Title Page

-

IQC-sub material

-

Supplier name

-

Purchase Order (PO#)

-

Detail : SKU#, item code, HS code, item name-description (size/color) / total quantity order (Pcs/unit/m/pail/Kg/crate/pallet).

-

Supplier category

-

1 Local

-

2 Import

-

Material/Product & Order category

-

1. Sub material adhesive/glue, finishing, chemical

-

2. Sub material hardware (metal, plastic)

-

3. Sub material printing, label, sticker, offset, accessories

-

4. Sub material packing, carton box

-

5. Sub material (lainnya)

-

1. Export order (D000)

-

2. Local order (B000)

-

3. Online (B100)

-

4. Project (A/C/F)

-

Inspection type

-

1. IQC Inspection

-

2. Re-IQC Inspection

-

Inspection date

-

Inspector team

-

Viewer name

-

Supplier representative

-

Inspector signature

-

Inspection on-site area

-

PERHATIAN : Inspection Report ini diterbitkan oleh QA Department. Hasil inspeksi berdasarkan

temuan Quality Inspector pada waktu dan ditempat inspeksi dilakukan. Status inspeksi tidak

dibebaskan Supplier dari tanggung jawab atas material/produk cacat atau cacat yang tidak ampak dan/atau tersembunyi dan tidak terdeteksi selama inspeksi.

ATTENTION : This Inspection Report is published by QA Department. The results of the inspection

are based on the findings of the Quality Inspector at the time and place of the inspection.

Inspection status does not exempt the Supplier from responsibility for material/product defects or defects that are not detected during inspection conducted.

INSPECTION STATUS SUMMARY

-

Order overview, packaging & shipping mark (Detail >>A)

-

Material/product conformity (Detail >>B)

-

On-site testing & measurement (Detail >>C)

-

Visual/workmanship (Detail >>E)

INSPECTION RESULT

A. Order overview, packaging & shipping mark verification

-

1. PO, Packing list documents check. Periksa kesesuaian material/product (jenis, type, warna, barcode, jumlah box/pallet/crate dll) verifikasi dengan PO, Packing list. Verifikasi tidak sesuai, status inspeksi PENDING.

-

2. Material category/product certificate check. Periksa sertifikat : CoA, Laboratory test, Transit carton box drop test report, etc

-

CoA (Certificate of Analysis), bahan finishing tidak melampirkan CoA, status inspeksi FAIL.

-

Product/production laboratory test, transit carton box drop test report, etc

-

Certificate (lainnya)

-

3. Unloading check. Periksa kondisi barang dibongkar (no plat kendaraan, no container, kondisi dalam angkutan, saat penurunan, penempatan/penumpukan diarea bongkar).

-

4. WPM (Wood Packaging Material) IPPC logo marking check. Material/product import, periksa marking logo IPPC pallet/crate kayu. Sample minimal 1 pallet per type/ukuran.

-

5. Shipping mark & identity label/sticker/UPC shipping barcode check. Periksa label, sticker, shipping mark (keterangan identitas barang). Sample minimal 3 box/crate/pallet per type.

-

6. Carton box/pallet/crate sampling size selection. Ambil sample secara acak dari posisi dan area tumpukan. Tulis no carton box/crate/pallet yang dipilih/diambil.

B. Material/Product conformity verification

-

7. Master/approval/reference/golden sample verification. Periksa kondisi fisik : approval sample, color panel (sheet), shade band finishing, technical drawing, carton box & shipping mark printing layout dll. Cross check validasinya (type, color, size, tgl terbit, approval dan expired date).

-

8. Packing material & structure check. Periksa komposisi, susunan dan kondisi aktual material packing (inner packing, protector, silica gel, bobbin, pipa, dll). Sample minimal 1 box/pallet/crate per type.

-

9. Material/product review. Periksa kesesuaiannya type, jenis material, detail komposisi, jumlah, daftar komponen dll. AI (assembly instruction) atau master/approval sample. Sample minimal 1 unit/pcs per type.

C. On-site testing & measurement

-

10. Size/dimension measurement. Periksa ukuran (tebal, lebar, panjang, tinggi, diagonal) actual sample inspeksi dengan spesifikasi/standard/persyaratan dan tolerance. Sample minimal 1 unit/pcs per type.

-

11. Density, weight measurement. Periksa density (kepadatan), berat NW/GW actual dengan spesifikasi/standard dan tolerance. Sample minimal 1 unit/pcs per type.

-

12. Color conformity test. Periksa actual warna dengan spesifikasi/standard dan tolerance. Sample minimal 1 unit/pcs per type.

-

13. Glossy (sheen) test. Periksa actual glossy dengan spesifikasi/standard dan tolerance. Sample minimal 1 unit/pcs per type.

-

14. Surface, texture & embossed check. Periksa actual permukaan, gradasi, motif, pola warna, tekstur, pola serat dll dengan standard dan tolerance. Sample minimal 1 unit/pcs per type.

-

15. Full assembly test. Assembling lengkap sesuai instruksi (AI), periksa konstruksi, sambungan (joint assembling) dll. Sample 1 unit/pcs per type.

-

16. Basic function test. Periksa siklus operasi fungsi dasar 10-20x. Sample size sama visual/workmanship.

-

17. Barcode scan test. Periksa pembacaan UPC dengan barcode scanner. Sample sama visual/workmanship.

-

18. Moisture content (MC) measurement. Pengukuran MC di 3-5 titik diarea secara diagonal dipermukaan. Sample 1-3 unit/pcs per type.

