Title Page

-

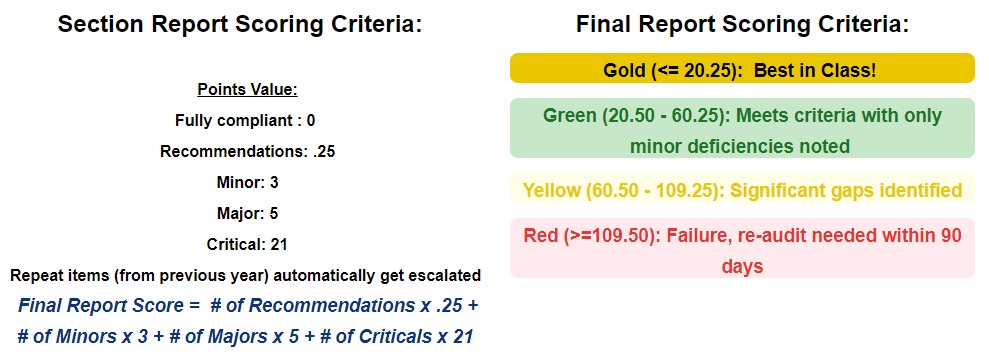

Final Audit Score

- 0

- .25

- .50

- .75

- 1.00

- 1.25

- 1.50

- 1.75

- 2.00

- 2.25

- 2.50

- 2.75

- 3.00

- 3.25

- 3.50

- 3.75

- 4.00

- 4.25

- 4.50

- 4.75

- 5.00

- 5.25

- 5.50

- 5.75

- 6.00

- 6.25

- 6.50

- 6.75

- 7.00

- 7.25

- 7.50

- 7.75

- 8.00

- 8.25

- 8.50

- 8.75

- 9.00

- 9.25

- 9.50

- 9.75

- 10.00

- 10.25

- 10.50

- 10.75

- 11.00

- 11.25

- 11.50

- 11.75

- 12.00

- 12.25

- 12.50

- 12.75

- 13.00

- 13.25

- 13.50

- 13.75

- 14.00

- 14.25

- 14.50

- 14.75

- 15.00

- 15.25

- 15.50

- 15.75

- 16.00

- 16.25

- 16.50

- 16.75

- 17.00

- 17.25

- 17.50

- 17.75

- 18.00

- 18.25

- 18.50

- 18.75

- 19.00

- 19.25

- 19.50

- 19.75

- 20.00

- 20.25

- 20.50

- 20.75

- 21.00

- 21.25

- 21.50

- 21.75

- 22.00

- 22.25

- 22.50

- 22.75

- 23.00

- 23.25

- 23.50

- 23.75

- 24.00

- 24.25

- 24.50

- 24.75

- 25.00

- 25.25

- 25.50

- 25.75

- 26.00

- 26.25

- 26.50

- 26.75

- 27.00

- 27.25

- 27.50

- 27.75

- 28.00

- 28.25

- 28.50

- 28.75

- 29.00

- 29.25

- 29.50

- 29.75

- 30.00

- 30.25

- 30.50

- 30.75

- 31.00

- 31.25

- 31.50

- 31.75

- 32.00

- 32.25

- 32.50

- 32.75

- 33.00

- 33.25

- 33.50

- 33.75

- 34.00

- 34.25

- 34.50

- 34.75

- 35.00

- 35.25

- 35.50

- 35.75

- 36.00

- 36.25

- 36.50

- 36.75

- 37.00

- 37.25

- 37.50

- 37.75

- 38.00

- 38.25

- 38.50

- 38.75

- 39.00

- 39.25

- 39.50

- 39.75

- 40.00

- 40.25

- 40.50

- 40.75

- 41.00

- 41.25

- 41.50

- 41.75

- 42.00

- 42.25

- 42.50

- 42.75

- 43.00

- 43.25

- 43.50

- 43.75

- 44.00

- 44.25

- 44.50

- 44.75

- 45.00

- 45.25

- 45.50

- 45.75

- 46.00

- 46.25

- 46.50

- 46.75

- 47.00

- 47.25

- 47.50

- 47.75

- 48.00

- 48.25

- 48.50

- 48.75

- 49.00

- 49.25

- 49.50

- 49.75

- 50.00

- 50.25

- 50.50

- 50.75

- 51.00

- 51.25

- 51.50

- 51.75

- 52.00

- 52.25

- 52.50

- 52.75

- 53.00

- 53.25

- 53.50

- 53.75

- 54.00

- 54.25

- 54.50

- 54.75

- 55.00

- 55.25

- 55.50

- 55.75

- 56.00

- 56.25

- 56.50

- 56.75

- 57.00

- 57.25

- 57.50

- 57.75

- 58.00

- 58.25

- 58.50

- 58.75

- 59.00

- 59.25

- 59.50

- 59.75

- 60.00

- 60.25

- 60.50

- 60.75

- 61.00

- 61.25

- 61.50

- 61.75

- 62.00

- 62.25

- 62.50

- 62.75

- 63.00

- 63.25

- 63.50

- 63.75

- 64.00

- 64.25

- 64.50

- 64.75

- 65.00

- 65.25

- 65.50

- 65.75

- 66.00

- 66.25

- 66.50

- 66.75

- 67.00

- 67.25

- 67.50

- 67.75

- 68.00

- 68.25

- 68.50

- 68.75

- 69.00

- 69.25

- 69.50

- 69.75

- 70.00

- 70.25

- 70.50

- 70.75

- 71.00

- 71.25

- 71.50

- 71.75

- 72.00

- 72.25

- 72.50

- 72.75

- 73.00

- 73.25

- 73.50

- 73.75

- 74.00

- 74.25

- 74.50

- 74.75

- 75.00

- 75.25

- 75.50

- 75.75

- 76.00

- 76.25

- 76.50

- 76.75

- 77.00

- 77.25

- 77.50

- 77.75

- 78.00

- 78.25

- 78.50

- 78.75

- 79.00

- 79.25

- 79.50

- 79.75

- 80.00

- 80.25

- 80.50

- 80.75

- 81.00

- 81.25

- 81.50

- 81.75

- 82.00

- 82.25

- 82.50

- 82.75

- 83.00

- 83.25

- 83.50

- 83.75

- 84.00

- 84.25

- 84.50

- 84.75

- 85.00

- 85.25

- 85.50

- 85.75

- 86.00

- 86.25

- 86.50

- 86.75

- 87.00

- 87.25

- 87.50

- 87.75

- 88.00

- 88.25

- 88.50

- 88.75

- 89.00

- 89.25

- 89.50

- 89.75

- 90.00

- 90.25

- 90.50

- 90.75

- 91.00

- 91.25

- 91.50

- 91.75

- 92.00

- 92.25

- 92.50

- 92.75

