Title Page

-

Welcome on LPS3 frame v8 control checklist.

The purpose of this checklist is to make sure you don't forget any checkpoints when receiving the LPS3 frames.

Please make sure to fill in every point even if there is nothing to declare. -

Frame number (use STM number and index A, B, C, ... ex : STM-XXXX-A)

Main informations

-

Controled by

-

Conducted on

-

Supplier Name

-

Supplier Location

General Quality

-

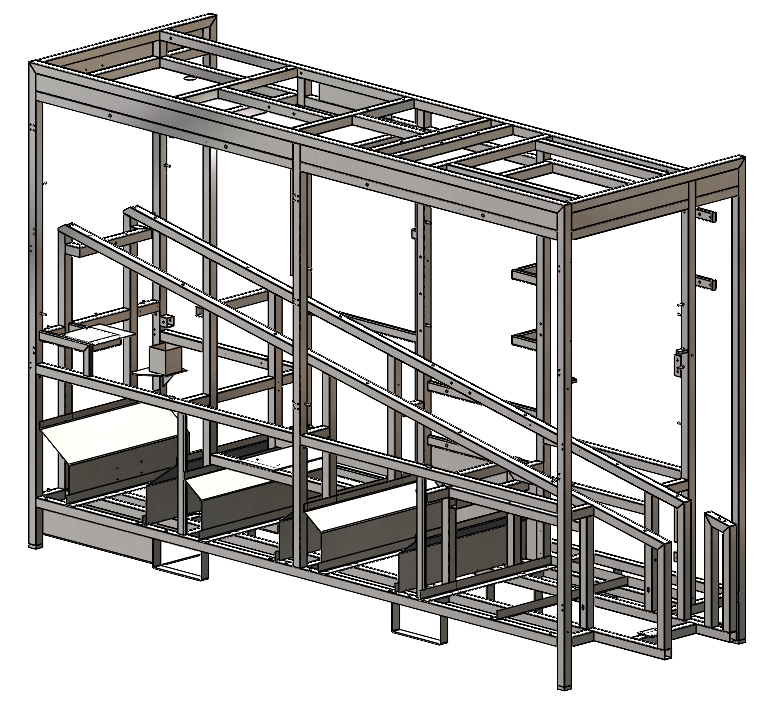

Add front view of the frame for general looking

-

Is the material used of superior quality and meets the required specifications ? (304L Stainless Steel)

-

What is the used material for this frame ?

-

Does the overall appearance of the frame have any signs of damage, deformation, or discoloration ?

-

Is the quality of the finish uniform across the entire surface of the frame ?

-

Are the welds smooth, uniform, and without burrs ?

-

Are the corners and edges uniform and without burrs ?

-

Is the frame well balanced and stable ?

-

Is the ceilling painted matt black ?

Added items

-

Are all sheet metal parts present, clean, well positioned and correctly welded ?

-

Are the gussets and supports present, well positioned and correctly welded ?

-

Are all screws present (x21), well positioned and correctly welded ?

Specific dimensions

Have the global height, width, and depth of the frame been measured to ensure they correspond to the specified dimensions ?

-

Width = 3350 +/- 1 mm

-

Height = 1968,5 +/- 1 mm

-

Depth = 1002 +/- 1 mm

Does the drawings conform to the final product ? (Make 15 random tubes measurements tol. +/- 1mm)

-

Measure 1

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 2

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 3

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 4

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 5

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 6

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 7

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 8

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 9

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 10

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 11

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 12

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 13

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 14

-

Tube number ?

-

Is this tube have major impact ?

-

Measure 15

-

Tube number ?

-

Is this tube have major impact ?

-

Does the thickness of the stainless steel tubes meet the required specifications ? (3mm)

-

Does the section dimension of the stainless steel tubes meet the required specifications ? (40x40 R 1,5mm)

Are the two main tubes (item 44 and 45) of the frame flat and without curvature ? (Use straight metal beam)

-

Is tube n°44 straight and flat ?

-

Picture tube n°44 with straight metal beam :

-

Is tube n°45 straight and flat ?

-

Picture tube n°45 with straight metal beam :

Are the two aluminium profiles are fixed on the frame, flat and without curvature ? (Use straight metal beam)

-

Are the two aluminium profiles fixed on the frame ?

-

Is firtst aluminium profile straight and flat ?

-

Picture aluminium profile 1 with straight metal beam :

-

Is second aluminium profile straight and flat ?

-

Picture aluminium profile 2 with straight metal beam :

Are the two main tubes (item 44 and 45) of the frame parallels ? (Make 5 random measurements between the two tubes)

-

Measure n°1 = 320 +/- 1 mm

-

Measure n°2 = 320 +/- 1 mm

-

Measure n°3 = 320 +/- 1 mm

-

Measure n°4 = 320 +/- 1 mm

-

Measure n°5 = 320 +/- 1 mm

-

Avarage = 320 +/- 1 mm

Are all holes and threaded holes are well done and correctly positioned ? (Make 10 random measurements tol. +/- 0,5mm)

Threaded holes

-

Threaded hole measure n°1

-

Threaded hole measure n°2

-

Threaded hole measure n°3

-

Threaded hole measure n°4

-

Threaded hole measure n°5

- Pass

- Fail

Smooth holes

-

Smooth hole measure n°1

-

Smooth hole measure n°2

-

Smooth hole measure n°3

-

Smooth hole measure n°4

-

Smooth hole measure n°5

Are the tubes supporting lamella chain conveyor (item 46 and 47) straight and holes well positioned ?

-

Is tube n°46 straight and flat ?

-

Is the upper hole on tube n°46 well positioned and trought all ?

-

Is tube n°47 straight and flat ?

-

Is the upper hole on tube n°47 well positioned and trought all ?

Are the tubes supporting lamella chain conveyor (item 48 and 49) straight and square with item 46 and 47 ?

-

Is tube n°48 straight and flat ?

-

Is the tube 48 square with 47 ?

-

Is tube n°49 straight and flat ?

-

Is the tube 49 square with 46 ?

-

Are main vertical tubes (58/77/78) straight and square with main horizontal tubes (56/57/63/64) ?

Comments

-

Add comment :

Signature

-

Sign off