Title Page

-

OPCO / Site

-

Prepared by

-

Location of Incident:

Incident Investigation Information

-

Date of Incident:

-

Date of Investigation:

-

EMCOR Company:

-

Jobsite Location:

-

Investigation Team:

-

Safety Manager:

-

Injured Employee Name:

Root Cause Analysis Worksheet - Refer to EBS SWP3 Accident Investigation for further info

-

Step 1 - Incident Event: Describe the incident (injury, illness, other losses). Describe the sequence of relevant events (prior-during-immediately after) incident.

-

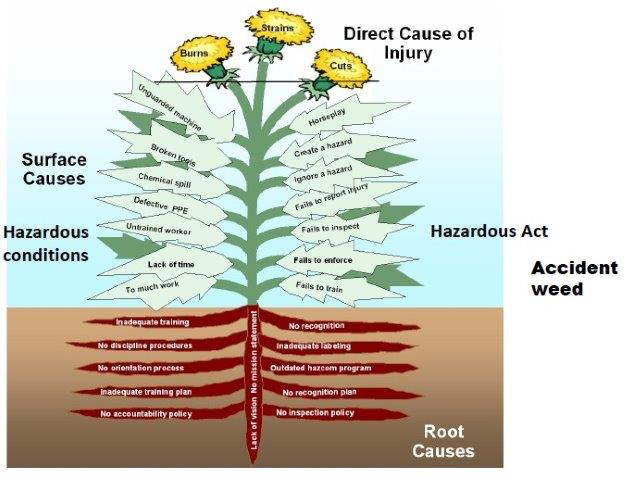

Step 2 - Identify the Direct Cause of the incident. What is the DIRECT CAUSE of the incident? The simplest answer is the best. THIS IS THE MOST IMPORTANT STEP IN THE PROCESS.

-

Step 3 - Sequence of Events: Develop sequence of events from start to finish, based on interviews and physical evidence. Describe each event as an occurrence with one noun/verb. Describe the events precisely as they happen.

-

Step 4 - After the DIRECT cause, identify the primary surface cause. Was it a Hazardous Condition or Unsafe Behavior? Refer to accident weed for help.

-

Hazardous Condition:

-

Unsafe Behavior:

-

Step 5 - Event Analysis - The 5 Why Process: This step involves asking the 5 Whys (why, why, why, why, why). Begin with the basic direct cause of the incident. Start by asking the first why to the direct cause. One why uncovers one reason and generates another why.

Determine indirect cause (Hazardous Condition and Unsafe Behavior) from the sequence of events. -

Why:

-

Why:

-

Why:

-

Why:

-

Why:

-

Step 6 - System Analysis: (Root Cause). This step should identify missing standards, controls that management did not design or failed to implement. Continue asking "why" in order to develop the information needed to establish root causes. Note: Root causes are program, management and/or system breakdowns or inadequacies. Determine system design and system implementation causes for each of the indirect causes.

-

7. Corrective Action: List the Corrective Action to avoid future occurrences.

-

Add Photos