Title Page

-

Company Name:

-

Client / Site

-

Site Overview Photograph

-

Location

-

Conducted on

-

Prepared by

-

The services performed by Marsh & McLennan Agency (MMA) on this project have been conducted with that level of care or skill ordinarily exercised by reputable members of the profession, practicing in the same locality under similar budget and time constraints. No other warranty is expressed or implied.

-

Information contained herein was obtained by means of on-site observations and analytical data. Conclusions of this exposure monitoring report are based on reasonably accessible information pertaining specifically to this project. However, this is not to suggest that the information obtained is a complete compilation of all existing information, which may be pertinent to this project location.

-

This report is intended for the sole use of MMA’s client. This report may not be used or relied upon by any other party without the written consent of MMA. The scope of services performed in execution of the evaluation may not be appropriate to satisfy the needs of other users, and the use or re-use of this document or the findings, conclusions, or recommendations is at the risk of said user.

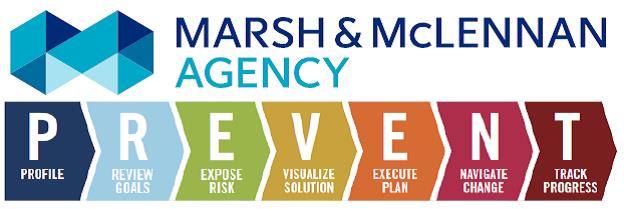

IH Sampling Best Practices

-

IH Sampling Best Practices

-

Competent sample collection requires frequent observations of conditions and operations that could impact the sample results. Document major work activities during sample collection. Field notes should be detailed enough to be able to provide an explanation of the sample results, uncover any issues with sample tampering, or any other issues that arose during sample collection.

Field blanks are required for all sampling activities. Field blanks are used by the lab to determine if contamination has occurred before analysis or during sample handling, shipping, or storage. Field blanks (e.g., sorbet tubes, filters, absorbing solution) are clean sample media that are taken and opened in a clean area at the sampling site, but they are not used to take samples. They should be handled, stored and shipped in the same manner as other sampling media used in sampling air contaminants, with the exception that no air is drawn through them. Field blanks are required for each requested analysis and for each lot number of sampling media. Prepare field blanks during the sampling period for each type of sample collected. One field blank will usually suffice for up to 20 samples for any given analysis/sampling period.

-

Area Sampling

-

Indoor or outdoor sampling activity?

-

Document Environmental Conditions (Temp, Humidity, Wind Speed/Direction, etc.):

-

Other information that may impact sampling results:

-

Add media

-

Document Environmental Conditions:

-

Other information that may impact sampling results:

-

Add media

-

Add drawing

Area

-

Area:

Sample

-

Sample Type:

- Hexavalent Chromium

- Asbestos (airborne) PCM-Personal)

- Silica, Respirable Crystalline (Quartz, Cristobalite, Trydymite) AND Particulates/Dust, Respirable

- Other

- Weld Fume (Metals Only)

- Weld Fume Total (Gravimetric and Metals)

- Diacetyl

-

Enter analytical information:

-

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: OSHA 1012

MEDIA: Silica Gel Tubes Part A and Part B collected in series

FLOW RATE: STEL Sampling 15 min at 0.2 L/min (3.0 L), TWA Sampling 180 min at 0.05 L/min (9.0 L)

VOLUME: 3.0 (STEL) to 9.0 (TWA) Liters

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Samples are prone to overloading. Protect tubes from light during and after sampling with aluminum foil or opaque tape. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7500 (GRAV)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 2 piece (yellow band)

FLOW RATE: ~2.5 L/min w/Aluminum Cyclone

VOLUME: 100 to 960Liters

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Ensure grit pot is present on the cyclone, an absent grit pot permits massive leakage and prevents proper sample collection.

Never invert cyclone separator during or after sample collection, this will cause erroneous high results.

PRIOR TO SAMPLING: Clean all parts of the cyclone, including the interior of the grit

pot, with mild soapy water. The cyclone may be wiped with a clean dust-free tissue, air

dried, blown dry, or wiped with isopropyl alcohol. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7500 (GRAV)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 2 piece (yellow band)

FLOW RATE: ~2 L/min VOLUME: 100 to 960Liters

BLANKS: One blank per set of samples -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: NIOSH 0600 and NIOSH 7500/OSHA ID-142 (XRD)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 3 piece (yellow band)

FLOW RATE: ~2.5 L/min w/Aluminum Cyclone

VOLUME: 200 to 1,000 Liters (be careful of overloading cassette at high end).

*** WOHL has 5 ug reporting limit, ~200 Liters will reach the AL (25 ug/m3)

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Ensure grit pot is present on the cyclone, an absent grit pot permits massive leakage and prevents proper sample collection.

Never invert cyclone separator during or after sample collection, this will cause erroneous high results.

