Title Page

-

Trade as / Town

-

Conducted on

-

Officer

- Stuart Adkins

- Nadine Buckland

- Laura Cowlishaw

- Denise Ingram-Hall

- Donna Shaw

- Victoria Spanovic

- Alison Whitmore

-

Food Business Operator

-

Premises Address

-

Premises Telephone Number

-

Email address

Premises History

-

Red Flag e.g. factors to be aware of from this inspection and any previous officers visits/complaints that may be significant or require follow up

-

Red Flags

-

Issues at last inspection

-

Previous schedule

-

Civica checked

-

Current registration

-

Date of latest registration

-

Previous risk rating

- A

- B

- C

- D

- E

- Unrated

-

Previous FHRS

- 5

- 4

- 3

- 2

- 1

- 0

- Not Applicable

Premises

Premises Details

-

Description of business

- Primary Producer

- Manufacturer / Packer

- Importer / Exporter

- Distributor / Transporter

- Supermarket / Hypermarket

- Small Retailer

- Restaurant / Cafe / Canteen

- Hotel / Guesthouse

- Pub / Club

- Take Away

- Caring Premises

- School / College

- Mobile Food Unit

- Restaurants & Caterers other

-

Opening times

-

Mobile phone number

-

Head Office

-

Primary Authority

-

Ownership

-

Food Hazards / Significant Risks / Allergy free food

- Vacuum Packing

- Sous Vide

- Lightly Cooked Foods

- Modified Atmosphere Packaging

- Open Raw

- Open RTE

- Low risk foods

- Frozen foods

- Wrapped high risk

- Allergy free dishes

-

Raw foods

- Chicken

- Beef

- Burgers

- Eggs

- Fish

- Shellfish

- Vegetables

- Carpaccio

- Pork / Gammon

- Turkey

- Sushi

- Bacon

- Sausages

- Shashmi

- Mince

-

High Risk Foods / Dishes

- Cooked Meats

- Salad items

- Sandwiches

- Rice

- Roasts / Carvery

- Desserts

- Pate

- Pies

- Kebabs

- Indian cuisine

- Chinese cuisine

- Buffet foods

- Mayonnaise

- Pasta

- Casserole / Stew

- Quiche

- Sausage rolls

- Coleslaw

- Pizza / Pizza Toppings

- Soup - veg based

- Soup - meat based

- High risk ready meals

-

Other Food Types

Staff / Customers Details

-

Name

-

Position

- Food Business Operator

- Manager

- Head Chef

- Chef

- Cook

- Kitchen Assistant

- Staff member

- Shop assistant

-

First Language

- Chinese

- English

- Bengali

- Polish

- Punjabi

- Urdu

- Arabic

- Turkish

- Mandarin

- Romanian

- Gujarati

-

Number of staff

- 0-10

- 10-20

- 20-50

- 50 +

-

Staff Interviewed

-

Number of customers

- <20

- 20-50

- 50-100

- 200-300

- 500+

-

Vulnerable Groups

- Hospital

- Nursery

- Elderly

- None

-

Scale of operation

Purchase and Receipt / Distribution/ Storage

Purchase and receipt

-

Reputable supplies

-

Suppliers audited

-

Delivery temperature check

-

Separated raw / cooked

-

Are all eggs used Class A (Catering)

-

If providing lightly cooked egg dishes to vulnerable groups check if accredited e.g Lion Brand

Distribution from premises

-

Transport of food

-

Area covered

-

Temperature records

-

Raw and ready to eat separated

-

Is a refrigerated vehicle used

-

Cool box / Hot box used

-

Is outside catering undertaken

Cold Storage

-

Storage temperatures checks

-

Records

-

Separation raw / cooked

-

Unwrapped food protected

-

Adequate stock rotation

-

Stock labeling

- Day dots

- Dated labels

- None

-

Number of days (high risk foods)

