Information

-

Conducted on

-

Prepared by

-

Location

-

Personnel

-

Select date

-

Add location

-

C (5) - Certified manager on duty<br>

-

C (5) - Certification is obtained from an accredited program

-

C (5) - Certificate is on file in the unit

-

C (5) - Certificate obtained with in the last five years<br>

-

C (5) - Local jurisdiction requirements are met<br>

-

C (5) - Food handler/employees have valid Food Handler Cards. <br>

-

C (5) - Facility has required documentation<br>

-

C (5) - Shellstock with harvester ID<br>

-

C (5) - Shellstock with harvesting date<br>

-

C (5) - Shellstock with harvest location<br>

-

N-C (2) - Shellstock in chronological order<br>

-

N-C (2) - Shellstock tag held for 90 days<br>

-

N-C (2) - Shellstock dated with last use date from batch<br>

-

C (5) - Fish Frozen by supplier documentation<br>

-

C (5) - Fish Frozen at restaurant has documentation<br>

-

C (5) - Parasite Destruction letter indicates what it was fed<br>

-

C (5) - Parasite Destruction letter indicates that it's been farm raised<br>

-

C (5) - Parasite Destruction letter held for 90 days<br>

-

Info (0) - The most current health department inspection is available at the facility

-

N-C (2) - Have all of the C (5) findings on the previous health department inspection been fixed<br><br>

-

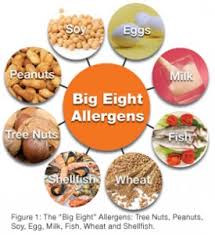

N-C (2) - The manager can respond sufficiently to questions about common allergens<br>

-

Eggs, Milk, Fish, Wheat, Shellfish, Tree Nuts, Peanuts, Soy

-

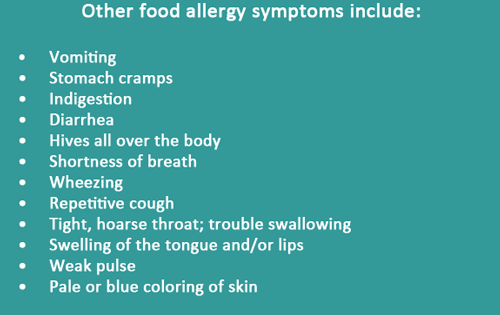

N-C (2) - The manager can respond sufficiently to questions about common symptoms

-

Tingling or itching in the mouth.

Hives

Swelling of the lips, face, tongue and throat or other parts of the body.

Wheezing, congestion or trouble breathing.

Abdominal pain, diarrhea, nausea or vomiting.

Dizziness, lightheadedness or fainting. -

Auto Fail (20) - No sick employees/managers working. Restrictions are in place to be properly excluded/restricted from food service tasks<br>

-

Auto Fail (20) - There are no sick/symptomatic workers <br>

-

C (5) - Documented Health policy & manager can demonstrate knowledge as required (symptoms/restrictions)<br>

-

C (5) Documented Health policy & manager can demonstrate knowledge (employee reporting illness)<br>

-

C (5) - Verification in employee files of training on self-reporting (excludable illness form)<br>

-

N-C (2) Procedures are present for the clean-up of vomiting and diarrhea<br>

-

N-C (2) - 1 bodily fluid clean up kit available<br>

-

N-C (2) - Bodily fluid clean up kits available<br>

-

C (5) - No employees were observed smoking (yes if no one was observed, no if you did see someone smoking.

-

C (5) - Employees were not chewing gum<br>

-

C (5) - Employee were not chewing tobacco<br>

-

C (5) - No Cigarettes/tobacco/butts/ashes in food service area<br>

-

C (5) -No Employees are eating in food prep/service areas<br>

-

C (5) - No Employee evidence of eating (partially eaten food or food wrappers) in food service area<br>

-

C (5) -All employees drinks have a lid and straw in food prep/service area<br>

-

C (5) - Employee drinks are stored properly<br>

-

C (5) -No employees were seen tasting food with soiled utensils or fingers.<br>

-

N-C (2) - Single-use gloves are available in the restaurant<br>

-

N-C (2) - Employee (as required) wearing a hair restraint<br>

-

N-C (2) - Employee wearing proper hair restraint<br>

-

N-C (2) - Employee wearing a beard guard when required (1/4" or more)<br>

-

N-C (2) -No employees handling food have improper jewelry on their arms or hands<br>

