Title Page

-

Site

-

Date

-

Conducted by

-

Some questions require evidence to be provided which may be an explanatory note, picture etc. Pictures can be taken with phone/tablet camera or uploaded from the desktop PC.

-

Negative responses may require an action to raised which will be indicated where appropriate.

Fire Risk Assessment

-

Is the fire risk assessment up to date, relevant and completed by a trained manager (if "Yes" enter date of last FRA)?

Fire Evacuation Plan

-

Is there a current and accurate fire evacuation plan for the site?

-

Are there signs around the site advising what the fire evacuation procedure is?

-

Fire action notices located at key points i.e., MCP

-

Are contractors and visitors made aware of the emergency evacuation procedures?

Fire Detection & Alarm Systems

-

Is a fire detection system installed?

-

Is an annual service undertaken?

Emergency lighting

-

Is the building adequately covered by emergency lighting?

-

Escape routes, fire exits, unlit rooms, work areas i.e., workshop etc.

-

Is the lighting system subject to a service and maintenance contract?

-

Are the service records maintained in the fire log book?

-

Is the lighting system compliant with BS5266 part 1?

-

Do monthly tests of the lighting system take place?

-

Are the system tests recorded in the fire logbook?

Fire Extinguishers

-

Are there sufficient numbers of fire extinguishers for the risk?

-

Is the fire fighting equipment suitable for the type of fire risk?

-

Are fire extinguisher, hose reels provided with suitable signage and suitably positioned (wall hung, stand etc.)?

-

Is the fire fighting equipment subject to a service and maintenance contract?

-

Are equipment service maintenance records maintained in the fire log book?

Fire Wardens

-

Are there a sufficient number of fire Wardens for the site and hours of operation?

-

Are FW suitably trained?

-

Sample employee training records

-

Do Fire Wardens carry out monthly site inspections?

-

are these recorded through SafetyCulture?

Responsible Person for the Site Fire Safety

-

Is the SRP person trained in fire safety?

-

Suitable courses are the Nebosh Fire Certificate, or the companies internal safety management course that includes fire safety and is directed at Managers and business leaders.

-

Date of training

-

Are non conformances from fire audits, fire risk assessment and fire inspections recorded and resolved?

-

Is the site responsible person aware of their responsibilities and the Fire Safety SOP13?

Fire and Emergency Evacuation

-

Is there a site plan?

-

Where applicable does the site plan detail high risk locations such as gas stores?

-

Can the plans be accessed in the event of an emergency evacuation easily?

-

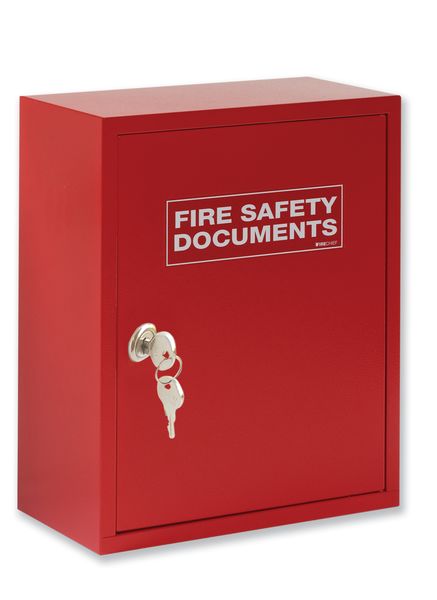

Fire documents should be stored in a fire box located next to the main fire alarm panel.

-

Do fire drills take place once a year during the night and are they recorded in the Fire Log? (Guidance only as a minimum, more frequent is recommended)

-

What is the date of the last fire drill?

-

Are fire drills timed and recorded? (Continuously improve the efficiently of a speedy evacuation to save life.)

-

Do fire drill debriefs take place to capture lessons learnt?

-

Are there any colleagues on site who require a PEEP (Personal Emergency Evacuation Plan)?

-

Is there a PEEP in place for this person?

-

Is the PEEP shared with the fire warden(s) and the individual?

Fire log book

-

Is there a fire log book for the site?

-

Is the fire log book easily accessible?

-

Fire log book should be stored in a fire box located next to the main fire alarm panel.

Fire signage

-

Is there suitable and sufficient fire signage to mark escape routes and fire exits.

-

Is there signage detailing where the fire assembly point is?

-

Is there no smoking signage around the site and offices?

-

Is there suitable signage near high-risk storage of compressed gases and combustible materials?

Storage and waste management

-

Are combustible materials stored away from sources of ignition?

