Information

-

Document No.

-

Client / Site (inc Site Code)

-

Location

-

Review Panel Members

Rules

Rules

-

You must walk each site and every space that is currently marked or you believe could be marked as a 'Confined Space'. Each space needs to be assessed and have appropriate signage installed or if deemed no longer required removed.

-

Access to all confined spaces shall only be made after completion of the appropriate documented 'Confined Space Permit'.

-

You must either, remove or remark and number each space assessed, at each entry point, and attach a photo of all the entry points and signage both pre and post assessment and marking. This applies to all spaces assessed not just those assessed as confined spaces as our ability to show the methodology behind why we no longer deem a space to be a confined space is equally important.

-

In a situation where you journey down to get to a tunnel. The ranking of the tunnel will apply to all area's on that level and above including the elevator tower. The ranking for the boot will similarly also apply to all levels below it.

-

Please ensure you locate and review and previous 'Confined Space' site registers before undertaking this assessment.

-

Please refer to the external OSHEM Report (if you do not have this your Health & Safety Advisor will be able to supply a copy). In summary the following general overview classification (without considering the individual differences) was provided on each storage type. It is recommended you read this report prior or at least review similar type storages. Please note similar type storage ie. design will carry in most cases a similar ranking ie. S122 and S098.

The OSHEM report assessed and determined the following storage types, areas and spaces as-

Not a confined space:

SA Silo's, Haunstrop Silo's, Perrin Shed, Hex Bin (SX16), A200 Reclaim Pit, C288 Tunnel, S095 Tunnel, S068, S100, A299 Tunnel, S082 Tunnel, C409 Short Tunnel, S150 Tunnel, S054 Tunnel, A191 Tunnel, C351, S300, C409, S052, S122, S300 Tunnel.

The OSHEM report assessed and determined the following storage types, areas and spaces as-

Confined Spaces.

Munroe Silo's, A200 Squat Bin, S060, C288 Boot Pit, S095 Boot Pit, D150 Boot Pit, A191 Boot Pit, CLS Blue Elevator Boot Pit, C1100 Cotton Hopper, A299 Boot Pit, S082 Boot Pit, S150 Boot Pit, S054 Boot Pit, A191 Boot Pit, Weighbridge Pit's, A23 Boot Pit, S122 Boot Pit, E270 Boot Pit, S300 Boot Pit

Please make note of the other hazards and risks identified in the external consultant's OSHEM report and check to see if your area's and/or plant have some of the identified risks present and if so please address. -

The numbering and lettering identification sequence for each space can be found in the top left hand corner once each space is identified and is automatically generated by the audit tool. Sequences will look as follows: Weighbridge Pit (WB1,WB2etc), Bin Bases (BB1, BB2 etc).

Guidelines

-

Forced ventilation does not make something “not” a confined space (i.e. fans that start automatically when the lights are turned on).

If a tunnel or boot has valves in it, it will typically be seen as being designed to be occupied by a person. Conversely, bin bases, hoppers and under weighbridge spaces are not.

A shed, sealed or not is typically not considered a confined space.

2 points of entry and exit is not mandatory for something not to be deemed a confined space.

Register

-

Add Weighbridge Pit

Weighbridge Pit - WB

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

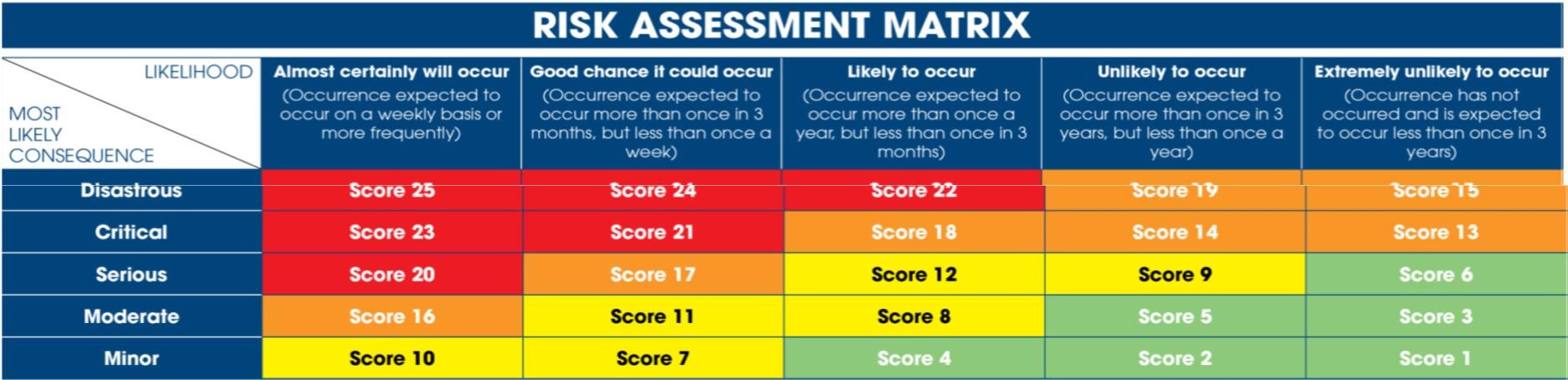

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Bin Base

Bin Base - BB

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Boot Pit

Boot Pit - BP

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Receival Hopper

Receival Hopper - RH

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Garner Bin

Garner Bin - GB

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Under Silo

Under Silo - US

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Tunnel

Tunnel - TU

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Septic Tank

Septic Tank - ST

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Add Other (inc Dust System)