-

C (5) Proper handwashing technique<br>

-

C (5) - Does not use hand sanitizer or wiping hands on sanitized towel <br>

-

C (5) - Hands are properly dried<br>

-

C (5) - Other (handwashing procedures)<br>

-

C (5) - Washes hands upon entering kitchen<br>

-

C (5) - Washes hands when returning to food prep from a break or other tasks<br>

-

C (5) - Washes hands after coughing or sneezing<br>

-

C (5) - Washing hands after touching face, hair, body or people<br>

-

C (5) - Hands are washed between glove change<br>

-

C (5) - Other (handwashing sink accessible)<br>

-

Info (0) - Not washing hands when returning to food prep from a break or other tasks

-

Info (0) - Not washing hands before garnishing drinks with bare hands

-

Info (0) - Not washing hands after coughing or sneezing

-

Info (0) - Not washing hands after touching face, hair, body or people

-

Info (0) - Hands not washed between glove change

-

Info (0) - Other (handwashing times at BAR only)

-

C (5) - Din not observe employee having bare-hand contact with ready-to-eat food (other than bar)<br>

-

C (5) - All bandages were covered with a glove<br>

-

C (5) - Did not see gloves removed from hands then reused<br>

-

C (5) - Hands ere not “washed” with gloves on<br>

-

C (5) - Gloves changed between tasks<br>

-

C (5) -No employee with cast or brace using glove or handling food<br>

-

C (5) - No employee wearing fingernail polish or artificial nails handing food<br>

-

C (5) - Employee nails are trimmed and filed with smooth edges<br>

-

C (5) - Handwashing sink is not obstructed by objects stored in the sink<br>

-

C (5) - Handwashing sink is not obstructed by items blocking access to the sink<br>

