Information

-

Document No.

-

Audit Title (Site-SPCC-Month-Year)

-

Site Name & Permit Authorization Number

-

Division

-

Location

-

Inspection Conducted on

Site Inspection

Monthly Routine Inspection

-

Have any changes in the facility design, construction, operation, or maintenance that affect the facility's potential to discharge oil been documented in the Plan Review Log in appendix E? <br><br>These changes include but are not limited to:<br>1. commissioning or decommissioning of containers<br>2. Reconstruction, replacement, or movement of containers or piping systems<br>3. Alteration of secondary containment structures<br>4. Changes in Product<br>5. Revisions is standard operation, modification of testing or inspection procedures, changes in industry standards or maintenance procedures

-

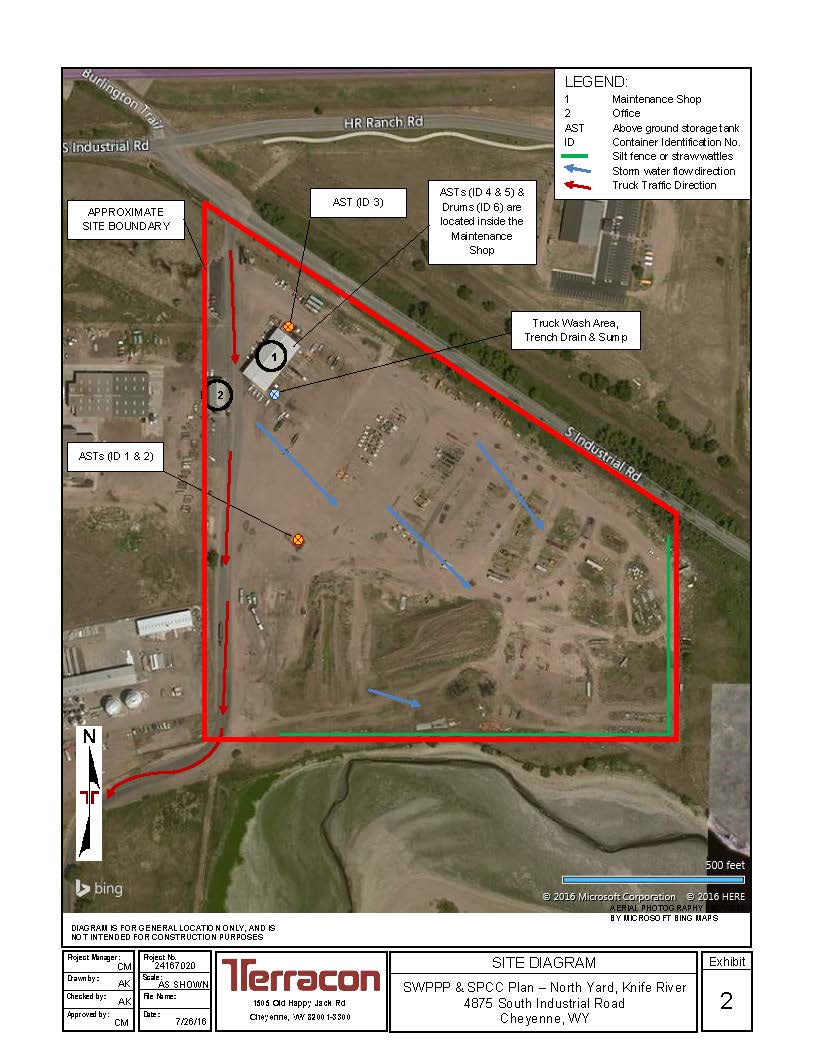

Select all of the SPCC Regulated Oil Containers to be inspected in the North Yard. Refer to Table 2-1 of the SPCC for further AST descriptions. Refer to Appendix A of the SPCC Plan for AST Locations.

