Title Page

-

Technician

-

FSP

-

Workorder or NMI

-

Location

-

Retailer / Client

-

Conducted on

-

Conducted By

Site Details

Work Details

-

Details about the work being Audited

-

What kind of work is being undertaken? Is it a consolidation? Was it just a Meter Exchange? Like for Like?

-

Employee or Sub Contractor

-

Photo of Job prior to Commencement

Personnel on Site

-

Lead Technician

-

Select Checkbox if additional people are onsite

Non Negotiables Matrix Compliance

-

JSA

-

Observation Comments

-

Supporting Images

-

PPE

-

Observation Comments

-

Supporting Images

-

ID Card from Retailer

-

Observation Comments

-

Supporting Images

-

Electrical License

-

Observation Comments

-

Supporting Images

-

Images that may support any Observations

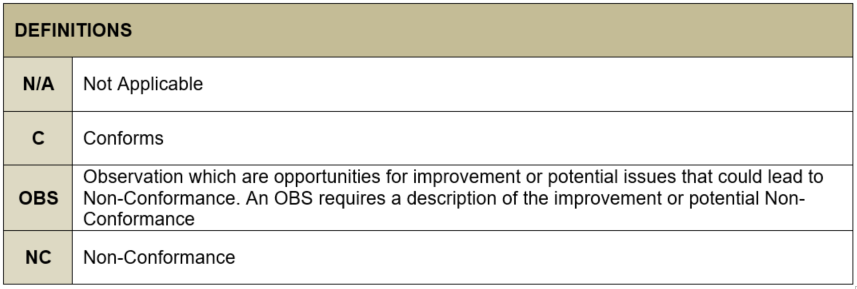

Definitions

Audit Pre-Work

1.0 Customer Checks

-

1.1 All relevant SWMS and Work Procedures are available, including retailer specific processes and collateral

-

Comments

-

1.2 Technician has access to all work order details

-

Comments

-

1.3 Copies of all required authorities (licences and cards) on site as required? (e.g. ID, Construction Induction card, A grade licence etc.)

-

Comments

-

Please select one of these and provide a copy

-

Add media

-

1.4 Is a current version of the Electrical Safety Rules on site? Rules and appropriate Handbooks.

-

Comments

-

1.5 Do employees have their Electrical Network Passport on site?

-

Comments

-

1.6 Is training in ESI passport up to date?

-

Comments

-

Additional Comments

2.0 Plant and Equipment

-

2.1 Vehicles are clean, well-kept with the appropriate signage, and well maintained?

-

Comments

-

External photo of Vehicle being used, including Rego

-

2.2 Is the emergency equipment identifiable and easily accessible to all personnel? Are there labels for First Aid kits, fire extinguishers, and spill kits?

-

Comments

-

2.3 Is the LV Rescue kit fully stocked?

-

Comments

-

2.4 Are all fire extinguishers charged, tagged and in date?

-

Comments

-

2.5 Are First Aid Kits serviceable and Type B for Electrical Workers Compliant? Content and audit checklist present?

-

Comments

-

Refer to ISSC14 Guide to Electrical Workers Safety Equipment - Table 3.1

-

2.6 Are "Sharps Kits" on vehicles?

-

Comments

-

2.7 Are gas bottles, chemicals & equipment appropriately stored in designated cabinets?

-

Comments

-

2.8 Is equipment that requires Test & Tag, Testing or Calibration up to date (electrical leads, modiwark, meggers, multimeters, NST testers, height sticks, gas detectors, slings, lifting equipment etc) Record Details of equipment and next test / calibration date:

-

Comments

-

Supporting Photos

-

Multimeter

-

Clampmeter

-

NST Tester

-

Continuity Tester

-

Additional Comments

3.0 PPE

-

3.1 Are hard hats serviceable? Are they dated and initialled? Are they less than 2 years old? Are they free of labels/stickers on them?

-

Comments

-

Date Issued

-

Initials

-

3.2 Is the appropriate safety clothing worn by all personnel? Wrist to ankle in industry approved apparel for the state or jurisdiction the work is being conducted.

-

Comments

-

For NSW, all workers in the Electrical Industry, must be wearing Wrist to Ankle HRC2 Rated High Visibility Clothing.

-

3.3 Are suitable safety boots worn by all personnel? Are they in reasonable condition? Are steel caps covered?

-

Comments

-

3.4 Are ear muffs or plugs being worn for tasks as required or if not being worn are available?

-

Comments

-

3.5 Are safety glasses being worn by personnel? Are the appropriate safety glasses being worn for the task?

-

Comments

-

3.6 Are LV Gloves being worn by Electrical Workers? Are they serviceable? (random check for air leaks)

-

Comments

-

3.7 Are appropriate work gloves being worn for non-line work?

-

Comments

-

3.8 Is sunscreen available for use?

-

Comments

-

Additional Comments

4.0 JSA, Hazard Assessment and Environment

-

4.1 Were you asked to be inducted and signed onto the JSA for the site?

-

Comments

-

4.2 Were you read / or have read the JSA?

-

Comments

-

4.3 Were you advised of the site hazards and control measure?

-

Comments

-

4.4 Is the location of the Job Site correctly recorded and dated?

-

Comments

-

4.5 Is the task/s to be performed correctly recorded?

-

Comments

-

4.6 Have the Hazards been identified on the site documentation and control measures put in place?

-

Comments

-

4.7 Are all the personnel on site been recorded and signed onto the Daily Site Risk Assessment? Including sub-contractors e.g. Traffic Control, Crane operators etc.