Fridges and Freezers / Preparation / Sinks / Dishwasher

Fridges and Freezers

-

How many refrigeration units / equipment are in the premises

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 10 plus

-

Where are they located

- Main kitchen

- Preparation Room

- Bar

- Cellar

- Dry Store

- Garage

- First floor storage

- Front servery

- Shop

- Walk in Fridge

- Walk in Freezer

- Mobile Unit

- Inside Toilet

- Outside Toilet

- Other

-

Details

-

Non compliant units

Unit

-

Type

- Fridge

- Freezer

- Display fridge

- Self select

- Pizza topping chilled bed

- Walk in fridge

- Walk in freezer

-

Location

- Main kitchen

- Preparation Room

- Bar

- Cellar

- Dry Store

- Garage

- First floor storage

- Front servery

- Shop

- Walk in Fridge

- Walk in Freezer

- Mobile Unit

- Inside Toilet

- Outside Toilet

- Other

-

Condition

- Damaged / Split seals

- Dirty seals

- Dirty interior

- Dirty handles

- Rusty shelving

- Damaged exterior

- Damaged interior

- Damaged handles

- Damaged top

-

Add media

-

Officers temperature reading (degrees C)

-

Temperature monitoring equipment used by food business

- Probe

- Display

- Gauge

- IR

- None

- Food substitute

Preparation

-

Adequare work surfaces / Appropriate prep time / temperature

-

Separate areas for raw and cooked prep

-

Separate equipment for raw and cooked

-

Details of separation

- Separate work surfaces

- Separate equipment inc utensils/ boards

- Time separation

- Cleaning and Disinfection between activity

- Separate staff

- Designated sinks

- Separate raw/cooked fridges

- Separate fridges

-

Service / Handling methods

- Gloves

- Hands

- Tongs

- Scrapers

- Knives

- Spoon's

- No touch techniques

- Other

-

Other method

-

Defrosting

- Fridge

- Cold Water

- Ambient

- Microwave

-

Equipment colour coded

- Chopping boards

- Knives

- Tongs

- Chopping board stand

- Buckets

- Mops

-

Repair / Condition of equipment

-

Equipment issues

Sinks / Dishwasher

-

Is there an adequate number of sinks

-

Use of sinks

- Time separation

- 2 stage cleaning

- Designated sinks

- Raw only sink

- Veg only sink

- Salad use bowl / collander

-

Dishwasher

-

Rinse temperature above 82 degrees

-

Sterilising sinks

Cleaning / Cloths

Cleaning

-

2 stage cleaning and disinfection in place

-

Stage 1

-

HSW = Hot Soapy Water / TSC = Trigger Spray Cleaner / CWO = Cold Water Only / ABC = Antibacterial Cleaner

-

Cleaning

- Hot water only

- Hot water and detergent

- Trigger spray cleaner

- Cold water only

- Anti bacterial cleaner

-

Method

- Reusable cloths / scourer

- Disposable cloths

-

Stage 2

-

Disinfection

- Anti Bacterial Spray

- None

- Heat

-

Method

- Reusable cloths / scourer

- Disposable cloths

-

Brand

- Asda

- Dettol

- Aldi

- Tesco

- Sainsbury

- Astonish

- Chemex Uk

- Clean Pro / Clean Pro Plus

- Clover Chemicals

- Ecolab

- Happy Shopper

- Jangro

- Jeyes

- Milton

- Nilco

- Star drops

- D10

- Aldi

- Other

-

Details

-

British Standard

- BSEN1276:1997

- BSEN13697:2001

- Not BSEN compliant

- Unknown

-

Contact time

- Instant

- 30 seconds

- 1 minute

- 5 minutes

- >5 minutes

- Left to dry

-

Dilution rate

- Ready to Use

- Dosing System

- Other

-

Further Details

-

Details

-

Is sanitiser / disinfectant used in accordance with manufacturers instructions

-

ICT = Incorrect Contact Time / ID = Incorrect Dilution / IBS = Incorrect Bottle Storage

-

Incorrect use of sanitiser/ disinfectant

- Incorrect contact time

- Incorrect dilution

- Incorrect bottle storage

Cleaning cloths

-

What type of cloths are you using

- Reuseable

- Disposable

-

Cleaning

- Cold water

- Cold water and bleach / detergent

- Hot water

- Hot water and bleach / detergent

- Washing machine >82 degrees

- Washing machine <60 degrees

- Boiling water and detergent

-

Colour coded cloths

-

Details

Cooking / Hot Holding / Reheating / Cooling / Probes

Cooking

-

Are cooking temperatures checked

-

Records

-

Core temperature

-

Validated cooking procedures

- Cut open

- Boiling

- Colour change

- Steaming

- Juices clear

- Texture change

-

Probe in use

-

PW = Probe Wipes / HSWO = Hot Soapy Water Only / HSWS = Hot Soapy Water & Sanitiser / NON = None / SPT = Sanitiser & Paper Towels