PRIOR TO SAMPLING: Clean all parts of the cyclone, including the interior of the grit

pot, with mild soapy water. The cyclone may be wiped with a clean dust-free tissue, air

dried, blown dry, or wiped with isopropyl alcohol. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: OSHA ID-215

MEDIA: 2PYF, Welding and Non-Acidic Environments use 37mm Unweighed PVC 5 micron 2 piece (labeled Na/K/Cr6)

Plating and Acidic Environments use 37mm Quartz NaOH treated 2 piece (labeled Cr6 Acid)

FLOW RATE: 2 L/min

VOLUME: 200 to 960 Liters

BLANKS: One per set of samples

SPECIAL INSTRUCTIONS: Samples must be shipped overnight to lab within 24 hours of collection -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7400 (PCM) Method

MEDIA: MCE, 25mm, 0.8 micron, 3 piece cassette, sample open faced.

FLOW RATE: 0.5 to 2.5 L/min

CALIBRATION: Calibrate in-line with calibration cassette

VOLUME: 15+ Liters (Do not overload, visible dust 100L, minimal dust 240L, office environment 400+L)

BLANKS: 2 or 10% of total samples submitted

SPECIAL INSTRUCTIONS: -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

Personal Sampling

-

Indoor or outdoor sampling activity?

-

Document Environmental Conditions (Temp, Humidity, Wind Speed/Direction, etc.)

-

Other information that may impact sampling results:

-

Add media

-

Document Environmental Conditions:

-

Add media

-

Add drawing

Employee

-

Employee Name:

Sample

-

Sample Type:

- Hexavalent Chromium

- Asbestos (airborne) PCM-Personal)

- Silica, Respirable Crystalline (Quartz, Cristobalite, Trydymite) AND Particulates/Dust, Respirable

- Other

- Weld Fume (Metals Only)

- Weld Fume Total (Gravimetric and Metals)

- Diacetyl

-

ANALYTICAL METHOD: OSHA 1012

MEDIA: Silica Gel Tubes Part A and Part B collected in series

FLOW RATE: STEL Sampling 15 min at 0.2 L/min (3.0 L), TWA Sampling 180 min at 0.05 L/min (9.0 L)

VOLUME: 3.0 (STEL) to 9.0 (TWA) Liters

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Samples are prone to overloading. Protect tubes from light during and after sampling with aluminum foil or opaque tape. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7500 (GRAV)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 2 piece (yellow band)

FLOW RATE: ~2 L/min VOLUME: 100 to 960Liters

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7500 (GRAV)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 2 piece (yellow band)

FLOW RATE: ~2.5 L/min w/Aluminum Cyclone

VOLUME: 100 to 960Liters

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Ensure grit pot is present on the cyclone, an absent grit pot permits massive leakage and prevents proper sample collection.

Never invert cyclone separator during or after sample collection, this will cause erroneous high results.

PRIOR TO SAMPLING: Clean all parts of the cyclone, including the interior of the grit

pot, with mild soapy water. The cyclone may be wiped with a clean dust-free tissue, air

dried, blown dry, or wiped with isopropyl alcohol. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: NIOSH 0600 and NIOSH 7500/OSHA ID-142 (XRD)

MEDIA: 2PYF, 37mm Pre-weighed PVC 5 micron 3 piece (yellow band)

FLOW RATE: ~2.5 L/min w/Aluminum Cyclone

VOLUME: 200 to 1,000 Liters (be careful of overloading cassette at high end).

*** WOHL has 5 ug reporting limit, ~200 Liters will reach the AL (25 ug/m3)

BLANKS: One blank per set of samples

SPECIAL INSTRUCTIONS: Ensure grit pot is present on the cyclone, an absent grit pot permits massive leakage and prevents proper sample collection.

Never invert cyclone separator during or after sample collection, this will cause erroneous high results.

PRIOR TO SAMPLING: Clean all parts of the cyclone, including the interior of the grit

pot, with mild soapy water. The cyclone may be wiped with a clean dust-free tissue, air

dried, blown dry, or wiped with isopropyl alcohol. -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: OSHA ID-215

MEDIA: Welding and Non-Acidic Environments use 37mm Unweighed PVC 5 micron 2 piece (labeled Na/K/Cr6)

Plating and Acidic Environments use 37mm Quartz NaOH treated 2 piece (labeled Cr6 Acid)

FLOW RATE: 2 L/min

VOLUME: 200 to 960 Liters

BLANKS: One per set of samples

SPECIAL INSTRUCTIONS: Samples must be shipped overnight to lab within 24 hours of collection -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

ANALYTICAL METHOD: Niosh 7400 (PCM) Method

MEDIA: MCE, 25mm, 0.8 micron, 3 piece cassette, sample open faced.

FLOW RATE: 0.5 to 2.5 L/min

CALIBRATION: Calibrate in-line with calibration cassette

VOLUME: 15+ Liters (Do not overload, visible dust 100L, minimal dust 240L, office environment 400+L)

BLANKS: 2 or 10% of total samples submitted

SPECIAL INSTRUCTIONS: -

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media

-

Enter analytical information:

-

Sample Number / Pump Number:

-

Initial Flow Rate:

-

Sample Start Time:

-

Final Flow Rate:

-

Sample End Time:

-

Document activities performed during sample duration:

-

Add media