Title Page

-

Company

-

Site

-

Task

-

Location

-

Date and Time of Assessment

-

Assessment prepared by

RISK ASSESSMENT PUSHING AND PULLING

PRELIMINARY

-

Task Name

-

Task Description

-

Load Weight

-

Frequency of Operation

-

Push/pull Distances

-

Are other push/pull tasks carried out by these operators?

-

Assessment discussed with employees/safety representatives:

-

Operations covered by this assessment (detailed description):

-

Locations

-

Personnel involved

-

Date of Assessment

RISK ASSESSMENT PUSHING AND PULLING

PUSHING AND PULLING

-

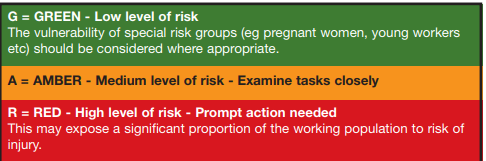

Levels of Risk:

DO THE TASKS INVOLVE:

-

High initial forces to get the load moving?

-

Advice

-

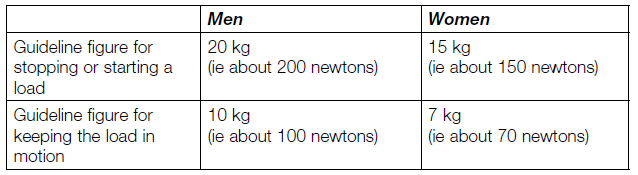

- The initial push or pull forces used to start moving an object or to change its direction are usually noticeably higher than the forces used to keep the object moving, so keep them to a minimum. See Table for Guidelines for safe pushing and pulling.

-

High forces to keep the load in motion?

-

Advice

-

- Avoid high sustained forces.

-

Sudden movements to start, stop or manoeuvre the load?

-

Advice

-

- Avoid frequent starting, stopping and manoeuvring, as well as jerky movements.

-

Twisting/manoeuvring of the load into position or around obstacles?

-

Advice

-

- Lack of space can force the worker to adopt awkward postures.

-

One-handed operations?

-

The hands below the waist or above shoulder height?

-

Advice

-

- Being able to adopt a comfortable, stable posture is important, as is avoiding twisted or bent postures. Make sure the hands are not applied to the load much below waist height or above shoulder height.

-

Movement at high speed?

-

Movement over long distances?

-

Advice

-

- Is the length of the route as short as possible?

-

Repetitive pushing/pulling?

-

Advice

-

- The risk of injury increases without sufficient recovery time.

THE LOAD OR OBJECT TO BE MOVED:

-

Does it lack good handholds?

-

Advice

-

- It is important to ensure the equipment being used is provided with a handle at a suitable height. Good handholds will help apply force and control the load. Vertical handles allow users to choose the heights they push at.

- Look at the handle height in relation to the different users as this can be a risk factor for their posture.

- Design handholds suitable for the size and weight of the load. The best ones allow a ‘power grip’ where the fingers and thumb can wrap round a cylindrical handle.

- Any spaces for the hand need to be wide enough for a large hand wearing gloves. Avoid handholds which are only large enough for fingertip contact. -

Is it unstable/unpredictable?

-

Advice

-

- Ensure the load is stacked, so that heavier items are at the bottom. Avoid putting heavier items at the top which increases the risk of the load becoming unstable, e.g. when using a roll cage.

-

Is it sharp/hot?

-

Is vision over/around it restricted?

-

Advice

-

- Plan the route and ensure the worker can safely see over and/or around the load.

IF ON WHEELS/CASTORS, ARE THEY:

-

Unsuitable for the type of load?

-

Advice

-

- It is important to ensure the equipment, including wheels and castors, are the correct type for the load involved.

-

Unsuitable for the floor surface/work environment?

-

Advice

-

- Equipment should be fitted with the correct type of wheels, so that they run easily over the surfaces involved, e.g. are the wheels on the device suitable for movement over carpet?

-

Difficult to steer?

-

Advice

-

- Ensure the load is sufficiently stable for negotiating any slopes, corners or rough surfaces.

-

Easily damaged or defective?

-

Advice

-

- Equipment must be well maintained, particularly any wheels and braking system.

