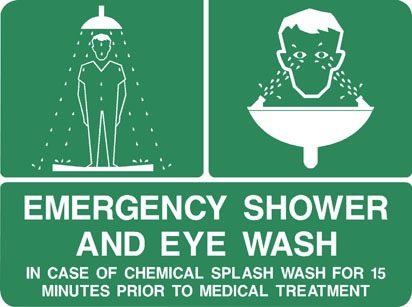

Are eyewash stations, showers and fire blankets available, inspected and working properly?

-

Are first aid kits available, applicable for the facility, stocked and readily available?

-

Person responsible

-

date for action to be closed out.

-

Auditor comments

Emergency Preparedness

-

Emergency preparedness issues observed

-

Evacuation plan displayed and understood by all employees?

-

Evacuation plan and maps displayed and understood by all employees?

-

Do employees know where to go (a safe zone) and do you have roll call procedures in place?

-

Do you conduct mock drills annually to prepare workers and staff for an emergency?

-

Are emergency numbers posted and up to date in a conspicuous location?

-

Person responsible

-

Date for action to be closed out.

-

Auditors comments

Fire Prevention

-

Fire prevention hazards observed

-

Oily rags and combustible refuse stored in covered metal containers?

-

Fire alarm system, if fitted, functioning correctly?

-

Are Fire Extinguishers inspected monthly, documented and clear of obstructions?

-

Are Fire hoses inspected annually and clear of obstructions?

-

Have automated sprinkler systems and risers been certified within the last 5 years and are they clear of materials?

-

Is paper, rubbish and flammable material stored away from potential fire or combustion hazards?

-

Person responsible

-

Date actions to be closed out

-

Auditor comments

6-Environmental

Environmental Hazards

-

Environmental issues were observed!

-

Is hazardous waste labeled legibly and properly with contents?

-

Observed potential sewer or storm drain pollution.

-

Have employees that handle hazardous waste been trained on spill and leak procedures?

-

Person responsible

-

date for action to be closed out

-

Auditor comments

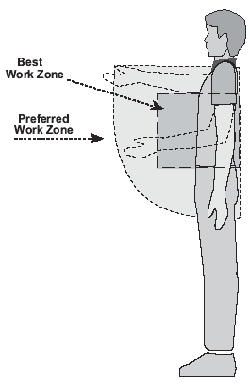

7-Ergonomics

Ergonomics

-

Ergonomic hazards observed

-

Can work be done without repetitive twisting, bending or lifting? Is the work area above shoulder level?

-

Can employees keep their hands or wrists in a neutral position when they are working?

-

All managers have received formal training in safety and health management responsibilities?

-

Where workers are exposed to strains and sprains do you conduct warmup exercises or rotate workers to prevent repetitive motion injuries?

-

If workers have to push or pull objects using great amounts of force, are mechanical aids provided?

-

Are there sufficient rest breaks, in addition to scheduled rest breaks, to relieve stress from repetitive-motion tasks?

-

Is work arranged so that workers are not required to lift and carry too much weight?

-

Are pressure points on body parts such as wrists, forearms and backs of thighs avoided?

-

Are workers exposed to excessive vibration from tools or equipment?

-

Are chairs and work benches adjusted, positioned, and arranged to minimise strain on the body?

-

Are tools, instruments, and machinery shaped, positioned, and handled so that tasks can be performed comfortably?

-

Are mechanical assists available to the worker performing materials-handling tasks?

-

Person responsible

-

Date action to be closed out.

-

Auditor comments

8-Exits

Exits

-

Means of egress deficiencies observed

-

Exits clear of obstructions?

-

Are doors on cold-storage rooms provided with inside release mechanisms that release the latches and open the doors?

-

Where exit doors open directly onto an area where vehicles may be operated, are adequate barriers and warnings provided to prevent employees from stepping directly into traffic?

-

Emergency exit lighting and illuminated exits in place and operable?

-

Where exits are not visible are directional signs provided?

-

Are exit doors able to open from the direction of exit travel without the use of a key or special knowledge or effort?

-

Person responsible.

-

Date action to be closed out.

-

Auditor comments

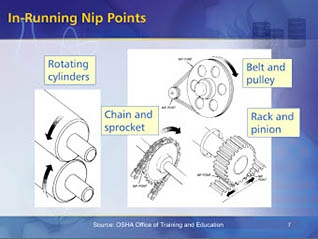

9-Guarding & LOTO

Machine Guarding

-

Machine Guarding Hazards Observed

-

Guards firmly secured and not easily removable?

-

Observed removed or damaged machine guards. SERIOUS HAZARD

-

Guards prevent workers from reaching under, around or behind guarded area?

-

Point-of-operation guards provided and in place?

-

Observed bypassed safety switches or interlocks. SERIOUS HAZARD<br>

-

Pinch points and inward running rollers are properly guarded?

-

Belts, chains, gears, sprockets, pulleys and flywheels guarded?

-

Machine controls within easy reach of the operator?

-

Guards provided for any other hazardous moving part of the machine?

