Information

-

Document No.

-

Audit Title (Plant-OOO-Month-Year)

-

Plant Name & Air Quality Permit Number

-

Plant Name & Air Quality Permit Number

-

Site Name

- Alaska Pit

- Amyx Pit

- Anderson

- Belgrade Pit

- Big Sky

- Biggerstaff

- Boise Pit

- Casper

- Cranny Pit

- Hesper

- Laramie Plant Site

- LaSalle

- Lola Pit

- Mullan

- North Site

- Notus

- Other Pit

- River Pit

- Sindelar

- Star Pit #1

- VR Pit

- Wilson

-

Division

- Belgrade

- Billings

- Boise

- Casper

- Cheyenne

- Idaho Falls

- Northern Idaho

- Western Montana

-

Location

-

Inspection Conducted on

-

Prepared by

-

Additional Personnel conducting Inspection

Weather & Site Conditions

Weather Conditions at Time of Inspection

-

Current Site Conditions

- Sunny

- Overcast

- Dry

- Wet

- Frozen

- Stabilized

-

Wind Direction

- North

- South

- East

- West

- Northwest

- Northeast

- Southwest

- Southeast

Site Inspection

Monthly Inspections of Dust Controls and Spray Bars

-

Check the Box to view the Applicability of 40 CFR Part 60, Subpart OOO.

-

The provisions of this subpart are applicable to the following affected facilities that commenced construction, modification, or reconstruction after August 31, 1983 in fixed or portable nonmetallic mineral processing plants: each crusher, grinding mill, screening operation, bucket elevator, belt conveyor, bagging operation, storage bin, enclosed truck or railcar loading station. Also, crushers and grinding mills at hot mix asphalt facilities that reduce the size of nonmetallic minerals embedded in recycled asphalt pavement and subsequent affected facilities up to, but not including, the first storage silo or bin are subject to the provisions of this subpart.

Portable sand and gravel plants and crushed stone plants with capacities, as defined in § 60.671, of 136 megagrams per hour (150 tons per hour) or less are not subject to the provisions of this subpart. -

Check the Box to view the monthly periodic inspection requirement as required in 40 CFR Part 60, Subpart OOO.

-

The owner or operator of any affected facility for which construction, modification, or reconstruction commenced on or after April 22, 2008, that uses wet suppression to control emissions from the affected facility must perform monthly periodic inspections to check that water is flowing to discharge spray nozzles in the wet suppression system. The owner or operator must initiate corrective action within 24 hours and complete corrective action as expediently as practical if the owner or operator finds that water is not flowing properly during an inspection of the water spray nozzles. The owner or operator must record each inspection of the water spray nozzles, including the date of each inspection and any corrective actions taken, in the logbook required under § 60.676(b). The owner or operator must keep the logbook onsite and make hard or electronic copies (whichever is requested) of the logbook available to the Administrator upon request.

If an affected facility relies on water carryover from upstream water sprays to control fugitive emissions, then that affected facility is exempt from the 5-year repeat testing requirement specified in Table 3 of this subpart provided that the affected facility meets the criteria in paragraphs (b)(1)(i) and (ii) of this section:

(i) The owner or operator of the affected facility conducts periodic inspections of the upstream water spray(s) that are responsible for controlling fugitive emissions from the affected facility. These inspections are conducted according to paragraph (b) of this section and § 60.676(b), and

(ii) The owner or operator of the affected facility designates which upstream water spray(s) will be periodically inspected at the time of the initial performance test required under § 60.11 of this part and § 60.675 of this subpart. -

Is the Crushing plant currently in operation

-

Is water is flowing to discharge spray nozzles in the wet suppression system? if No, please explain why the facilities ceased operation of the water sprays or is using a control mechanism to reduce fugitive emissions other than water sprays during the monthly inspection (for example, water from recent rainfall).

-

Are there any visible emissions from Material Transfer Points?

-

Are there any visible emissions from Material Conveyances?

-

Are there any incidents of noncompliance observed?

-

Are there any dust control measures needing maintenance or repairs?

-

Are there any failed dust control measures that need replacement?

-

Are any additional dust control measures needed to comply with the permit requirements?

