Title Page

-

Conducted on

-

Prepared by

Certified Handlers

-

Are there substances in your area that require certified handler control <br> <br> <br>

-

Number of certified handlers to cover operational hours <br> <br>

-

Designated authority sign off (see training records signed off by Certified Handler in area) <br> <br> <br>

-

Certified handler keys <br> <br>

-

Compound area secured <br> <br>

-

Certified Handler certificates available <br> <br> <br>

-

Certified Handler 1 questions <br>What substances are you approved Handler for <br>Watch your responsibilities in an emergency. <br> <br> <br> <br>

-

Certified Handler 2 questions <br>What substances are you approved Handler for <br>Watch your responsibilities in an emergency.

Stationary bulk Containers (Pipework section)

-

Is the wording current and correct <br>

-

Is the label colour correct <br>

-

Are the directional arrows going the right way <br>

-

Read the labels from a safe distance approximately 10 m <br>

-

Labels on each side of wall penetrations <br>

-

Labels after valves <br>

-

If the pipe is hidden from view. Are labels Visible before it disappears and also were the pipe reappears. <br>

-

Are the labels no more than 8 m apart <br>

-

Are the labels visible from the ground <br>

-

Labels on chemical in-load caps <br>

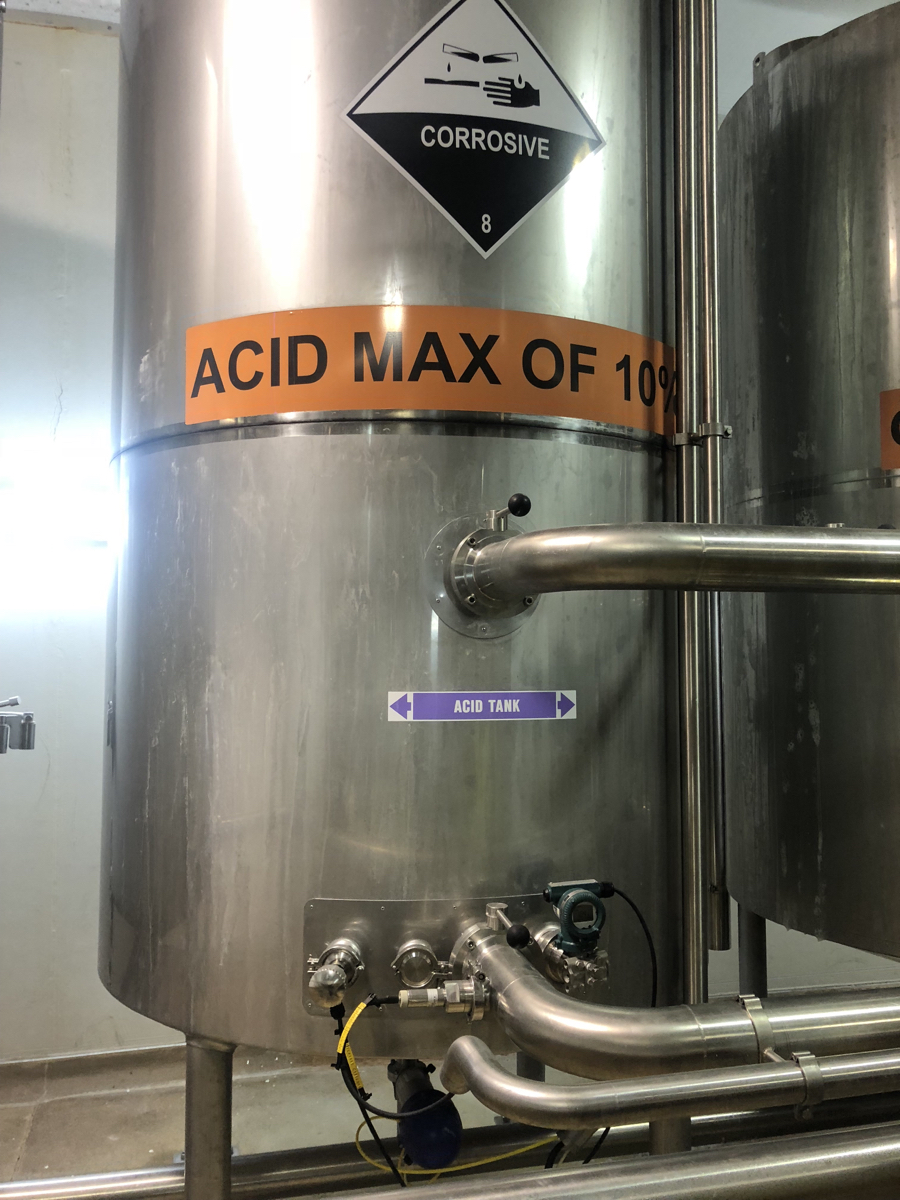

Stationary bulk Containers (Tank section)

-

Does the signage on the tank match the product in the tank and can it be read from a safe distance

-

Is the tank signage correct including suppliers detail, emergency numbers UN numbers

-

Does the signage require replacing due to damage

-

Does the pictogram require replacing due to damage and are they the correct ones for the vessel

-

Can you read the safe fill level from inload point for tank

-

Does the tank have a current SBC certificate

-

Have PM routs been established and followed

-

Is the tank dossier current

-

Has there been any alterations, including pipework compare physical state to PID drawings

-

Is there safety showers in area (refer to emergency equipment and PPE Section)

-

Is there a PPE shed in the area (refer to emergency equipment and PPE Section)

-

Are there fire extinguishers are satiated with SBC

Process vessels (Pipework section )

-

Is the wording current and correct

-