-

Person responsible.

-

Date for action to be closed out.

-

Auditor comments

Lock out/Tag out

-

Control of hazardous energy (LOTO) issues observed

-

Have written Lockout/Tagout procedures been developed for all hazardous equipment?

-

Have the required periodic audits of energy control procedures been performed and documented? 1910.147(c)(6)(ii)

-

Is Lockout/Tagout equipment available? Are all lockouts documented?

-

Have employees performing lockout tagout been effectively trained?

-

Person responsible.

-

Date action to be closed out.

-

Auditor comments

10-Housekeeping & Inspections

Housekeeping

-

Housekeeping hazards observed

-

Entry and walkways kept clear of materials and blockage?

-

Walkways adequately and clearly marked?

-

Floor surfaces even and uncluttered?

-

Are footpaths in good condition?

-

Are railings in good condition?

-

Are fall preventive measures in place and used where gaps occur in railings?

-

Stairs and risers kept clear?

-

Are liquid spills removed quickly?

-

Intersections kept clear of boxes, pallets, etc?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

Inspections and Procedures

-

Control of hazardous energy (LOTO) or Inspection issues observed

-

Are weekly hazardous waste inspections performed if applicable?

-

Are you conducting monthly period safety inspections to document a safe work environment?

-

Do you inspect eyewash stations, emergency lighting, fire extinguishers and any other emergency equipment regularly?

-

Date action to be closed out

-

Person responsible

-

Auditor comments

11-Machine Shop

Machine Shop and Maintenance Areas

-

Machine shop was inspected

-

When welding is the proper ventilation in place, is there a shield to protect other workers and are employees trained on safe welding and hot work procedures?

-

Are maintenance records kept to show PM or other regular maintenance on equipment and to verify equipment in facility is kept in safe working condition?

-

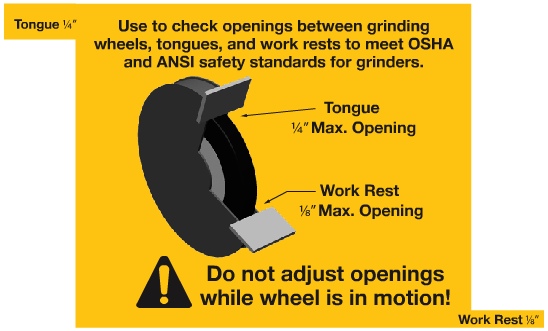

Bench Grinders - Shields in place, tool rest adjusted within 1/16", grinder securely mounted, no non-ferrous material in wheel? 1910.215(b)(1)(iii)

-

Are ladders over 6' and other equipment safely secured to prevent falling?

-

Are hand tools in safe working order? Are electrical cords in good condition?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

12-Noise Exposure

Noise Exposure

-

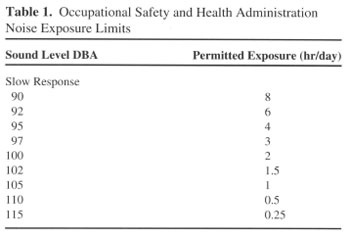

Noise from equipment or process was found to exceed safe Decibel levels of 85 DB

-

Are noise levels in any areas at or above 90 decibels for an 8 hour period?

-

If yes are employees required to wear hearing protection and is it well stocked and readily available?

-

Do you have a written Hearing Conservation Program?

-

Do you conduct annual audiometric testing for workers exposed to excessive noise?

-

Are areas posted where hearing protection is required?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

13-Training & PPE

Personal Protective Equipment -PPE

-

PPE hazards

-

Personal protective equipment is well stocked and available for the hazards present at this facility?

-

Fall protection PPE is available where applicable and areas where required are posted to restrict access to trained personnel only?

-

Are respirators or dust masks being utilized properly where applicable?

-

Do you have a written Respiratory Program if respirator use is required? Are all employees using respirators trained?

-

Have all workers using PPE been trained on the proper use, fit and limitations of the PPE?

-

Are engineering controls in place to protect workers before PPE is utilized?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

Employee Training

-

Employee training issues observed

-

Facility conducts comprehensive employee hazard training and ensures all participate; in addition, employees can demonstrate proficiency in, and support of areas covered by training?

-

Facility ensures workers receive documented safety training for the equipment they will be operating. <br>Workers are informed of the hazards of the equipment, PPE required, engineering controls and safe operating procedures utilising operators manuals or safe work procedures.

-

Basic First Aid training

-

Confined Space - Does the employer have documentation of each employee’s name, the signatures or initials of trainers and the dates of the training?

-

Lockout Tagout - Does the employer have certification that training has been accomplished and kept up to date including each employees name and training dates?

-

New Employee Training: are all employees being trained properly before beginning work for specific hazards associated with their task and general hazards in the facility. Additionally are they trained where emergency equipment and supplies are located and what to do in an emergency or spill of a chemical?

-

Personal Protective Equipment - Does the employer have certification with employee’s name, date and subject for personal protective equipment training?