- 93.00

- 93.25

- 93.50

- 93.75

- 94.00

- 94.25

- 94.50

- 94.75

- 95.00

- 95.25

- 95.50

- 95.75

- 96.00

- 96.25

- 96.50

- 96.75

- 97.00

- 97.25

- 97.50

- 97.75

- 98.00

- 98.25

- 98.50

- 98.75

- 99.00

- 99.25

- 99.50

- 99.75

- 100.00

- 100.25

- 100.50

- 100.75

- 101.00

- 101.25

- 101.50

- 101.75

- 102.00

- 102.25

- 102.50

- 102.75

- 103.00

- 103.25

- 103.50

- 103.75

- 104.00

- 104.25

- 104.50

- 104.75

- 105.00

- 105.25

- 105.50

- 105.75

- 106.00

- 106.25

- 106.50

- 106.75

- 107.00

- 107.25

- 107.50

- 107.75

- 108.00

- 108.25

- 108.50

- 108.75

- 109.00

- 109.25

- 109.50

- 109.75

- 110.00

- 110.25

- 110.50

- 110.75

- 111.00

- 111.25

- 111.50

- 111.75

- 112.00

- 112.25

- 112.50

- 112.75

- 113.00

- 113.25

- 113.50

- 113.75

- 114.00

- 114.25

- 114.50

- 114.75

- 115.00

- 115.25

- 115.50

- 115.75

- 116.00

- 116.25

- 116.50

- 116.75

- 117.00

- 117.25

- 117.50

- 117.75

- 118.00

- 118.25

- 118.50

- 118.75

- 119.00

- 119.25

- 119.50

- 119.75

- 120.00

- 120.25

- 120.50

- 120.75

- 121.00

- 121.25

- 121.50

- 121.75

- 122.00

- 122.25

- 122.50

- 122.75

- 123.00

- 123.25

- 123.50

- 123.75

- 124.00

- 124.25

- 124.50

- 124.75

- 125.00

- 125.25

- 125.50

- 125.75

- 126.00

- 126.25

- 126.50

- 126.75

- 127.00

- 127.25

- 127.50

- 127.75

- 128.00

- 128.25

- 128.50

- 128.75

- 129.00

- 129.25

- 129.50

- 129.75

- 130.00

- 130.25

- 130.50

- 130.75

- 131.00

- 131.25

- 131.50

- 131.75

- 132.00

- 132.25

- 132.50

- 132.75

- 133.00

- 133.25

- 133.50

- 133.75

- 134.00

- 134.25

- 134.50

- 134.75

- 135.00

- 135.25

- 135.50

- 135.75

- 136.00

- 136.25

- 136.50

- 136.75

- 137.00

- 137.25

- 137.50

- 137.75

- 138.00

- 138.25

- 138.50

- 138.75

- 139.00

- 139.25

- 139.50

- 139.75

- 140.00

- 140.25

- 140.50

- 140.75

- 141.00

- 141.25

- 141.50

- 141.75

- 142.00

- 142.25

- 142.50

- 142.75

- 143.00

- 143.25

- 143.50

- 143.75

- 144.00

- 144.25

- 144.50

- 144.75

- 145.00

- 145.25

- 145.50

- 145.75

- 146.00

- 146.25

- 146.50

- 146.75

- 147.00

- 147.25

- 147.50

- 147.75

- 148.00

- 148.25

- 148.50

- 148.75

- 149.00

- 149.25

- 149.50

- 149.75

- 150.00

- 150.25

- Exceeded max score of 150.00

-

Site

-

Facility

-

Conducted on

-

Participants

-

Assessor(s)

-

Assessor(s)

-

Type of Audit

- On-site

- Desktop

- Remote

Final Audit Score Outline

Final Audit Score Outline

-

Total Number of Recommendations

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

-

Total Number of Minors

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

-

Total Number of Majors

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

-

Total Number of Criticals

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

-

Total Number of Repeat Findings

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

Scoring Summary

Scoring Information

-

-

If not corrected, repeated findings from the previous year will result in an escalation.

Example: Section 7.2 .2 documented in 2022 as a Recommendation. Section 7.2.2 observed in 2023 as a Recommendation but due to this being a repeat it will be documented as a Minor. -

A Critical finding results in an auto-failure for both the section and overall assessment. A re-assessment is required within 90 days.

