Title Page

-

Name of audited location

-

Conducted on

-

Name and designation of auditor

-

Address of audited location

-

Auditee and their designation

-

Equipment inspected

-

Name and designation of audit observers (e.g. customer employees, staff from regulatory authorities, etc.)

-

Proton work activity assessment for audit purposes (e.g. servicing the couch, replacing parts on the gantry, etc.)

-

Work activity documentation from iSiR or SAP system (e.g. PB-BAW-50007818)

-

Audit document number for reference (e.g. 1-CIMC-Minokamo-Japan-31-Sep-2022). Ensure the PDF report file name is the same as the audit document number.

IMPORTANT REMINDER - Always ensure the health and safety of yourself and all other persons around you. When completing this checklist, please take action immediately to rectify any critical safety issues, rather than waiting to complete the report. Capture any details and escalate to your manager and the EHS team if required. All incidents and near misses should be reported immediately in the Healthineers EHS reporting tool myCority within 24hours.

Inspection Page 1/3

1) Emergency Evacuation & Preparedness

-

1.1-Aisles, passageways, and exit doors are free from obstruction?

-

1.1.1-Take photo(s) or video(s) of obstructed aisles, passageways, exit doors, etc.

-

1.2-Corridors/passageways are sufficiently wide for emergency evacuation?

-

1.2.1-Take photo(s) or video(s) of narrow corridors/passageways.

-

1.3-First aid kit in a well-lit and accessible location?

-

1.3.1-Record expiry date of first aid kits [Add note for additional first aid kits]

-

1.3.2-List of first aiders clearly marked at a visible location?

-

1.3.2.1-Take photo of first aider list.

-

1.3.3-Is first aid kit inventory checked regularly?

-

1.3.3.1-Take photo of first aid kit inventory check record.

-

1.3.4-First aid kit is well stocked?

-

1.3.1-Take photo(s) or video(s) of first aid kit in dark or inaccessible location.

-

1.3.2-Record expiry date of first aid kits (yyyymmdd) [Add note for additional first aid kits]

-

1.3.3-List of first aiders clearly marked at a visible location?

-

1.3.4-First aid kit inventory checked regularly?

-

1.4.5-First aid kit is well stocked?

-

1.4-Customer safety signs such as emergency evacuation map/emergency exits/hazard communication/emergency contacts are present and clearly visible to staff?

-

Comments/Notes/Findings not captured in checklist for Emergency Evacuation & Preparedness

2) General Workplace Safety and Health

-

2.1-Customer staff (supervisor, health physicist, doctor etc.) is present during inspection?

-

2.2-The workplace is not overcrowded or cramped?

-

2.2.1-Take photo(s) or video(s) of overcrowded or cramped workplace.

-

2.3-Toilets/restrooms are clean, sufficient, well-ventilated with good lighting?

-

2.3.1-Take photo(s) or video(s) of toilets/restrooms which are unclean/poorly ventilated/poorly illuminated.

-

2.4-The environmental conditions at the workplace is suitable and adequate with regards to temperature, light, humidity, noise, ventilation, dust, vibration, etc.

-

2.4.1-Take photo(s) or video(s) of workplace with poor environmental conditions (e.g. dusty, humid, noisy, etc.).

-

2.5- Varian employees do not display prohibited practices (smoking, alcohol consumption, apply cosmetics, etc.)?

-

2.6-The workplace displays good housekeeping practice to minimize slip, trip, fall, fire hazards?

-

2.6.1-Take photo(s) or video(s) of workplace with poor housekeeping.

-

2.7-Are shelves/racks used at the workplace?

-

2.7.1-Shelves/racks display the safe working load (SWL)?

-

2.7.1.1-Take photo of the SWL.

-

2.7.2-Shelves/racks are sturdy (not wobbly)?

-

2.7.2.1-Take photo(s) or video(s) of wobbly shelves or racks.

-

2.7.3-Shelves/racks have good structural integrity (no sunken platform/rusting/missing parts, etc.)?