-

Probe cleaning

- Probe wipes

- Hot soapy water only

- Hot soapy water & Sanitiser

- Sanitiser & paper towels

- None

-

Is probe calibrated

-

Boiling water

-

Ice water

-

Other

-

Details

-

Safe handling procedures

Hot holding equipment

-

Hot cupboard

Food Temperature

-

Is the unit running at the correct temperature

-

Bain marie

Food Temperature

-

Is the unit running at the correct temperature

-

Pie warmer

Food Temperature

-

Is the unit running at the correct temperature

-

Rice cooker

Food Temperature

-

Is the unit running at the correct temperature

Reheating

-

Does the food business reheat any foods

-

Reheating Practices

-

Are reheating temperatures checked

-

Records

Cooling

-

Does the food business cool hot foods to be used again

-

BC = Blast Chiller / ST = Shallow Trays / AM = Ambient / ICW =Iced Water, Cold Water / OTH = Other

-

Cooling methods

- Blast chiller

- Shallow trays

- Ambient

- Iced water / cold water

- Other

-

Other

-

Are cooling temperatures checked

-

Records

HACCP / Documentation

Documented systems

-

Does the business require a documented system

-

Pre requisites

- Cleaning

- Pest Control

- Training

- Maintenance

- Stock Control

- Food Policy e.g recall, foreign body policy

- Waste Disposal

-

Is there a documented food safety system

-

Type of documented system

- SFBB

- In house system

- NCASS

- School Food Support Service

- Subway Global Food Policy

- Mitchell's and Butlers

- Greene King

- Spirit Group

-

System details

-

Is there traceability on site for food items

Safer Food Better Business

-

Diary completed (Inc opening and closing checks)

-

Is the SFBB pack regularly reviewed / updated

-

Issues non compliance

- Not all safe methods completed

- Not all sections completed

- Out of date / not reviewed

- Staff training not completed

- Not following SFBB pack

- Other

In house documented system

-

Records

- Cold temperatures

- Cooked temperatures

- Delivery records

- Cleaning schedule

- Cleaning rota

- Internal Audits

- Staff questionnaire

- Pest control

- Sampling records

- Buffet record

- Hot holding

-

Alternative record keeping

-

Photos of systems

Training / Hand Washing / Over clothing

Staff Training

-

Are staff trained in appropriate food safety

-

Training

Staff member

-

Name

-

Training

- Lvl 1 Award Food Safety

- Lvl 2 Award Food Safety

- Lvl 2 Award in HACCP

- Lvl 3 Award Food Safety

- Lvl 3 Award in HACCP

- Lvl 4 Award Food Safety

- In house training

- SFBB Training

-

Date of training

-

Certificates

-

HACCP Training

-

Digital copies

-

Sickness policy are staff aware

-

Use 48 hours clear

Personal Hygiene

-

Handwashing

-

Appropriate hand washing observed

-

Hand washing technique acceptable

-

Are staff trained / instructed on effective hand washing

-

Are staff wearing suitable overclothing

-

Protective clothing

- Chef Whites

- Hat

- Hairnet

- Apron

- Disposable Apron

- Uniform (on site only)

Allergen Control

Allergen Management and Training

-

Is there a policy / procedure in place on how the business manage food allergens

-

Have staff been provided with allergen awareness training incl company procedures and policies with regard to dealing with allergenic customers

-

Has someone been appointed with responsibility for food allergens

-

Have emergency procedures been considered in the event of an incident

Allergen free food

-

Do you provide allergen free foods incl at events / buffets

-

Allergen free food

Dish

-

Name of dish

-

Allergens free from

- Celery

- Cereals con Gluten

- Molluscs

- Crustaceans

- Fish

- Nuts

- Peanuts

- Eggs

- Milk

- Soya

- Lupin

- Mustard

- Sulphites

- Sesame seeds

-

Controls

- Sealed Container / Unopened packaging

- Separate storage area

- Decanted food labelled with allergens

- Spillage policy / Contaminated product controls

- Separate area

- Allocated food handler incl when absent

- Separate equipment / utensils

- Separate cleaning equipment

- Effective cleaning of prep area and utensils

- Effective hand washing

- Separate PPE

- Colour coded equipment

- Sauces and Garnishes considered

- Buffet - Plated food

- Composite ingredient check

-

Have cross contamination risks been identified and adequate controls put in place in storage, preparation and service