-

C (5) - Other (handwashing sink accessible)<br>

-

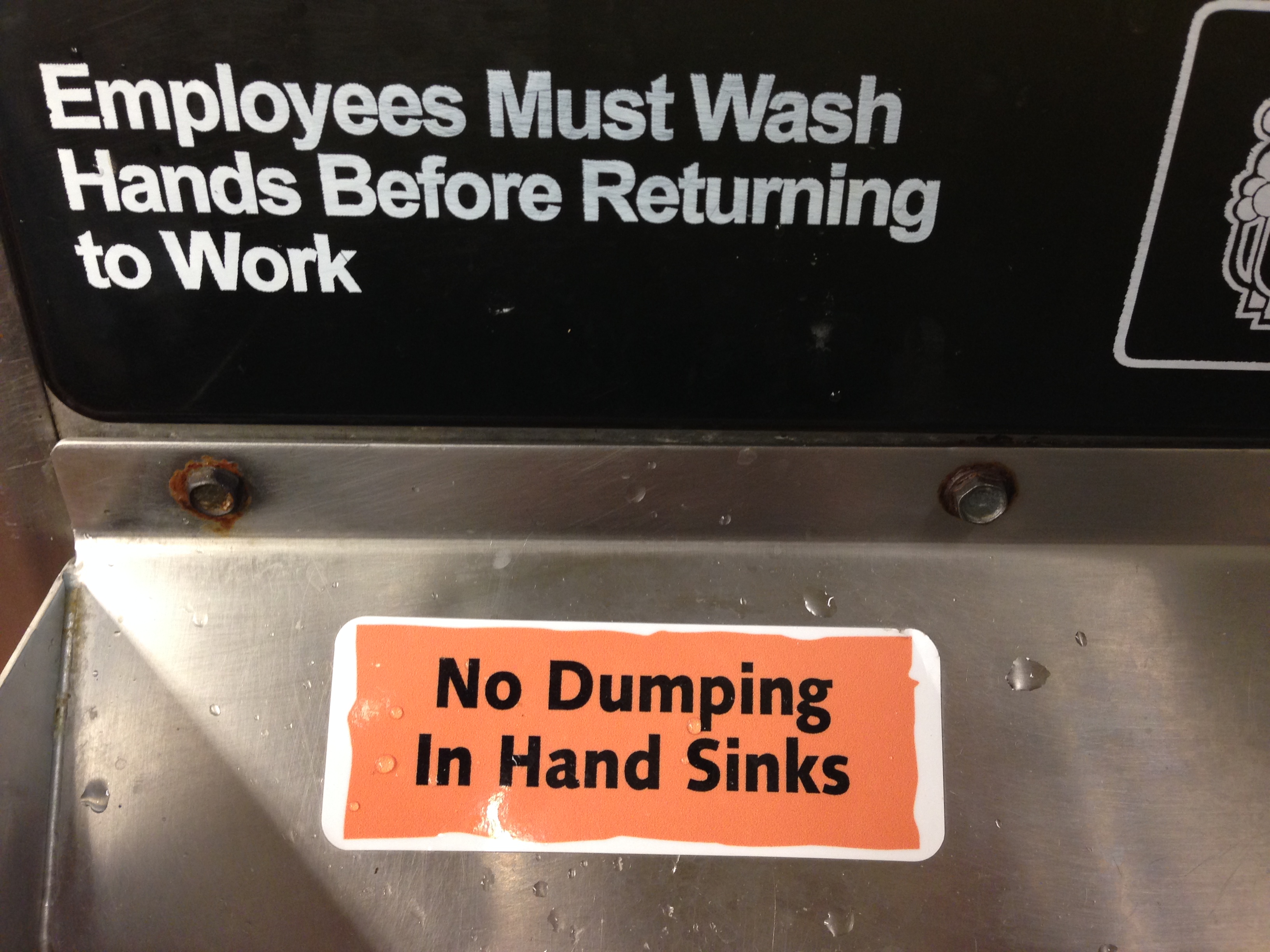

C (5) - No food, utensils, equipment, or wiping cloths are rinsed or washed in hand washing sink<br>

-

C (5) - No pitchers or other containers filled at handwashing sink<br>

-

C (5) - Other (handwashing sink used for other purpose)<br>

-

C (5) - Handwashing sinks are regularly cleaned due to excessive food, dirt, and grime build up evidence<br>