-

2.7.3.1-Take photo(s) or video(s) of shelves/racks with poor structural integrity (rusty, sunken platform, parts missing, etc.)

-

2.8-Gas cylinders are safely secured to a fixed object and restrained?

-

2.8.1-Gas detectors are installed?

-

2.8.1-Take photo(s) of installed gas detector.

-

2.8.2-Gas detectors are up-to-date on calibration, servicing, and maintenance?

-

2.8.3-Are the labels on the cylinders legible (can be read easily)?

-

2.8.3.1-Take photo(s) or video(s) of defaced or unclear labels on the gas cylinder.

-

2.8.4-Unused cylinders have valve protection cap securely in place?

-

2.8.4.1-Take photo(s) or video(s) of gas cylinders without valve protection cap in place.

-

2.8.5-Workers have access to the safety data sheets for the gas cylinders?

-

2.8.5.1-Why do the workers do not have access to the safety data sheets?

-

2.8.6-Gas regulators show no signs of visible damage or deformity?

-

2.8.6.1-Take photo(s) or video(s) of gas regulators.

-

2.9-Only compatible works are carried out? Example of incompatible work is working directly under another work activity that involves falling object hazards.

-

2.10-Staff (record name in notes) can briefly describe what is incompatible work?

-

2.11-Are non-Work-At-Height PPE (eyewear, ear plugs, masks, helmets, footwear, clothing, gloves, etc.) available for staff to use?

-

2.12-List of PPE available?

-

2.13-Are auditees wearing the correct PPE during the audit?

-

Comments/Notes/Findings not captured in checklist for General Workplace Safety and Health

Inspection Page 2/3

3) Electrical Safety

-

3.1-Electrical safety signs are visible at appropriate locations?

-

3.1.1-Take photo(s) or video(s) of missing electrical safety signs.

-

3.2-Cables are not damaged (frayed/worn/exposed wiring/cut/etc.)?

-

3.2.1-Take photo(s) or video(s) of damaged electrical cables.

-

3.3-Electrical connections (breakers/switches/plugs/etc.) are not damaged (burn marks/exposed wiring/holes/rust/etc.)?

-

3.3.1-Take photo(s) or video(s) of damaged electrical connections.

-

3.4-Electrical connections are not likely to come in contact with water or other liquids?

-

3.4.1-Take photo(s) or video(s) of electrical connections in close contact with water or liquids.

-

3.5-Cables and connections show no sign of unsafe modifications?

-

3.5.1-Take photo(s) or video(s) of unsafe modifications on cables.

-

3.6-Extension cords are not daisy-chained (several extension cords connected together to increase accesibility to electrical power source)?

-

3.6.1-Take photo(s) or video(s) of daisy-chained extension cords.

-

3.7-Plugs in use have safety logo?

-

3.7.1-Take photo(s) or video(s) of plugs without safety logo.

-

Comments/Notes/Findings not captured in checklist for Electrical Safety

4) Fire Safety

-

4.1-Fire extinguishers are inspected, not expired, in visibly good working condition and unobstructed?

-

4.1.1-Take photo(s) or video(s) of uninspected/expired/damaged/obstructed fire extinguishers.

-

4.2-Fire hose reels are inspected, not expired, in visibly good working condition and unobstructed?

-

4.2.1-Take photo(s) or video(s) of uninspected/expired/damaged/obstructed fire hose reels.

-

4.3-Fire detection system (smoke/heat/flame) is present?

-

4.3.1-What is the fire detection system used?

-

4.3.2-Take photo(s) or video(s) of fire detection system.

-

4.3.3-Does the fire detection system show no visible signs of damage/corrosion?

-

4.3.3.1-Take photo(s) or video(s) of damaged fire detection system.

-

4.3.1-Why the fire detection system is not present?

-

4.4-Fire suppression systems are present?

-

4.4.1-What is the type of fire suppression system (e.g. water, chemical, gas, foam, etc.)?

-

4.4.2-Take photo(s) or video(s) of fire suppression system.

-

4.4.3-Does the fire suppression system show no visible signs of damage/corrosion?

-

4.4.1-Why the fire suppression system is not present?