-

Comments

-

4.8 Have all personnel on site been advised of site hazards? Ask them questions about the hazards and see if they know the control

-

Comments

-

4.9 Are environmental risks identified and control measures in place? Noise, asbestos, spills, weeds, disease control

-

Comments

-

4.10 Are vehicles, plant & equipment managed to prevent environmental hazard? Plant / machinery / equipment cannot transfer dirt / mud onto the road?

-

Comments

-

4.11 Is vegetation well protected from moving plant and equipment?

-

Comments

-

4.12 Is all site rubbish correctly stored for removal from site?

-

Comments

-

Additional Comments

Audit Work Processes

5.0 Customer and Doorstep

-

5.1 Was the Life Support Status checked against the work order?

-

Comments

-

5.2 Doorstep Protocol Followed?

-

Comments

-

Customer was home?

-

5.1.1 Was the customer satisfied?

-

Comments

-

5.1.2 Did tech introduce themselves?

-

Comments

-

5.1.3 Did tech show ID?

-

Comments

-

5.1.4 Was the customer asked about life support?

-

Comments

-

Additional Comments

6.0 Pre-Test and Inspection

-

6.1 Safe Approach Test completed?

-

Comments

-

6.2 Has JSA been completed?

-

Comments

-

6.3 Signal test completed?

-

Comments

-

6.4 Have the site details been verified?

-

Comments

-

6.5 Have the meter reads been finalised?

-

Comments

-

6.6 Installation under test sign displayed?

-

Comments

-

6.7 Ladderwork Required for Installation

-

6.7.1 Are the ladders in a serviceable condition and appropriate for use?

-

Comments

-

6.7.2 Is the ladder at a 1:4 incline or wall and being footed?

-

Comments

-

6.7.3 Is ascent and descent being conducted correctly with 3 points of contact maintained and climbing belt being used?

-

Comments

-

6.7.4 Is any ladder being carried being carried correctly?

-

Comments

-

6.7.5 Has heights risk assessment been completed?

-

Comments

-

Additional Comments

7.0 Electrical Pre-Testing and Isolation Practices

-

7.1 Polarity test completed?

-

Comments

-

7.2 Phase Sequence test completed?

-

Comments

-

7.3 NITP Identified?

-

Comments

-

Please select NITP used

-

7.4 NST test completed?

-

Comments

-

7.5 Site has been Isolated using the appropriate Techniques including the Prove Test Prove method

-

Comments

-

Additional Comments

8.0 Work Processes

-

8.1 Have the work instructions been followed?

-

Comments

-

8.2 Have correct techniques been followed?

-

Comments

-

8.3 ACM present onsite?

-

Comments

-

Select if ACM Present

-

8.3.1 Have asbestos procedures been added in the JSA?

-

Comments

-

8.3.2 Is the correct Asbestos equipment available?

-

Comments

-

8.3.3 Was the appropriate drilling process used?

-

Comments

-

Additional Comments

9.0 Electrical Testing

-

9.1 Polarity test completed?

-

Comments

-

9.2 Phase Sequence test completed?

-

Comments

-

9.3 NITP Identified?

-

Comments

-

Please select NITP used

-

9.4 NST test completed?

-

Comments

-

9.5 Load Test Completed for All Elements and applicable Registers

-

Comments

-

Additional Comments

10.0 Meter Commissioning

-

10.1 Display working?

-

Comments

-

10.2 Date and time settings correct?

-

Comments

-

10.3 Correct configuration programmed

-

Comments

-

10.4 Equipment correctly mounted?

-

Comments

-

10.5 No exposed copper on tails?

-

Comments

-

10.6 Correct ripple relay installed?

-

Comments

-

10.7 Ripple LED pulsing?

-

Comments

-

10.8 Is the board adequately tagged/marked?

-

Comments

-

10.9 Correct Aerial installed with relation to the Signal Test Result?

-

Comments

-

10.10 Are meter terminals at correct tightness - 1.8nm?

-

Comments

-

10.11 Terminal screws not damaged?

-

Comments

-

Additional Comments

11.0 Site Closure

-

11.1 Has the Technician taken a final photo with all equipment sealed?

-

Comments

-

11.2 Has the Technician the cleaned up debris from the work site?

-

Comments

-

11.3 If ACM was onsite, has all Waste Bags been goose necked properly?

-

Comments

-

11.4 Has the Technician contacted the customer (if present) to inform them of the completion of works?

-

Comments

-

11.5 Has the Technician left the appropriate retailer collateral with the customer (if present) or; left in a convenient location e.g. letter box?

-

Comments

-

Additional Comments

-

Photo of Completed job

-

Please scan the installed meter number

Sign-Off and Closure

Technician Sign Off

-

I accept and acknowledge the feedback from this Audit Report

-

Add signature

-

Technician Comments and Feedback

Auditor Sign-Off

-

The information in this Audit report is true and correct, and I have discussed the results with the technician.

-

Add signature

-

Any additional Comments