-

Are flammable materials stored in suitable cabinets?

-

Are cabinets secure and suitably labeled?

-

Is appropriate fire fighting and detection equipment evident in high risk areas?

Fire Escape Routes

-

Are escape routes free from obstructions?

-

Are escape routes safe and free from combustible materials?

-

Notices, posters etc. should be limited and securely secured to the wall, preferably within a protected noticeboard. Items such as bunting should not adorn the walls or ceilings.

-

Do escape routes lead to a place of safety?

Building Fabric

-

Are there procedures in place to make sure compartmentation is maintained?

-

Is there any evidence of failure of compartmentation i.e. holes in walls, poorly fitting fire doors etc.?

-

Is there an understanding of the risk of fire spread and adequate controls in place to prevent it?

Fire Doors

-

Are fire escape doors clearly indicated with appropriate signage?

-

Are fire escape doors in good condition?

-

Check for condition of glazing, door furniture, condition of door etc.

-

Do fire doors comply with current regulations when closed i.e. seal, gap etc.

-

Fire doors closed and not wedged open?

-

Doors may be held open with approved devices which release upon activation of fire alarm.

-

Are fire door windows covered and/or obscured preventing vision into the room.

Final Fire Exit

-

Do fire exit doors have correct signage?

-

Should indicate final exit door (no arrows).

-

Are fire exit doors in good condition and open easily?

-

Do fire exit doors push open without requiring turning a catch etc.?

-

Do fire exit doors have a push bar or push pad to open (key locks are not permitted)?

-

Are there any obstructions behind the fire exit door?

-

Do fire exits open onto safe walkways leading to assembly point?

Fire assembly points

-

Are the fire assembly points clearly indicated with appropriate signage?

-

Signage should be visible upon exiting the building

-

Are there directional signs leading to the fire assembly point?

-

Is there a safe route, including adequate lighting, to the assembly point?

-

Are the assembly points in a safe location, suitable distance from building and other fire risks and suitable for the number of evacuees?

-

Is there information for visitors and contractors on where the fire assembly point is and what the procedures are (notice normally placed next to MCP)?

Fire incident reporting

-

Are all incidents of fire, both vehicle and building reporting using the approved procedure and all necessary persons emailed? Ask the site responsible person to provide an example and discuss the process.

-

Are all incidents investigated with findings and lessons learned shared?

Wet and dry risers and hydrants

-

Are wet/dry risers located on site?

-

Are the risers maintained?

-

Are fire hydrants located on the site?

-

Are the hydrants inspected monthly?

-

Are the hydrants serviced and inspected annually by a suitable contractor?

-

Please provide date of last external inspection.

Alternative Fuel Vehicles

-

Does this site have alternative fuel vehicles and/or alternative fuel types on site?

-

What type of fuel is on this site? (Select all that apply)

-

Does the fire risk assessment include alternative fuel risks and controls?

Lithium Ion Batteries

-

If Battery Electric Vehicles or Hydrogen are at this site, are their suitable controls in place to prevent thermal runaway from overcharging and damaged batteries?

-

Are there arrangements in place to ensure charging of lithium ion batteries is carried out in a safe way, ensuring charging is supervised and there is no risk of overcharging?

-

Is charging carried out away from combustible materials?

-

Are there storage controls in place for the safe disposal of damaged lithium ion batteries?

-

Are these controls detailed in the site fire risk assessment?

DSEAR

Gas Cylinders

-

Are gas cylinders stored on site?

-

Are gas cylinders, which are not in use, stored in an appropriate external cage?

-

Example of cage.

-

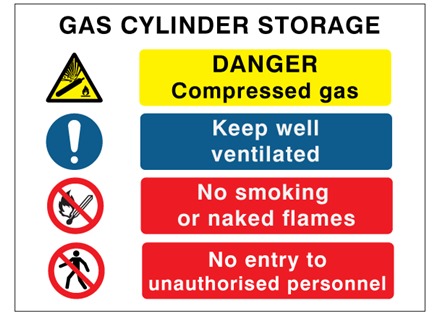

Is there suitable and clear signage displayed (example shown below)?

-

Example of signage.

-

Is the storage cage free from combustible materials?

-

Is the storage cage away from drains, manhole covers etc.?

-

Is the cage secure to prevent unauthorised access?

-

Is a 9Kg powder extinguisher located in the vicinity of the cylinder storage area (flammable gases)?

-

Is the extinguisher in good condition with no signs of corrosion etc.?

-

Is the extinguisher stored in a suitable cabinet?

-

Typical external extinguisher cabinet.