-

4.5-Electrical connections are not likely to come in contact with flammable materials?

-

4.6-No stack/pile of combustible or flammable materials?

-

4.6.1-Take photo(s) or video(s) of stack/pile of combustible or flammable materials.

-

Comments/Notes/Findings not captured in checklist for Fire Safety

5) Chemical Safety

-

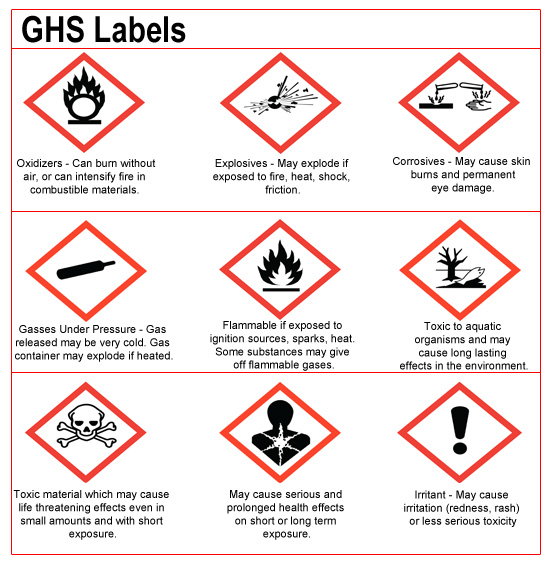

Under the Globally Harmonized System of Classification and Labelling of Chemicals (effective 01 JAN 2017), it is the responsibility of the manufacturer/importer to determine if their product is a hazardous chemical and if so, to correctly classify their product. If you are unsure about the classification of a chemical, you should contact your chemical supplier or the manufacturer/importer for more information. There are nine hazard pictograms in the GHS which represent the physical, health and environmental hazards. These are named: Explosives, Flammables, Oxidisers, Gasses under pressure, Corrosives, Acute toxicity, Environmental hazard, Harmful/irritant to ozone layer and Severe health hazards.

-

5.1-Chemicals are properly labeled according to GHS guidelines?

-

5.1.1-Take photo(s) or video(s) of chemicals not labelled according to GHS guidelines.

-

5.2-Chemicals (including waste) are properly stored prior to disposal?

-

5.2.1-Take photo(s) or video(s) of improperly stored chemicals (including waste).

-

5.3-Chemical spill kit is available for use at the site?

-

5.3.1-Take photo(s) or video(s) of available chemical spill kit.

-

5.4-Staff are able to briefly explain how to properly use the chemical spill kit?

-

Comments/Notes/Findings not captured in checklist for Chemical Safety

Inspection Page 3/3

6) Work-at-Height (WAH) Safety

-

6.1-There are no open sides from which a person could fall from?

-

6.1.1-Take photo(s) or video(s) of open sides from which a person could fall from.

-

6.2-There are no openings on the floor from which a person could fall into?

-

6.2.1-Take photo(s) or video(s) of openings on the floor from which a person could fall into.

-

6.3-Height of guard rails comply with local regulations?

-

6.3.1-If the height of the guard rails are non-compliant, what are the additional risk controls adopted?

-

6.3.2-Take photo(s) or video(s) of non-compliant guard rail height.

-

6.4-Gap distance in the guard rail comply with local regulations?

-

6.4.1-Take photo(s) or video(s) of non-compliant gap distance in the guard rail.

-

6.5-Is/are the field engineers(s) aware to inspect WAH PPE before each use?

-

6.5.1-Could staff briefly describe how to inspect WAH PPE before use in a satisfactory manner?

-

6.6-There are no fragile surfaces from which a person could fall from?

-

6.6.1-Take photo(s) or video(s) of fragile surfaces from which a person could fall from.

-

6.7-Ladders show no visible damage/deformity?

-

6.7.1-Take photo(s) or video(s) of damaged or deformed ladder.

-

6.8-Take photos of ladders with attached safety standard label

-

6.9-Are staff aware of the need to inspect the ladder before use?