Opacity Test

Opacity Test

-

Check the Box to view Fugitive Emission Limits as outlined in 40CFR Part 60, Subpart OOO

-

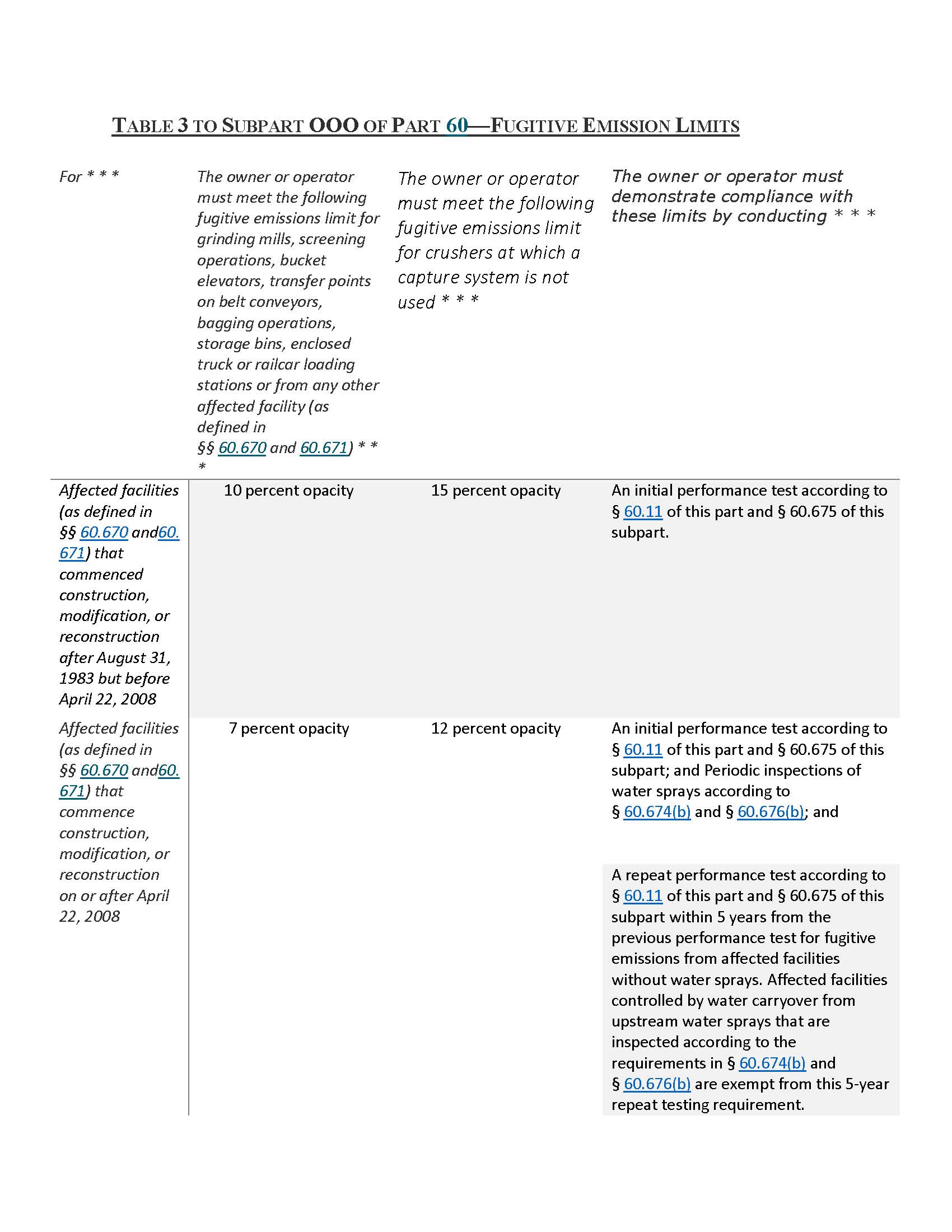

Affected facilities must meet the fugitive emission limits and compliance requirements in Table 3 of this subpart within 60 days after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup as required under § 60.11. The requirements in Table 3 of this subpart apply for fugitive emissions from affected facilities without capture systems and for fugitive emissions escaping capture systems.

If the initial performance test date for an affected facility falls during a seasonal shut down (as defined in § 60.671 of this subpart) of the affected facility, then with approval from the permitting authority, the owner or operator may postpone the initial performance test until no later than 60 calendar days after resuming operation of the affected facility.

Truck dumping of nonmetallic minerals into any screening operation, feed hopper, or crusher is exempt from the requirements of this section.