-

C (5) - Soap is available at kitchen handwashing sink<br>

-

C (5) - Soap available at bar handwashing sink<br>

-

C (5) - Soap available at restroom handwashing sink<br>

-

C (5) - Towels are available at kitchen handwashing sink<br>

-

C (5) - Towels are available in restrooms and mechanical dryer not present<br>

-

C (5) - Towels are available at bar handwashing sink<br>

-

C (5) - When only mechanical dryer present, it is working<br>

-

C (5) - Common cloth towel is not used<br>

-

N-C (2) - Handwashing signs are are posted in BOH, where required<br>

-

Hand Sink Sign

-

N-C (2) - Employee use restroom that has a handwashing reminder sign<br>

-

N-C (2) - Women’s restroom has a covered waste container<br>

-

C (5) - Food packages received with out holes/tears<br>

-

C (5) - Food packages received with out indication of temperature abuse<br>

-

C (5) - Food Items received are with in shelf life<br>

-

C (5) - Food product condition is verified<br>

-

C (5) - Food items (damaged) are marked and segregated for return<br>

-

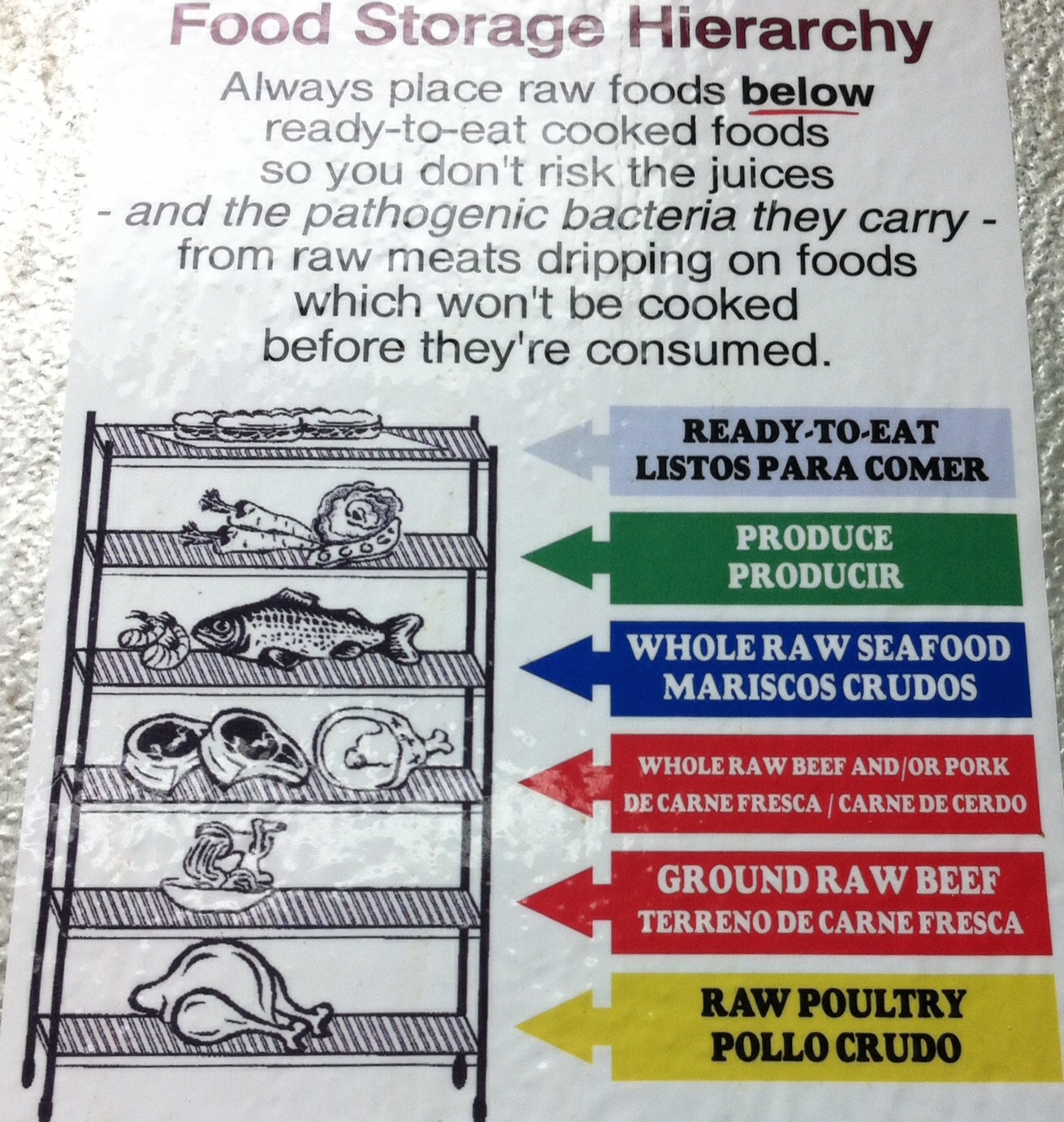

C (5) - Proper hierarchy in coolers<br>

-

Hierarchy Chart

-

C (5) - Proper hierarchy in cold drawers<br>

-

C (5) - Proper hierarchy in cold lines<br>

-

C (5) - Other (hierarchy)<br>

-

N-C (2) - Open bags or other packaging are closed or in a covered container<br>

-

N-C (2) - Container holding unwrapped food is covered with a lid<br>

-

N-C (2) - Ice bins are closed during non-rush hours<br>

-

N-C (2) - Cold well/prep line items are covered during off-peak hours<br>

-

N-C (2) - Foods are cooling with adequate protection from contamination<br>

-

N-C (2) - Food and food supplies are stored 6” above the floor<br>

-

N-C (2) - Food contact items are stored 6” above the floor<br>

-

N-C (2) - Food and food supplies are not stored in a moist/dirty location<br>

-

N-C (2) - Food and food supplies stored are not exposed to splash, dust or other contamination<br>

