Information

-

Document No.

-

Audit Title

-

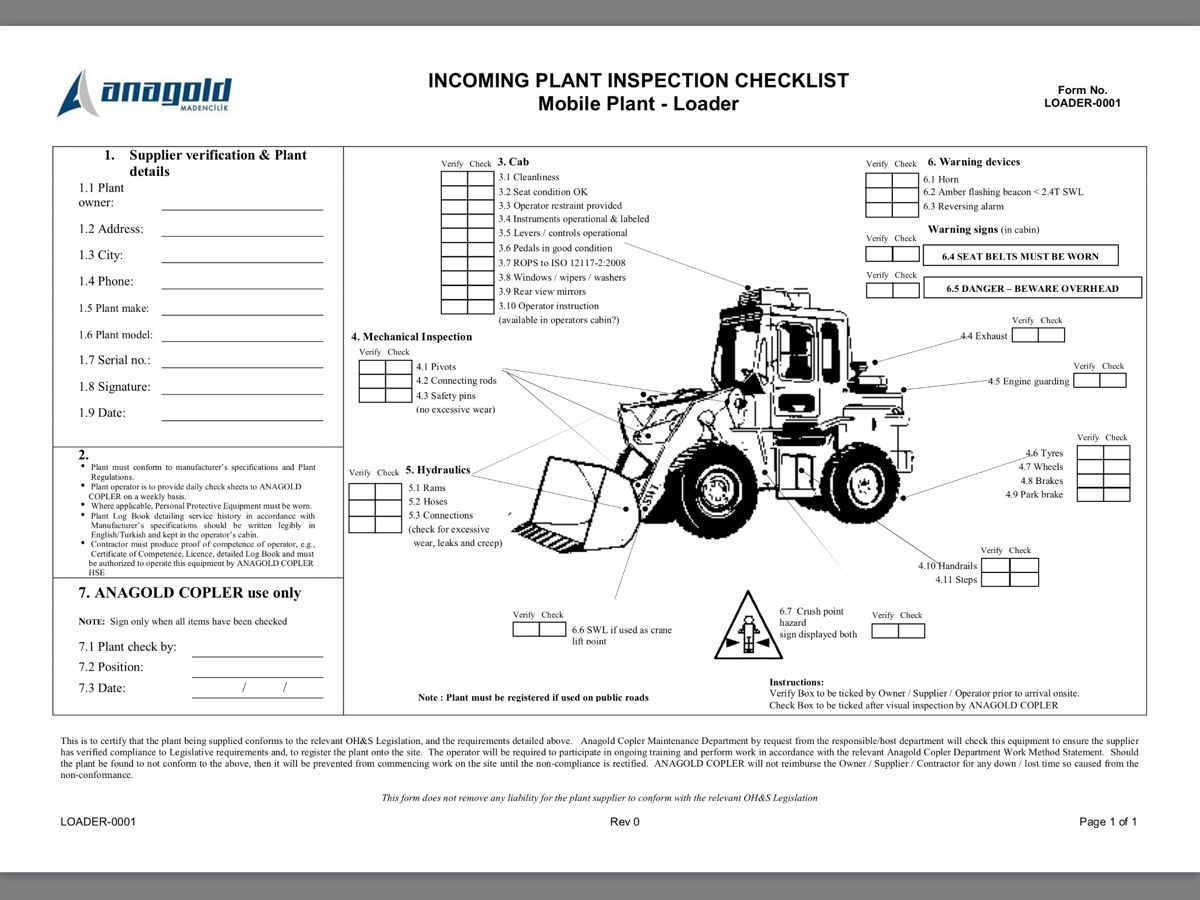

Photograph of Equipment Including the Identification Number Plate or Equipment Number

-

Anagold Department Responsible for this Mobile Plant

-

Conducted on

-

Inspection Prepared by:

-

Anagold Copler Inspection Location

OBJECTIVE

-

The purpose of this inspection is to certify that the mobile plant being supplied conforms and is compliant to the relevant Occupational Health, Safety and Environmental legislation in Turkey and the requirements are in detail in this inspection checklist. Anagold Copler Maintenance Department at the request from the responsible/host Anagold Department will inspect this equipment to ensure the supplier has verified compliance to the legislative requirements and to register this equipment on/at this Project Site Location. The contractor operator will be required to participate in the Anagold OHSE safety training and perform his or her work in accordance with the relevant Anagold Copler Department Work Method Statement (SOP). Should the mobile plant not meet the Anagold Copler compliance standards in this inspection, then it will be prevented from commencing work on this project site location until the non-compliance is rectified and passed by the inspecting department as completed. ANAGOLD COPLER will not reimburse the the Owner/Supplier/Contractor for any machine down or lost time as a result of non-conformance to the applied standards.