- 1 - Diesel - 10,000 Gal AST

- 2 - Gasoline -4,000 Gal AST

- 3 - Used Oil - 1,000 Gal AST

- 4 - Motor Oil - 500 Gal AST

- 5 - Hydraulic Oil - 500 Gal AST

- 6 - Hydraulic Oil, Gear Oil, Degreaser, Parts Cleaner - 935 Gal - 55 gal Drums

-

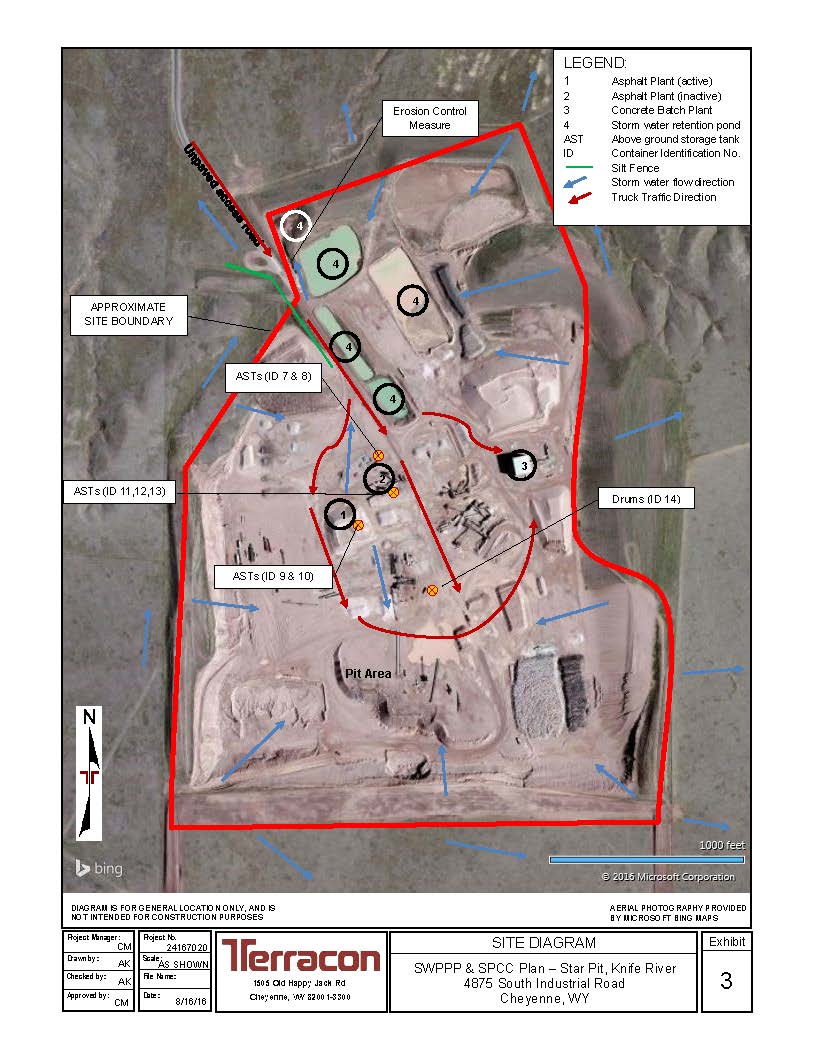

Select all of the SPCC Regulated Oil Containers to be inspected in the Star Pit. Refer to Table 2-1 of the SPCC for further AST descriptions. Refer to Appendix A of the SPCC Plan for AST Locations.

- 7 - Diesel - 12,000 Gal AST

- 8 - Diesel - 8,000 Gal AST

- 9 - Diesel - 2,000 Gal AST

- 10 - Tack Oil - 15,000 Gal AST

- 11 - Empty & not in use - former contents unknown - 10,000 Gal AST

- 12 - Tack Oil - 15,000 Gal AST

- 13 - Tack Oil - 15,000 Gal AST

- 14 - Gear oil, hydraulic fluid, motor oil - 495 Gal (55 Gal Drums)

-

Check the box to view the Facility Diagram and AST Locations

-

North Yard Site Diagram and AST Locations

-

Star Pit Site Diagram and AST Locations

Storage Tanks

-

Tank surfaces are free from signs of leakage.

-

Tanks are free from damage, rust or deterioration.

-

Bolts, rivets, or seams are free from damage.

-

Tank supports are free from deterioration or buckling.

-

Tank foundations have not eroded or settled.

-

Level gauges are operative.

-

Vents are unobstructed.

-

Secondary Containment free from damage or staining.

-

Secondary Containment is free from storm water and adequate to contain a complete failure from the largest container.

-

Interstice of double-walled tanks are free from water/product.

-

Dike drainage valve is closed or is locked.

Portable Containers

-

Container surfaces are free from signs of leakage.

-

Containers are free of damage, rust or deterioration.

Piping

-

Valve seals, gaskets, or other appurtenances are not leaking.

-

Pipelines or supports are free from damage or deterioration.

-

Joints, valves and other appurtenances are not leaking.

Security

-

Fencing, gates, or lighting are functional.

-

Pumps and valves are locked if not in use.

Response Equipment

-

Spill kit discharge response equipment inventories will be verified during facility inspections and will be replenished as needed. An individual inventory for each specific spill kit should be maintained on or near the spill kit itself. The following inventory is a general inventory to be used as guidance when stocking and/or replenishing spill kits.

-

Check the boxes below to confirm that Spill Kits include adequate supplies of the listed materials.

-

Empty 55-gallons drums to hold contaminated material

-

Loose absorbent material

-

Absorbent pads

-

Nitrile gloves

-

Neoprene gloves

-

Vinyl/PVC pull-on overboots

-

Non-sparking shovels

-

Brooms

Corrective Actions

Please list any corrective actions identified, date identified and date the corrective actions were completed.

-

Describe any incidents of non-compliance observed and not described in the prior questions:

Incidents of Non-Compliance

-

Incidents of Non-Compliance

-

Use this space for any additional notes or observations from the inspection:

-

Name & Signature