Information

-

Conducted on

-

Pit Audited

-

Location

-

Project Name

-

Type of location

-

Location type

-

Reason for Audit

-

Point(s) of Contact/Title

-

Auditor

-

Type of work being performed

Administration

Administration

-

First Aid Supplies immediately available/ adequately stocked

-

Jobsite warning signs posted as necessary (Confined Space, Flammable, High Voltage)

Weather

-

-

Weather Conditions

- Clear

- Partly Cloudy

- Overcast

- Windy

- Raining

- Thunderstorm

- Snowing

- Breezy

-

Ground Conditions

-

Temperature Expected for the day

-

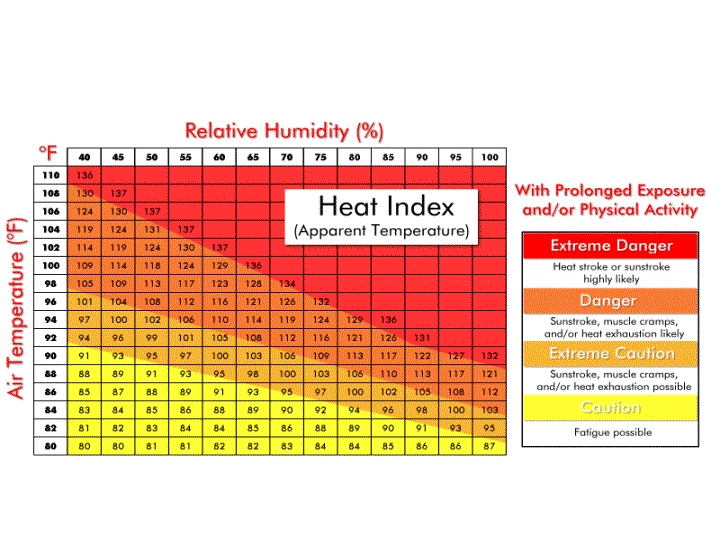

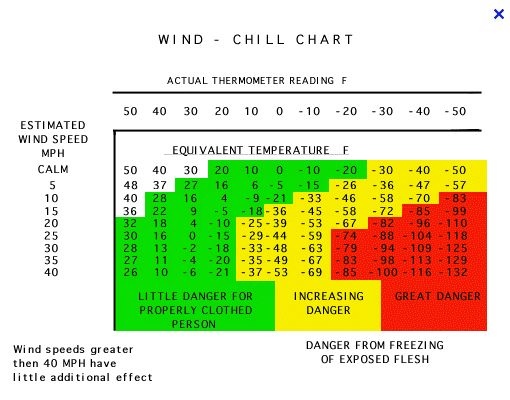

If temperatures are below 50 degrees or above 80, there is a chance for weather-related issues. Please refer to the graphics below to determine if weather might be a safety issue.

-

Heat Index

-

Wind Chill Index

-

Temperature Index Cautions

- Heat - Caution

- Heat - Extreme Caution

- Heat - Danger

- Heat - Extreme Danger

- Wind Chill - Caution

- Wind Chill - Danger

- Wind Chill - Great Danger

- N/A

Utility Notification

-

Ground disturbance occurring

-

Has Utility Locate been notified

-

Working near overhead utility lines

-

Precautions in place to prevent contact

Required Permits

-

Hot Work

-

Permit completed/on-site

-

Fire watch identified/present

-

Fire extinguisher present

-

Confined Space

-

Permit completed/on-site

-

Competent person identified/present

-

Other permits required

Required Permit

-

Permit completed

-

Permit completed/on-site

-

Required Permit

Housekeeping & Sanitation

Staging Area

-

General neatness of working areas & walkways

-

Eye flushing facilities available

-

Slip/Trip/Fall hazards eliminated in staging area

-

Are materials, scraps, or debris, piled and stored as to not create a hazard?