-

N-C (2) - No food is stored with employee food items<br>

-

N-C (2) - Food and food supplies stored in restrooms/garbage areas<br>

-

N-C (2) - Food contact items and single use containers/plastic are inverted or protected<br>

-

N-C (2) - Other (food storage location)<br>

-

N-C (2) - Food packages do not have holes/tears or evidence of temperature abuse<br>

-

N-C (2) - Cans are with out dents<br>

-

N-C (2) - Food products (damaged) are stored separately<br>

-

N-C (2) - Other (damaged foods)<br>

-

C (5) - Utensils are cleaned/sanitized between preparation of raw and ready-to-eat foods<br>

-

C (5) - Unpacked foods are protected from contamination during food prep<br>

-

C (5) - Raw fruits/vegetables are washed<br>

-

C (5) - Prepped produce placed into new holding container not it's original container<br>

-

C (5) - Ice used as coolant is never used as food<br>

-

C (5) -No physical contaminant present such as dust, debris, bottle tops, twist ties, etc.<br>

-

C (5) - Other (cross contamination during food prep)<br>

-

C (5) - FPS cleaned and sanitized prior to food preparation<br>

-

C (5) - FPS cleaned and sanitized between raw and cooked or RTE products<br>

-

C (5) FPS cleaned and sanitized at a minimum of every four hours (or 24 hours if kept ≤ 41° F)<br>

-

C (5) - No discolored shell eggs (2+)<br><br>

-

C (5) - No shell eggs with small cracks in shell (2+)<br>

-

C (5) - Any shell eggs (damaged) are stored separately (2+)<br>

-

C (5) - Shell stock is clean<br>

-

C (5) - No shell stock is open or broken<br>

-

C (5) - No shell stock has strong fish odor<br>

-

C (5) - No shell stock has slimy texture<br>

-

C (5) - Shell stock is never combined/mixed with other lots before sale or service at the unit<br>

-

N-C (2) - Utensils are being stored in prepared food without handles touching food<br>

-

N-C (2) - Scoops are being stored in ice without handles touching food<br>

-

N-C (2) - Utensils are free from being stored in standing water <140ºF<br>

-

N-C (2) - No utensils stored on a dirty surface while in use<br>

-

N-C (2) - Utensils never stored on a dirty surface between uses<br>

-

N-C (2) - Utensils not left in containers of bulk foods with handles contacting food<br>

-

N-C (2) - Utensils not stored in sanitizer between uses<br>

-

N-C (2) - Other (improper food utensils storage)<br>

-

N-C (2) - Equipment isn't broken and is w/o chips<br>

-

N-C (2) - Equipment is rust free<br>

-

N-C (2) - Utensils are not cracked, chipped or broken<br>

-

N-C (2) - Utensils are not rusted<br>

-

N-C (2) - Shelves are rust free<br>

-

N-C (2) - No ice scoop with chips, cracks, or broken<br>

-

N-C (2) - Ice bucket are without chips, cracks, or broken<br>

-

N-C (2) - Can openers are sharp and w/o metal shavings present<br>

-

N-C (2) - Cutting boards are strain and scratch free<br>

-

N-C (2) - Other (utensils in good repair)<br>

-

N-C (2) - All equipment is food grade (NSF, ANSI); for open food storage (no residential equipment)<br>

-

NSF - National Safety Foundation the NSF stamp validates and meets the design, construction and safety requirements.

ANSI - American National Standards Institute -

N-C (2) - Materials are non absorbent, have a smooth surface and/or are easily cleanable<br>

-

N-C (2) - No cutting boards that are hard maple wood or plastic<br>

-

N-C (2) - Equipment is free from cardboard liners<br>

-

N-C (2) - All wood is finished versus unfinished wood<br>

-

N-C (2) - Single use containers are discarded and not reused<br>

-

N-C (2) - Condiment bottles are not combined into one<br>

-

N-C (2) - Bottles are never refilled from a bulk dispenser without being washed, rinsed and sanitized first<br>

-

C (5) - The surface temperature measures <160° F<br>

-

C (5) - Sanitizer concentration falls within the specified range - 3-comp sink (Product & PPM:<br>

-

C (5) - Sanitizer concentration falls within the specified range - Dish machine (Product & PPM:<br>

-

C (5) - Food contact surfaces are cleaned as required<br>

-

C (5) - No mold inside ice machine<br>

-

-

C (5) - Magnetic knife bars are clean<br>

-

C (5) - All stored items are clean (list items) if any are unclean<br>

-

C (5) - Items stored in a location where they can't become contaminated<br>

-

C (5) - Clean-in-place equipment food contact surfaces clean (prep table, mixers, etc.)