-

Is the extinguisher clearly identified with appropriate signage?

-

Has the extinguisher been serviced in the last 12 months?

-

Are different gases stored at least 3m apart from each other?

-

Are empty and full cylinders stored separately?

-

Are valves closed and cylinders labeled (full/empty)?

-

Are oxy-fuel sets stored internally, sited at least 2m from fixed sources of ignition?

-

If spare cylinders are stored inside, are they secured upright against a wall (max.2 permitted internally)? Please add note if N/A selected.

Flammable Substances

-

Are flammable substances stored on site (also consider small quantities i.e., cleaning products)?

-

Is appropriate signage on display in the storage area?

-

Example of sign.

-

Are all flammable substances stored in a robust steel, fire-resistant cabinet of approved type?

-

Example of typical cabinet.

-

Are flammable substances stored away from sources of ignition?

-

Are flammable storage areas free from combustible materials?

-

Is the storage of flammable liquids kept to a minimum (max. 250 litres flammable / 50 litres highly flammable)?

-

Are aerosols stored in suitable cabinets or cages?

-

Is there adequate ventilation and earthing for decanting / dispensing flammable solvents?

-

Is suitable secondary containment / bunded trays or similar utilised for holding flammable containers?

-

Are the required separation distances maintained for different classes of materials?

-

Segregation Chart

Air Bags

-

Are airbags stored on site?

-

Are airbags stored in a robust steel, fire-resistant cabinet of approved type?

-

Is the storage cabinet locked when not in use?

-

Is the storage cabinet separated from doorways, sources of heat and ignition by at least 2m?

-

Is the airbag storage area free from combustible material?

-

Is appropriate signage displayed in the storage area?

-

Example of sign.

Ventilation & Extraction

-

Is ventilation adequate in areas where flammable substances, gases etc. are stored?

-

Is appropriate warning signage displayed at dust extraction equipment?

-

Example of sign.

Batteries & Battery Charging

-

There is a risk of thermal runaway where lithium ion batteries are left to charge overnight or unsupervised. make sure they are NEVER on charge in an area that is not supervised and charging areas are well away from combustible materials.

-

Is battery charging undertaken on site?

-

Is battery charging conducted with at least 2m clearance from combustible material?

-

Are EV batteries adequately segregated from other combustible substances?

-

If observed, is the charging of lithium-ion batteries supervised?

-

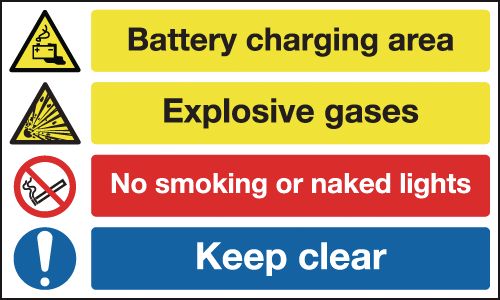

Is appropriate safety warning signage displayed in the charging areas?

-

Example of sign.

Fuel Delivery & Storage

-

Is bulk fuel delivered to site i.e., diesel?

-

Is there an earthing point in the delivery area?

-

Is the earthing point accessible and in good condition?

-

Is the delivery and storage area free from combustible materials?

-

Is fuel storage away from sources of ignition?

-

Is appropriate safety warning signage displayed in the fuel area (relative to type of fuel stored)?

-

Is the signage in good condition and conforms to current regulations?

Isolation

-

Are mains gas supplies (or other hazardous gases) fed into the property?

-

Are main isolation valves clearly identified with suitable signage (gases)?

-

Are isolation valves easily accessible?

-

Is the main gas incomer free from accumulated debris?

Coating Process

-

Do coating processes take place on site i.e., spray booths etc.?

-

Are combustible materials kept away from spray areas?

-

Is decanting of solvents conducted with adequate ventilation present?

-

Are containers kept closed to prevent escape of vapours?

-

Is all equipment adequately earthed?

-

Is dust accumulation kept to a minimum on surfaces, ledges etc.?

-

Is there adequate LEV in use to extract dusts?

-

Is the storage of flammable liquids kept to a minimum (max. 250 litres flammable / 50 litres highly flammable)?

-

Are all solvent based paints kept in appropriate cabinets in single layers (COSHH approved)?

-

Example of typical cabinet.

-

-

Are the cabinets away from sources of ignition?

-

Are trays / lipped edges in use on mixing benches and tables?

-

Is housekeeping to a good standard?

I, the undersigned, confirm this audit took place and was completed accurately.

-

Name

-

Date

-

Signature