-

Officers must consider any complex equipment used inc vacuum packers, mincers and slicers

Rooms / Layout

Layout / Design / Construction / Size

-

Does the general layout of the premises allow adequate cleaning

-

Does the general layout of the premises prevent cross contamination

Structural / Layout issues non compliance only

-

Location

- Main kitchen

- Preparation Room

- Bar

- Cellar

- Dry Store

- Garage

- First floor storage

- Front servery

- Shop

- Walk in Fridge

- Walk in Freezer

- Mobile Unit

- Inside Toilet

- Outside Toilet

- Other

-

Structural / Layout Issues

Item

-

Item

- Floor

- Wall

- Suspended ceiling

- Ceiling

- Window

- Door

- Hand Contact Point

- Work surface

- Other

-

Construction

- Painted plaster

- Plastic cladding

- Stainless steel

- Metal

- Painted metal

- Stone

- Ceramic tile

- Quarry tile

- Melamine

- Bare wood

- Painted wood

- Carpet

- Altro

- Linoleum

- Laminate

- Concrete

-

Condition

- Dirty

- Damaged

- Unsealed

- Disrepair

- Cracked

- Mouldy

- Re-decoration

- Porous

- Toxic material

- non washable

-

Add media

WHB / Toilet / Waste / Changing / Washing Facilities / Drainage / Light / Ventilation

General structure

-

How many WHBs are in the premises

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 10 plus

-

Where are they located

- Main kitchen

- Preparation Room

- Bar

- Cellar

- Dry Store

- Garage

- First floor storage

- Front servery

- Shop

- Walk in Fridge

- Walk in Freezer

- Mobile Unit

- Inside Toilet

- Outside Toilet

- Other

-

Detail

-

Non compliant WHB

WHB

-

Location

- Main kitchen

- Preparation Room

- Bar

- Cellar

- Dry Store

- Garage

- First floor storage

- Front servery

- Shop

- Walk in Fridge

- Walk in Freezer

- Mobile Unit

- Inside Toilet

- Outside Toilet

- Other

-

Details

- No hot water

- No cold water

- No soap

- No hand drying

- Dirty basin

- Damaged basin

- Broken tap

- Dirty taps

- Leaking tap

- No adequate drainage

- Blocked drainage

-

Add media

-

Toilet Compliant

-

Lobby / Intervening space

-

Ventilation

-

Changing facilities

-

Food Waste Compliant

-

Company details

- Biffa

- Veiolia

- Bakers

- Wastecycle

- Sita

- CBC

- Other

-

Details

-

Frequency of collection

- 1 per week

- 2 per week

- 3 per week

- Other

-

Details

-

Oil used onsite

-

Company details

- Olleco

- I C Oils

- Bookers

- Makro

- Bidvest

- Other

-

Details

-

Water supply Compliant

-

Type of supply

-

Please refer premises to private water supply officer

-

Drainage Compliant

-

Type of supply

- Mains drainage

- Private drainage

- Container

-

Lighting Compliant

-

Type

- Natural light

- Fluorescent tubes

- Light bulbs

-

Diffusers

-

Ventilation Compliant

-

Type

- Natural

- Mechanical

-

DGF = Dirty, Greasy Filters / FM = Filters Missing / GG = Greasy Gulleys / DF = Dirty Fans

-

Issues

- Dirty / Greasy filters

- Filters missing

- Gulleys greasy

- Dirty fans

Pest Control

Pest control

-

Is the premises free from pests

-

Pest(s) present on site

- Rats

- Mice

- Cockroaches

- Flies

- Ants

- Stored product insects

- Insects - General

- Birds / Vertebrates

-

Response by FBO

- Nothing

- Contacted contractor

- DIY

-

Does the business carry out its own pest checks

-

Is there a pest control contract

-

Company

- Rentokill

- Nottingham Pest

- Ecolabs

- Pest Force

- Target

- Pest Away

- Four Seasons

- Conquer

- Mitie

- First class hygiene

- Cannon

- Interserve

- Other

-

Other provide details

-

Pests listed

- Rodents

- Insects

- Birds

-

Date of last visit

Complex Equipment

Complex Equipment

-

Is there any complex equipment on site

-

Types of equipment

-

Vacuum packer on site

-

Ensure that vacuum packers are NOT shared use (Ecoli O157 Guidance) if shared immediately stop any use and assess with FBO