-

C (5) - Soda nozzles/bar guns kept clean<br>

-

C (5) - Cutting boards stored on clean surface<br>

-

C (5) - Other (food contact surfaces clean)<br>

-

Info (0) - Compartments are properly labeled WASH-RINSE-SANITIZE in order

-

Info (0) - Completes all three steps (wash, rinse, sanitize) in washing dishes/utensils

-

Info (0) - 3 comp sink is set up in the correct order (wash-rinse-sanitize)

-

Info (0) - The rinse sink (empty vs. full) is being used according to client specifications

-

Info (0) - 3 comp sink is set up where ware washing machine is not functioning

-

Info (0) - 3 comp sink basins are large enough to submerge and properly clean equipment and utensils

-

N-C (2) - Test strips are available or accessible<br>

-

N-C (2) - Test strips are for the correct chemicals<br>

-

N-C (2) - Test strips available are usable (not damaged)<br>

-

N-C (2) - Moisture is non existant between stacked food service items (6+)<br>

-

N-C (2) - Cloths used for raw animal foods are kept separate from other cloths<br>

-

N-C (2) - Wet wiping cloth used for surface cleaning is never used to wipe edges of plates in service<br>

-

N-C (2) - Only sanitary dry towels are used

-

N-C (2) - No sponges in place of towels<br>

-

N-C (2) - Wiping cloths are stored in sanitizer solution (2+)<br>

-

N-C (2) - Wiping cloths are w/o food debris and/or visible soil<br>

-

C (5) - Sanitizer solution is at the required concentration for wiping cloths<br>

-

C (5) - Correct concentration - wiping cloth storage (Product & PPM:<br>

-

N-C (2) - Non-food contact surfaces are properly constructed<br>

-

N-C (2) - Non-food contact surfaces are not scratched, rusted or in otherwise poor repair<br>

-

N-C (2) - Non-food contact surfaces are cleaned regularly as seen by the build-up of dust and debris<br>

-

N-C (2) - Shelves are not rusted / dirty or not in good repair<br>

-

N-C (2) - Gaskets are not torn or damaged<br>

-

N-C (2) - Gaskets don't have build-up of dirt or debris<br>

-

N-C (2) - Light bulbs are protected and present a contamination risk to food or food supplies<br>

-

N-C (2) -Adequate lighting is present for safe and adequate performance of food safety and cleaning activities<br>

-

N-C (2) - Trash receptacles aren't overflowing<br>

-

N-C (2) - Dumpster area properly cleaned; debris present<br>

-

N-C (2) - Dumpster plug is in place<br>

-

N-C (2) - Garbage containers are in good repair (will not contain the garbage and make the container hard to clean)<br>

-

N-C (2) - Proper storage of garbage to avoid attracting insects/rodents<br>

-

N-C (2) - Dumpster lid is closed<br>

-

C (5) - Ingredients are cooked to the proper temperature based on the ingredient type (Product & Temp:<br>

-

C (5) - Children’s ground meat menu items are cooked to a minimum of 155° F<br>

-

C (5) - Restaurant is taking orders from the children’s menu cooked to order more than 155° F (Product & Temp:<br>

-

C (5) - Foods are reheated <165° F (Product & Temp:<br><br>

-

C (5) - Items in active cooling were > 70° F after 2 hours of cooling (Product & Temp:<br>

-

C (5) - Items in active cooling were > 41° F after 6 total hours of cooling<br>

-

C (5) - Cooling items from previous day (carryover) are <41° F (Product & Temp:<br>