Is the label colour correct

-

Are the directional arrows going the right way

-

Read the labels from a safe distance approximately 10 m

-

Labels on each side of wall penetrations

-

Labels after valves

-

If the pipe is hidden from view. Are labels Visible before it disappears and also were the pipe reappears.

-

Are the labels no more than 8 m apart

-

Are the labels visible from the ground

Process vessels (Tank section)

-

Does the signage on the tank match the product in the tank and can it be read from a safe distance

-

Does the signage require replacing due to damage

-

Can you read the safe fill level from in-load point for tank

-

Does the tank have a current SBC certificate

-

Have PM routs been established and followed

-

Is the tank dossier current

-

Has there been any alterations, including pipework compare physical state to PID drawings

-

Is there safety showers in area (refer to emergency equipment and PPE Section)

-

Is there a PPE available in the area (refer to emergency equipment and PPE Section)

Class 2 Flammables Gas section

-

Do the quantities in area trigger secure areas 2.1.1A = 100kg perm gas or 100m3 gas non perm <br>2.1.2A *Aerosol* = (3000L aggregate water capacity) <br>

-

Do quantities trigger haz substance location

Inside quantities may need to be added depending on floor space and sep distance -

2.1.1A and B = 100m3 gas or 100kg <br>2.1.2A *Aerosol* = (3000L aggregate water capacity) <br>

-

Do quantities trigger, atmosphere drawings & requirements

Need to check drawings in dossier and maps to ensure they have the right reference for atmosphere zones -

2.1.1A and B = 30m3 gas or 100kg <br>2.1.2A *Aerosol* = (3000L aggregate water capacity) <br>

-

Do quantities trigger level III plans

All quantities require level I and level II plans on site

Level I label information, level II. Safety data sheets -

2.1.1A = 300kg or 200m3 gas <br>2.1.1B = 1000kg or 600m3 gas <br>2.1.2A(Aerosol) = 3000L aggregate water capacity <br>

-

Do quantities trigger fire extinguishers

You do not have to add fire extinguishers quantities together

For example 50L of 3.1A, and 250L of 3.1B is still only 2 extinguishers -

2.1.1A (50kg or 30m3 gas) = 1 extinguisher <br>2.1.1B (200kg or 120m3 gas) = 2 extinguisher <br>2.1.2A (3000L aggregate water capacity) = 1 extinguisher <br>