-

Without brakes or difficult to stop?

-

Advice

-

- Equipment should be fitted with brakes (if needed) that are easy to apply and release.

-

With brakes, but the brakes are poor/ineffective?

-

Without a planned inspection and maintenance regime based on a frequency that keeps them in working order?

-

Advice

-

- All equipment provided for use during manual handling, including handling aids and PPE, should be included in a planned preventive maintenance programme which should include a defect reporting and correction system.

- For equipment used for pushing and pulling, this should include any wheels.

- A system for tagging defective equipment is one way to indicate that it should be taken out of use and sent for repair or disposal.

CONSIDER THE WORKING ENVIRONMENT, ARE THERE:

-

Constraints on body posture/positioning?

-

Advice

-

If the working environment prevents adopting a good posture, the risk of injury from manual handling will

be increased. For example:

- restricted headroom will result in a stooping posture;

- furniture, fixtures or other obstructions may increase the need for twisting or leaning;

- constricted working areas and narrow gangways will make it more difficult to push and pull bulky loads. -

Confined spaces/narrow doorways?

-

Advice

-

- Check if the route is wide enough for the load and wheeled equipment.

-

Surfaces or edges to cause cuts/abrasions/burns to hands or body?

-

Rutted/damaged/slippery floors?

-

Advice

-

- Pushing and pulling activities are safest when floor or ground surfaces are level, clean, dry and unbroken. - Ensure that a good grip can be achieved between the foot and the floor to prevent slipping? If the floor slopes or can be wet or contaminated, make sure the footwear is suitable for the conditions.

- Slip-resistant surfaces and suitable slip-resistant footwear may reduce the risk of slips due to manual handling. Clear away promptly any spillages of water, oil, soap, food scraps and other substances likely to make the floor slippery. -

Ramps/slopes/uneven surfaces?

-

Advice

-

- Can kerbs, steps or slopes be avoided? Make full use of ramps and lifts.

- Uneven surfaces can dramatically increase the forces required to start and keep loads moving, and increase the risk of injury. If there are slopes, they should not be so steep as to make keeping control of the load difficult.

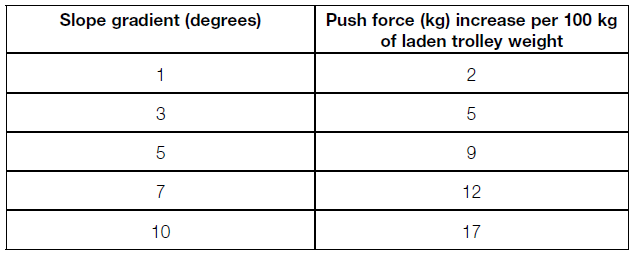

More force is needed to push a load up a slope because of gravity.

- The Table below shows the approximate increase in push forces that can be expected per 100 kg of load, on different slope gradients. For example, for a load of 400 kg and a slope of 1 in 12 (4.8º), the

additional force required is 33 kg (330 newtons). This is above the guideline weight for males and well in excess of the guideline weight for females. -

Trapping or tripping hazards

-

Advice

-

- Handling in confined spaces and narrow passages/doorways could cause a trapping/abrasion injury, especially to the hands. - Ensure the traffic route is clearly marked and is free of tripping hazards.

-

Poor lighting conditions?

-

Advice

-

- Dimness or glare may cause poor posture, for example by encouraging stooping

- Contrast between areas of bright light and deep shadow can hinder the accurate judgement of height and distance and make it difficult to see tripping hazards. -

Hot/cold/humid conditions?

-

Advice

-

- Extreme thermal conditions increase risk. For example, high temperatures or humidity can cause rapid fatigue and perspiration on the hands which may reduce grip or on the face may obstruct visibility. Work at extremely low temperatures may impair dexterity.

-

Strong air movements?

-

Advice

-

- Effect of air movement on working temperatures - the greater the wind chill factor, the higher the risk.

- Inadequate ventilation can hasten fatigue, increasing the risk of injury.

- Sudden air movements, whether caused by a ventilation system or the wind, can make large loads more difficult to manage safely.

CONSIDER INDIVIDUAL CAPABILITY - DOES THE JOB:

-

Require unusual capability?