-

Are there designated / separate vacuum packers for raw and ready to eat foods (if no fully detail cleaning procedures)

-

Cleaning

- Hot water only

- Hot water and detergent

- Trigger spray cleaner

- Cold water only

- Anti bacterial cleaner

-

Separated raw and ready to eat packaging

-

Are all vacuum packed foods given 10 days or less shelf life

-

Mincer on site

-

Cleaning

- Hot water only

- Hot water and detergent

- Trigger spray cleaner

- Cold water only

- Anti bacterial cleaner

-

Slicer on site

-

Are there separate slicers

-

Cleaning

- Hot water only

- Hot water and detergent

- Trigger spray cleaner

- Cold water only

- Anti bacterial cleaner

-

Separated raw and ready to eat packaging

-

Mixer / Food Processor / Robot Coupes on site

-

Cleaning

- Hot water only

- Hot water and detergent

- Trigger spray cleaner

- Cold water only

- Anti bacterial cleaner

Additional Notes / Revisits

-

Additional Notes

-

Notes

-

Extra photos

Risk Rating (FHRS)

-

(5 rating = 0-15 No score >5) (4 rating = 20 No score >10) (3 rating = 25-30 No score >10) (2 rating = 35-40 No score >15) (1 rating = 45-50 No score >20) (0 rating =>50)

-

Level of current compliance (food hygiene / safety / temperature)

- 25 Almost total non compliance

- 20 General failure

- 15 Some major non compliance

- 10 Some non compliance

- 5 High standard - minor

- 0 High standard

-

Level of current compliance (structure / cleaning / layout)

- 25 Almost total non compliance

- 20 General failure

- 15 Some major non compliance

- 10 Some non compliance

- 5 High standard - minor

- 0 High standard

-

Risk Rating 30 = Poor record / No FSMS, 20 = Varying record / No FSMS, 10 = Satisfactory record / Progress FSMS, 5 = Good record / Effective FSMS, 0 = Excellent record / Full FSMS

-

Confidence in management / control procedures

-

New FHRS

-

New FHRS sticker issued on site

-

Does the premises require a revisit

-

Timescale

Revisit

-

Revisit

-

Type

-

Officer

- Stuart Adkins

- Nadine Buckland

- Laura Cowlishaw

- Denise Ingram-Hall

- Donna Shaw

- Victoria Spanovic

- Alison Whitmore

-

Select date

-

Has the revisit been carried out by the set timescale

-

Have all the legal requirements been completed

-

Further action required

- Revisit

- Improvement Notice

- Self certification

- Letter

- Coaching / Advice

-

FHRS Re score

- 5

- 4

- 3

- 2

- 1

- 0

- Not Applicable

Health and Safety Interventions

-

Is the ‘Beverage gases in the hospitality industry’ health and safety intervention relevant to this visit?

-

Where do they store their gas cylinders

-

Can the external area only be accessed by authorised personnel

-

How is the area ventilated

-

Has a risk assessment been carried out of the ‘cellar’ area

-

Have safe systems of work been identified for activities in the ‘cellar’

-

Are there any gas alarms to the ‘cellar’ area

-

If yes, do they know what to do if it does?

-

Do they have procedures that they can use to assist in the identification of gas leaks

DISPENSING SYSTEM

-

Is there an installation certificate for each installation

-

Are the pressure systems inspected by a competent engineer every five years or to a schedule produced by a competent engineer (Written Scheme of Examination)

-

When is the next inspection due

-

Are safety signs and procedures on display

GAS CYLINDERS

-

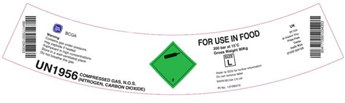

What gas cylinders do they have?

