Title Page

-

Site Location

-

Document Number

-

Conducted on

-

Prepared by

-

Inspection Location

Health & Safety Inspection

Pre Inspection Checks

-

Previous inspection checked for any outstanding issues

Housekeeping

-

General cleanliness of all areas

-

Work areas accessible and well laid out

-

Storage facilities neat, tidy, signed and accessible

-

Noticeboard present, with correctly displayed documents

Storage

-

Correct storage of lifting accessories etc.

-

Racking not overloaded and safe stacking practices observed

-

Segregation of inappropriate materials/reactants

-

Clear unobstructed access to stored items

-

Flammable/hazardous materials stored appropriately and locked away where neccesary

Tools & Electrical Hazards

-

Damage to cables extension leads etc.

-

Electrical cupboards locked as appropriate

-

Electrical Devices appropriate to the site?

-

Correct use of tools

-

Defective tools removed from service and marked appropriately

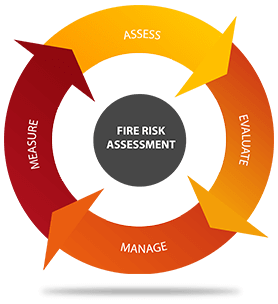

Fire & Emergency Evacuation

-

Lighting ventilation etc. satisfactory for the area and working correctly

-

Evacuation routes are free from obstructions

-

Fire extinguishers and call points visibly present?

-

Fire alarm tests and drills completed

-

Trained Fire Marshalls on site

-

Staff have appropriate knowledge and training in fire / evacuation procedures

Site Vehicles & Vehicle Storage

-

Fork lift vehicle checks completed

-

Drivers observed obeying safety rules e.g speed limits

-

Vehicles parked / stored safely

-

Dangerous vehicles marked (Electric/badly damaged) where required

Training & Safety Signs

-

Safety Signs Visible and In good condition

-

Safety Signs Correctly displayed where required

-

Staff observed to be working correctly and aware of safe systems of work

- Safe

- At Risk

- N/A

-

Training/safe systems of work followed

-

Any outstanding training requirements?

Other Issues

-

Description of the Issue

Yearly Checks

-

Do yearly checks need completing on this visit?

Machinery Guarding & Safety

Manual Handling & Lifting equipment

-

Damaged racks/stacks/pallets etc. reported and procedures followed

-

Safe working loads clearly marked

-

Staff trained and aware of safe handling methods

-

Suitable manual handling aids available and in use

-

Periodic inspections \ certifications up to date (LOLER)

Staff Welfare

-

Emergency lighting available, fit for purpose

-

Adequate rest area, facilities available

-

Sanitation, washing facilities

-

Drinking water available

-

Cleanliness of facilities

First Aid

-

First aider list posted and up to date.

-

Sufficient trained personnel on site

-

Adequate emergency first aid facilities for the site e.g. Eye wash

-

First aid boxes well stocked and items in date

PPE

-

PPE provided for all site tasks

-

Correct usage and storage, right suitability and fitting, comfort

-

PPE worn where required

COSHH

-

Storage areas locked and correct signage

-

Correct use of chemicals, flammables

-

Adequate ventilation of area

-

Correct disposal process in place

-

Suitable emergency procedures and spill procedures

-

Correctly labelled containers

-

Environmental hazards properly controlled, bund trays used where required

-

COSHH assessments msds register available and up to date

Compressed Air / Pressure Washer

-

Compressors, Washers are correctly marked with safe working procedures

-

Equipment adequately tested, yearly inspection records available

-

Staff are trained in use of equipment

-

Standard operating polices and policies in place / staff aware

Summary

Inspection Schedule

-

Date of last Inspection

-

Any other comments

-

Next Inspection due on