-

N-C (2) -Acceptable cooling techniques are being used<br><br>

-

C (5) -Hot item is being held ≤140° F (Product & Temp:<br>

-

C (5) - Roast beef is being held more than 130° F<br>

-

C (5) - Rare roast beef requirements are met (Product & Temp:)<br>

-

N-C (2) - Hot holding equipment functioning properly to maintain temperature of TCS products at ≥140° F (60°C)<br>

-

N-C (2) - Facility is aware that a hot holding device is not functioning and discontinues to use it to hold TCS products<br>

-

C (5) - Any TCS food in cold holding is > 41° F (Product & Temp:<br>

-

N-C (2) - Any TCS food in the freezer is found is completely frozen<br>

-

N-C (2) - No evidence of temperature abuse is observed (Product & Temp:)<br>

-

N-C (2) - Cold-holding equipment is properly functioning<br>

-

N-C (2) - Cold-holding equipment is stocked at levels to keep food cold (not overstocked)<br>

-

Auto Fail (20) - Walk in cooler is functioning properly and product temperatures are below ≥ 50°F<br>

-

C (5) - Products are being time monitored when taken out of temperature control, or a time that they will expire<br>

-

C (5) - Product is not found out of temperature control for more than 4 hours<br>

-

C (5) - Unit can produce written procedures for time only used as a control factor<br>

-

N-C (2) - RTE foods prepared on site and TCS - dated by which they must be served or discarded<br>

-

N-C (2) - Commercially prepared and opened on site TCS food is dated when opened<br>

-

N-C (2) - No items are present past the expiration times/dates written on them<br>

-

N-C (2) - All items have holding times and manager can validate expiration date/time<br>

-

N-C (2) - Food thermometers are present<br>

-

N-C (2) - Food thermometer readily available (back ups)<br>

-

N-C (2) - Food thermometers are calibrated<br>

-

N-C (2) - No items are present thawing at room temperature<br>

-

N-C (2) - No items are thawing in standing water (at any temperature)<br>

-

N-C (2) - No items thawing items in running water > 70° F and ice is added<br>

-

N-C (2) - Any thawed items in microwave are cooked immediately<br>

-

N-C (2) - Walk-in cooler does has internal thermometer<br>

-

N-C (2) - Walk-in cooler has an internal thermometer that is properly calibrated<br><br>

-

N-C (2) - Walk-in coolers thermometers are properly placed to capture an accurate reading of unit temperatures<br>

-

N-C (2) - Reach-in coolers have internal thermometer<br>

-

N-C (2) - Reach-in cooler has an internal thermometer that is properly calibrated<br>

-

N-C (2) - Reach-in coolers thermometer is properly placed to capture an accurate reading of unit temperatures<br>

-

N-C (2) -No present chemicals in the facility that have not been approved by BBI <br>

-

N-C (2) - MSDS (SDS) sheets are available for the chemicals in the unit<br>

-

- MSDS (SDS) sheets are present for the chemicals in the unit<br>

-

N-C (2) - MSDS (SDS) sheets are readily available to employees<br>

-

C (5) - Chemicals are labeled<br>

-

C (5) - Chemicals are properly labeled<br>

-

C (5) - Chemical label is legible<br>

-

C (5) - All chemicals stored are capped or covered<br>

-

C (5) - All chemicals stored in BOH chemical storage area<br>

-

C (5) - No chemicals are stored over food, food packaging, food preparation areas, prep sinks, or the 3-compartment sink<br>

-

C (5) - Chemicals are stored ≥ 1 foot from food/packaging/preparation equipment/surfaces (same shelf)<br>

-

C (5) - Chemicals are stored ≥ 3 feet from sources of heat or flame<br>

-

C (5) - No liquid soap or hand sanitizer dispensers mounted over a prep or 3-compartment sink<br>

-

C (5) - Other (chemicals stored and labeled)<br>

-

Info (0) - No one other than the PCO applies pesticides without written direction to do so

-

Info (0) - No professional pesticide on premise without written instructions from PCO

-

Info (0) - No consumer/retail pesticides are present

-

C (5) - No poisonous rodent bait found in open bait stations<br>

-

C (5) - No flies landing in or on food<br>

-

C (5) - No dead cockroach(s) sightings<br>

-

C (5) - No chewed bags (rodents)<br>

-

C (5) - No rodent droppings<br>

-

Auto Fail (20) -No live cockroach(s) sightings (more than 2) in food prep area<br>