-

Advice

-

- Do the personal attributes, such as height or strength significantly limit the ability of a large number of the workforce to carry out the task?

Note: An individual's physical capability varies with age, typically climbing until the early twenties and then gradually declining. This decline becomes more significant from the mid-forties. The risk of manual handling injury may therefore be slightly higher for employees in their teens or those in their fifties and sixties. Particular care is needed in the design of tasks for these groups who are more likely to be working close to their maximum capacity in manual handling. Also, older workers may tire more quickly and will take longer to recover from musculoskeletal injury. However, the range of individual capability is large and the benefits of experience and maturity should not be overlooked. -

Pose a risk to those with a health problem or a physical or learning difficulty?

-

Advice

-

- An employee's manual handling capability can be affected by their health status, for example care needs to be taken when considering placing an individual with a history of back pain in a job which involves heavy manual handling. In cases of doubt, the help of an occupational health professional should be sought. However, individuals should not be excluded from work unless there is a good medical reason for restricting their activity.

- Allowance should also be made for any health problem of which the employer could reasonably be expected to be aware and which might have a bearing on the ability to carry out manual handling operations in safety. If there is good reason to suspect that an individual's state of health might significantly increase the risk of injury from manual handling operations, seek medical advice. -

Pose a risk to those who are pregnant?

-

Advice

-

- Allowance should be made for pregnancy where the employer could reasonably be expected to be aware of it, i.e. where the pregnancy is visibly apparent or the employee has informed her employer that she is pregnant. Manual handling has significant implications for the health of the pregnant worker (and the foetus), particularly if combined with long periods of standing and/or walking. Hormonal changes during pregnancy can affect the ligaments and joints increasing the risk of injury during the last three months. As pregnancy progresses it also becomes more difficult to achieve and maintain good postures and this further reduces manual handling capability. Particular care should also be taken for women who may handle loads during the three months following a return to work after childbirth. Special consideration should also be given to new and expectant mothers whose capabilities may be affected by hormonal changes.

- When an employee informs her employer that she is pregnant, the risks to the health and safety of the worker and her unborn child must be assessed in accordance with the duties under the Management Regulations. A useful way to ensure compliance and make certain that workers can continue to work safely during pregnancy is to have a well-defined plan on how to respond when pregnancy is confirmed. Such a plan may include:

- re-assessment of the handling task (positioning of the load and feet, frequency of lifting) to consider what improvements might be made;

- training in recognising ways in which the work may be altered to help with changes in posture and physical capability, including the timing and frequency of rest periods;

- consideration of job-sharing, relocation or suspension on full pay where the risk cannot be reduced by a change to the working conditions;

- liaison with the GP to confirm that the pregnant worker is capable of performing work duties; and

- careful monitoring of the employees returning to work following childbirth to assess the need for changes to work organisation. -

Pose a risk to new workers/young people?

-

Advice

-

- Young workers may be more at risk of manual handling injury as their muscle strength may not be fully developed and they may be less skilled in handling techniques or in pacing the work according to their ability.

- Also take account of the extra risks to those new to the job, because of their lack of experience or unfamiliarity with the workplace. -

Require special information/training?

-

Advice

-

- The HSE does not publish prescriptive guidance on what a `good' manual handling training course should include or how long it should last. However, in general, courses should be suitable for the individual, tasks and environment involved, use relevant examples and last long enough to cover all the relevant information.

EQUIPMENT:

-

Is movement or posture hindered by clothing or personal protective equipment?

-

Advice

-

- Work clothing, often in the form of PPE should be considered as part of the manual handling assessment. Tight fitting clothes can restrict movement, for example making pushing and pulling more difficult. Gloves, whilst important in protecting hands from injuries, can reduce or increase the level of grip required for manual handling activities.

-

Is there an absence of the correct/suitable PPE being worn?

-

Advice

-

- In considering the risk posed by manual handling to what extent does the absence of correct / suitable PPE increase the level of risk?

-

Are trolleys/carts poorly maintained/cleaned/repaired?

-

Advice

-

- All equipment provided for use during manual handling, should be well maintained and regularly cleaned, especially where wheels and castors can become jammed with shrink wrap, which can make it more difficult to push a load and can lead to a load becoming unstable.

