Information

-

Project Name

-

Client

-

Conducted on

-

Workgroup

-

Number of Employees

-

Job Titles

-

Prepared by

-

Location

-

Personnel (first and last name)

-

Audit Guidance: -All unsafe acts shall be stopped immediately. -Field Observations shall include photos for both safe and unsafe operations. Photos should be annotated with what the observer is focused on at the time of the audit. -Any item marked as a deficiency shall have a photo (if possible) and a detailed description. -All comments should identify those crew members performing the task correctly and/or incorrectly. -Equipment being inspected shall be listed and/or have a photo with the unit number displayed. -All audits shall be reviewed with the PIC prior to departure from the site. Corrective actions shall be assigned with due dates and noted on the audit. -Any audits being forwarded to the client shall be reviewed by more than one safety team member prior to being sent.

-

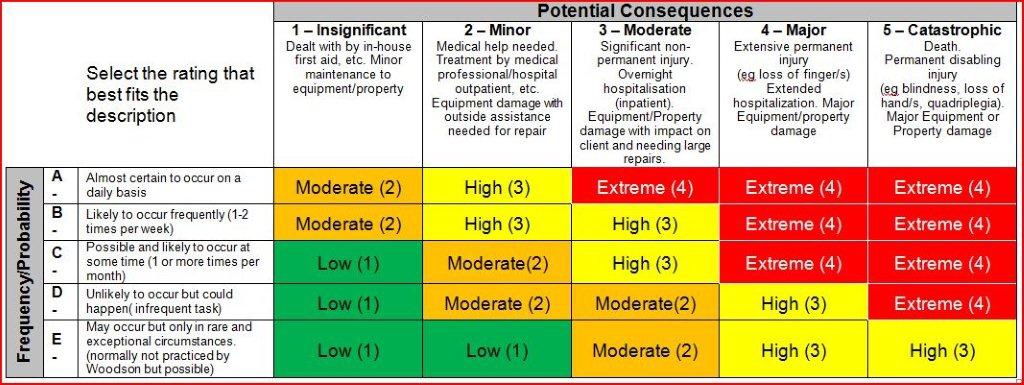

All audit findings shall have an assigned weight (1-4) assigned per the below matrix. Document the weighted number rating in the comment section associated with the applicable question.

Communication

-

Prior to making a decision, do the crew use star?

-

Human Performance tools observed and bieng utilized correctly?

-

Is Stop Work Authority discussed and documented on the JSA,JHA?

-

Cell phone use by Supervision only?

Procedures and Documents

-

When was the last time you were coached from a member of management on safety?

-

Entergy fatal rules being complied with?

-

Tailboard/Job Hazard analysis completed?

-

Weekly/Daily inspection sheets complete?

-

Are SDS available for all hazardous chemicals on site ?

Displays and Labels

-

Is the work site properly marked and/or barricaded? (open holes ,trenches, stationary objects, around cranes, spoil piles marked 10' from leading edge).

-

Add media

-

Is appropriate signage in place on entry?

-

Add media

-

Proper signage in control house for (exits, fire extinguishers, batteries hazards and required PPE)

-

Is emergency exit plan posted in the control house.

-

Proper use of hand signals and flagging techniques? Spotters used appropriately?

Environmental

-

Controls in place prior to moving soil?

-

Secondary containment in place? Units parked away from waterways?

-

Spill kits available and stocked? Spill response understood and practiced? Spills reported?

Schedule

-

Crew schedules identified and fatigue management addressed?

-

Schedules communicated for multiple operations?

Work Practices

-

Taglines when moving suspended loads?

-

Drop Zones properly barricaded when aerial work is being performed?

-

Are uncovered trim ways properly barricaded with OSHA.ANSI compliance?

-

Add media

-

Are appropriate excavation and trenching techniques being used (shoring required if over 5 feet deep or in unstable soil)?

-

Confined Space hazards identified and controlled per OSHA 1910.146?

-

Are proper lifting/carrying techniques utilized or discussed in the JHA / JSA?

-

Are proper pushing/pulling techniques utilized and discussed in the JHA/JSA ?

-

Are employees using 3 points of contact when ascending, descending, and climbing?

-

Are line of fire and pinch points identified and mitigated?

-

Proper rigging, lifting, hand signals, and good communication being utilized?