- CO2

- Nitrogen

- Mixed Gas

- Other

-

What other gas cylinders do they have

-

Are their cylinders obtained from a reputable supplier

-

Are the cylinder contents clearly identified on the cylinder label

-

-

Are the product traceability labels visible

-

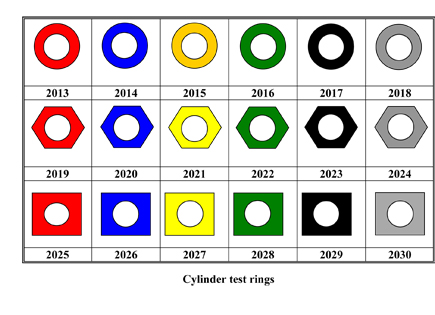

Are there current coloured plastic test date rings between the valve and the cylinder

-

-

Have they been supplied with the product safety data sheets

-

Are the cylinder valves sealed when delivered

-

Are the cylinder valves in good condition with no evidence of tampering with the residual pressure valve (RPV)

-

Do they have spare washers available

-

Do the cylinders look in good condition i.e. no excessive rust, dents, gouges, bulges or defacing of any kind.

-

Are cylinders properly secured

-

Used in an upright position in a safe, secure, dry place

-

Are numbers of cylinders kept to a minimum

-

Are empty cylinders stored separately to full cylinders

-

Are cylinders moved around safely

-

Is the cellar floor free from obstructions and spillages

-

Are gloves available for the handling of gas cylinders

ACCESS AND TRAINING

-

Is the entry to the ‘cellar’ area restricted to authorised persons only

-

Do they tell someone else when going to enter the cellar

-

Have all authorised people being suitably informed, instructed and/or trained with regards to 'cellar safety'

-

The following areas need further instruction, information and / or training

- ALL

- Pressure systems used on site

- Manual handling of cylinders

- Understanding associated hazards

- Access and work in confined spaces

- Safe storage of cylinders

- Cylinder changeover procedures

- Use of PPE

- Ventialtion and Monitoring Systems

- Action to be taken in an emergency

BEER LINE CLEANER

-

Has a COSSH assessment been carried out of the beer line cleaner

-

Is changing the beer lines carried out by a competent person

-

Are all containers clearly labelled

-

What PPE do they use

- None

- Gloves

- Goggles

- Apron

- Safety Shoes

-

Are the beer lines cleaned during open hours

-

How do they inform others when a line is being cleaned?

-

How do they inform others when the line is safe to use again.

Inspection Evaluation

Basis for recommendation

-

Please pick the appropriate type of intervention applied this time and / or the outcome. This will determine your recommendation on the next section

-

Interventions

- Cat A, B or not "broadly compliant" C risk rating

- Cat C "broadly compliant" risk rating. This intervention was an Inspection

- Cat C "broadly compliant" risk rating. This intervention was a partial inspection

- Cat C "broadly compliant" risk rating. This intervention was an audit

- Cat C "broadly compliant" risk rating. This intervention was an "other official control"

- Cat D risk rating. This intervention was an official control

- Cat D risk rating. This intervention was a non official control

- Cat E risk rating

-

Any comments / areas particularly focused on at this intervention?

Recommended next intervention / alternative enforcement strategy (AES)

-

Bearing in mind the requirements and options available in the Code of Practice, on the basis of information above, the following is suggested for consideration at the next due date:

-

IF = Inspection Full / IP = Inspection Partial / OOCI = Other Official Control Intervention / NOCI = Non Official Control Intervention / AES = Alternative Enforcement Strategy

-

Interventions

-

If "Other official control intervention" or "Non official control intervention" chosen suggest which or if "AES" suggest what

-

Where a partial audit/inspection/other intervention is suggested - any particular area(s) to focus on?

-

Reason(s) why, where other intervention options are available, a full inspection is suggested

Photography Consent

-

To help us comply with the Data Protection Act 1998, we would like your consent before we take a photograph or recording of you, your child or the vulnerable adult you are responsible for. The images would be used to help promote the Council services and events.<br>The photograph or recording may be used by the media, on Council websites, Council social media accounts, in Council or partner publications or in exhibitions<br>I have read and understood the information and give permission for Charnwood Borough Council to use the photographs/recordings as detailed above

-

Signature

-

If signing on behalf of a child or person unable to sign or give verbal consent for themselves, please give their name and your relationship to them

-

Name

-

Relationship

-

Telephone Number

-

Council Officer

- Stuart Adkins

- Nadine Buckland

- Laura Cowlishaw

- Denise Ingram-Hall

- Donna Shaw

- Victoria Spanovic

- Alison Whitmore