Information

-

Name of employee

-

Conducted on

-

Name of Auditor

Employee Competencies

-

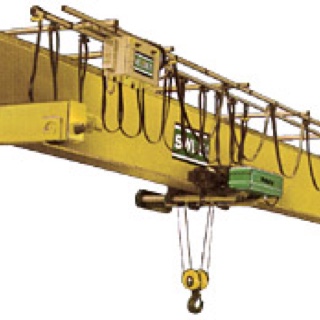

Crane type

- Bay 1 - 1 - M11241C - 12.5 T

- Bay 1 - 2 - M11231A - 7.5 T

- Bay 2 - 1 - 511905 - 5 T

- Bay 3 - 2 - 559067 - 3.2 T

- Bay 4 - 2 - M11231 - 7.5 T

- Workshop - M2 - 5T

-

Does the employee have an up to date licence which allows them to operate this crane ?

-

Employee can describe the rated load capacity of the crane .<br>

-

Employees can describe how they perform a pre-use inspection on the crane.

-

Is the hoist chain or hoist rope free of kinks or twists and not be wrapped around the load?

Observation of Work Practices

-

What lifting equipment is being used?

- Bay 1-10 T Beam

- Bay 1-2 T Slings

- Bay 1-2 T Vac lift

- Bay 1-6.5 Ton Dog

- Bay 2-500kg Vac Lift (tilt)

- Bay 2-440 kg Vac LIft

- Bay 2-3 Ton Slings

- Bay 2- 0>25mm Grabs

- Bay 2- 0>70mm Small Dogs

- Bay 3-1 Ton Slings

- Bay 3-2 Ton Slings

- Bay 4- 0>25mm Grabs

- Bay 4- 0>70mm Small Dogs

- Bay 4-500kg Vac Lift

- Bay 4-2 Ton Vac Lift (tilt)

- Bay 4-Single Leg Chains

-

Is the equipment tagged with the correct safety tag ( correct colour)

-

Is this lifting equipment appropriate for the task ?

-

Does the operator plan the lift ?

-

Has a path of travel been established and are persons kept out of path of travel in an appropriate manner?

-

What is the current authorised colour?

-

Does the operators pass under a suspended load on the hook

-

Is the load balanced or are adjustments made to balance the load?

-

Is movement of the load conducted in a manner that prevents swinging of the load?

-

Is there a clear path of travel and are areas free from obstructions?

-

Is the risk of colliding with other overhead cranes properly managed?

Assessors Recommendation and Evaluation

-

Assessors evaluation of operator safety

-

Comments

-

Auditor(s) Signature

-

Operators signature