-

Is there a lack of regular maintenance procedures for the equipment?

-

Advice

-

- All equipment provided for use during manual handling, including handling aids and PPE, should be included in a planned preventive maintenance programme which should include a defect reporting and correction system.

WORK ORGANISATION (psychosocial factors)

-

Lack of consideration given to the planning and scheduling of tasks/rest breaks?

-

Advice

-

- The effective planning and scheduling of tasks (including rest breaks) involving manual handling should help reduce the risk of injury.

-

Poor communication between managers and employees (eg not involved in risk assessments or decisions on changes in system of work)?

-

Advice

-

Effective communication between managers and employees are considered key in reducing risks. A combination of informal and formal communications are considered important. There should be a balance between the two. Effective communications are likely to include a combination of the following elements and be relevant to manual handling tasks:-

- Risk assessments (and safe systems of work and method statements where the task is complex) are formally communicated to relevant personnel and records maintained of the communication.

- There are established communication forums such as safety committee meetings, team briefings and staff suggestion schemes.

- Managers / supervisors engage regularly with staff on the `shop floor' and deliver risk based discussions on manual handling. These are sometimes referred to as Tool Box Talks in some sectors.

- Health and safety inspections take place on a regular basis and involve the views and feedback of staff relating to their tasks.

- Incidents relating to manual handling are investigated and involve the participation of relevant personnel in helping to determine remedies and improvements.

- Records of formal communications are maintained and available for review.

- News letters are produced including feedback and input from staff.

- Staff surveys are conducted targeting the effectiveness of the communication process.

- There is a collaborative culture where staff are able to, and feel comfortable in communicating with management on areas of improving processes and reducing risk.

Note: It is not necessary, depending on the size and structure of the business for all of these elements to be in place. However, where formal communications are established it is important to be able to demonstrate an audit trail. In all cases the effectiveness of communications should be reviewed regularly and particularly in the light of any incident relating to manual handling. -

Are there sudden changes in workload, or seasonal changes in volume without mechanisms for dealing with the change?

-

Advice

-

- It is possible that the level of risk associated in sudden changes in work load, or seasonal changes will increase in relation to manual handling tasks. Where the exposure is high this should be reflected within the risk controls / remedial actions contained within the manual handling risk assessment.

-

Not enough training and information to carry out the task successfully?

-

Advice

-

- This should be reviewed objectively in the context of the perception of the person(s) carrying out the task and the level of training provided. Whilst consultation is important it is important to note that in some cases the operative(s) may feel that they have received sufficient training. However this may not be the case when objectively reviewed. Similarly they may consider that they have not received enough training and information to carry out the task safely. In either case the perceptions need to be tested in the context of the identified hazards and the required risk controls. The list below provides examples of testing if the worker feels they have been provided with enough training and information to carry out the task successfully in terms of risk.

- Direct feedback provided by the worker via a staff survey

- Direct feedback from the worker either formally or informally

- Evidence of training provided to the worker with a successfully passed test or certificate

- Communication of a risk assessment relating to the task coupled to a signature and date declaring understanding of the process.

- Records of team briefings, with supporting attendance times and dates along with the signature of the individual

- Accident / incident performance of the individual in relation to the task

- Inspections and safety audits relating to the individual and in the context of the task

- Feedback from the workers supervisor / manager in the context of their competency to carry out the task

- Any feedback or concerns fed back from the individuals colleagues

OVERALL ASSESSMENT

-

Risk of Injury?

-

Advice

-

High level of risk - prompt action needed:- If a significant number of relevant points identified above are missing then it is likely that the risk of injury is high. Remedial actions should be identified and actioned.

Medium level of risk: - examine tasks closely: There remains some gaps that are relevant and would limit the current level of risk further. Remedial actions should be identified and actioned.

Low Risk:- The current controls include all relevant examples and are available as a matter of record. Outside of the overall risk review process, (including an annual review and additional reviews in the context of any incidents or changes in working processes) there are no identified remedial actions.

REVIEW

-

Date for Review of Assessment

COMPLETION

-

Full Name and Signature of Assessor