Information

-

Area Lead Full Clean Final Check Title (i.e. Fluid Bed # 473/ Nifedipine ER/ 10/01/16)

-

Fluid Bed #:

-

Product Name:

-

Lot #:

-

NDC # (Last Four(4) Digits):

-

Clean Type:

-

Conducted on

-

Prepared by

Supervisor Assessment

Supervisor Assessment

-

Are all cleaning sheets up to date?

-

1. Check lights, ceiling, walls, floor, doors and windows for powder or residue.

-

Door jams and on the floor around sliding or swinging doors.

-

Floor under computer cabinet.

-

Special attention to floor under plenum and the back wall behind fluid bed.

-

Do any of the above items require further attention? If so document with comments and photos.

-

2. Check inside upper chamber of fluid bed.

-

Exhaust valves. Are they free of beads, pellets, or powder?

-

Bag shake pistons and attached cables

-

Bag seal track, ledges, and the bag seals themselves. Inspect the entire length of each bag seal.

-

Inspect cross bar for product build up.

-

-

Do any of the above items require further attention? If so document with comments and photos.

-

3. Upper Fluid Bed Exterior

-

Exterior lip/ledge at bottom of upper chamber

-

Upper chamber seal track

-

Do any of the above items require further attention? If so document with comments and photos.

-

4. Check Plenum and Inlet Area

-

Inspect interior bowl area of plenum, including drain hole, rotor coupler (threaded holes), and inlet air entry area.

-

Using a flash light inspect the inlet duct work as far as visually possible as well as the inlet air seal area.

-

Examine the exterior of the plenum bowl, particularly underneath the bowl and the support beams.

-

Step 4 -

-

Do any of the above items require further attention? If so document with comments and photos.

-

5. Check Bed Framing and Attachments

-

Vertical Support Beams

-

On top of winch housings.

-

Product temperature probe storage tube.

-

Pump area including the pump caps.

-

Nooks and crannies in the area of the air pressure gauges.

-

Hoses, tubing, and cords that are present on the fluid bed.

-

-

Do any of the above items require further attention? Is so document with comments and photos.

-

6. Check Gral Bowl and Associated Assemblies

-

Inspect the bowl interior including any drain holes.

-

Inspect the interior ceiling of the gral particularly where the impeller and chopper blades attach.

-

Inspect impeller and chopper bladdes

-

Using a ladder if necessary, inspect the very top of the gral house for product build up.

-

Inspect all ports for the sight glasses, gral socks, and probes that exist on the top of the gral.

-

Inspect the discharge valve assembly. Pay close attention to areas around shafts, areas underneath the valve area that are out of sight and around any ledges or protrusions.

-

Inspect underneath the gral bowl and it's supporting arms.

-

-

Do any of the above items require further attention? If so document with comments and photos.

-

7. Check for moisture in inner closet

-

8. Is room dry enough for AQL inspection?

-

9. Room is ready for Quality Check. IF FAIL, what rework is necessary?

-

Add media

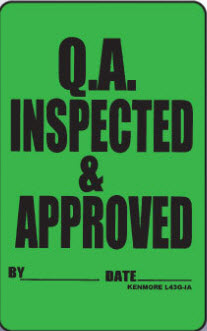

Assessment Results

Quality Results

-

-

Did the Quality Check pass? If NO Response, Make notation of what rework was necessary.

-

Add signature