-

Eye safety for hazards present

-

Emergency Preparedness

-

Respirator training, fit testing and medical evaluations are completed when required?

-

Slips Trips and Falls training

-

Safe lift or Industrial Ergonomics

-

Other site specific training deficiencies noted where applicable?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

14-Office

Office Areas

-

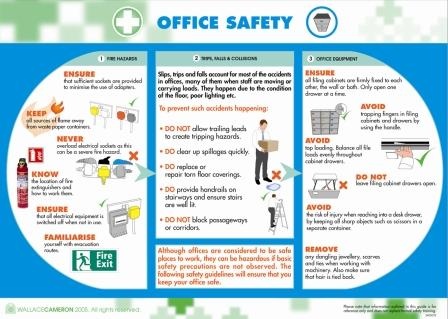

Office areas were inspected and hazards were found.

-

Exit paths are free of boxes/materials at all times?

-

Aisles, walkways, and work areas are free of trip and fall hazards (i.e. torn carpets, turned up edges of door mats, boxes etc.)

-

Illuminated exit and emergency lighting working properly?

-

First aid kits and fire extinguishers available and inspected regularly?

-

36” clearance is maintained in front of all electrical panels and fire extinguishers?

-

Electrical cords and plugs are in good condition: not frayed, taped, spliced, covered with carpet or the ground prong missing?

-

Work and storage areas are free of improper storage (e.g., heavy, high and/or unstable storage)

-

Shelf and wall units over 2mts or by exit aisles are secured to prevent tip over?

-

Computer work stations and work areas are ergonomically correct and workers are working safely?

-

The use of space heaters is kept to a minimum and the area around them kept clear of combustible materials?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

15-Postings and Signage

Signs and Posters

-

Legislation required posting

-

HSE posters are current and the information that is required to be filled out by the employer is up to date?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

Warning Signs and Labels

-

Warning signs, labels and postings

-

Warning signs, stickers or labels were placed in areas or on equipment to notify or warn employees of specific hazards.

-

Are areas where PPE is critical and hazards are prevalent posted to remind workers to wear their assigned PPE?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

16-Mobile plant

Mobile plant

-

Mobile plant hazards observed

-

Do mobile plant operators have current training certifications and are they operating the plant safely?

-

Are plant items in safe working condition? Tires good, horn works, backup alarm operational, no cracks in hoses, chains even and greased, etc.

-

Are daily plant checklists being completed, communicated and defects closed out?

-

Person responsible

-

Date action to be closed out

-

Auditor comments

17 Written plans/procedures

Written Plans and Procedures.

-

Written plans and procedures were checked.

-

Is your company's Health and Safety policy up to date and being applied? Has it been reviewed and signed by an officer of the company in the last year?

-

Do you have required written plans such as a respiratory protection program , a chemical hygiene plan, a lockout tagout program or noise exposure program in place and being applied per the plan?

-

Do you have a written emergency preparedness programme or fire safety programme and is it complied with?

-

Do you have documented employee accountability programme in place with progressive discipline for safety violations?

-

Do you have a Heat Illness Prevention Programme that applies to all employees that may be at risk of heat illness and applies to all indoor and outdoor places of employment where environmental risk factors for heat illness are present.

-

Fire prevention plan

-

Person responsible

-

Date action to be closed out

-

Auditor comments

18 Walking Surfaces/Ladders

Walking, Work Surfaces and stairs

-

Walking work surface hazards observed.

-

Catwalks, walkways and coverings must be free from hazardous openings, fall hazards or trip hazards

-

Aisles and passageways are kept clear of obstruction causing a hazard, sufficiently wide for equipment to operate and permanent Aisles are marked clearly to indicate the path.

-

Open pits, tanks, vats, ditches and vaults must be safely covered and or have protective guardrails to protect workers from fall hazards.

-

Load rating plates must be posted for mezzanine and storage areas

-

Stairs with 4 or more risers must have railings or hand rails. Stairs min width 22" , with slip resistant surface recommended

-

Person responsible

-

Date action to be closed out

-

Auditor comments

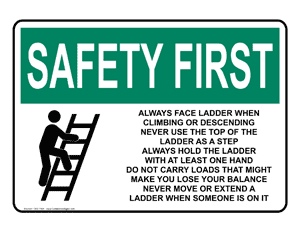

Ladders, step stools and platforms.

-

Ladders safety violations observed.

-

Ladders must support 4 Times the intended load.

-

Ladders are secured when not in use

-

Ladders and step stools are used safely. not standing on top step, fully opened, on a flat safe surface

-

Step stools are designed with handles to support workers when reaching or stacking items.

-

Fixed ladders are in safe operating condition and do not put workers in an unsafe hazardous position.

-

Person responsible

-

Date action to be closed out

-

Auditor comments

Confirmation & Signature

-

Reviewed audit items with staff

-

Reviewed with:

-

Safety Manager Signature

-

Supervisor Or Manager Signature

-

I have received and acknowledged the attached safety audit.

-

Select date