Title Page

-

Site

-

Conducted on

-

Management Team Member completing risk focus verification

Team members supporting manager

-

Add name of team member

Risk methodology

-

This Risk Focus is for your site to apply and confirm that risk controls are in place for defined hazards for our operations. Work through the checklist and confirm risk controls are in place.

If risk is not applicable to your operations, just select Not Applicable (N/A)

If NOT in place, use the Actions icon to:

Generate an iAuditor action to control the hazard

Close out the action under the Actions tab in iAuditor

Use the Note icon to:

Describe any further relevant details about the hazard

Use the Photos icon to: Capture an relevant photos about the hazard -

For each Hazard the following process has been applied to identify hazard, outline risk value and outline existing controls for verification.

Step 1. Identify Hazard and outline detail.

e.g. Risk of collapse of structure, crushing customer on sales floor.

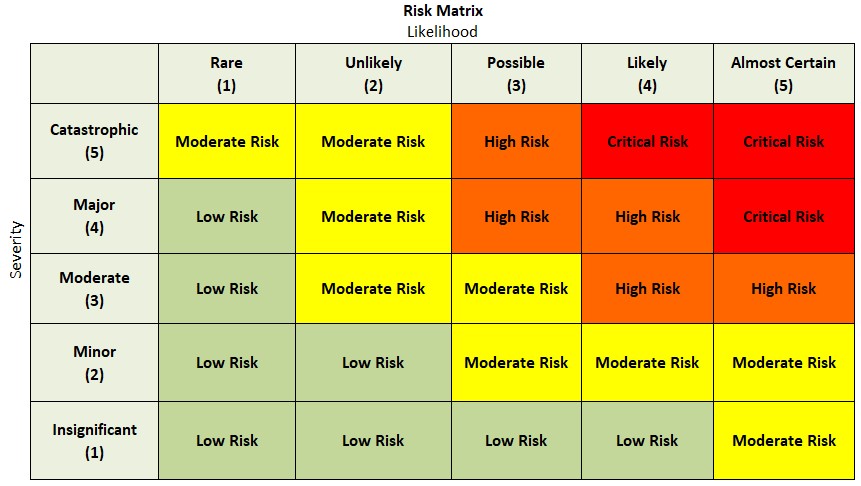

Step 2. Assign Risk Level based upon Risk Value with controls in place.

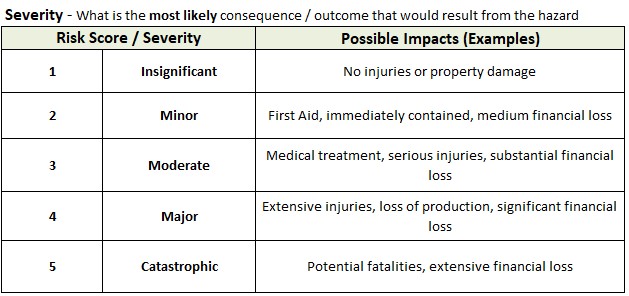

Severity – What is the most likely consequence/outcome that would result from the hazard?

Step 3. Outline existing controls in place or already instigated

e.g. Redesign: Structure has been engineering and tested to hold minimum 250kg. -

Risk Matrix

-

Risk Severity descriptors

-

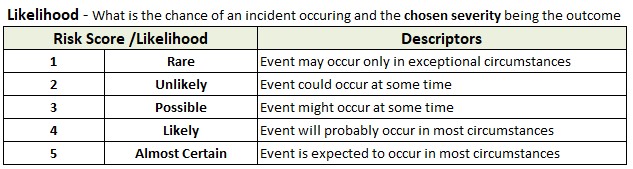

Risk Likelihood descriptors

Risk Controls for Pallets - Receiving, Handling and Storing (RA01-01)

Risk Controls for Pallets - Receiving, Handling and Storing

-

Confirm all controls listed are in place. If control not in place, generate "Action" and close out

Step / Topic - Manual Handling Hazard (including outcome): Lower back, neck and shoulder muscle strains from handling product and other heavy items: Residual Risk Rating (3x1=3 Low)

-

Safety controls

Isolation. Team members to use mechanical means to handle pallets.

Administration. Team members to use correct manual handling techniques when handling empty pallets. Always use a team lift, try and use team members of similar height and ensure clear communication and teamwork is used. -

Do team members handle pallets at your site.