Method 9 and the procedures in § 60.11 shall be used to determine opacity. When determining compliance with the fugitive emissions standard for any affected facility described under § 60.672(b) or § 60.672(e)(1) of this subpart, the duration of the Method 9 (40 CFR part 60, Appendix A-4) observations must be 30 minutes (five 6-minute averages). Compliance with the applicable fugitive emission limits in Table 3 of this subpart must be based on the average of the five 6-minute averages. -

Check the Box to view Table 3: Fugitive Emission Limits as outlined in 40CFR Part 60, Subpart OOO

-

Table 3: Fugitive Emission Limits

-

Check the Box to view Method 9 Opacity Testing Procedures

-

The observer qualified in accordance with section 3 of this method shall use the following procedures for visually determining the opacity of emissions:

2.1 Position. The qualified observer shall stand at a distance sufficient to provide a clear view of the emissions with the sun oriented in the 140° sector to his back. Consistent with maintaining the above requirement, the observer shall, as much as possible, make his observations from a position such that his

line of vision is approximately perpendicular to the plume direction, and when observing opacity of emissions from rectangular outlets (e.g., roof monitors, open baghouses, noncircular stacks), approximately perpendicular to the longer axis of the outlet. The observer's line of sight should not include more than one plume at a time when multiple stacks are involved, and in any case the observer should make his observations with his line of sight perpendicular to the longer axis of such a set of multiple stacks (e.g., stub stacks on baghouses).

2.2 Field Records. The observer shall record the name of the plant, emission location, type facility, observer's name and affiliation, a sketch of the observer's position relative to the source, and the date on a field data sheet (Figure 9–1). The time, estimated distance to the emission location, approximate wind direction, estimated wind speed, description of the sky condition (presence and color of clouds), and plume background are recorded on a field data sheet at the time opacity readings are initiated and completed.

2.3 Observations. Opacity observations shall be made at the point of greatest opacity in that portion of the plume where condensed water vapor is not present. The observer shall not look continuously at the plume, but instead shall observe the plume momentarily at 15-second intervals.

2.3.1 Attached Steam Plumes. When condensed water vapor is present within the plume as it emerges from the emission outlet, opacity observations shall be made beyond the point in the plume at which condensed water vapor is no longer visible. The observer shall record the approximate distance from the emission outlet to the point in the plume at which the observations are made.

2.3.2 Detached Steam Plume. When water vapor in the plume condenses and becomes visible at a distinct distance from the emission outlet, the opacity of missions should be evaluated at the emission outlet prior to the condensation of water vapor and the formation of the steam plume.

2.4 Recording Observations. Opacity observations shall be recorded to the nearest 5 percent at 15-second intervals on an observational record sheet. A minimum of 24 observations shall be recorded. Each momentary observation recorded shall be deemed to represent the average opacity of emissions for a 15-second period.

2.5 Data Reduction. Opacity shall be determined as an average of 24 consecutive observations recorded at 15-second intervals. Divide the observations recorded on the record sheet into sets of 24 consecutive observations. A set is composed of any 24 consecutive observations. Sets need not be consecutive in time and in no case shall two sets overlap. For each set of 24 observations, calculate the average by summing the opacity of the 24 observations and dividing this sum by 24. If an applicable standard specifies an averaging time requiring more than 24 observations, calculate the average for all observations made during the specified time period. Record the average opacity on a record sheet. -

Was an Opacity Test Performed?

-

Date & Time of Opacity Test

-

Attach a completed Method 9 Observation form to this Inspection.

Opacity Test Results

-

Calculated Opacity

- 5%

- 10%

- 15%

- 20%

- 25%

- 30%

- 35%

- 40%

- 45%

- 50%

- 55%

- 60%

- 65%

- 70%

- 75%

- 80%

-

Is the Facility operating within the Conditions of Table 3 in 40CFR Part 60, Subpart OOO?<br>

-

Contact the Facility Manager and the Environmental Manager (Joe Smith @ 406-876-4637)

Corrective Actions

Corrective Actions

-

Please list corrective actions identified, date identified and date the corrective actions were completed. The owner or operator must initiate corrective action within 24 hours and complete corrective action as expediently as practical if the owner or operator finds that water is not flowing properly during an inspection of the water spray nozzles.

Corrective Actions

-

Corrective Action Needed

-

Describe any additional control measures needed to comply with the permit requirements:

Additional Control Measures

-

Additional Control Measures

-

Use this space for any additional notes or observations from the inspection:

-

Signature: