Information

-

Confirmation No.

-

Conducted on

-

Confirmation completed by:

- Riyad Eltom

- Joe Russo

- Tiago Muinz

- Rob Trowler

- Gary Crawford

- Melissa Anastasia

- Mark Chapman

- Brett Griffiths

- Simon Knight

- Lucas Delucyk

Tools and Techniques / Visual Management

-

Relevant photos for the report

-

General notes

Tools and Techniques / Visual Management

-

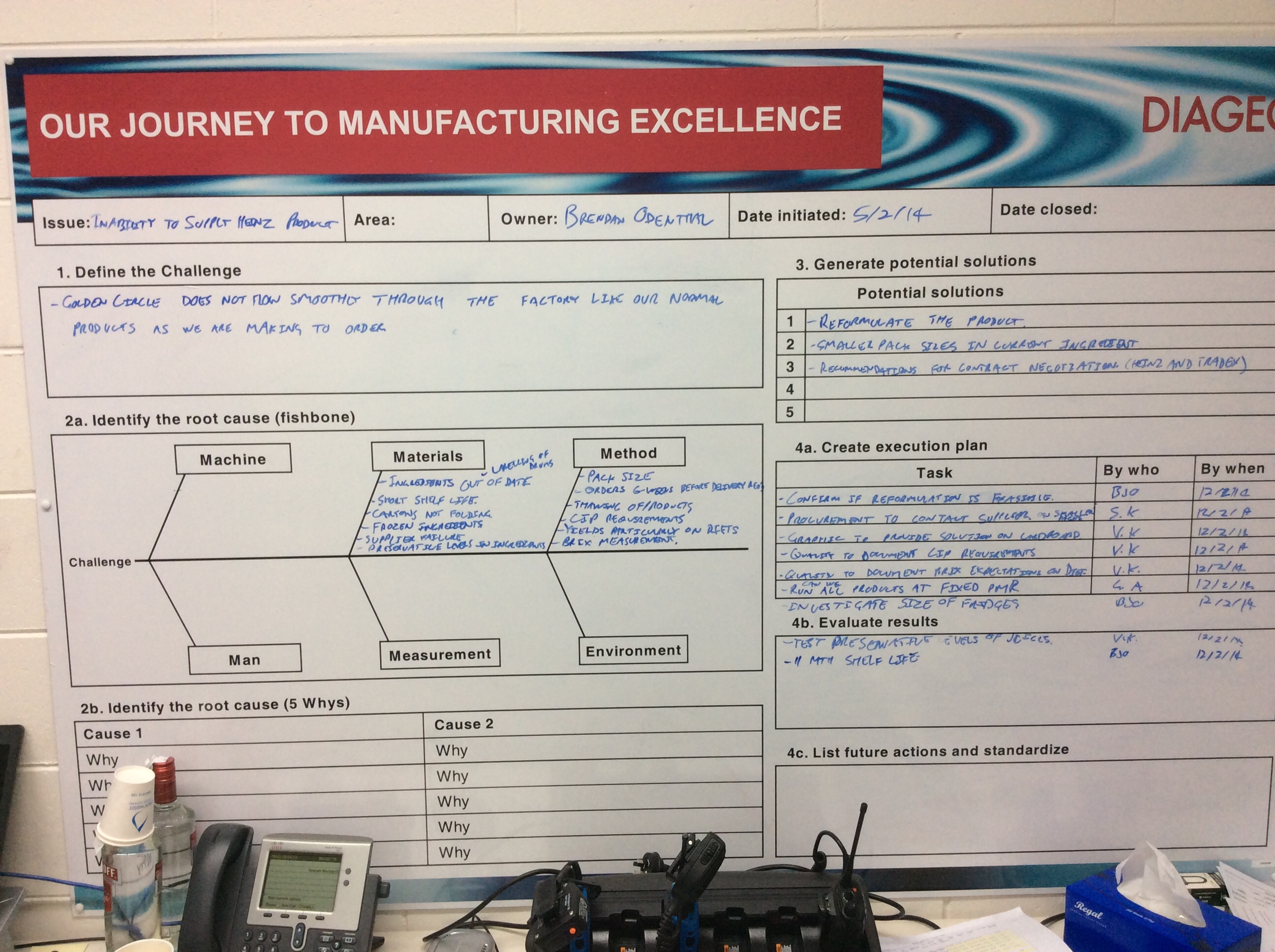

RCPS Room

-

RCPS boards are up to date with relevant information on live RCAs

-

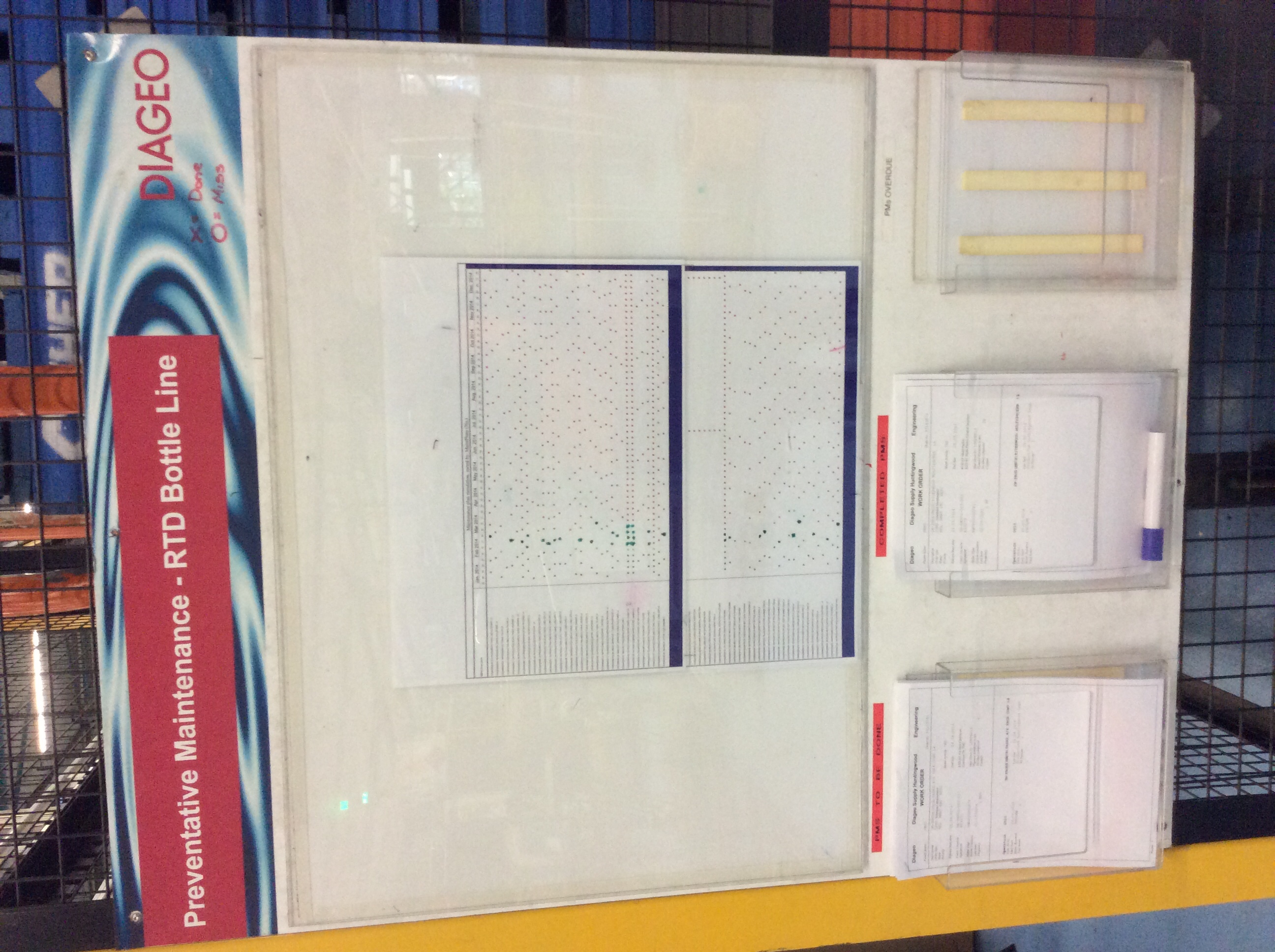

PM's Boards - look for evidence the A3 form is being marked off against recent dates for PMs

-

Check on each line that the PM's are up to date, according to the planner on each line. There are three boards in total

-

1st Checks. Check 1st check cards are being filled out and placed at each line performance board

-

Are all 1st checks up to date on each line?

-

Rosters

-

Are rosters up to date and displayed on the team boards? There is one board for each team, please check at least one of the three boards

-

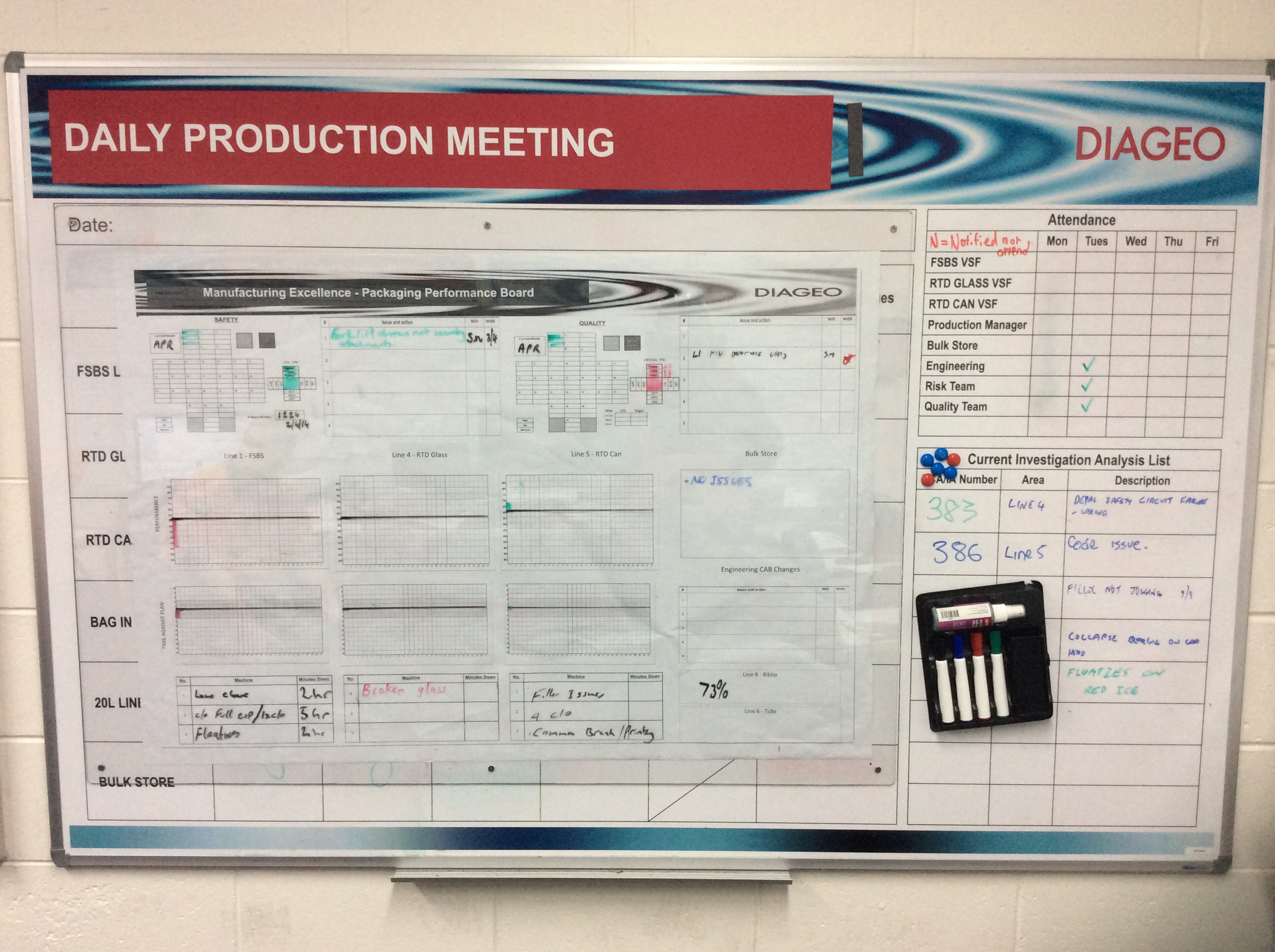

Daily Production Meeting - in RCPS Room

-

DPM occurring daily with the board updated and actions captured

-

Shift Startup Meetings

-

Start up meetings are occurring on each shift and attendance is high. Check with an operator if meeting has occurred at the performance board

-

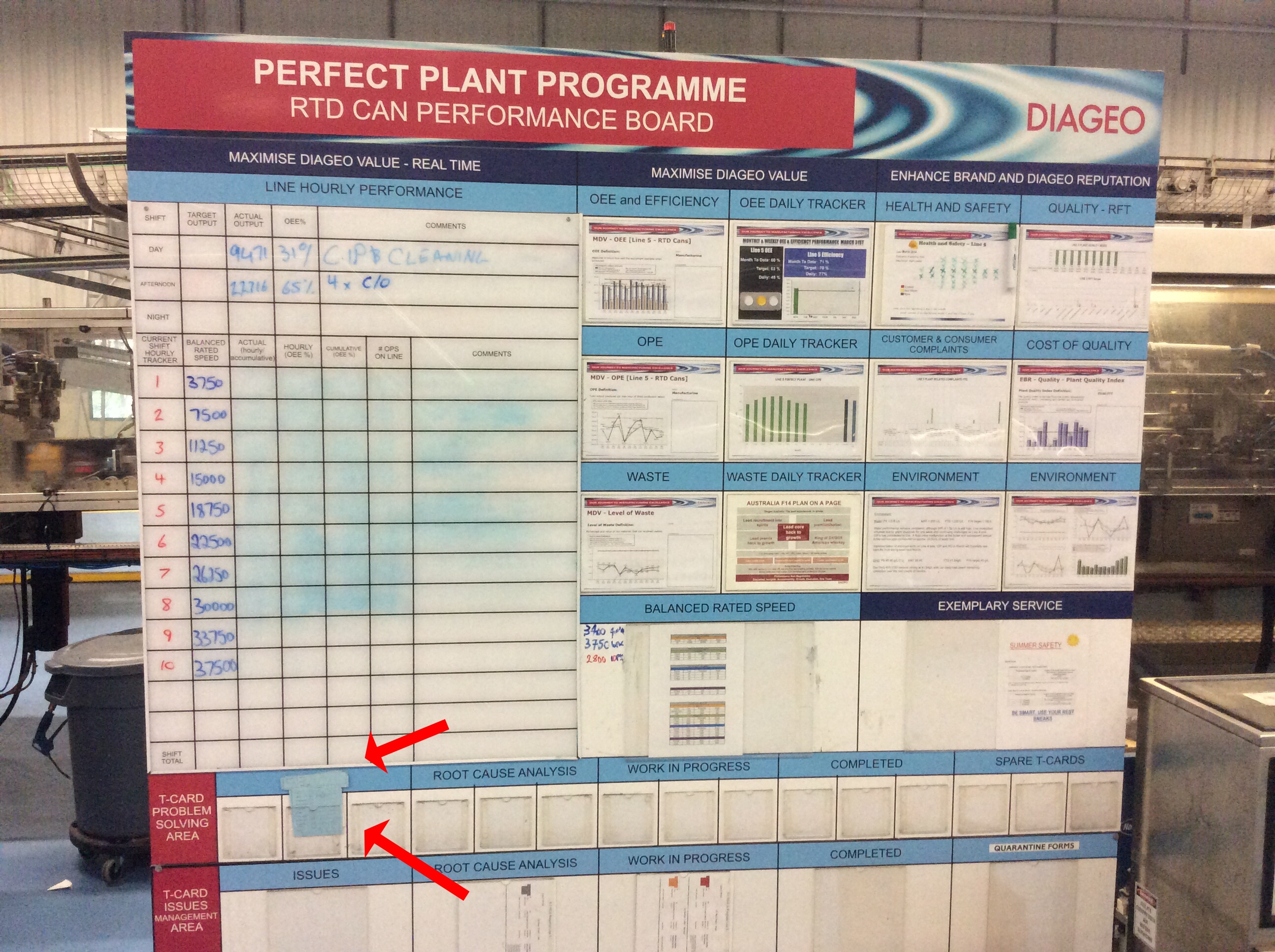

Line Board - Hourly OEE and Safety, Quality, Cost and Performance metrics

-

Check at least two Line Boards for up to date information. Is hourly OEE recorded with comments and are all Safety, Quality, Cost and Performance slides updated

