Information

-

PREMISES RISK ASSESSMENT FOR:

-

DATE CONDUCTED:

-

SITE FOR WHERE EQUIPMENT IS KEPT:

- GLC - GATEWAY

- GLC - FREE SCHOOL (GPFS)

- GLC - LANSDOWNE

- GLC - HERRINGHAM

- GLC - PIONEER

- GLC BUILDING FUTURES

-

INSPECTION BY:

- Lee Spall

- Maggie Earey

- Rob MacMillan

- Daniel Starns

- Angela Ruston

- Jane Tyson

- Anne Fraser

- Kathryn Luckin

- Paul Luke

- Charlie Spall

- Jordan Jerram

- Jake Pumfleet

- Dean March

- Scott March

- OTHER

-

NAME OF ASSESSOR:

-

Please report any matters that may affect the outcome of the risk assessment:

H&S - EQUIPMENT CHECKLIST

-

IMPORTANT PLEASE READ:

TO HELP CARRY OUT CHECKS ON MULTIPLE EQUIPMENT IT IS RECOMMEND THAT YOU HAVE A PRINTED COPY OF THE CHECKLIST AT HAND FOR EASY REFERENCE.

WHEN REPORTING DEFECTS PLEASE ENSURE YOU STATE THE TYPE OF EQUIPMENT THAT HAS BEEN AFFECTED.

EQUIPMENT SELECTED FOR INSPECTION:

-

EQUIPMENT SELECTED FOR INSPECTION:

- OUTDOOR GYM EQUIPMENT (Lottery)

- OUTDOOR ACTIVITY PLAY (Lottery)

- SHELTERS

- BENCHING

- OUTDOOR CLIMBING WALL

- INDOOR CLIMBING WALL

- SWING TYPES

- PLATFORMS & STAGING

- INDOOR PLATFORMS & STAGING

- TREE / WENDY HOUSE

- ADVENTURE PLAY EQUIPMENT

- SLIDES

- MONKEY BARS

- NETBALL GOALS

- FOOTBALL GOALS

- AIR WALK DUO

- AIR WALKER DUO

- CYCLE

- CYCLE ARM BIKE

- CROSS RIDER

- CROSS RYDER DUO

- SKIER

- OTHER:

-

EQUIPMENT DESCRIBED:

-

STRUCTURES:

-

01). ARE THERE ANY SIGNS OF CRACKING?

02). ARE THERE ANY SIGNS OF BREAKING?

03). ARE THERE ANY SIGNS OF WARPING?

04). ARE THERE ANY SIGNS OF LOOSENING?

05). ARE THERE ANY SIGNS OF BENDING? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

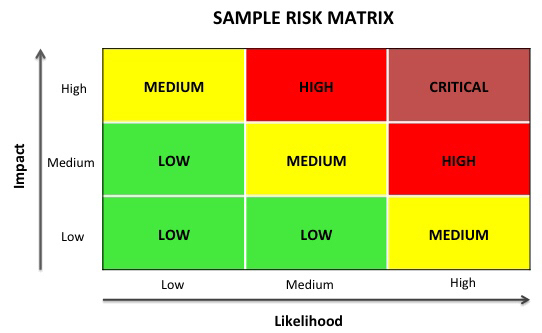

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

SURFACES AND FINISHES:

-

01). ARE ANY PROTECTIVE COATINGS MISSING?

02). ARE PROTECTIVE COATINGS CRACKED?

03). IS EQUIPMENT RUST FREE?

04). ARE SURFACES FREE FROM SPLINTERS? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

FITTINGS & CONSUMABLE PARTS:

-

01). ARE THERE ANY PARTS MISSING?

02). ARE THERE ANY PARTS BENT?

03). ARE THERE ANY BROKEN PARTS?

04). ARE ANY PARTS LOOSENING?

05). IS THERE ANY SIGNS OF WEAR?

06). ARE THERE ANY OPEN HOOKS ETC.? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

EDGES:

-

01). ARE THERE ANY PROTRUDING EDGES?