-

When Team Members handle pallets do they use mechanical aids where possible to handle pallets (e.g. manual pallet jack).

-

If handling pallets, do team members physically use a team lift, try and use team members of similar height and ensure clear communication and teamwork is used.

Step / Topic - Receiving Hazard (including outcome): Contact with splinters, nails and metal brackets protruding from pallets leading to cuts and abrasions. Exposure to pallet debris and sharp objects may lead to cuts and abrasions. Residual Risk Rating (2x1=2 Low)

-

Safety controls

Administration. Pallets sourced from national contracts. Only approved pallets are provided to sites.

Administration. Team check that pallets are in a safe operational condition prior to use. -

Do team members handle pallets at your site.

-

If a pallet is damaged or unstable, for example splintered, nails protruding or loose boards, do team members remove pallets from circulation.

-

Team members wear gloves when handling pallets by hand.

-

Team members check pallets are in a safe operational condition prior to use.

Step / Topic - Stacking pallets in racking Hazard (including outcome): Pallet falling from racking causing multiple and serious injuries that may include contusions and crushing-type: Residual Risk Rating (4x1=4 Low)

-

Safety First program controls

Isolation. Forklift fleet is fitted with roll over protection structures and seatbelts.

Administration. Equipment is not to be used within close proximity to exposed raised platform or dock area.

Administration. SWP – Strapping Product to Pallets developed to outline company standards in relation to strapping, putting away, secure and remove.

Administration. Racking inspections conducted to inspect pallet standards put away in racking.

Administration. The correct lock in pallets used in all locations (excluding the floor).

Administration. Some pallets are marked in red or yellow and are not be to be used for picking (this includes standard CHEP style pallets).

PPE. Team members wear steel toed footwear when working with pallets. -

Team members when putting away pallets do so in accordance with Safe Work Practice – Strapping Product to Pallet

-

All Team Members wear steel toe footwear when working with pallets

-

Site has completed monthly racking inspection during Monthly Safety Review to ensure pallet put away standards are maintained.

Step / Topic - Stacking pallets in racking Hazard (including outcome): Storage racking collapse causing multiple and serious injuries that may include contusions and crushing-type: Residual Risk Rating (4x1=4 Low)

-

Safety First program controls

Administration. Pallet racking installed in accordance with Australian Standards. Includes safe weight load information displayed on racking to reduce risk of overloading.

Administration. Annual racking inspections completed by third party as per Australian Standards.

Administration. Monthly racking inspections conducted during location reviews to inspect pallet standards put away in racking.

Administration. Team members are instructed to report instances where racking may be damaged so repairs can be arranged. -

Team members report instances where racking may be damaged.

Step / Topic - Block Stacking (pallets stacked on top of one another) Hazard (including outcome): Falling stock hitting people from block laden pallets causing multiple and serious injuries such as contusions and crushing-type injuries: Residual Risk Rating (4x1=4 Low)

-

Safety First program controls

Administration. Sites are not to stack pallet on another pallet that is not level or of suitable strength (i.e. lower pallet will not collapse under the weight of any above pallets).

Administration. Pedestrians are not located within 3m of forklift whilst stacking or removing pallets. -

Team members when floor pallet stacking do so in accordance with Safe Work Practice - Safely Store Pallets of Product.

Step / Topic - Strapping pallets Hazard (including outcome): Team member being injured by Handheld Strapping Tension Device: Residual Risk Rating (3x1=4 Low)

-

Safety First program controls

Substitution. Approved handheld strapping device provided to sites for use.

Administration. Safety Habit 18 – Handheld Strapping Tension Device developed for team members who use device. -

Team members when strapping pallets with Handheld Strapping Device do so in accordance with Safety Habit 14 or 29– Strapping Product to Pallets and Safety Habit 18 – Handheld Strapping Tension Device.

Additional hazards

-

Is there any other associated hazards not addressed (if applicable)

-

Outline the hazard identified.

-

List controls to address hazard.

-

Does this hazard need to be escalated to the Quality, Health, Safety and Environment Team (QHSE team).

-

Please escalate to the QHSE team.

Sign off

Sign off

-

Sign off who is completing risk focus verification

-

Team member involved with consultation

Any other team member sign off involved with consultation

-

Team member involved with consultation