-

Auto Fail (20) - No rodent(s) in food prep area<br>

-

Auto Fail (20) - No major fly infestation in food prep area<br>

-

N-C (2) - Insect control devices are designed to retain the insect within the device<br>

-

N-C (2) - Insect control devices are not over food prep or food storage areas<br>

-

N-C (2) - Insect control devices are not located where dead insects may fall onto food/utensils/food contact surfaces<br>

-

N-C (2) - Insect control devices are emptied of dead or trapped insects frequently enough to prevent accumulation<br>

-

N-C (2) - No windows are open without screens<br>

-

N-C (2) - Window or door screens are well sealed or securely in place or are w/o damage<br>

-

N-C (2) - Doors are not left propped open when not in use for an active delivery<br>

-

N-C (2) - No gaps exist around entryways, pipes, ductwork, etc.<br>

-

N-C (2) - All ceiling tiles are present, none are missing

-

N-C (2) - No cracks or missing tiles in walls present<br>

-

Auto Fail (20) -No observed sewage backup <br>

-

N-C (2) - No handsink without hot water (only one)<br>

-

Auto Fail (20) - Water of ≥100° F is verified at all handwashing sinks<br>

-

Auto Fail (20) - Water of ≥110° F is present at utility sinks<br>

-

Auto Fail (20) - There is hot water in the facility<br>

-

Auto Fail (20) - There is water service to the unit<br>

-

N-C (2) - Backflow device or air gaps are present at mop sink<br>

-

N-C (2) - Backflow device or air gaps are present at 3-part sink<br>

-

N-C (2) - Backflow device or air gaps are present at food prep sinks<br>

-

N-C (2) - Backflow device or air gaps are present at ice machines<br>

-

N-C (2) - The sprayer hose in the 3-part sink doesn't fall below the rim of the sink<br>

-

N-C (2) - Backflow device or air gaps are attached to beverage dispenser that are attached to a water line<br>

-

N-C (2) - All toilets or urinal that does not flush completely when the handle is pushed and is not marked “Out of Order”<br>

-

N-C (2) - All toilets functioning at facility<br><br><br>

-

N-C (2) - No plumbing leaks<br>

-

N-C (2) - Plumbing is in good repair<br>

-

N-C (2) - Restroom fixtures are in good repair<br>

-

N-C (2) - Plumbing shows no evidence of contamination<br>

-

Info (0) - All employee clothing and personal belongings are properly stored out of food storage or food prep areas

-

N-C (2) - Mops are stored properly to allow proper drying<br>

-

N-C (2) - Maintenance tools are stored in a way to prevent contamination<br>

-

N-C (2) - Maintenance tools are stored in an orderly fashion<br>

-

Auto Fail (20) - Electricity is throughout facility<br>

-

Info (0) - Every employee is wearing cut resistant glove

-

Info (0) -Wearing disposable glove over cut resistant glove

-

Info (0) - Cut resistant gloves in good condition

-

Info (0) - Cut resistant gloves are in use are stored improperly

-

Info (0) - Polishing gloves are used when required

-

Info (0) - Polishing gloves are used and stored properly

-

Info (0) - All FOH employee are wearing slip resistant shoes

-

Managers, Managing Partner and JVP wearing slip resistant shoes

-

Info (0) - BOH employee wearing slip resistant shoes

-

Info (0) - FOH employee with good tread on slip resistant shoes

-

Info (0) - BOH employee with good tread on slip resistant shoes

-

Info (0) - Mats in the dish room are placed together, to not cause a trip hazard

-

Info (0) - Mats are cleaned w/o excessive build up

-

Info (0) - Heavy items stored below waist level

-

Info (0) - Aprons used as required (apron worn full not half)

-

Info (0) - Aprons are stocked as required

-

Info (0) - Gloves are used as required

-

Info (0) - Gloves are stocked as required

-

Info (0) - Goggles used as required

-

Info (0) - Goggles stocked as required

-

Info (0) - Band-Aids available

-

Info (0) - First aid kit accessible to all employees