02). ARE THERE ANY SHARP EDGES? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

PINCH OR CRUSH POINTS:

-

01). ARE THERE ANY EXPOSED MOVING JOINTS - OTHER THAN DESIGN?

02). ARE THERE ANY EXPOSED MOVING COMPONENTS - OTHER THAN DESIGN? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

MOVING PARTS:

-

01). ARE THERE ANY WORN MOVING PARTS?

02). ARE THERE ANY COMPONENTS REQUIRING LUBRICATION?

03). ARE THERE ANY PARTS SEIZED?

04). IS THERE ANY EXCESSIVE MOVEMENTS - OTHER THAN DESIGN? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

GUARDS, HANDRAILS, SWINGING BARRIERS:

-

01). ARE THERE ANY GUARDS, HANDRAILS, OR SWINGING BARRIERS MISSING?

02). ARE THERE ANY BENT OR BROKEN GUARDS OR HANDRAILS?

03). ARE GUARDS, HANDRAILS, SWINGING BARRIERS SECURED? E.G. NOT LOOSE. -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

ACCESS:

-

01). ARE THERE ANY MISSING OR BROKEN RUNGS?

02). ARE THERE ANY MISSING STEPS OR TREADS? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

SWING & OTHER SEAT TYPES:

-

01). ARE THERE ANY PARTS MISSING?

02). ARE THERE ANY PARTS DAMAGED?

03). ARE THERE ITEMS LOOSE PARTS? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

IMPACT ABSORBING SURFACES:

-

01). INEFFECTIVE BY SURFACES BEING COMPACTED, DISPLACED OR NOT EXTENSIVE ENOUGH TO COVER POSSIBLE IMPACT AREA?

-

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

FOUNDATIONS:

-

01). ARE FOUNDATIONS FREE FROM CRACKS?

02). IS THE EQUIPMENT DESIGNED TO BE FIX INTO THE GROUND? IF SO IS IT SECURE? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

DETAILS ON COMPLETION: (Post Inspection).

-

COMPLETED BY:

-

DATE COMPLETED:

-

NOTES / FURTHER ACTIONS:

ENVIRONMENT & EQUIPMENT SURROUNDINGS:

-

01). IS THE PLACEMENT AREA OF THE EQUIPMENT SUITABLE FOR ITS SURROUNDING?

02). ARE THERE ANY DANGERS FROM IMPALEMENT WHERE BY A STUDENT COULD POSSIBLY FALL ON TO A SHARP OBJECT?

03). IS THE AREA FREE FROM SHARPS E.G BROKEN GLASS?

04). ARE THERE ANY LOW GROWING TREES, SHRUBS, OR BRAMBLES THAT POTENTIALLY COULD INJURY SMALL STUDENT - ESPECIALLY THAT COULD AFFECT THE EYES? -

SAFE NO ISSUES ✅

-

PROBLEMS IDENTIFIED ❌

-

REPORTING:

-

ACTIONS REQUIRED:

-

PRIORITY - TIME LINE:

- Immediately

- Within 12hrs

- Within 24hrs

- Within 48hrs

- 3 Working days

- 5 Working days

- 2 Weeks

- 3 Weeks

- 1 Month

- 3 Months

- 6 Months

- 12 Months

- On-going

- 1-2 Weeks

- 2-3 Weeks

- 3-4 Weeks

-

JOB/DEFECT ASSIGNED TO:

- Site Manager

- Cleaning Manager

- Site Staff

- Cleaning Personnel

- Catering Manager

- Head of Faculty

- Technician

- Line Manager

- IT Manager/department

- Office Manager

- Admin Department

- First Aid Manager

- Lettings Manager

- Contractor

- Senior Management

- CEO

- Local Authorities

- Business Manager

- Learn to Build

- Head of school

- Site Manager, Business Manager, Head of School

- Site Manage, Office Manager, Head of School

- Grounds Contractor

- Dept. Manager

-

INSPECTION BY:

-

IMPORTANT PLEASE READ:

PLEASE SAVE YOUR REPORT.

SEND YOUR FINISHED REPORT TO YOUR LINE MANAGER.