-

6.10-Scaffolds and their components are regularly inspected by a competent person according to local regulations?

-

6.10.1-Take photo(s) or video(s) of scaffold inspection record.

-

6.11-Scaffolds show no sign of visible damage/deformity?

-

6.11.1-Take photo(s) or video(s) of damaged or deformed scaffolds.

-

6.12-Are staff aware of the need to inspect the scaffold before use?

-

6.13-Two horizontal and parallel guardrails on each side are in place and properly installed?

-

6.13.1-Take photo(s) or video(s) of scaffold showing missing guardrail.

-

6.14-The scaffolds platforms have toe-boards on all sides?

-

6.15-Does the scaffold come with a user manual supplied by the manufacturer?

-

6.16-Was the scaffold built to a recognized safety standard?

-

6.17-Sample several WAH PPE. Do these show no visible signs of damage/deformity?

-

6.17.1-Take photo(s) or video(s) of damaged or deformed WAH PPE.

-

6.18-Sample several WAH PPE. Are these current and not past expiry date?

-

6.18.1-Take photo(s) or video(s) of expired WAH PPE.

-

6.19-Are the WAH PPE properly stored and easily accessible?

-

6.19.1-Take photo(s) or video(s) of improperly stored or inaccessible WAH PPE.

-

Comments/Notes/Findings not captured in checklist for WAH Safety

7) Lifting Equipment Safety (e.g. crane/hoist/pulleys/rope/etc.)

-

7.1-Lifting tools/equipment show no signs of visible damage/deformity?

-

7.1.1-Take photo(s) or video(s) of damaged or deformed lifting tools/equipment.

-

7.2-Lifting tools/equipment are regularly inspected by a competent person according to local regulations?

-

7.3-Are staff aware of the need to inspect the lifting equipment/tool before use?

-

Comments/Notes/Findings not captured in checklist for Lifting Equipment Safety

8) Lockout and Tagout (LOTO)

-

8.1-Lockout devices have no visible damage/deformity?

-

8.1.1-Take photo(s) or video(s) of damaged or deformed lockout devices.

-

8.2-Tags are legible, robust, and and understandable by all staff who may be in the area?

-

8.2.1-Take photo(s) or video(s) of unreadable or damaged tags.

-

Comments/Notes/Findings not captured in checklist for LOTO Safety

9) Inspection on Other Equipment and Hand Tools

-

9.1-Sample several hand tools. Tools show no visible signs of damage/deformity?

-

9.1.1-Take photo(s) or video(s) of damaged or deformed hand tools.

-

9.2-Where applicable, safety labels/signs are clear and affixed to the equipment?

-

9.3-Patient treatment room/couch is clean and free from any observable potential biological hazards?

-

9.3.1-Take photo(s) or video(s) of couch with observable potential biological hazards.

-

9.4-Hand tools are stored safely in an organized manner?

-

9.4.1-Take photo(s) or video(s) of properly stored hand tools.

-

Comments/Notes/Findings not captured in checklist for Equipment and Hand Tools Inspection

10) Waste Management (excludes chemical, radioactive waste)

-

10.1-Is there an agreement with the Customer for waste management (parts for scrapping, e-waste, etc.)?

-

10.2-Is the waste properly segregated and stored prior to disposal?

-

10.2.1-Take photo(s) or video(s) of improperly stored or segregated waste.

-

Comments/Notes/Findings not captured in checklist for Waste Management

B) Document Review

1) Emergency Evacuation & Preparedness

-

1.1-Has Varian staff received EHS instruction/training/communication from customer?

-

1.1.1-Take photo(s) or video(s) of document/record showing EHS instruction/training/communication.

-

1.2-First aider keeps a record of treatments?

-

Comments/Notes/Findings not captured above for Emergency Evacuation & Preparedness

2) General Workplace Safety and Health

-

2.1-Staff has access to updated EHS documents (procedures/risk assessments, etc.) from Varian Corporate EHS?

-

2.2-Staff has access to the latest work procedures either on the iSiR, SAP, or GCS platform?

-

2.3-How many courses in the VPS training matrix have been completed? Do also state the total number of courses in the matrix.

-

2.4-Is there an appointed safety officer/lead to oversee daily EHS activities at the workplace?

-

2.4.1-Provide the name and designation of the appointed safety officer/lead.

-

2.5-Do staff perform work using electric or gas welding machines?

-

2.5.1-Please provide evidence of relevant training.

-

2.6-Do staff operate forklifts?

-

2.6.1-Please provide evidence of relevant training.

-

2.7-Where required by local regulations and excluding radiation safety, has staff completed medical examinations as a requirement to perform work?

-

2.7.1-Please provide evidence of medical examinations (e.g. tax invoice, confirmation notice from medical examiner, etc.).

-

2.8-Site employees know to report incidents, near misses, and good observations to EHS and to the Site Manager?

-

2.9-The site performs the monthly safety audit/inspections?

-

2.9.1-Take photo(s) or video(s) of completed monthly safety audits or inspections records.

-

2.9.2-Document evidence that a process is in place to correct discrepancies found in the monthly safety audit/inspections.

-

Comments/Notes/Findings not captured above for General Workplace Safety and Health

3) Electrical Safety

-

3.1-Staff have completed Electrical Safety training courses on Learn4U? Examples of such training are VPS Electrical Safety Part 1 and Part 2 and VPS Electrical Safety Checklist.

-

3.1.1-Please provide training records.

-

3.2-Provide evidence of other electrical safety training, if applicable.

-

Comments/Notes/Findings not captured above for Electrical Safety.

4) Fire Safety

-

4.1-Provide evidence of fire safety training, if applicable.

-

4.2-Is there a list of appointed fire wardens?

-

4.2.1-Take photo(s) or video(s) of fire warden list.

-

4.3-Provide evidence of fire warden training.

-

Comments/Notes/Findings not captured above for Fire Safety

5) Chemical Safety

-

5.1-Workers have access to Safety data sheets (SDS), either in paper or softcopy?

-

5.1.1-Take photo(s) or video(s) showing how workers access Safety Data Sheets.

-

5.2-Provide evidence of chemical safety training, if applicable.

-

5.3-Inventory of hazardous chemicals maintained and accessible on-site?

-

5.3.1-Take photo(s) or video(s) of hazardous chemical inventory.

-

Comments/Notes/Findings not captured above for Chemical Safety.

6) Work-at-Height (WAH) Safety

-

6.1-Staff performing WAH activities have the required license/training?

-

6.1.1-Take photo(s) or video(s) showing records of WAH licenses/trainings.

-

6.2-Staff managing WAH activities have the required license/training?

-

6.2.1-Take photo(s) or video(s) showing records of WAH licenses/trainings.

-

6.3-Is a list of WAH PPE assigned to staff available?

-

6.3.1-Take photo(s) or video(s) of WAH PPE assignment list.

-

6.4-WAH PPE are under a regular maintenance/inspection program?

-

6.4.1-Take photo(s) or video(s) of showing records of regular maintenance/inspection program.

-

6.5-Are there safe means of entry and exit for WAH work activities?

-

6.5.1-Take photo(s) or video(s) of unsafe means of entry and exit for WAH activities.

-

6.6-Varian staff using ladders at work have completed Ladder Safety training on Learn4U? Examples of such training are EHS Safe Ladder Operation.

-

6.6.1-Take photo(s) or video(s) of records showing ladder safety training.

-

6.7-Staff who move, operate, and inspect the scaffold are trained to recognize the hazards associated with it?

-

6.7.1-Take photo(s) or video(s) of records showing scaffold operation and inspection training.

-

6.8-Staff have completed the EHS Fall Protection training on Learn4U?

-

Comments/Notes/Findings not captured above for Work-at-Height Safety.

7) Lifting Equipment Safety (e.g. crane/hoist/pulleys/rope/etc.)

-

7.1-Is there a list of lifting tools/equipment used by staff?

-

7.2-Staff have completed training on operating overhead cranes?

-

7.3-Lifting equipment/tools have valid Lifting Machine (LM) certificate or equivalent document?

