Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

-

Warehouse Manager Name

-

X Ray Manufacturer

-

Model

-

Serial Number

-

Optimum Position of the Test Piece ( L, M, R )

Guidance Notes for Daily X-Ray Test

-

Pass the test piece through the x-ray that gives the best image possible; left, right, middle etc.

-

Use any image enhancements needed to be able to view the image to the criteria

-

Complete tests 1 to 6, confirming you can see the required image criteria

-

If the image fails any of the tests, the X-Ray must be faulted and the fault number logged under Notes. Rapiscan / Smiths detection must be called out and the fault reference number recorded under fault reference

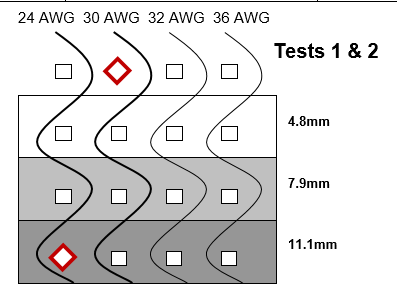

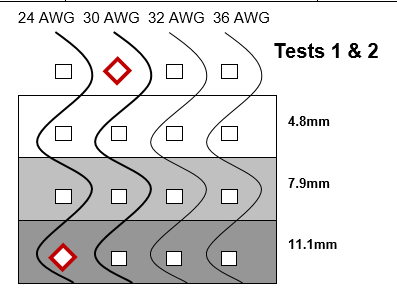

Test 1

-

Confirm you can see the Single wire resolution - 30 AWG wire visible when not covered by aluminum step wedge as per image below

-

Test 2

-

Confirm you can see the Useful Penetration - 24 AWG wire visible behind 11.1mm of aluminum step wire as per image below

-

Confirm you can see the Useful Penetration - 24 AWG wire visible behind 11.1mm of aluminum step wire as per image below

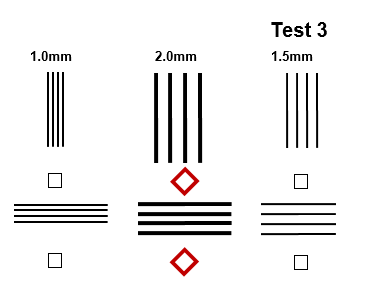

Test 3

-

Confirm you can see the Spatial resolution - 2.0mm Copper sheet gratings visible as per image below

-

Confirm you can see the Spatial resolution - 2.0mm Copper sheet gratings visible as per image below

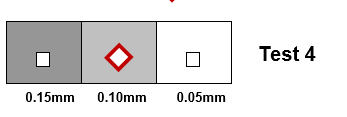

Test 4

-

Confirm you can see the Single pentation ( Thin Material Imaging ) - 0.1mm Steel Shim Visible as per image below

-

Confirm you can see the Single pentation ( Thin Material Imaging ) - 0.1mm Steel Shim Visible as per image below

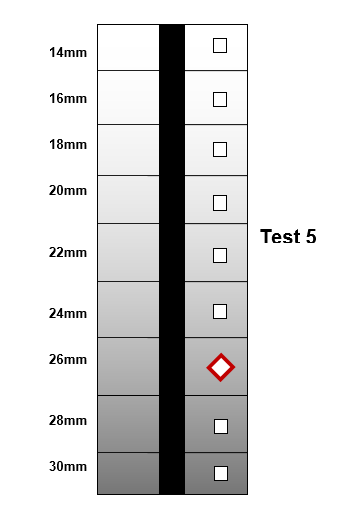

Test 5

-

Confirm you can see the Single Penetration (Dense Material Imaging ) - Lead Strip visible behind 26mm steel wedge as per image below

-

Confirm you can see the Single Penetration (Dense Material Imaging ) - Lead Strip visible behind 26mm steel wedge as per image below

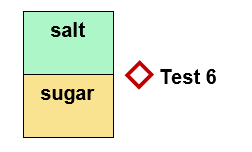

Test 6

-

Confirm you can see the Material Discrimination - Different colors visible for salt and sugar as per image below

-

Confirm you can see the Material Discrimination - Different colors visible for salt and sugar as per image below

H&S Daily Checks

-

Confirm Loading tray Belt in good condition

-

Confirm Trips / Flaps in good condition

-

Confirm Lead Curtains in good condition

-

Confirm Warning Lights in good condition

-

Confirm Rollers in good condition

-

Confirm Emergency Stops in good condition

-

Confirm you have a Clean Screen

-

Confirm Cables in good condition

-

Confirm Chairs / Benches in good condition

Faults

-

Make Model and Serial Number of machine

-

X-Ray Fault Details

-

Fault Reference

Tests Complete

-

By signing this form, the named GLCC Warehouse Manager acknowledges that the tests for the X-Ray have been completed in line with this form that all details have been checked and all follow up actions are in hand or complete

-

Select date

-

Add signature