-

Are there any incompatible is in storage area Class 1, 3, 4, 5 also check SDS for others *2.1.2 & 2.1.1 incompatible* <br>

-

Are there any ignition sources within atmosphere zones

-

Is area signed correctly (Information correct)

-

Are all labels and signs fit for purpose

-

Does the area match with chemical list if inside building check sq-foot area and how much is stored there <br>

-

If there are new chemicals in the area check A7 process

Class 3 Flammables Liquids

-

Do the quantities in area trigger secure areas

-

3.1A = 100 L (Petrol) *other 3.1A check HSNO Approval Any amount*

-

3.1B = 250 in > 5L containers

-

3.1B = 500 in < 5L containers

-

Do quantities trigger, atmosphere drawings & requirements Trigger for atmosphere zones 3.1A, 3.1B, 3.1C <br>100 L Closed <br>25L Decanting <br>5L open occasionally <br>1L open container for continuous use <br> <br>

-

There should be no more than 3 Flammable cabinets inside a building

-

Do quantities to trigger hazardous substance location. Inside a building quantities may need to be added together depending on floor space and separation distance

-

3.1A = 50L (Petrol) *other 3.1A 20Land check HSNO approval*

-

3.1B in > 5L containers = 100L Closed containers or 50L use occurring

-

3.1B in < 5L containers = 250L Closed containers or 50L use occurring

-

3.1C in > 5L containers = 500L Closed containers or 250L use occuring

-

3.1C in < 5L containers = 1500L Closed containers or 250L use occuring

-

Do quantities trigger level III plans

All quantities require level I and level II plans on site

Level I label information, level II. Safety data sheets -

Level III plans triggers <br>3.1A 100L <br>3.1B 1000L <br>

-

Do quantities trigger fire extinguishers

You do not have to add fire extinguishers quantities together

For example 50L of 3.1A, and 250L of 3.1B is still only 2 extinguishers -

3.1A 50L = 1 extinguisher and 200L = 2 extinguishers <br>3.1B 250L = 2 extinguisher <br>3.1C & 3.1D 500L = 2 extinguisher <br>

-

Are there any incompatibles in the storage area Class 1, 2, 3.2, 4, 5 check SDS for others

-

Are there any ignition sources within atmosphere zones

-

Is area signed correctly (Information correct)

-

Are all labels and signs fit for purpose

-

Does the area match with chemical list (if inside building check sq-foot area and how much is store there) If there are new chemicals in the area check A7 process

-

If there are new chemicals in the area check A7 process <br>

Class 5 Oxidiser section

-

Do the quantities need to be secure when unattended

-

5.1.1A = any amount

-

5.1.1B = 500kg or 500L

-

5.1.1C = 1000kg or 1000L

-

5.1.2A = 250kg or 200m3 Example of 5.1.2A would be oxygen cylinders

-

Do quantities trigger control zone separation *incompatible*

-

5.1.1A = 0 to 1000kg or litres = 5m

-

5.1.1A = 1000kg or litres to 10000kg or litres = 8m

-

5.1.1A = 10000kg or litres and over = 10m

-

5.1.1B = 0 to 1000kg or litres = 3m

-

5.1.1B = 1000kg or litres to 10000kg or litres = 5m

-

5.1.1B = 10000kg or litres and over = 8m

-

5.1.1C = 1000kg or litres to 10000kg or litres = 3m

-

5.1.1C = 10000kg or litres and over = 5m

-

5.1.2A = 250kg or 200m3 = 3m

-

5.1.2A = more than 250kg or 200m3 = 5m

-

Trigger points for hazardous substance location

Storage is not opened and not going to be opened in that area. In use is has been opened or is going to be opened to be used -

5.1.1A = 50kg or 50L in storage and 5kg or 5L in use

-

5.1.1B = 500kg or 500L in storage and 50kg or 50L in use

-

5.1.1C = 1000kg or 1000L in storage and 100kg or 100L in use

-

Separation distance ignition sources & other hazardous substances 5.1.1A, 5.1.1B & 5.1.1C = 5m closed & 8m open or in use

5.1.2A = 3m closed & 5m open or in use -

5.1.2A= 100kg or 200m3 in storage and 50kg or 50m3 in use

IBC compound

-

Are compounds secured

-

Is pipework label correctly to AS1345

-

Maintenance replacement program for flexible piping

-

Are the bays labelled correctly

-

Are the IBC's labels still fit the purpose

-

Is the PPE shed in the area (refer to PPE, check sheet ) Are the safety showers in the area (Refer to safety shower, check sheet)

-

Are there for flammable storage sheds in the area (Refer to flammable check sheet)

-

Are the containers Bunded correctly

-

Are the chemicals in the area on the chemical register

-

Are IBCs or drums secured in or on bund

-

Are spill kits available and does it match site Spill kit map

-

Are the SDS available in area and are they current

Safety Shower and eye wash stations

-

Have the daily/weekly, monthly checks being completed

-

Is the signage in place and in good condition

-

Are the units clean and in good working order

-

Is backflow prevention required and has it been checked

-

Is the safety shower within 10 seconds of hazard

-

Yearly flow test completed and verified to ANSI Z358.1 2009

-

Safety shower pipework labelled to AS1345

-

Physically test eyewash units and showerheads for flow and check water for visual signs of contamination If portable eyewash units check dates

PPE

-

Is there a PPE shed associated with the area

-

Check that the audits had been completed of the PPE shed

-

Carry out a audit of PPE equipment as per audit sheet

-

Check equipment is in good condition, clean and tidy

-

Signage on the shed in good order and appropriate

-

Safety data sheets compliant

-

Other areas with no PPE shed checks

-

Is there a PPE assessment process and is that been followed

-

Is the PPE in good order *Carry out visual check*

-

Is there a regular check on PPE equipment

-

Is the any specialised PPE requiring certification

Flammable cupboards or cabinets

-

Need to use the appropriate flammable check sheet

-

Are cupboards and cabinets in good condition

-

Signage is appropriate for contents

-

Check chemical register and contents

-

Check for incompatible substances or classes

-

Check dossier drawings and maps

-

Does quantity inside match cabinet compatibility

Chlorine UN1017

-

Use Certified handler check sheet (any amount)

-

Location test certificate

-

Tracking is treated at any amount check documents

-

Check specialise PPE equipment

-

Escape Hoods

-

Check SOP for changing cylinders

-

Check signage

-

Check emergency information and safety data sheets

-

There should also be checked around equipment used

-

1 A person in charge of a class 6, 8.2, 8.3, or 9 substance must ensure that equipment used to handle the substance—

-

(a) retains the substance, without leakage, at all of the temperatures and pressures that it is used in; and

-

(b) dispenses or applies the substance, without leakage, at a rate and in a manner that the equipment is designed for.

-

2The equipment must be accompanied by documentation containing information about the use and maintenance of the equipment to enable the equipment to be used and maintained in a manner that complies with subclause (1).

Lab and can cupboards

-

Is the lab and exempt lab?

-

Check dossier and drawings for fume cupboards

-

Are fume cupboard certified

-

Check quantities of substances inside fume cupboard

-

All storage areas identified and labelled accordingly

-

Check quantities and storage area against chemical register

-

Any specialised PPE required

-

Our staff trained in specialised PPE requirements

-

If flammable cabinets are in the area check quantities

-

Safety shower eyewash equipment in area

-

Are spill trays/drip trays in use where appropriate

-

All signage appropriate for area and in good order

-

Check how small quantities of flammables are stored in relationship to ignition sources (for example is there a designated area and how is it identified

Inventory

-

Does the Site /Plant /area have an inventory of all Hazardous substances

-

Has it been reviewed in the last 12mths

-

Does it include hazardous waste