Information

-

Document No.

-

Conducted on

-

Personnel

-

Factory/Department

Pre audit checks

-

Previous inspection checked for outstanding issues

Dust control.

-

Local exhaust ventilation working correctly and used properly

-

Mixer lids, filter doors etc fitting correctly and closed properly during use.

-

Procedures to minimise dust release correctly followed as per work instructions and training.

-

Bag/sack and dried ingredient handling procedures correctly followed.

-

If any of the dust related questions cannot be ticked an immediate report should be made to the health and safety department and the specific concern documented here.

Housekeeping

-

General cleanliness of all areas

-

Unobstructed routes and width adequate for needs

-

Work areas accessible and well laid out

-

Storage facilities neat, tidy, signed and accessible

-

Environmental hazards properly controlled

-

Safety equipment well maintained and in use, bump caps, gloves etc.

-

Welfare facilities suitable for the needs of the area

-

Lighting ventilation etc. satisfactory for the area and working correctly

-

Stairs are well lit and properly maintained

Warehousing/storage

-

Overloaded racking/poor stacking practices

-

Bulk stacks for stability

-

Aisles for accesibility

-

Damaged racks/stacks/pallets etc. defect reports used for damage

-

Flammable/hazardous materials stored appropriately and locked away where neccesary

-

Stored goods not affecting sprinkler systems

Hand/power tools

-

Defective tools

-

Correct use of tools

-

Use of unauthorised tools

Electrical hazards

-

Fixed wiring

-

Portable appliances

-

Damage to cables extension leads etc.

-

Switch rooms, distribution boards locked as appropriate

Fire/emergency evacuation

-

Evacuation routes are free from obstructions

-

Emergency equipment e.g. Fire extinguishers

-

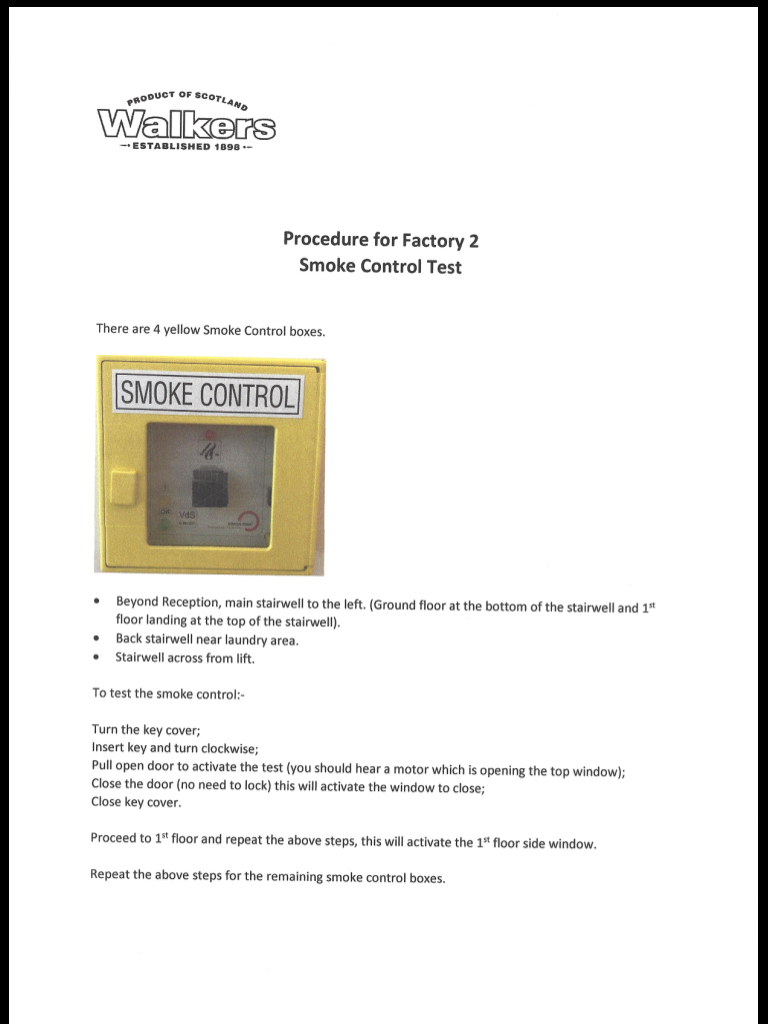

Elgin Factory 2 Smoke control vents should be checked using the instructions below.

