Title Page

-

P35 Assembly

-

SOP #1

-

Department: Production

-

Location: 57-87 Lockwood Road, Erskine Park NSW 2759

-

Conducted on

-

Prepared by: Anna Sampson

Task Specific Information

Purpose

-

The purpose of this Standard Operating Procedure (SOP) is to outline the comprehensive steps and protocols to manufacture the P35 product. This SOP aims to ensure the manufacturing process adheres to all established safety requirements, regulatory standards and quality control measures.

-

This SOP aims to guarantee consistent production of high quality products, while prioritizing the safety and wellbeing of our people involved in the manfuaccturing process

Scope

-

This SOP is to be used to manufacture the P35 product in the Production area

-

The SOP has been specifically designed to provide information for Operators, Production Supervisors and Managers

-

This SOP only applies to the assembly of the P35 products. Manufacturing of the P20 product is included in the machine SOP for machine 14

Procedures

-

Ensure all PPE is worn as above

-

Review area for hazards

-

Report hazards in TeamAssurance or hazard book

-

Ensure parts are set up to ensure efficient assembly and no waste

-

Collect packing trolley

-

Place timber pallet onto the bottom of the trolley - 2400x210mm

-

Assembly table is clear of debris

-

Take two peices of P20 from trolley and place on the assembly table

-

Align P20 peices back to back

-

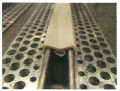

Take a peice of PVC joiner from trolley

-

Line up the end of the PVC to the start of the P20 lengths

-

Slide the PVC joiner into the middle of the P20's until the PVC reaches the end of the lengths

-

Ensure the PVC joiner protrudes no further than 10mm at either end of the product

-

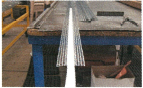

Pick up the assembled peice and insert into the jig with legs folded down

-

Once assemble peices has been inserted, get the black tape

-

From left side, start to tape along the length

-

Ensure the ends are secured with tape

-

Slide assembled P35 out of the jig and place on to pack trolley

-

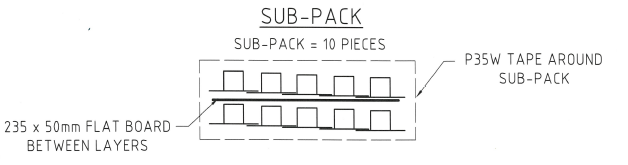

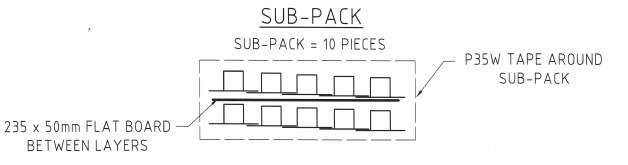

Continue to assemble pieces until first row of the sub-pack is completed as per QC checklist (5 pieces per row)

-

Place flat board on top of the first row

-

Assemble 5 peices for the second row

-

Tape the two rows together with P35W Rondo Tape - 1mtr in from either side

-

Continue assembly until you have 10 subpacks on the trolley. - the masterpack is then complete

Packaging

-

Placet timber pallet on the top of the masterpack

-

Use strapping gun to apply straps to the middle & ends of the masterpack

-

Apply product label on the forklift side of the product, between 1m and 2m on the right side of the masterpack

Completion

-

Full Name and Signature of Employee