Title Page

-

Workplace Inspection - Admin & Carpark

-

Inspection Date

-

Inspection Team

-

Site

Instructions

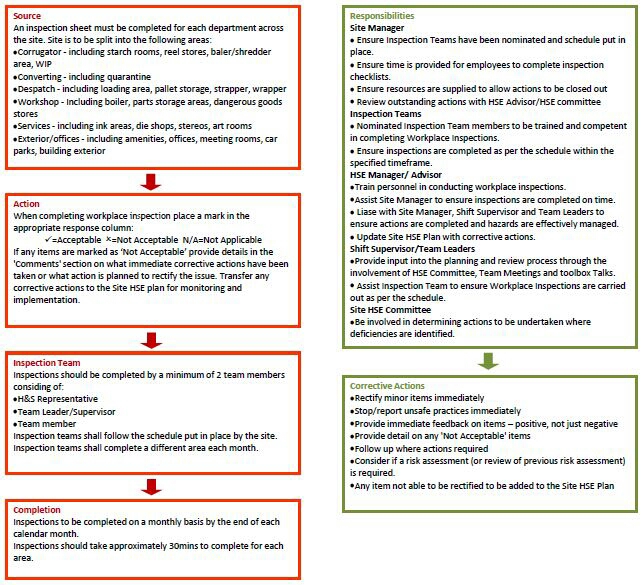

Workplace Inspection Instructions

-

Workplace Inspections are a practical tool to support our legislative requirements of monitoring safety and environmental practices on our sites. The tool is used to visibly check the working areas and helps to support our hazard management programsd. It is an assessment of how well our other safety and environmental systems are working. A workplace inspectiom should not take a lengthy amount of time to complete or generate a large number of corrective actions. If this is the case, then we could say we are not managing safety effectively on a day-to-day basis and letting things buildup. The workplace inspection needs to be completed on a monthly basis. Corrective actions that are not able to be rectified on the spot or require more intervention then these need to be added to the site HSE plan. Workplace inspections assist our teams to create a postive H&S culture. Positive involvement from all team members is key to making them effective.

-

How to complete

-

Select Yes, No or N/A to answer all sections in the audit. If items marked 'No' provide details in the comments section on what immediate corrective actions have been taken or what action is planned to rectify the issue. Transfer any corrective actions to the site HSE plan for monitoring implentation.

General work area

-

Check that there is no rubbish, cardboard, strapping, equipment or other materials left on the floor that presents a trip hazard. Check that equipment (eg ladders, trolleys, toolboxes) not in use, are stored in their designated areas.

-

Are general work areas tidy, free from rubbish and obstructions ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibility

-

Date for completion of corrective action

Pedestrian walkways

-

Check that there is no rubbish, cardboard, strapping, equipment or other materials left on the floor that presents a trip hazard. Check for items that might obstruct access or vision at intersections.

-

Are designated pedestrian walkways free from slip / trip hazards ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibility

-

Date for completion on corrective action

Floors

-

Check general work area and designated walkway floors have an even surface and there are no potholes, protrusions or cracks that could present a trip hazard.

-

Are floor surfaces in good condition and do not present any trip hazards ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibility

-

Date for completion of corrective action

Walkways

-

Check line markings are visible, not worn or faded.

-

Are designated walkway line markings in good condition and visible ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibility

-

Date for completion of corrective action

Fire Extinguisher

-

Check that there is no equipment, product or waste blocking access to the extinguisher. Check that there is a sign indicating its location and that the test tag is in date.

-

Are all fire extinguishers easily accessible, clearly marked, within test date and visible at all times ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Hose Reels

-

Check that there is no equipment, product or waste blocking access to the hose reel.

Check that there is a sign indicating its location and that the test tag is in date. -

Are all hose reels easily accessible, clearly marked, within test date and visible at all times ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Emergency Exits

-

Check that illuminated emergency exit signs are in working order. Check there are no items blocking access. Check that the door is functional and not locked.

-

Are all Emergency Exits in good working order, accessible and clear from obstructions ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

First aid kits

-

Check kit is stocked adequately (as per contents if available). Check stock expiry date and ensure its not out of date.

-

Are all First Aid Kits clean, adequately stocked and accessible?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

First aid room

-

Check that the first aid room is clean and tidy. Check that the defibrillator (if present) is within date

-

Is the First Aid Room in good order ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Knowledge of evacuation procedure

-

Ask a team member if they are aware of what to do in an emergency situation.

Do they know what to do at the warning tone and then at the emergency tone.

Check that they know who their warden is and that they know where their designated assembly areas are. -

Do team members know what to do in the event of the Warning and Evacuation tones sounding?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Displayed emergency procedure

-

Check this indicates what to do and where to go in the event of an emergency

-

Is there an emergency procedure / floor plan on display in the area?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Electrical switchboard

-

Check there is no stock, waste or other material blocking access? (recommend a clearance of 1 metre around the switchboards)

-

Is there clear access to electrical switchboards at all times ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Electrical cabinets

-

Check that the cabinets are all locked and only accessible via the key

-

Are all electrical cabinets closed and locked to prevent unauthorised access?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Electrical equipment

-

Check that the equipment has been tested & tagged and the label indicates that it is within inspection date frequency.

Check if equipment is in good working order.

Check cord is not visibly damaged (i.e. insulation casing is not cracked or split)

Check plugs, sockets, switches are not broken -

Is electrical equipment (power chords, extension leads, power boards) in good working order, tested and tagged?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Electrical leads

-

Check that leads are not lying across floors unprotected, leads are not twisted, over-stretched or crushed by other equipment, leads are not hanging without support and leads are away from potential water sources.

-

Are all electrical leads protected from potential damage ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Fans - portable and fixed

-

Check that guarding is in good condition and fingers can not access blades. Check that cables are in good condition and not damaged. Check that it has an in date test and tag attached

-

Are all portable and fixed fans safe and in good condition?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Lighting

-

Check the area for any light fittings that are not in operation. Check for lights that are flickering

-

Are light fittings operational?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Chemicals

-

Check all containers and if it contains a chemical it has been labelled correctly. Check Safety Data Sheets (SDS) are available for chemicals used in the area.

-

Are chemical containers labelled correctly?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Steps and landings

-

Check that there is no cardboard, boxes, equipment, tools on stairs or landings that could cause a trip hazard.

-

Are all steps and landings clear of equipment, product and waste ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Handrails

-

Check that there are handrails present for all staircases and that they are in good condition.

-

Are handrails on staircases in good condition?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Stair surface

-

Check that non slip tread, tape or other surfaces non slip surfaces applied are in good condition, not damaged and still providing slip resistance as designed.

-

Are non-slip surfaces on stairs in good condition ? (not worn?)

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Personal Protective Equipment (PPE)

-

Check PPE signage is not faded or worn. Check PPE signage can be clearly seen

-

Are signs indicating the need for particular PPE in place, visible and in good repair ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

HSE signs

-

Check that any signs providing instruction on HSE matters are in good condition, not faded or worn and can be read by team members, contractors or visitors.

-

Are all HSE signs readable & good condition ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Kitchen / meal break rooms

-

Check the area is clean. Check if clean, cool drinking water available? Are hot water units in good condition/not leaking? Are benches/microwaves clean?

-

Are Kitchen / Meal break rooms up to standard?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Personal belongings

-

Bags and computer cases should be stowed under desks

-

Personal belongings - stowed away as not to cause a trip hazard ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Ergonomics

-

Are all work areas easily accessible? Check awkward postures (e.g. twisting) Are items in constant use within easy reach.

Are chairs of the correct design and do people know how to make adjustments to them. -

Are good ergonomics being followed?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Carpark

-

Check that cars are not parked in a way as to block people exiting the buildings in an emergency or preventing emergency access by the emergency services

-

Are Cars parked correctly in the car park ?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

Unauthorised Tools

-

Check for homemade knives, scrappers, or any other modified tools that may have been created for clearing jam, blockages etc. Check for any unauthorised tools that look unsafe.

-

Are hand tools authorised to be used to perform tasks required?

-

Action(s) required: identify who is responsible and when to action by

Action

-

Description of corrective action

-

Responsibiliy

-

Date for completion of corrective action

New check

-

New Site Specific Check (for adding additional or one off checks)

New Check

-

New check

-

What needs to be checked?

-

Is this safe?

-

Comments / actions (detail by who / when or work order No.)

-

(photo / video if required)

Acknowledgement

-

Reviewed by department manager

-

Select date

-

Site improvement plan updated by :

-

Select date