-

-

Emergency lighting

-

Provision is made for disabled and temporarily incapacitated persons where appropriate

-

Fire alarm tests and drills completed

-

-

Staff have appropriate knowledge and training in procedures

Hand pallet trucks, sack trucks, trolleys etc.

-

Hand pallet trucks are in good condition with no oil leaks, damaged wheels and functioning correctly

-

Trucks, trolleys and any other handling aids are in good condition and wheel freely

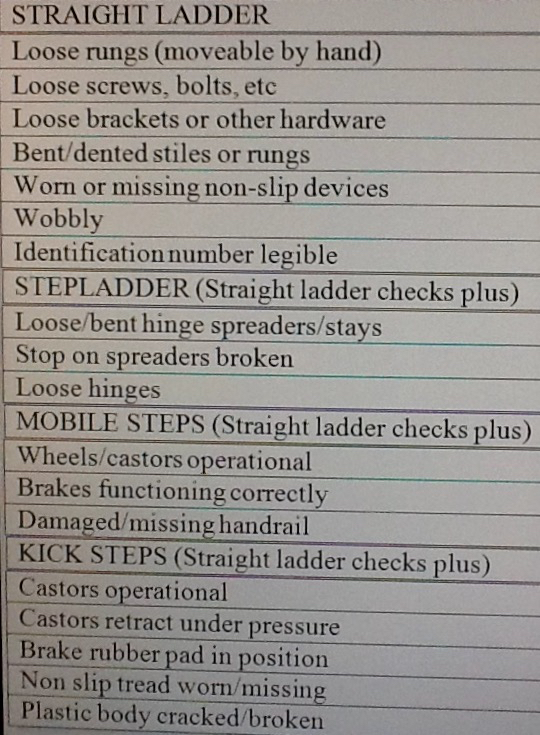

Ladders/access equipment

-

Click the add button for each separate ladder.

-

Scan barcode of access equipment.

-

Check the items on the list below and note the condition. Detail any issues.

-

Mewps/lifting equipment

-

Safe working loads clearly marked

-

Safety harnesses in good condition and used and stored correctly.

-

Training/safe systems of work followed

-

Correct storage of lifting accessories etc.

Internal transport

-

Per use checks completed

-

Unauthorised use of internal transport

-

Unauthorised carriage of passengers

-

Road markings clearly marked

-

Banks men operating correctly

-

Drivers disregarding safety rules e.g speed limits

-

Road and pedestrian routes in good order

-

Unsafe practices e.g. Travelling with raised forks

Machinery guarding/safety

-

All dangerous parts guarded e.g. Chains sprockets

-

All guards in good condition and correctly fitted

-

Emergency stop controls are accessible,working, and correctly fitted

-

Access to any dangerous part is prevented whilst machine in motion

-

Trip devices where fitted function correctly e.g. Interlocked guards.

-

Machinery can be positively isolated

-

Only trained and competent persons operate machinery

Environmental/welfare

-

Lighting, heating, ventilation,humidity, dust suppression, fume extraction etc.

-

Seating

-

Sanitation, washing facilities

-

Drinking water available

-

Cleanliness of facilities

First aid

-

First aider list posted

-

Accident forms in good supply

-

Sufficient trained personnel

-

First aid box checks completed

Chemicals, flammables

-

Storage areas locked and correct signage

-

Correct use of chemicals, flammables

-

Adequate ventilation of area

-

Correct disposal

-

Suitable emergency procedures and spill procedures

-

Correctly labelled containers

-

Emergency first aid facilities e.g. Eye wash

-

COSHH assessments msds available

Compressed air

-

Staff are trained and are using compressed air correctly

Protective clothing,equipment

-

Suitability and fitting, comfort

-

Correct usage and storage, care and maintenance

-

Worn where required

Safety signs

-

In good condition

-

Visible

-

Correctly displayed where required

Manual handling

-

Staff training and aware of safe handling methods

-

Suitable manual handling aids available and in use

-

Ergonomic issues

Training, supervision

-

Evidence of induction or other suitable training

-

Familiar with Work/cleaning instructions or safe systems of work

-

Adequate supervision of vulnerable people e.g. Young persons

-

Observed to be working correctly.