Quality

-

Relevant photos for the report

-

General notes

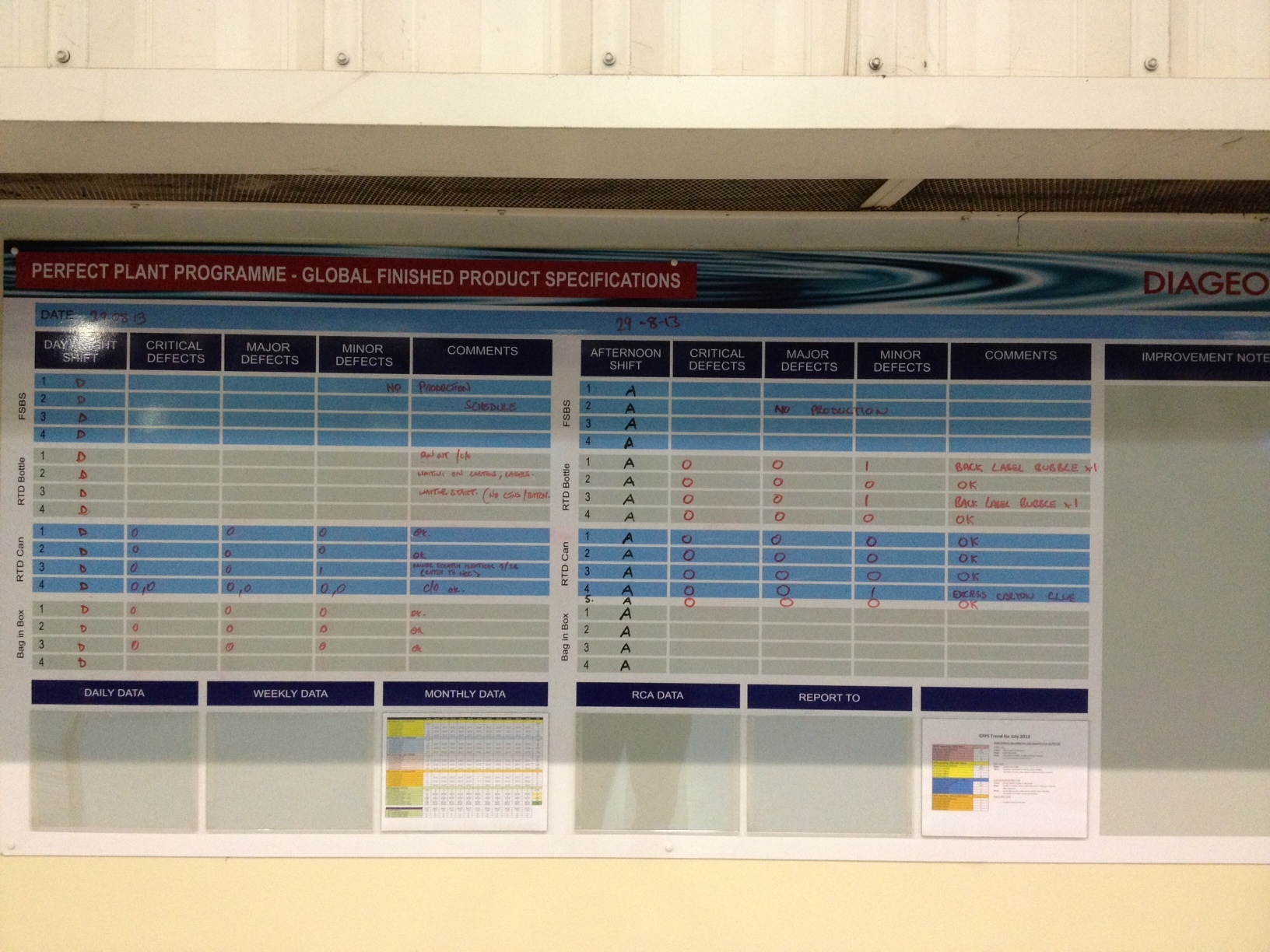

QUALITY - GFPS system followed to ensure quality is maintained at high standards

-

WHAT TO CHECK

Operators are following relevant guidelines that aim to maximize quality and are completing the necessary documentation -

Visually check lines 1 and 4 fillers and rinsers for evidence of broken glass inside the assets. Did you find broken glass?

-

Have you had the conversation with the individual?

-

Check GFPS board next to packaging hall entrance

-

GFPS - Is the GFPS board up to date?

-

Are there any Critical Defects identified

Cleaning

-

Each line has colour coded cleaning equipment at designated locations. Check two of those locations anywhere in the packaging hall for availability and condition of the equipment is satisfactory

-

Are buckets emptied of dirty liquid

-

As you walk around, we're there any product spillages on the floor

-

Line 1 - General housekeeping in good condition?

-

Line 4 - General housekeeping in good condition?

-

Line 5 - General housekeeping in good condition?

5S - Sort Set in order Shine Standardize Sustain

-

Relevant photos for the report

-

General notes

Everything is in its place - observe as you walk around, you are not expected to check every instance

-

Are bins located in marked positions on the floor?

-

Are tools located where they belong, for example shadow boards or marked storage areas?

-

Are production materials located in marked or designated areas?

Pictures of 5S standards for an area are displayed. Check at least 2 areas in the packaging hall

-

Did you find the 5S standards for at least two areas when you looked for them

-

Which line or lines

- Line 1

- Line 4

- Line 5

- Line 8

-

Specific area description

-

Does the 5S standard document accurately reflect the area

-

Please write down what was the discrepancy