-

Are portable gas containers properly stored according to OSHA reg.1926.152?

-

Add media

-

Is housekeeping kept in order and documented on the job site?

-

Add media

Work Planning

-

Job Plan (does everyone know the job duties or the tasks that need to be performed )?

-

Have the job hazards been identified, prioritized, and documented?

-

Work area clearly defined on JSA?

-

Are all hazards that can be eliminated have been eliminated or mitigated ?

-

Has an effective control/mitigation plan for identified hazards been developed?

-

Ingress, Egress routes and parking areas communicated with proper signs in place?

-

Severe weather contingency plan discussed and documented?(tornados, thunderstorms, lightning)

-

Has the emergency plan been documented and understood? (evacuation plan in place)

-

Is fall protection equipment in good condition and rescue plan in place?

-

If more than one crew present (contract or Entergy), lead(s) are identified and communication is occuring?

-

Animals, insects and plants mitigated?

Supervision

-

Emphasis of schedule exceeding safe work?

-

Is supervision conveying safety first Practices

-

Have new Entergy rules for the use of proper cutting tools been implemented and discussed, documented with all employees?

-

Supervision verifying the job hazard analysis/job plan is being followed?

-

Crew lead demonstrated leadership ability?

Training/Qualification

-

Powersafe complete and up to date

-

Crew members qualified and trained to operate equipment on site?(credentials on site)

-

Crew Members qualified for task being performed?(digging, operating, driving)

Change Management

-

JSA updated periodically and whenever work task changes?

-

Scope changes time stamped?

External Influence

-

Weather conditions discussed and documented?

-

Heat/cold weather mitigation plan in use and documented?

-

Public encrouchment on job site discussed and documented on JSA?

System/Equipment Operation

-

If work is being performed inside the substation or switchyard, is the gate locked or barricaded?

-

Are seat belts being used on applicable equipment while in operation?

-

Appropriate PPE and equipment for welding and cutting operations (FR clothing etc.)?

-

Are Fire extinguisher near or present for any hot work done in substation.

-

Add media

-

All PPE in good order and utilized? hard hat, Z-87 eye protection, FR clothing , hearing protection, high viz vest, EH footwear, gloves, face shield, chaps etc.

-

Cut resistant gloves utilized when stripping, cutting conduit or anytime sharp objects are present?

-

Arc flash protection being utilized (correct class)?

-

If applicable, 100% fall protection being utilized?

Personnel and Materials Management

-

Sufficient personnel assigned to task? (spotter, signal, flagger, insulated matts, fiberglass ladder, ex.)

-

Adequate materials provided to complete task?

Equipment Selection and use

-

Is all equipment set up for safe use (outriggers set up properly as applicable ,Barricades on equipment )?

-

Are fire extinguishers on site, with up date inspections,(annual, mouthy) and in good working order?

-

Skinning and Stripping tools utilized and in good condition?(Entergy approved cutting tools only)

-

Hot Sticks/shotguns inspected and in good condition?

-

GFI equipment and extension cords in good working order and inspected prior to use?

-

Are ladders (fiberglass only) in good condition with all labels legible and tied off as needed?

-

Ladders inspected prior to use and load rating tags applied?

-

Are guards in place on grinders, portable saws, etc?

-

Are the proper tools for the job being utilized, and are tools in good condition with no modifications?

-

Eye wash station or solution in good working order and readily available?

-

Are proper PPE available for entrance in the battery storage rooms in the control house.

Management

-

Short service employee's identified?

-

Does management covey, care, trust and commitment to employees?

-

Policies, practices, procedures properly defined and accessible to emplyees?

-

incidents/near misses reported and documented in a timely manner?

Machine Maintenance/Testing

-

Equipment photos on site.

-

Has the crew performed and documented an inspection of the equipment prior to work to assure equipment is in safe operating condition?

-

Are safety/medical/first aid equipment/ goods on site and within date?

-

Di-electric testing on booms completed?

-

Slings and rigging properly inspected and adequate?

-

Back up alarms working properly

-

Is equipment damage/malfunctions recorded?

Design Configuration

-

Are appropriate (DOT, OSHA) signs and cones in place?

Summary and signatures

-

Positive observations. List crew members and specific items they are doing correctly:

-

Inspectors signature

-

Crew lead signature