1.0 Senior Management Commitment

1.1 Management Responsibility

-

1.1.1 The site shall have a documented Food Safety, Quality and Regulatory Compliance Policy Statement which states the site's commitment to meet its obligation to produce and supply safe, legal, and authentic products to the specified quality and its responsibility to its customers. The policy includes: - site's intention to comply with all customer and regulatory requirements in the country where products are manufactured and also in markets products are exported to - site's commitment to continually improve food safety, quality and regulatory compliance management systems -site's commitment to assess and improve the food safety and quality culture -site's commitment to effective food defense and food fraud prevention. This Policy Statement shall: -be signed by the person with overall responsibility for the site -be displayed in prominent locations and effectively communicated to all site personnel in the languages understood by all site personnel -be reviewed at least once per year or when major changes are made in the organization. Method used to communicate the policy shall be stated in the Policy Statement. All employees shall be aware of the policy and should be able to demonstrate understanding of the Policy Statement. Written communication from managment to production employees encouraging feedback is present. Note: Even if the company has a company-wide FSQR Policy, the local facility must have a facility Policy Statement. Identification of objectives, key indicators and method to measure them. Senior management shall designate PCQI practitioner.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive Action -

-

Repeat

-

Corrective action -

-

Preventive action -

-

Repeat

-

Corrective Action -

-

Preventive Action -

-

Repeat -

-

1.1.2 The company's senior management shall provide, document human & financial resources required to implement and improve the processes of the quality management, food safety / HACCP plan, infrastructure and quality culture. This includes: - availability of resources - adequate staffing - skill and competency level - training & documentation and resources including: - maintenance for production - suitable equipment - allocations of budget for food safety - HACCP training. The food safety and quality systems are designed, implemented and maintained. The plan shall also include behaviors needed to achieve the intended positive culture change. This shall include: - defined activities involving all sections of the site that have an impact on product safety. As a minimum, these activities shall be designed around: - clear and open communication on product safety - feedback from employees - behavior changes required to improve product safety processes - performance measurement on product safety, authenticity, legality and quality related activities - an action plan indicating how the activities will be undertaken and measured, and the intended timescales - a review of the effectiveness of completed activities. Site management shall ensure departments and operations are appropriately staffed.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.3 There shall be clear communication & reporting channels to Sr. management for departments responsible for monitoring compliance. Each department responsible for compliance shall show evidence that they regularly report compliance to and deviations from targets. These objectives shall be: - documented and include targets or clear measures of success - clearly communicated to relevant staff - monitored and results reported at least quarterly to site senior management and all staff.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.4 Senior Management shall establish food safety, authenticity, legality and quality objectives. These objectives are established, documented, monitored and reviewed at least quarterly with relevant staff. Significant food safety metrics shall inlcude: - environmental analysis - operators hygiene measures - microbiological analysis/ pathogen testing on products - identification of food safety risk /zones - customer complaints - continuous improvement

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.5 Senior Management shall ensure that there is a process to identify and address any safety, legal or regulatory issues at a strategic level. There shall be clear communication & reporting channels to Sr. management for departments responsible for monitoring compliance. Each department responsible for compliance shall show evidence that they regularly report compliance to and deviations from targets. Targets for food safety & quality and other key performance indicators, such as cost and productivity are equally measured. The site shall have a demonstrable meeting program which enables food safety, authenticity, legality, and quality issues to be brought to the attention of senior management. These meetings shall occur at least monthly. The company’s senior management shall have a process for assessing any concerns raised. Records of the assessment and, where appropriate, actions taken, shall be documented. Serious issues shall be addressed at the Senior Management level up to Corporate office. Implications to the company’s business are adequately addressed so changes may be made when necessary.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.6 Organization chart & supporting documents shall provide a snapshot of how positions interact & share responsibility for Food Safety. (Org. chart, Job descriptions & backup personnel or other on a separate document). The interrelationship between FS & Quality must be defined. It shall be clearly documented who deputizes in the absence of the responsible person. A process is in place to ensure the integrity of food safety & quality management systems is maintained in the event of change within the company. Includes organizational or management change. Job descriptions that define food safety and quality responsibilities shall be documented (personnel performing key process steps and responsible for achieving quality requirements shall be documented and include provisions for coverage in the absence of key personnel). - The supplier will establish a food safety culture program at all levels of the organization. Senior management will provide evidence of the commitment to implementing and maintaining the organization's food safety culture. - Guidelines: Personnel roles, responsibilities and authorities for food safety and quality management are well defined, communicated and understood. - A member of the site's management team (and a designee) must be nominated having overall responsibility for compliance with SQMS standards and McDonald's Global and Market requirements.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.7 There shall be a current version of any standards the site is audited against (BRCGS, Conagra, YUM!, GSF Readiness Assessment, SQF, Global GAP, or other programs approved by the customer.etc.).

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.8 Most senior Production or Operations manager shall participate in the opening and closing meetings of this assessment and be available during the audit for a discussion on effective implementation of the food safety and quality culture plan.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.9 Operations manager or above shall accompany auditor during facilities walkthrough. The site is expected to be prepared to meet requirements at all times and to have appropriate team members available.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.10 Operations, QA or any manager shall accompany auditor during QA & Sanitation walkthroughs.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.11 Last GFSI audit CAPA completed according to established timeline. Note: Verification of CAPA to be performed during the plant visit.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.1.12 Previous year's Readiness Assessment CAPA was submitted within 28 calendar days after final report was issued (variances requested and proof present, if applicable). All corrective actions have been completed according to established timelines.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

1.2 Management Review

-

1.2.1 Senior management shall take responsibility for the review process, ensuring that a complete management review of the Food Safety (including HACCP) & Quality Systems occurs. All management reviews must have a formal agenda to cover the following items as a minimum: - customer requirements - operations - maintenance - effectiveness and - ongoing improvement The review process shall be undertaken at planned intervals, at a minimum of annually, to insure critical evaluation of the food safety plan & the HACCP system's suitability, adequacy and effectiveness.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.2.2 Records of management reviews shall be comprehensively documented and retained. Reviews shall include, at a minimum: - internal, second party and third party audits - previous management review documents - action plans & timeframes - customer performance indicators - complaints and feedback - incidents (including both recalls and withdrawals) - corrective actions - out of specification results & non-conforming materials - process performance and deviation from defined parameters - reviews of the HACCP based system - review of latest quality culture surveys - food defense and authenticity - quality culture - previous managment review and action plan - legislative compliance - to include changes (and upcoming/potential changes) to legislation. - developments in scientific information associated with the products within the scope - customer specifications - microbiological results including the enviornmental monitoring program - allergen verification results (where applicable - foreign material results - emerging risks - resource requirements. Corrective actions, and timescales for their implementation, shall be agreed and their completion verified. As a minimum a summary of the results shall be reviewed in the management review meetings

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat

-

Corrective action -

-

Preventive action -

-

Repeat -

-

1.2.3 Decisions and actions agreed upon within the review process shall be effectively communicated to appropriate staff, and actions implemented within agreed timeframes. Records shall be updated to show when actions have been completed. As a minimum the following must be included: - formal minutes - action tracker and timelines - specific responsibilities (single person) for all actions

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

2. 0 HACCP/Food Safety Program

2.1 HACCP/Food Safety Team

-

2.1.1 - A HACCP Food Safety Team is formed consisting of cross functional relevant skills and knowledge. - The HACCP Food Safety Team members have documented qualifications and training in the principles of HACCP. - A HACCP Food Safety Team Leader is present and has documentation of competency. This is by documentation of an industry recognized HACCP training course and demonstrated knowledgeable of the HACCP Plan and systems. - The lead individual who is responsible for the maintenance and updating of the HACCP program has had formal HACCP (or PCQI) training - For FDA plants, the Team leader is a Certified PCQI (Preventative Control Qualified Individual). - For sites complying with SQF criteria, the facility is to have a list of all McD's product made at the facility being audited. A Primary and substitute SQF practioner shall be designated for each site.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.1.2 The HAACP Food Safety Team or designated person meets at a frequency that is sufficient to maintain the Plan(s), and when any changes in: -operations -structure -engineering or -formulation occur which may affect Food Safety. The process includes changes to raw ingredients and packaging that may affect Food Safety. The team's activities and meetings shall be documented and communicated to relevant personnel.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat

-

Corrective action -

-

Preventive action

-

Repeat -

-

2.1.3 The HACCP Food Safety Team shall verify and validate the HACCP/Food Safety Plan a minimum of once per year even if there are no changes. This shall be documented and include: - Flow Diagram - CCPs - Critical Limits - Corrective Actions - Monitoring procedures - Scientific literature and - Validation. This includes any change to process flow, emergence of a known adulteration of an ingredient, following a recall or as identified as an emerging risk. A written revision history that includes the reason for the change(s) shall be maintained. Verification shall occur annually or when any of the following occur, but is not limited to: - Change in ingredients and/or recipe, - Change in processing conditions - Process flow or equipment, - Updated or new processing line for product - Change in food contact packaging - Storage or distribution conditions - Change in consumer use of finished product - Emergence of a new risk (e.g. known adulteration of an ingredient) - Responding to customer complaint reviews to prevent reoccurrence - Following a recall/withdrawal - New developments within industry including scientific information associated with ingredients, process or product. Food Safety Risk Assessments must addresses all potential hazards. Includes hazards identified by HACCP program and also potential hazards related to and include, but are not limited to: - Food allergens - Foreign material - Sanitation - Suppliers - Environment and others. A risk assessment is a thorough evaluation of the likelihood that a foreseeable hazard could be present and the severity this would have on a consumer. The HACCP food safety team shall specify and document the corrective action to be taken when monitored results indicate a failure to meet a control limit, or when monitored results indicate a trend towards loss of control. See RA 2.2.7 Dairy: YUM! FSAL 13.2 5 Only dairy products produced from pasteurized milk shall be used. In any case where unpasteurized dairy is considered, a risk assessment is required and use shall be approved by the Global Food Safety Council

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.1.4 The plan must be verified and validated before the product is mass produced. The food safety team shall validate all of the critical limits to ensure the level of control of the identified food safety hazard(s) and that all critical limits and control measures individually or in combination effectively provide the level of control required Validation includes (this is not an exhaustive list): - Internal audits - Review of records where acceptable limits have been exceeded - Review of compaints by enforcement authorities or customers - Review of incidents of product withdrawel or recall. Results shall be recorded and communicated.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.1.5 All personnel who enter production areas should have adequate training about the importance of health and hygiene in preventing contamination of food and food production areas; - Human resource personnel should have training adequate to enable them to ensure that all personnel receive training necessary to perform their assigned functions. - Personnel with responsibilities for purchasing should have adequate training regarding the importance of applicable food safety specifications and supply-chain controls (with associated supplier approval and verification activities) for the raw materials and other ingredients that they purchase. - Personnel with responsibilities for receiving raw materials and other ingredients should have adequate training regarding the importance of inspecting shipments at receipt and using proper storage conditions, including when applicable refrigeration and segregation (e.g.,when applicable, segregation of raw foods from RTE foods and segregation of foods with different food allergen profiles). - Personnel with responsibilities for maintenance should have adequate training regarding the potential for maintenance activities to introduce contamination or lead to allergen cross-contact. - Personnel with responsibilities for cleaning and sanitizing the plant, including food-contact surfaces, should have adequate training regarding each step in the cleaning/sanitizing process and actions to take if there are visual observations or other indication that a step was not performed correctly or was not effective. - Personnel with responsibilities for food production should have adequate training in the procedures for food production, including the importance of each step in production and actions to take if there is a problem during production. - Personnel with responsibilities for sampling surfaces for environmental pathogen should have adequate training in the procedures for collecting the samples. - Personnel with responsibilities for laboratory testing of food or environmental samples should have adequate training in conducting that laboratory testing. - Supervisory personnel should have adequate training in the procedures, included in the food safety plan, applicable to their supervisory responsibilities. - Plant management should have adequate training in the food safety plan as a whole.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.1.6 All management demonstrates knowledge of the HACCP/Food Safety plans and CCPs in each of their areas of responsibilities. The relationship between HACCP and legal compliance is understood. Employees monitoring CCPs are aware of CCPs and the critical limits in their area(s) and what action to take if the limit(s) are exceeded. (Determined through both interview and training records review). The HACCP / Food Safety plan team will be assessed.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

2.2 HACCP/Food Safety Plan follows Codex or NACMF requirements

-

2.2.1 A description of the product is present considering all aspects that may affect food safety. The description/scope contains: - Composition (ingredients) - Target consumer - Consideration of vulnerable populations (infants, elderly, allergen suffers) - Physical and chemical properties impacting food safety - Processing - Packaging - Storage - Distribution - Shelf life - Instructions for use (intended use as well as any alternative uses), and - Consider misuse. - Country of Origin for Raw Materials and Packaging (if filed in external source, then must specify) Where any processes are outsourced, including production, manufacture, processing or storage, the risks to the product safety, authenticity, integrity, legality and quality shall form part of the site’s food safety plan (HACCP plan). For SQF Facilities ONLY: Shall include a list of the products covered under the scope of the certification.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.2 An accurate flow diagram of the process containing all inputs and outputs, and CCP's is present. The HACCP food safety team shall verify the accuracy of the flow diagrams by on-site audit and challenge at least annually and whenever there are changes which may affect food safety. CCP (s) are identified in the process flow chart. Documentation of verification by the HACCP Food Safety Team is present for the diagram. Current flow diagram is signed & dated by HACCP team members. Included should be: -Site map of the premises, including equipment layout -Water distribution diagram for the site, including steam. - Raw Materials - Utilities - Packaging -Area zones (including high risk, high-care or ambient high-care) -Intermediate / semi-processed products -By-products (e.g. rework, recycle) -Waste. GSF Corp: Pre-weigh / Kitting process to be included in the process flow. Some of the components don't have to be in the actual HACCP/Food Safety plan on file, it could be part of the verification and validation by the team.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.3 Documented, risk based hazard analysis for each process step identifying all potential hazards and measures to control the hazards is present. Justification for exclusion or evidence of the effectiveness of an alternative control measure must be documented. Hazards to be considered include: -Microbiological: Microbiological contamination control measures must be validated, documented, and implemented for any known and potential microbiological hazards. The control measures shall be reviewed whenever there are changes to the product, processes, or when a new hazard is identified in the industry. -Physical contamination -Chemical -Radiological contamination - for incoming ingredients and facility location to radiological sites -Fraud (e.g. substitution or deliberate/intentional adulteration) -Malicious contamination of products -Allergen risks It shall also take account of the preceding and following steps in the process chain. Hazard analysis shall take into account: -Likely occurrence of hazard -Severity of the effects on consumer safety -Vulnerability of those exposed -Survival and multiplication of micro-organisms of specific concern to the product -Presence or production of toxins, chemicals or foreign bodies -Contamination of raw materials, intermediate/semi-processed product, or finished product.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.4 Risk assessments shall contain: -Ingredients (or group of raw materials), -Packaging (Food Contact) -Allergens (content or potential contamination) -Country of origin. Consider: foreign-body risks -Microbiological contamination -Chemical contamination -Variety or species cross-contamination, -Substitution or fraud -The storage location of where these assessments are filed needs to be documented in the HACCP / Food Safety Plan. -Risk Assessment justifications and hazards must match the Hazard Analysis if it is deemed a hazard. -Any risks associated with raw materials which are subject to legislative control or customer requirements. -Reference to reviewing FDA Appendix 1 needs to be documented in the HACCP / Food Safety Plan. Consideration shall also be given to the significance of a raw material to the quality of the final product. The risk assessment shall form the basis for the raw material acceptance and testing procedure and for the processes adopted for supplier approval and monitoring. The risk assessment for a raw material shall be updated when: -There is a change in a raw material or the processing of a raw material or the supplier of a raw material, if a new risk emerges, following a product recall or withdrawal, where a specific raw material has been implicated, at least every 3 years. Note: Country of origin is important for consideration of fraud. The site must have a written Vulnerability Assessment Critical Control Points (VACCP) process that identifies vulnerabilities (such as the potential for counterfeiting, dilution, mislabeling and intentional Adulteration) along with associated mitigations or corrective actions. The methodology used to develop the VACCP plan must be traceable to recognized science. The assessment shall be documented and reviewed periodically.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.5 CCP's/Preventative Controls shall be established at the proper process step with a critical limit to control the hazard. A documented monitoring procedure for all CCPs and preventive controls (if facility is under US FDA's jurisdiction) shall be present. For each CCP, the appropriate critical limits shall be defined in order to identify clearly whether the process is in or out of control. Critical limits shall be: - measurable wherever possible (e.g. time, temperature, pH) - supported by clear guidance or examples where measures are subjective (e.g. photographs)

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.6 Validation is present for all CCP's/Preventative Controls and Critical Limits. Literature, challenge studies, in-process studies, etc. can all be used to validate CCPs/Preventative Controls. Validation must be present whenever the HACCP Food Safety Plan is changed. See RA 2.1.4 for details. The HACCP plan is validated, revalidated, and reviewed when product/process changes occur. If there have been no changes, the HACCP plan must be reviewed annually. Records are maintained.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.7 Corrective Actions for any deviations beyond the critical limits are documented. Methods & responsibilities outlining how immediate corrections & corrective actions are investigated / resolved / managed shall be in evidence. Corrective Actions include root cause analysis and a permanent corrective actions. Records are analyzed for trends, then reviewed and signed by qualified management staff, to prevent reoccurrence.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.8 Verification procedures are written for the HACCP Food Safety. Plan to include: - Flow Diagrams - Validation - Scientific data - CCP's / Preventative Controls - Monitoring effectiveness completed a minimum of yearly. Other verifications such as line audits and records may occur as frequently as daily.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.9 A verification schedule shall be prepared and implemented for each activity. The schedule shall include: - Verification activities - Frequency of completion - (Designated) person responsible for each activity - A log of each of the activities. Results of verification shall be recorded and communicated to the HACCP food safety team. Record keeping and documentation is sufficient to demonstrate the HACCP controls are established and effective.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.2.10 - All revisions to the HACCP Food Safety Plan are documented. Documentation includes a record of the reason for any changes or amendments to documents. - Changes to HACCP programs that impact customer products or are in conflict with existing specifications shall be approved by the customer prior to implementation.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

2.3 HACCP/Food Safety Plan Implementation and Execution

-

2.3.1 CCP monitoring and documentation follows the HACCP Food Safety plan. Gaps in records indicate the reason. CCP / Preventive Controls checks are evaluated for continuity. Review of records, where acceptable limits have not been achieved, corrective actions for issues found are on file. Any gaps in records indicate the reason (e.g. line down). CCP / Preventive controls checks are evaluated for continuity.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.3.2 HACCP / Food Safety records are present and include the date, time and result of the measurement. A Pre-shipment review/verification signature / intitals and date are present on all records. Where records are in electronic form, there shall be evidence that records have been checked and verified.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action

-

Preventive action -

-

Repeat -

-

Corrective action

-

Preventive action -

-

Repeat -

-

2.3.3 HACCP Food Safety deviations are recorded and communicated daily. Documented corrective actions containing root cause analysis and verification exist.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.3.4 Corrective actions resulting in Holds, Recovery or other actions must have proper disposition and records. There shall be a procedure for handling and correcting failures identified in the food safety and quality management system. The corrective action records are reviewed and signed using initials or signature and dated by qualified management staff and analyzed for trends, to prevent reoccurrence. Completed root cause analysis and handling of preventive action shall be in evidence. The corrective action process shall include: -Clear documentation of the non-conformity -assessment of consequences by a suitably competent and authorised person -The corrective action to address the immediate issue -Completion of root cause analysis to identify the fundamental cause (root cause) of the non-conformity -Appropriate timescales for corrective and preventive actions -The person(s) responsible for corrective and preventive actions -Verification that the corrective and preventive actions have been implemented and are effective. Root cause analysis shall also be used to prevent recurrence of non-conformities and to implement ongoing improvements when analysis of non-conformities for trends shows there has been a significant increase in a type of non-conformity. The site shall ensure that any out-of-specification product is effectively managed to prevent unauthorised release.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

2.3.5 The Facility's HAACP and Food Safety Plans are audited by a third party at least once per year. If required by law or the customer, a HACCP certification for the facility is present or, if in the USA a HACCP PCQI certification. Records shall be present.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

3.0 Food Safety & Quality Systems

3.1 Food Safety and Quality Plan

-

3.1.1 All food safety and quality monitoring (not already documented in a HACCP Food Safety Plan) must have written procedures, which contain: -Person responsible -Frequency -Limits and corrective actions taken when those limits are exceeded. Monitoring must also be documented. Shall include: -Food Safety and Quality Policies (documentation that outlines the methods and procedures) -Processes and procedures comprising the Quality and Food Safety manual All polices and procedures must take account of and reference: -Customer requirements and expectations -Quality awareness with clear objectives -Applicable laws and regulations (as applicable in the country of manufacture and any countries exported to) -Clear identification of the person(s) responsible for approving changes to these documents Senior management has authorized and signed food safety and quality policies. The facility must be able to demonstrate that they have developed and maintained all documented procedures required for a food safety and quality management system. Documented procedures should show how the facility meets customer and local requirements. The facility must be able to show that they have access to laws and regulations by either having electronic access or maintaining a current list of laws/regulations.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.1.2 Each pre-requisite program / preventive controls must be validated, verified and must be signed off by the specific expert (SQF/QS-FS designee) indicating that the verification and validation have been completed. Frequency (at least annually) & methods used to validate food safety fundamentals are documented and meet their intended purpose. As a guide these may include the following, although this is not an exhaustive list: -Cleaning and sanitizing -Pest management -Maintenance programs for equipment and buildings -Personal hygiene requirements -Staff training -Supplier approval and purchasing or Supply Chain -Transportation arrangements, including receiving and shipping -Processes to prevent cross-contamination -Allergen controls management -Chemical control -Environmental monitoring program -Traceability / Recall -VACCP -TACCP -Good Agricultural Practices (where applicable),etc.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.1.3 The site shall have a documented procedure for handling and correcting failures identified in the FS & Quality system. Where a non-conformity places the safety, authenticity or legality of a product at risk, or where there is an adverse trend in quality, this shall be investigated and recorded including: -Clear documentation of the non-conformity -Assessment of consequences by a suitably competent and authorized person. Include: -The corrective action to address the immediate issue -Completion of root cause analysis to identify the fundamental cause (root cause) of the non-conformity -Appropriate timescales for corrections and corrective / preventive actions -The person(s) responsible for corrections and corrective / preventive actions -Verification that the corrections and corrective / preventive actions have been implemented and are effective. -A continuous improvement program shall be established for addressing failures. The program shall: - Define the process used for continuous improvement. - Define the measurement and tracking tools used. - Define goals and objectives. - Provide for performance to be measured against those goals.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.1.4 Product quality risk assessments shall be developed, effectively implemented and maintained in accordance with a risk-based method such as HACCP for all product categories produced by the supplier. The product quality risk assessment shall be independent from the food safety HACCP plan and must identify quality threats, key quality control points, and control measures used. The product quality risk assessments shall be developed and maintained by a multidisciplinary team that includes those facility staff with technical, production, engineering and product development knowledge of the relevant products and associated processes. The product quality risk assessments shall be reviewed following any significant changes to process, equipment or raw materials. Where no changes occur, the risk assessment shall be reviewed annually. The product quality risk assessments shall identify and outline key quality control points (QCP). Procedures shall include provisions for ensuring the production of the product is controlled. The supplier shall have an implemented procedure which shows: - The flow of products from point of material arrival through to shipping, using a flow chart or similar format. - A number, letter or similar designation for each step of the process that is used to control product quality as defined by the product quality risk assessment The steps identified on the process illustration shall be listed in a matrix or similar format and will include: - A reference for each key process stage to the appropriate standard operating procedure or work instruction used to control that stage - Method used to control each stage of the process identified as a QCP - Role responsible for controlling each stage identified as a QCP - Critical limits for each stage which will ensure specification limits are met - Corrective action to be taken when limits are not achieved - Records shall be maintained QCP's shall be routinely monitored during the production of product with records maintained.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.1.4.1 Supplier shall nominate customer specific Quality Teams if required who will drive quality management and improvement initiatives. Supplier shall nominate a cross functional Quality Team who, in addition to their normal roles, shall be responsible for coordinating product quality improvement initiatives. The quality team shall be at facility level and include functions who directly impact the production of product. The Quality team shall nominate a team leader. The leader shall not be the facility technical / quality assurance manager. The Quality Team shall be documented and have defined goals and objectives. Goals and objectives shall be reviewed at least annually. The Quality Team shall have action plans for goals and objectives which shall be subject to a quarterly senior management progress review. The Quality Team shall have a Management sponsor who has appropriate seniority to ensure quality improvement initiatives can be implemented. The Quality Team shall regularly review product quality and implement initiatives to drive continuous improvement. The Quality Team shall support in verifying the accuracy of the QAP against the production flow. A copy of the latest QAP, signed as accurate by the Quality Team leader shall be retained.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Preventive action -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.1.4.2 Key Performance Indicators (KPIs) shall be clearly defined for products. Supplier shall have documented, approved KPI's defined for all products unless otherwise approved in writing. KPI's shall be linked to the key steps of the process that define quality identified in the product quality risk assessment. Product KPI's defined shall be routinely monitored and analyzed. Product KPI's shall be monitored; with records kept at a frequency defined in the product specification. Records of KPI monitoring calibration shall be maintained and shall include: - Results of training sessions - Calibration records for all relevant monitoring equipment Production KPI data and analysis of the results shall be communicated to all levels at least monthly. Where KPI's are reported less frequently, the KPI's should be communicated each time. There is evidence that where appropriate Production KPI data is used to drive quality improvement.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action

-

Repeat -

3.2 Allergen Management

-

3.2.1 A written allergen management program is present and utilized. All allergens of interest, for the country where the facility is located are named. New & existing supplier verification for allergens is conducted. The program includes handling of raw materials, including: - receiving - color coding to designate allergens, including pre-weighing of allergen containing raw materials - dedicated storage bins & scoops for weighing, - WIP - rework - spills - cleanup - waste - tools - storage & segregation from non-allergen containing materials. The program includes compliance to specifications throughout the purchasing & supply chain, including the regulations in those countries where the product is to be shipped. A list of all allergen containing materials handled on-site, whether raw materials, intermediate products or finished products shall be present and maintained. Ingredients that are allergens are identified as such on all formulations, batch or raw material production records.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.2 The allergen program addresses food brought onto the site by staff, caterers specifying where allergen containing food is stored or stocked (snack machines). The program shall assure that traceability of rework & WIP is maintained. The program addresses: -The use of protective clothing while handling allergens -The use of identified, dedicated equipment and utensils for pre-weigh / kitting / processing / spills. -Updates to the program when new allergens & allergenic sources are brought into the facility. -Actions to take when there is an inadvertent event of cross-contamination. -Defines frequency of program review and reports exist -Allergen containing waste. The potential for cross-contamination at the raw material suppliers sites has been assessed & includes sensitivities. Allergen-specific training, including documentation, is provided to all employees who work with or handle allergens. Program addresses inadvertent cross-contamination during manufacture. The program shall include consideration of allergens in the Sanitary Design process.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.3 The program is verified & monitored regarding effectiveness & changed when & where necessary. Verification activities include -Incoming raw materials & subcomponents -Packaging & finished products -Manufacturing cross-contact -Label review -Label control for issuing, reconciliation from run to run, new & reprints. Results are documented.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat

-

3.2.4 A scheduling matrix has been developed and is used for scheduling production and sanitation activities. A procedure is established to maintain product quality during the startup and change over of operations and are documented. At a minimum, the procedures should include verification: -Ingredients -Allergen controls -Packaging material -Labels - pre-printed, batch printed, primary and secondary Changeovers: Removal of previous ingredients & verification, specifically addresses ensuring allergens are not transferred to a non-allergen containing product/other allergen products. -Sanitation -Change of ingredients -Packaging -Labeling. These shall include: - Start-up checklists that include verification of ingredients, packaging material, labeling with sign-off - A list of tasks for change-over that includes, removal of previous ingredients, allergen controls, sanitation, change of ingredients, packaging, and labeling, including any inconsistencies investigated and resolved. - Responsible parties for completing each task.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.5 A program is in place that includes packaging, identifies all allergens in products, including sub-components, for all markets and customers (including International, where applicable). The identification shall, as required by the customer, assess risk for all allergens & sensitivities. The risk assessment shall consider: - Consideration of the physical state of the allergenic material (i.e. powder, liquid, particulate) - Identification of potential points of cross-contamination (cross-contact) through the process flow - Assessment of the risk of allergen cross-contamination (cross-contact) at each process step - Identification of suitable controls to reduce or eliminate the risk of cross-contamination (cross-contact). There is a formal record of the risk assessment. Raw materials / ingredients, processing steps, processing aids, rework, manufacturing carryover are included in the assessment. Where claims are made regarding the suitability of a food for allergy or food sensitivity (where applicable), the claims shall be fully validated, being backed by documented data such as analysis of finished product, raw materials and post-cleaning swabs for specific allergens.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.6 Allergen testing including kits, PCR, visual, rinse water testing of CIP systems, external lab verification of presence/absence of allergens. Includes post Sanitation testing of lines and SSOPs that are specific to allergens, including dedicated cleaning equipment. An SSOP is present & in effect that addresses sanitation that occurs on an allergen containing line that is next to a non-allergen containing line. Frequency of testing shall be defined & backed by documented validation. CIP rinse water sample should be collected and tested for specific allergen on a weekly basis. Allergen testing should be performed randomly selected food contact surfaces on a weekly basis. Re-validation shall be done when process/product/ sanitation procedure changes occur. Limits of acceptable and unacceptable cleaning performance shall be defined for food contact surfaces and processing equipment. These limits shall be based on the potential hazards relevant to the product or processing area (e.g. microbiological, allergen, foreign-body contamination or product-to-product contamination). Therefore, acceptable levels of cleaning may be defined by visual appearance, ATP bioluminescence techniques (see glossary), microbiological testing, allergen testing or chemical testing as appropriate. Pre-Weight or Kitting Rooms are cleaned, inspected and swabbed on a frequency stated in procedures. High Risk Zone facilities: Production risk zones, including ambient- High-risk, high-care and ambient high-care production risk zones: Tested annually. - Layout, product flow and segregation - Building fabric - Maintenance - Staff facilities - Housekeeping and hygiene - Waste/waste disposal - Protective clothing

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.7 Ingredient statements must be verified to the: - raw material spec - ingredient disclosure or other - accompanying documents - including the COA for every raw material once every 12 months - when supplier is purchased by another company - when supplier is changed - as customer dictates. Where a justified, risk-based assessment demonstrates that the nature of the production process is such that: cross-contamination (cross-contact) from an allergen cannot be prevented, a warning should be included on the label. Legislation, national guidelines or codes of practice shall be used when making such a warning statement.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.8 Finished product labeling verification for product and packaging occurs for every product through Optiva or other electronic Product Life Cycle Management (PLM) system and anytime changes are made to the formula or packaging. There shall be effective process in place to ensure that labeling information is reviewed whenever changes occur to: - product recipe - raw materials - supplier of raw mats - country of origin of raw mats - legislation. Further label verification occurs at a minimum of every three years or as dictated by the customer.

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

3.2.9 Non-conformities relating to allergen control shall be included specifically in the management meetings. Complaints or issues, whether internal or external shall be discussed. The company shall have procedures in place to keep abreast of legislation or scientific information relevant to allergen containing materials (such as protein presence in highly refined soybean containing materials).

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

3.3 Environmental Monitoring Program

-

3.3.1 Zoning: the company shall assure that the process flow from receiving through finished product shall be arranged to minimize the risk of product contamination. Zones shall be defined and identified on a facility map. Establish mapping (Zone map) -Supplier shall have a clearly communicated microbiological monitoring and testing policy that states the facilities intentions to meet obligations to produce safe and legal products. The micro policy shall be: -Supplier shall have a microbiological and analytical monitoring and testing policy/procedure -Signed by the senior leader (s) -Available in languages appropriate to the staff -Communicated to all appropriate staff

- Critical

- Major

- Minor

- Recommendation

- BP

- Compliant

- N / A

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-

Corrective action -

-

Preventive action -

-

Repeat -

-