-

7.3.1-Take photo(s) or video(s) of certificate or equivalent document.

-

7.4-Is there an established and implemented Lifting Plan?

-

7.4.1-Take photo(s) or video(s) of Lifting Plan.

-

Comments/Notes/Findings not captured above for Lifting Equipment Safety.

8) Lockout and Tagout (LOTO)

-

8.1-Staff have completed EHS Electrical Safety and Lockout/Tagout (LOTO) training on Learn4U?

-

8.1.1-Please provide training records.

-

8.2-Staff could briefly describe the LOTO procedures in a satisfactory manner?

-

Comments/Notes/Findings not captured above for Lockout and Tagout (LOTO)

9) Lone Worker

-

9.1-Has the Site Manager identified the areas and tasks at the site where the Lone Worker Rule applies?

-

9.2-Were the site employees trained on the Lone Worker Rule before work began?

C) Structured Interview (choose several safety topics and staff for interview)

1) Work-at-Height (WAH) Safety

-

1.1-Name of interviewee and designation

-

1.2-Date of interview

-

1.3-Start time of interview

-

1.4-Staff could briefly describe the procedures to follow when working at the top of the gantry with the crane or lifeline as the anchor point?

-

1.5-Staff could briefly describe the emergency procedures for WAH activities?

-

1.6-End time of interview

-

Comments/Notes/Findings not captured above for Work-at-Height (WAH) Safety

2) Electrical Safety

-

2.1-Name of interviewee and designation

-

2.2-Date of interview

-

2.3-Start time of interview

-

2.4-Staff could briefly describe the observer rule for work on exposed energized circuits of 50 V or greater?

-

Comments/Notes/Findings not captured above for Electrical Safety

3) Lockout and Tagout (LOTO)

-

3.1-Name of interviewee and designation

-

3.2-Date of interview

-

3.3-Start time of interview

-

3.4-Staff could briefly describe how to communicate during LOTO work when out of line of sight?

-

Comments/Notes/Findings not captured above for Lockout and Tagout (LOTO)

4) Work-at-Height (WAH) Safety Harness Demonstration

-

4.1-Name of interviewee and designation

-

4.2-Date of interview

-

4.3-Start time of interview

-

4.4-Staff could demonstrate putting on a safety harness correctly and adjusting to ensure good fit?

-

Comments/Notes/Findings not captures above for WAH Safety Harness Demonstration

D) Work Activity Assessment

-

1.1-Name of staff to be assessed, and his/her designation

-

1.2-Date of assessment

-

1.3-Start time of assessment

1.4-Choose one of the following work activities for assessment.

-

1.4.1-Observe in real-time how the EHS monthly inspection is done by the site team using the provided checklist.

-

1.4.2-Mock demonstration of emergency rescue of fallen colleague hanging from a harness.

-

1.4.3-For specific work activity based on Varian maintenance and service documents, click Yes, and provide details in Question 1.5.

-

1.5-Description of work activity

-

1.5.1-Observed uncontrolled risks?

- General Safety and Health

- Electrical

- Fire

- Work-at-Height (WAH)

- Chemical

- Lockout-Tagout (LOTO)

- Radiation

- Lifting Equipment

- None observed

-

1.5.2-What are the uncontrolled risks?

-

Comments/Notes/Findings not captured above for Work Activity Assessment

E) Conclusion

-

1.1-Summary of audit findings

-

1.2-Summary of audit actions

-

1.3-Conclusion

F) Signatures and Acknowledgement

-

1.1-Auditor name and signature

-

1.2-Auditee name and signature

-

1.3-Auditee name and signature (sign as N.A if not applicable)

-

1.4-Auditee name and signature (sign as N.A if not applicable)

-

1.5-Auditee name and signature (sign as N.A if not applicable)

-

1.6-Auditee name and signature (sign as N.A if not applicable)

-

1.7-Auditee name and signature (sign as N.A if not applicable)

-

1.8-Audit observers (sign as N.A if not applicable)

-

1.9-Audit end date

-

1.10 Audit end time