Title Page

-

Unit Serial Number

-

Quality Control Unit I.D.

-

Location

Structure Inspections (All inspections must be verified by the drawing)

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is a skid required for this unit?

-

Is the skid fit up complete and accepted? (Length - Width - Height - Square)

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Are fork pockets required?

-

Is the layout complete and accepted ?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Are mounting holes required?

-

Is the mounting holes layout complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Are skid lifting eyes required? (These must be welded with flux core)

-

Is the skid lifting eye fit up complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the skid lifting eyes weld out complete and accepted w/ flux core?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the skid weld out and clean up (All accessible sharp edges and mounting holes included) complete and accepted?

-

Have you applied the QC Unit ID stamps? (front/rear left side)

-

Take photos of the QC Unit ID stamps. (QTY.2 photos required)

-

Did you fill out the QC Unit ID on the Title page?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is a plenum frame required for this unit?

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is frame legs and panels required for this unit?

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is a front frame required for this unit?

-

Is the layout for all the front frame components complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the front frame fit up complete?

-

Is the Length - Width - Height - Square dimensions accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is a bearing/motor support required?

-

Zero calibration should be set on the support side of the skid.

-

What is the digital level reading for the bearing/motor? Max Tolerance = (+/-) .3°

-

Take a photo of the digital level reading.

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is a diagonal (67.5°) brace required for the front frame?

-

What is the digital level reading for the diagonal (67.5°) component on the front frame sides? Max Tolerance = (+/-) .3°

-

Take photo of the digital level reading for both sides. (Qty. 2 photos required)

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the bearing/motor pad hole layout complete and accepted?

-

Is the bearing/motor pad fit up complete?

-

Is the bearing/motor pad center dimensions accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

What is the bearing/motor pad digital level reading compared to the skid level? Max Tolerance = (+/-) .3°

-

Take photo of digital level reading.

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Are front wall mounting brackets/clips required for this unit?

-

Is the fit up and weld out complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the front frame weld out and clean up (bolt hole slag included) complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is a rear frame required for this unit?

-

Has the layout for all the rear frame components been accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the rear frame fit up complete?

-

Is the rear frame Length - Width - Height - Square accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Are coil support gussets required?

-

Are the coil support gusset plates the correct size?

-

Is the coil support gussets fit up complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the coil support gussets weld out and clean up complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is a rear bearing/motor support required?

-

Zero calibration should be set on the support side of the skid.

-

What is the digital level reading of the rear bearing/motor support? Max Tolerance = (+/-) .3° (Photo Required)

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the rear frame weld out and clean up (bolt hole slag included) complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is the final overall inspection complete?

-

WRITE UNIT I.D. VISIBLY FOR PHOTO, UNDER OR ON THE GREEN MAGNET

-

Did you apply the green tag for release?

-

Is this unit complete and accepted for the first coating process? (Primer)

-

Have you notified a shop lead/foreman and quality lead? (Leads will notify paint lead)

-

QCI - ID

-

Date/Time

First Assembly Inspection

-

Has this unit been brought into the shop post primer coating applied?

-

QCI - ID

-

Date/Time

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Are floors required for this unit?

-

Is the floor installation and weld out complete and accepted?

-

Assembler/Welder - ID

-

QCI - ID

-

Date/Time

-

Are walls required for this unit?

-

Is the installation and weld out of all walls complete?

-

Are all the wall to structure bolted connections tightened correctly and accepted?

-

Are all gaps welded or bolted closed and accepted?

-

Assembler/Welder - ID

-

QCI - ID

-

Date/Time

-

Are fan rings required for this unit?

-

What is the quantity of fan rings for this unit?

-

Is the installation of the fan ring(s) complete?

-

Are the fan ring(s) to structure bolted connections tightened correctly and accepted?

-

Are all gaps welded or bolted closed and accepted?

-

Assembler/Welder - ID

-

QCI - ID

-

Date/Time

-

Are access door required?

-

What is the quantity of access doors required?

-

Is the access door(s) handle fit up and weld out complete and accepted?

-

Is the access door and hinge mounting to the unit complete and accepted?

-

Assembler/Welder - ID

-

QCI - ID

-

Date/Time

-

Did yo complete the final overall inspection?

-

WRITE UNIT I.D. VISIBLY FOR PHOTO, UNDER OR ON THE GREEN MAGNET

-

Have you applied the green magnet for release?

-

Have you notified a shop lead/foreman and quality lead? (Leads will notify paint lead)

-

QCI - ID

-

Date/Time

Post Interior/Partial Exterior Coating

Final Assembly Inspection

-

Has this unit been brought into the shop post interior/partial exterior coating?

-

QCI - ID

-

Date/Time

-

**ALWAYS REFER TO THE DRAWINGS NOT YOUR MEMORY OR ASSUMPTIONS FOR INSPECTIONS**

-

Is a front bearing pad required for this unit?

-

Bearing pad should be checked center of plenum. Measure the center to the holes if applicable if not, then measure center to the edges of the bearing pad.

-

Is the front bearing pad fit up complete and accepted?

-

Fitter/Welder - ID

-

QCI - ID

-

Date/Time

-

Is the bearing pad weld out complete and accepted?

-

Assembler/Welder - ID

-

QCI - ID

-

Date/Time

-

QCI - ID

-

Date/Time

-

Are bearings required for this unit?

-

Refer to units CCQF DWG. to collect qty's and types. (ex. (2-taf 2-15/16" bore size)

-

What are the bearing quantities and types required for this unit?

-

Take photos of the required bearings' ID tag. (photo Qty. should match Qty. of bearings required)

-

QCI - ID

-

Date/Time

-

QCI - ID

-

Date/Time

-

Was the shaft/keyway dimensions inspected prior to installation?

-

QCI - ID

-

Is the shaft installation complete and accepted?

-

Assembler - ID

-

QCI - ID

-

Date/Time

-

Is the bearing installation complete and accepted?

-

Assembler - ID

-

QCI - ID

-

Date/Time

-

Refer to QC information binder and CCQF to match type / part #

-

What is the hold down bolts required torque?

-

QCI - ID

-

Date/Time

-

What is the bearing retainer/collar required torque?

-

QCI - ID

-

Date/Time

-

Is the fan installation complete and accepted?

-

Is a motor required for this unit?

-

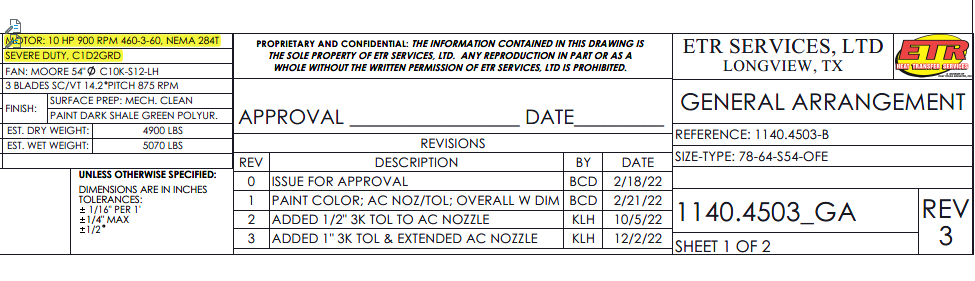

Refer to G.A. Dwg for motor information. See highlighted example.

-

What type of motor is needed?

-

Is the installation of the motor complete and accepted?

-

Assembler - ID

-

QCI - ID

-

Date/Time

-

Take photo of motor tag.