-

Sanitary, adequate bathroom facilities

-

Adequate supply of drinking water

-

Waste/garbage containers available

-

Containers labeled

-

Job trailer landing areas clear

-

If railings required, installed

-

Wheels chocked/blocked against movement

Personal Protective Equipment

-

No respirators worn by untrained employees, voluntary use of dust masks

-

PPE maintained properly

-

Proper PPE selected

-

Have all controls been implemented to minimize PPE requirements

-

Safety Glasses

-

Goggles

-

Face Shields

-

Hearing protection

-

Class II High-Visibility clothing

Fire Prevention

-

Adequate number & type of fire extinguisher(s) available

-

Fire extinguisher inspections accomplished (monthly/periodically/)

-

Gas Cylinders stored correctly

-

Gas Cylinders in use secured in upright position

-

Combustible scrap, debris, and waste materials stored in covered metal receptacles, and removed from the work site promptly

-

Proper storage methods used to minimize the risk of fire and spontaneous combustion

-

Flammable liquids kept in closed containers when not in use

-

Empty containers removed

-

Containers stored in approved and appropriate area(s)

-

Propane cylinders stored/secured in upright position

Rolling Stock

Motor Vehicles

-

Seat belt use

-

Operated properly?

-

Fire extinguishers serviced/inspected

-

Drivers compartment clear

-

Windshield free of obstructive cracks

-

Loose materials/trash secured/removed

-

Tools/Equipment secure

-

Beacons

-

Back-up alarms (1 ton and above)

Commercial Motor Vehicles

-

CMV's in use

-

Seat belt use

-

Operated properly?

-

Fire extinguishers serviced/inspected

-

Drivers compartment clear

-

Windshield/side windows free cracks/chips

-

Loose materials/trash secured/removed

-

Beacons

-

Back-up alarms

-

Paperwork complete: CMV Inspections/Logs

-

Defects corrected quickly

Heavy Equipment

-

Heavy Equipment in use

-

Seat belt use

-

Operated properly?

-

Fire extinguishers serviced/inspected

-

Drivers compartment clear

-

Windshield/side windows free cracks/chips

-

Loose materials/trash secured/removed

-

Beacons

-

Back-up alarms

-

Defects corrected quickly

Trailers

-

Trailers in use

-

Properly sized for load

-

Properly attached to tow unit

-

All tail/marker lights operatable

-

Decking secure/stable

-

Deck clear of debris

-

Wheels chocked/blocked from movement if parked

-

Load secured properly

-

Proper signs/placards

Powered Industrial Trucks (Forklifts/Telehandlers)

-

PITs in use

-

Properly sized for load

-

Properly attached to tow unit

-

All tail/marker lights operatable

-

Decking secure/stable

-

Deck clear of debris

-

Wheels chocked/blocked from movement if parked

-

Load secured properly

-

Proper signs/placards

-

Trailers in use

-

Properly sized for load

-

Properly attached to tow unit

-

All tail/marker lights operatable

-

Decking secure/stable

-

Deck clear of debris

-

Wheels chocked/blocked from movement if parked

-

Load secured properly

-

Proper signs/placards

Additional Rolling Stock Hazards Identified

-

Additional Rolling Stock Hazards Identified

Additional Rolling Stock Hazards Identified

-

Additional Rolling Stock Hazards Identified

-

Provisions in place

Other Hazards

Hand Tools

-

Proper tools and operator for the job task

-

Hand tools free from damage (shaft, head,<br>splinters, etc.)

-

Tools used properly

-

Pneumatic Tools - proper hoses and connections

-

Damaged tools repaired or replaced

-

Tools equipped with required guards

-

Tools stored properly when not in use

-

Cuttoffs/Kill Switches /Anti-restart functioning

Material Handling

-

Using mechanical lifting when possible

-

Materials secured/balanced

-

Materials moved as low as possible

-

Correct body positioning

-

Lifting with other employees

-

Other Hazards/Provisions

Other hazards identified/precautions

-

Other hazards

-

Provisions in place

Hot Work

-

Hot Work being performed

-

Gas cylinders properly stored, in or out of service

-

Welding cables: Leads, connectors & cable condition

-

Power cables protected & in good repair

-

Oxy/Acetylene torch sets, regulators, hoses and attachments in good repair

-

Proper PPE being utilized

-

Proper ventilation/filtering present

-

Fire Extinguisher within 25 feet

-

Flammable material protected or removed

-

Fire watch being utilized when required

Crusher

-

Crusher on site

-

Bin ramps bermed properly

-

Emergency Provider Checklist completed, displayed

-

Containment berms

-

Hot oil PPE present/maintained

-

Hard Hats, Safety Toed Boots, Eye and Hearing Protection utilized

-

Other Hazards/Provisions

Other hazards identified/precautions

-

Other hazards

-

Provisions in place

Closing

Closing

-

Findings/Comments

-

Findings/Comments

Signatures

-

On-Site Representative:

Auditor

-

Auditor: