Information

-

Site name

-

Conducted on

-

Conducted by

-

Prepared by

-

Personnel

What is the task being undertaken today

-

Choose task here

Framing Internal gutter

-

Is the area clear to work in?

Pre cast flooring units

Access

-

Do you require traffic management for the crane set up or work area?

-

Work must be undertaken within the traffic management area.

All work must be as per the traffic management plan. If you do not have a traffic management plan then work cannot commence. -

Is the work area clean and safe to work in?

-

have you informed the crane operator or other of any overhead or underground services that they need to be aware off?

-

Is the access for the crane clear to set up?

Installing pre cast flooring units

-

Are all the installers on the precast units experienced and familiar with the instillation?

-

See site Forman / leading hand for instructions on how to install safely. Record in the tool box talk at the end of this task analysis form.

-

Has the area under the precast flooring units be isolated to prevent other persons on site from entering under a suspended load?

-

Good planning. Insure this is monitored throughout the lift and stays isolated.

-

Assign someone to isolate the area prior to starting any lifting. This can be achieved by danger tape/ fences etc.

-

Who has been assigned to isolate the area?

-

Will you be using turfers to install the precast flooring units?

-

Be aware of the fixing point for the turfers insure fixing point is adequate for the material you are pulling.

Isolate the area below so no persons can enter under the area being moved with the turfers. -

Has the crane operator been given instruction on what is being lifted today including weights and a plan showing him?

-

Has a nominated dog man been chosen? And has person been made known to the crane operator?

-

Who will be the dogman?

-

You must nominate a person to be the dogman. This can change throughout the task as long as you update the crane operator

-

Has the site hazard I'd board been updated to reflect the work for this task?

-

Assign someone to update the site hazard inboard before proceeding?

-

Who has been nominated to update the hazard I'd board?

Panel lift

Access

-

Do you require traffic management for the crane set up or work area?

-

Work must be undertaken within the traffic management area.

All work must be as per the traffic management plan. If you do not have a traffic management plan then work cannot commence. -

Is the work area clean and safe to work in?

-

have you informed the crane operator or other of any overhead or underground services that they need to be aware off?

-

Is the access for the crane clear to set up?

Erection of panels

-

Has the crane operator and other persons on site been informed of the work being undertaken in this task?

-

Has the crane operator been given the weights and lifting diagrams?

-

Have all lifting eye's been cleaned out and checked?

-

Do you have a propping plan and the correct props as noted on the propping plan?

-

Do not proceed without a propping plan.

-

Are the panels being delivered via truck from an offsite location?

-

The truck operator is to be informed to stay with his truck. This is his load / work place it is up to him to hock up the lifting gear etc we are only to assist if asked by the truck driver and if so are to abide to his instructions.

-

Do we have any unskilled persons working in the task team today?

-

They are to be supervised by another team member and informed to stay clear of the lifted loaf

-

Note the names of the persons requiring supervising and who will be supervising them below.

-

Has a nominated dog man been chosen? And has person been made known to the crane operator?

-

Who will be the dogman?

-

You must nominate a person to be the dogman. This can change throughout the task as long as you update the crane operator

-

What task are you undertaking

-

Note any hazards involved in the task here

-

How will you manage the hazards noted above

Height safety

-

How will you be managing your height safety?

- EWP

- ladder

- man cage

- scaffold

- no height work involved

- other

- rope and harness

- static line

- inertia real

-

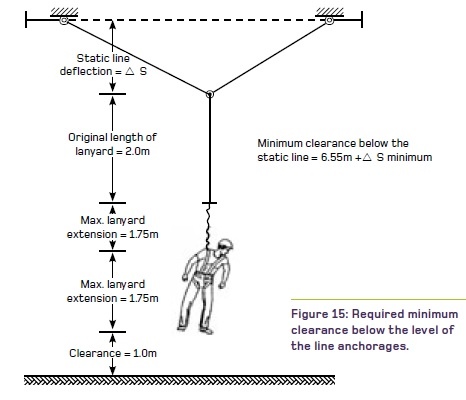

Check the expiry date on the static line. The static line is to be set up by a height trained person only, workers on the static line can work on if not height trained but must have some experience and be shown how the system works. Including the emergence rescue plan. There must be a height trained person working either on the system or near by to supervise other works.

-

Is there a height trained person setting up the system?

-

Name of person(s) setting up static line

-

Name of person(s) who will be supervising the static line system once installed? This person must be height trained?

-

Do not proceed under no circumstances may a static line be installed by a non height trained person.

-

Will the static line be set up for fall restraint or total restraint? <br>Fall arrest system is designed to support and hold a person in the event of a fall. It is not a work positioning system as they are not designed to support a person while working.<br>Total restraint system protects a user from approaching an unprotected edge, thereby preventing a free fall from occurring. ( this is the preferred option if possible)

-

It is best to install the static line above the worker if this is not possible then take into account what method of attaching the harness to the static line.

You cannot set the static line below the worker -

How will you be attaching the the harness to the static line?

-

Note down the item to be used in the system. There are some common items listen below to chose from Confirm that there used by dates are not expired. See the below diagram of static line located above with inertia real.

-

- lanyard

- shook absorber

- carabiners

-

-

Has the rope system been set up by a person trained to work at height

-

Do not proceed

See site Forman or leading hand for assistance in setting up or coming up with an alternative method -

Have the ropes ,harness,carabiners,lanyards and all other equipment been visually checked and expiry dates checked?

-

Who has set the rope system up?

-

Please take a photo of the rope system in use

-

Has the site Forman or leading hand inspected and at time of inspection ok'd the use of the rope system?

-

Site Forman / leading hand to sign

-

Have the site Forman or leading hand sign of prior to proceeding

-

Are the persons working in the internal gutters height trained

-

Proceed.

Insure all persons working in the gutter are aware to be harnessed at all times to the static line / rope system in place -

Do not proceed

See site Forman to discuss as all persons working at height particularly in internal gutters need to have some form of height training -

Please note how you will be managing your height safety

-

Proceed to next section

-

Has the scaffold been erected by a ticked scaffold

-

Proceed with height work.

You still need to confirm all handrails mid rails and to boards are in place with a safe means of access.

Do not ride on mobile scaffolds.

Check scaffold safe tag current and attached to scaffold -

Is the scaffold over 5m to the top of handrail?

-

Insure all handrails, mid rails toe boards are in place with a safe means of access as per the best practice guidelines.

Do not ride on mobile scaffold.

If you are unsure whether scaffold is safe see site Forman or leading hand for advice. -

You can not proceed until the scaffold has been inspected and tagged by a ticked scaffolder

-

Is the man change certified.

-

Do not proceed

-

Is the harness, lanyard and all other safety gear within its expiry date and visually looks in good condition

-

Do not proceed

-

Is there a safe means of access to the man cage and suitable harness fixing point

-

Do not proceed

-

Is the person in the cage height trained?

-

Do not proceed

-

Proceed insure that all PPE is worn at all times. The harness must not be disconnected at any time

-

Are the operators of the EWP licensed. I.e the silver card

-

Is there al least one licensed operator in the group for this task?

-

See site Forman / leading hand to discuss.

Depending on the task if you have a reasonable amount of experience you may proceed with the task. -

After discussing with the site Forman / leading hand are they happy for you to proceed?

-

Forman / leading hand to note down operators experience below

-

- EWP operator has informed us that they have 2 or more years experience in using the type of EWP being used for this task

- EWP operator has been shown how to use the EWP by a licensed operator

- EWP operator has demonstrated that they are capable of using in this instance

- you have had previous experience working with the EWP operator and are happy for them to proceed

-

Forman or leading hand to sign approval of use.

-

Do the other operators have experience in using EWP's

-

See site Forman / leading hand to assign other competent workers to the task.

-

The licensed operator is to select the other operators at his desecration, if he feels at any thine the operators are not competent stop work and see site Forman / leading hand to discuss.

-

What type of EWP is being used?

-

All operators of a boom lift must wear a harness at all times while operating.

-

-

As a harness is required you must have a rescue plan in place in the event of a fall. Pick from the list or note below your recovery method.

- Another EWP is on site we can use to rescue worker.

- work is being completed by the side of building where a ladder can be used

- a crane and man change is available on site to rescue

-

Before starting work you must determine whether a harness system will be needed to complete the job safely. Check manufactures instructions to help decide the requirement for a harness.

Follow the questions below to determine whether a harness is required. -

Is the scissor hoist being used on flat level ground?

-

Are there any penetrations / holes in the flat level ground. I.e recess for shower, pipe penetrations

-

If the penetrations in the flat level ground can be isolated from the hoists driving area then a harness is not required.

Alternatively you may choose to not move the scissor hoist while raised. -

A harness is not required. Complete a daily scissor hoist check to insure all ok prior to use.

-

Dose the scissor hoist have out riggers or a levelling system.

-

A harness is not required as long as the hoist will not be driven at height. Insure out riggers are on solid Bering before raising platform.

This can be achieved by a by a visual inspection once outriggers are set. -

If the EWP can not be levelled then a more suitable EWP should be used. See site Forman prior to continuing work.

-

Is a ladder the only option?

-

Do not proceed.

Initiate alternative height method. If gear required see site Forman or leading hand -

Is the ladder in good condition?

-

Do not proceed

-

Why is a ladder the only option?

-

Forman or leading hand to sign of prior to starting

Pre start tool box talk

-

Who attended?

-

General safety notes to remind workers off

- keep clear of suspended loads.

- ensure work areas are kept clear even if it means stopping work until safe

- check all electrical equipment is tagged and up to date

- if you see starter caps not on put one on as it is most likely sinning next to the starter

-

Meeting minutes

-

Add media