Information

-

Document #:

-

Company:

-

Location:

-

Conducted on:

-

Prepared by:

-

Personnel involved (as applicable):

MACHINE IDENTIFICATION

Machine Identification and General Information

-

Machine Name

-

Location (i.e. Department)

-

Manufacturer

-

Model

-

Serial Number

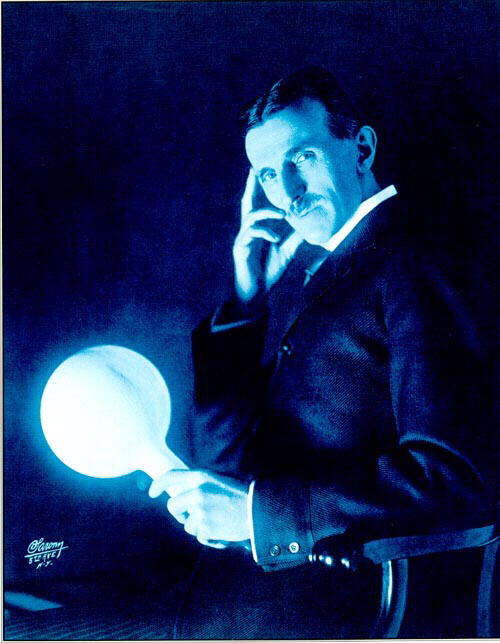

Photograph(s) of Equipment

-

Add media

Energy Sources

-

Identify Sources of Energy

- Electrical

- Pneumatic

- Hydraulic

- Gas

- Thermal

- Gravity

- Chemical/Coolant

- Steam

Affected Personnel

-

Noted Affected Personnel

- Maintenance Personnel

- Machine Operators

- Supervisors/Managers

- Visitors

- Temporary Workers

- Contractors

Sequence of Lockout Procedure

-

(1) Notify all affected personnel. (2) If the equipment is operating, shut it down by the normal stopping procedure. (2) Isolate all energy sources. (3) Lockout energy isolating devices with an assigned individual lock(s). (5) Verify the de-energization of all energy sources. After ensuring that no personnel are exposed and as a check on having disconnected the energy sources, operate the push button or other normal operating controls to make certain the equipment will not operate. CAUTION: Return operating controls to neutral position after the test.

Restoring Equipment to Service

-

(1) When the job is complete and equipment is ready for testing or normal service, check the equipment area to see that no one is exposed. (2) When equipment is clear, remove all locks. The energy isolating devices may be operated to restore energy to equipment.

ISOLATION DETAILS

Location(s) of Lockout/Isolation

-

Location/Description of Lockout/Isolation:

-

Add media

Lockout/Isolation Devices

-

Devices required:

- Individual Lock

- HASP and Locks

- Valve Lock

- Breaker Lock

- Plug Lock

- Chain & Lock

- Sign and Tag

- Lockout Box

- Controller Cover

-

Addtional Notes

Lockout/Isolation Procedure

-

Step