-

7.4 Anagold Supervisor Print Name and Signature

-

7.5 Position or Job Description of Anagold Supervisor?

-

7.5.1 Anagold Copler Supervisor's Department?

-

7.6 Date and Time of Supervisor's Review of the Inspection?

1. EQUIPMENT SUPPLIER VERIFICATION and MOBILE PLANT DETAILS

-

1.1 Mobile Plant Owner:

-

1.2 Mobile Plant Owner Address:

-

1.3 Mobile Plant Owner City location

-

1.4 Mobile Plant Owner Telephone Contact Number:

-

1.6 Model of Mobile Plant:

-

1.5 Make of Mobile Plant:

-

1.7 Mobile Plant Serial Number:

-

1.8 Signature of Supplier, Operator or Vendor

-

1.9 Date of this Inspection

2. INSPECTION GUIDELINE

-

- Mobile Plant must conform to the Manufacturer's Specifications and Project Site Regulations

- The Mobile Plant Operator is to provide daily check sheets to the Responsible Anagold Copler Department on a weekly basis as proof of pre-start compliance

- Where applicable and as per HSE Standards at Anagold Copler minimum Personal Protective Equipment must be worn correctly by the Operator and at all times

- Mobile Plant Maintenance Log Book detailing the Service History in Accordance the Manufacturer's recommended specifications should be written legibly in Turkish and kept in the Operator's Cabin

- The Contractor Operator must produce written proof of competency in the operation of the Mobile Plant e.g. "Certificate of Competence", "Licence", Detailed Log Book of Competence. The Operator must also be Authorized to Operate this Mobile Plant by Anagold Copler HSE Department.

3. Operator's Cabin Inspection

-

3.1 Is the Operator's Cabin in a clean condition?

-

3.9 Are all side and rear view mirrors in a good operational condition and clean?

-

3.8 Are the windows clean and are the Window Wipers and Window Washer working correctly?

-

3.10 Is there a copy of the Mobile Equipment Operational Instructions located in the Operator's Cabin for reference when required?

-

3.2 Is the condition of the Operator's seat functional and without any serious defects?

-

3.3 Is the Operator's seat belt in a good fully functional condition?

-

3.4 Are the Control Panel Instruments clearly labelled and in a working condition?

-

3.5 Are all of the controls and levers in the Operator's Cabin fully functional and working correctly?

-

3.6 Are the foot pedals operational and working correctly?

-

3.7 Does the Roll Over Protection (ROPS) meet the ISO Standard 1211-2:2008 and is it completely intact from the original manufacturer's specification?

4. MECHANICAL INSPECTION

-

4.1 Are all Pivot Points in good operating condition?

-

4.2 Are the connecting rods for the bucket operation in good operating condition?

-

4.3 Are all safety Pins in good operating condition (check for excessive wear)?

-

4.4 Is the exhaust pipe and manifold in good operating condition without leaks or defects?

-

4.5 Is the engine compartment guarding in good condition and are the access doors closed correctly and latched?

-

4.6 Are the tires correctly inflated and in a good operating condition without serious defects?

-

4.7 Are the wheels/rims in good condition and are all the wheel nuts tightened correctly?

-

4.8 Are the brakes fully operational and do they stop the machine with a reasonable foot pressure force?

-

4.9 Is the hand brake adjusted correctly and does it stop the machine from rolling forward on an incline?

-

4.10 Are all purpose built hand rails, hand holds or foot holds in good working condition e.g. Access Point to Operator's Cabin, Access the Engine Covers

-

4.11 Are all purpose built steps in good operating condition?

5. HYDRAULIC EQUIPMENT INSPECTION

-

5.1 Are all hydraulic cylinders and cylinder arms (rams) in good operating condition and without oil leaks?

-

5.2 Are all hydraulic hoses on the mobile plant in good operating condition without leaks and rubber deterioration?

-

5.3 Are all hydraulic connectors, clamps and pumps in good operating condition without excessive leaks, wear or creep?

6. WARNING SIGNS and SAFETY DEVICES

-

6.1 Does the horn work properly?

-

6.2 Is there an Amber colored flashing light or strobe fitted to the mobile and is it working correctly?

-

6.3 IS the reversing alarm working on this mobile plant?

-

6.4 IS there a sign in the operator's cabin telling the operator that "SEAT BELTS MUST BE WORN"?

-

6.5 Is there a warning sign in the operator's cabin saying "DANGER - BEWARE OVERHEAD"?

-

6.6 Are all lift points on the mobile plant identified and with a Safe Working Load (SWL) label at the lifting point?

-

6.7 Is there a "CRUSH POINT HAZARD" sign displayed at the pivot point of the machine?

7. ANAGOLD COPLER INSPECTION COMPLETION SIGN OFF PAGE (Note: Sign only when all items have been checked)

-

7.1 Anagold Inspector's Name and Signature

-

7.2 Position or Job Description of Anagold Inspector?

-

7.2.1 Anagold Department of Inspector?

-

7.3 Date and Time of Inspection Completion

-

7.4 Anagold Supervisor Print Name and Signature

-

7.5 Position or Job Description of Anagold Supervisor?

-

7.5.1 Anagold Copler Supervisor's Department?

-

7.6 Date and Time of Supervisor's Review of the Inspection?