-

19. Metal detectors test. Periksa benda asing metal tersembunyi (metal splinter) didalam upholstery (fabric/leather cushion : seat rest, back rest), MDF, PB, dll. Sample sama visual/workmanship.

-

20. The others testing & measurement. Tulis detail test dan pengukuran yang lain : viscosity, special gravity (berat jenis), loading test, impact test dll.

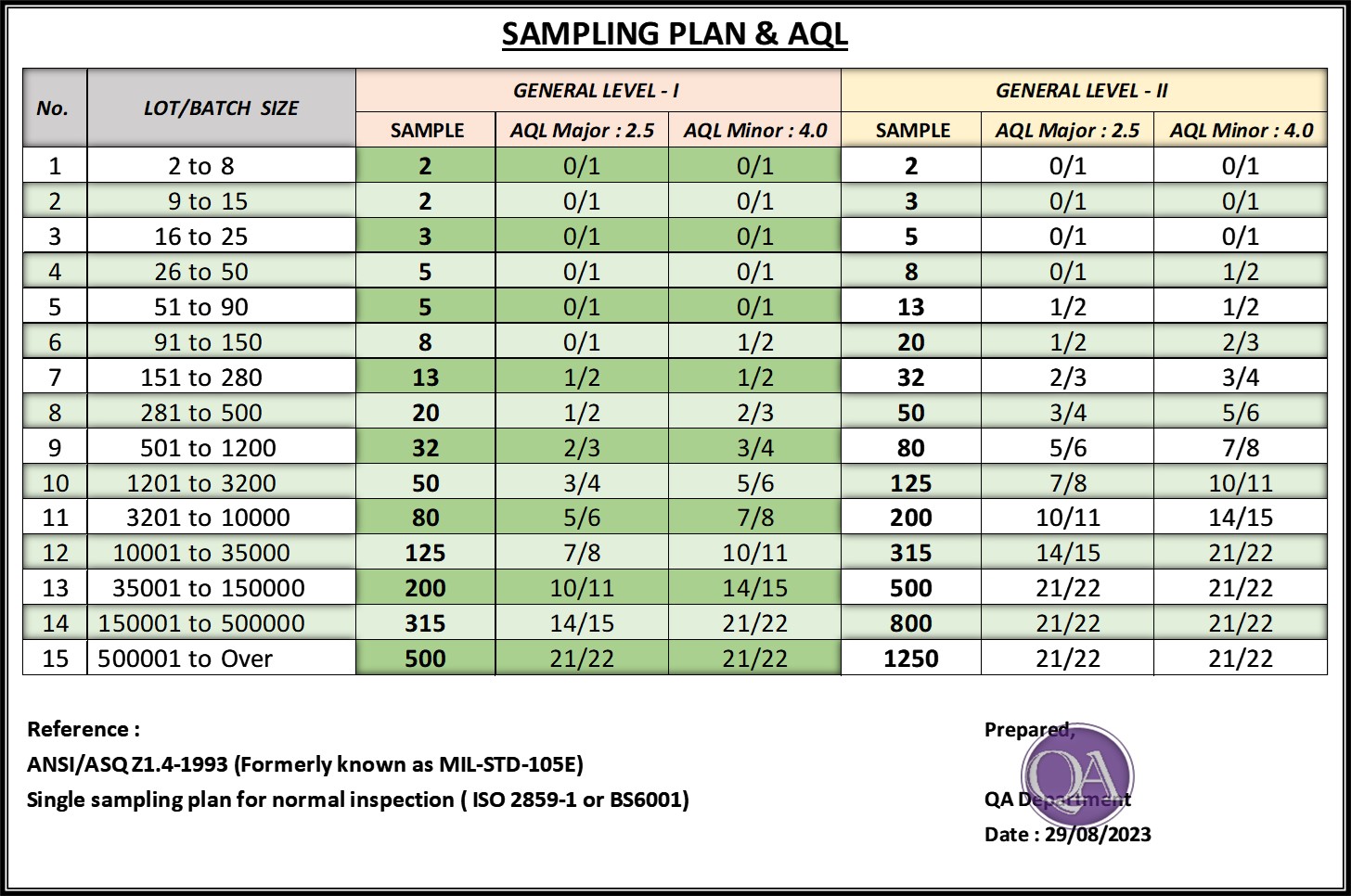

D. Sampling plan & AQL

-

1 General Inspection Level I / AQL : Cr (0) - Mj (2.5) - Mn (4.0).

-

2 General Inspection Level II / AQL : Cr (0) - Mj (2.5) - Mn (4.0).

-

3 Sampling NON Inspection Level & AQL.

-

Tulis total quantity order.

-

Tulis total sample size, perincian sample per SKU/item code (tulis di note).

-

Sampling Plan & AQL :

E. Visual/workmanship check

-

21. Critical defect. Photo jelas, tulis SKU/item code, jenis dan ukuran defect yang ditemukan.

-

Hitung jumlah defect Critical (Not allowed).

-

22. Major defect. Photo jelas, tulis SKU/item code, jenis dan ukuran defect yang ditemukan.

-

Hitung jumlah defect Major. Jumlah defect > AQL (Ac), Status FAIL.

-

23. Minor defect. Photo jelas, tulis SKU/item code, jenis dan ukuran defect yang ditemukan.

-

Hitung jumlah defect Minor. Jumlah defect > AQL (Ac), Status FAIL.