Other (inc. Dust System) - OT

-

Storage Code

-

Location (be detailed describe in words where the space is).

-

Image of Space being assessed (both before and after assessment and marking). Please include a photo of the space and each sign prior to assessment and then post assessment once it has been either re-marked or removed.

Criteria for classification of a Confined Space (ref' AS 2865__2009)

-

Is this space enclosed or partially enclosed?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space not designed or intended to be occupied by a person?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is this space designed or intended to be at normal atmospheric pressure whilst any person is in the space?

-

This space does not meet the criteria of a 'Confined Space', however may still present a work area with some inherent hazards and risks. Please continue.

-

Is the space likely to pose a risk to health and safety from one or more of the following: <br><br>• an atmosphere that does not have a safe oxygen level (a safe oxygen level means an oxygen content in air of between 19.5% – 23.5%) <br>• contaminants, for example airborne gases, vapours and dusts, that may cause injury from fire or explosion <br>• harmful concentrations of any airborne contaminants (if the contaminants are present at a concentration above the relevant exposure standard or if they are likely to cause impairment, loss of consciousness or asphyxiation) <br>• engulfment, for example:<br>o any liquid including oil or water in which a person can drown, or <br>o any solid including fly ash, grain, sawdust and sand that can flow and form a temporary cavity or bridge, which may collapse and surround a person, cutting off their air supply. <br>

-

This area is classified as a Confined Space. Continue with the risk assessment

-

This space does not meet the criteria to be classified as a 'Confined Space'. However it is still likely to be a work area with some inherent hazards and risks. Please continue with this audit and to complete the risk assessment.

Risk Assessment

-

What are the inherent hazards and risks of this space? (tap for drop down menu)

- Possible Changes in Atmosphere

- Asphyxiation or poisoning risk from gasses such as H2S, Co, PH3

- Restricted access and egress

- Dust

- Falls from Heights

- Manual Handling

- Fire/Explosion from Dust

- Lack of Communications

- Protruding Objects

- Engulfment if grain is present in storage

- Engulfment from grain entering storage

- Vehicle accessing area

- Engulfment from discharged grain

- Entrapment by fixed plant

-

Are there other inherent hazards and risks of this space?

-

Review any previous documented risk assessments for this space. A revised risk assessment must now be completed that considers the level of safety management from current existing controls, as well as the predicted enhanced level of safety that could be achieved upon implementation of further higher order controls. The ranking score and risk mitigation measures should be determined through application of the GrainCorp Risk Assessment Matrix and Hierarchy of Controls.

-

What is the Raw risk ranking? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What current and existing controls are in place to manage hazards risks for entry and work in this space? (tap and select existing controls)

- Exclusion Zones

- Danger Signs Erected

- Locked access when entry not required

- Atmospheric testing and monitoring

- Wear appropriate respiratory protection

- Harness and fall arrest device

- Extraction type ventilation

- Use intrinsically certified electronic communications

- Use appropriate PPE

- Isolate grain flow path

- Isolate all non-essential energies

-

Are there any other current and existing controls in place?

-

What is the revised risk ranking with the current and existing controls maintained? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

What are the recommended further actions, including medium and/or longer-term controls to either eliminate or further minimise risks associated with entry and/or work in this space?

-

What is the predicted revised risk ranking assuming these further actions including higher order controls are implemented? (tap and select one risk score)

- Total Score = 1

- Total Score = 2

- Total Score = 3

- Total Score = 4

- Total Score = 5

- Total Score = 6

- Total Score = 7

- Total Score = 8

- Total Score = 9

- Total Score = 10

- Total Score = 11

- Total Score = 12

- Total Score = 13

- Total Score = 14

- Total Score = 15

- Total Score = 16

- Total Score = 17

- Total Score = 18

- Total Score = 19

- Total Score = 20

- Total Score = 21

- Total Score = 22

- Total Score = 23

- Total Score = 24

- Total Score = 25

-

Have Corrective Actions been raised on SafeGuard to allocate and track agreed safety improvements?

-

List any Corrective Action ID numbers here

-

It is recommended that any and all relevant corrective actions be raised in SafeGuard as soon as possible.

-

Further comments/ notes: