Title Page

-

Prepared by

-

Conducted on

-

Location

-

Boats

-

Electrical Connections

-

Scenery / Canvas

-

Gates

-

Lights on Ride

-

Seat Belts

-

Seats

-

Bells

-

Steering Wheels

-

Tank

-

Sweep Connections

-

Frame Crackes

-

Play on Car / Loose

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Grease Gears

-

Grease Center

-

Grease Motor

-

Add media

-

Add signature

-

Fire Engines

-

Electrical Connections

-

Scenery

-

Gates

-

Lights on Ride

-

Seat Belts

-

Seats

-

Bells

-

Steering Wheels

-

Flooring

-

Sweep Connections

-

Frame Crackes

-

Wheels

-

Play on Car / Loose

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Grease Gears

-

Grease Center

-

Grease Wheels

-

Grease Motor

-

Add media

-

Add signature

-

Jets

-

Electrical Connections

-

Scenery

-

Gates

-

Seat Belts

-

Seats

-

Guns

-

Flooring

-

Sweep Connections

-

Safety Pins

-

Frame Crackes

-

Play on Car / Loose

-

Center Cylinder

-

Hydraulics

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Oil Chain

-

Grease Bearing

-

Grease Sweeps

-

Grease Motors

-

Add media

-

Add signature

-

Pony Carts

-

Electrical Connections

-

Scenery

-

Gates

-

Lights on Ride

-

Seat Belts

-

Seats

-

Bells

-

Reigns

-

Flooring

-

Sweep Connections

-

Frame Crackes

-

Wheels

-

Axles

-

Safety Pins

-

Play on Car / Loose

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Grease Gears

-

Grease Center

-

Grease Wheels

-

Oil Horses

-

Grease Motor

-

Add media

-

Add signature

-

Sea Serpent

-

Electrical Connections

-

Sign

-

Deck and Handrails

-

Gates

-

Track

-

Particular attention to cracks, supports, welds at cross members and joints, signs of car interference, debris

-

Anchor Bolts on Track

-

Lap Bars

-

Seatbelts

-

Seats

-

Play on Car / Loose

-

Cars Undercarriage / Frame Cracks

-

Wheels: Rubber

-

Wheels: Play / Loose

-

Axles

-

Trucks

-

Universals

-

Hitches

-

Dogs

-

Chain

-

Lift mechanism

-

Belts, Motor, and Clutch: Look for leaks, belt tension, loose components, alignment.

-

Compressor

-

Lights on Ride

-

Lift Mechanism Smooth Operation

-

Belts, Motor, and Clutch: Smooth operation

-

Test Run / Odd Sounds

-

Anti-Rollback Operation

-

E-Stop on hill. Do NOT make adjustments without securing car / train

-

E-Stop, Console Switches

-

Brakes

-

Safety Pins

-

Grease Sprocket Bearings - weekly

-

Grease Axle Pivot (center of axle) - weekly

-

Grease Wheel Trucks - weekly

-

Grease Hitch, Universal Joint - weekly

-

Grease Hitch Pivot - weekly

-

Grease Up-Stop Bearing- weekly

-

Grease And Oil Brakes - weekly

-

Oil Chain - weekly

-

Oiler Filled - as needed

-

Add media

-

Add signature

-

Speedway

-

Electrical Connections

-

Scenery

-

Gates

-

Lights on Ride

-

Seat Belts

-

Seats

-

Flooring / Stairs

-

Sweep Connections / Pivots

-

Play on Car / Loose

-

Car Springs / Sweeps

-

Chain

-

Plastic Track

-

Roller Bearings

-

Caster Wheels

-

Safety Pins

-

Frame Cracks (structure / welds)

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Cars Bracket Bolts

-

Grease Caster Wheels

-

Grease Roller Bearings

-

Grease Thrust Bearings and Teeth

-

Oil Chain

-

Thrust Bearing Teeth wear check (monthly)

-

Gearbox (monthly)

-

Electric Motor (monthly)

-

Bolts Torque (every 3 months)

-

Add media

-

Add signature

-

Twist and Shout

-

Electrical Connections

-

Scenery

-

Gates

-

Lights on Ride

-

Lap Bars

-

Gas Springs

-

Lap Bar Warning Light

-

Seatbelts

-

Seats

-

Flooring

-

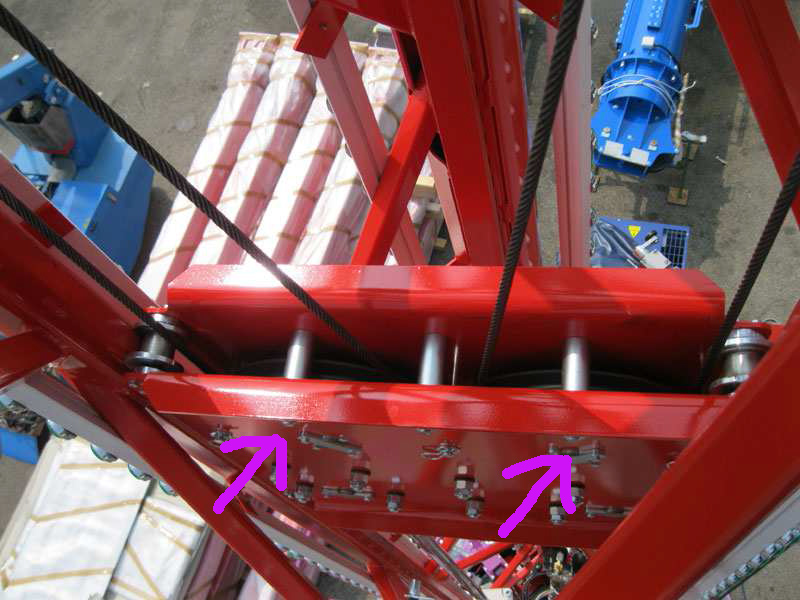

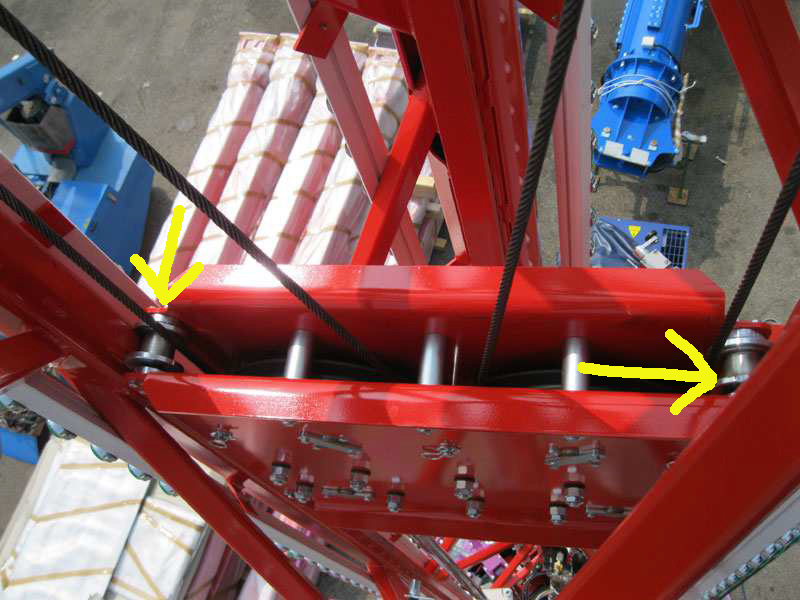

Wire Ropes

-

Safety Pins

-

Play on Car / Loose

-

Sensors and Limit Switches

-

Clean if necessary but do NOT use solvents

-

Test Run / Odd Sounds

-

E-Stop, Console Switches

-

Shock Absorbers and Compression Tanks

-

Normal pressure of 3.2 bar. Max of 6.5 bar

-

Sliding Guides of Shock Absorbers

-

Rubber Cleats of Shock Absorbers

-

Frame Crackes

-

Contacts for Vehicle Carriage

-

Wheels and Guide Plates in Vehicle

-

Yoke

-

-

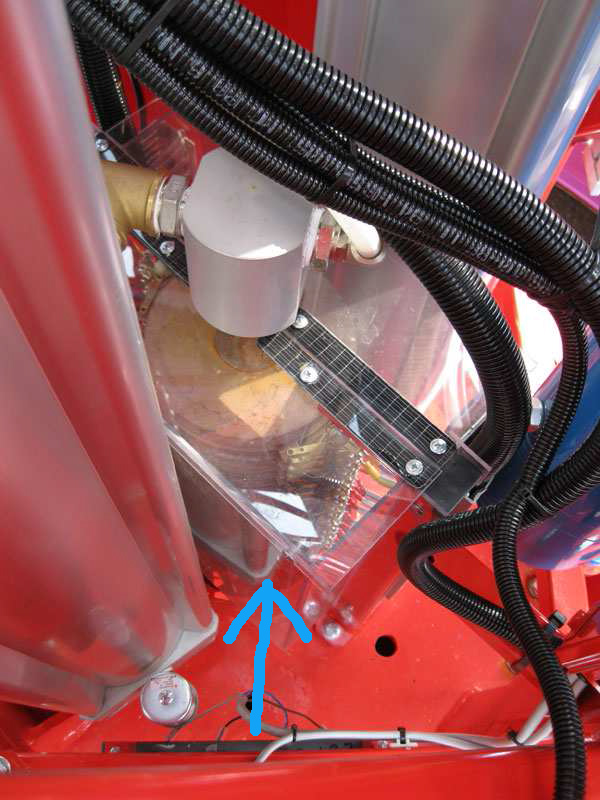

Pneumatic System

-

Check pressure at base is no more than 6.5 bar. Drain water through system. Clean filter as needed (monthly) with compressed air

-

Compressor

-

Pulleys (yoke and wear) - weekly

-

-

-

Wire Rope Accurate - weekly

-

As per ride manual section 20.2.1

-

Wire Rope Sensor - weekly

-

Bumpers (red ones on top) - monthly

-

Guide Roll and Guide Track check and Lubricant - weekly

-

-

Grease Pneumatic Cylinders (4 fittings total) - weekly

-

Grease Gears - as needed

-

Grease Bearing - every 100 hours of operation

-

Grease Lap Bars - every 100 hours of operation

-

Tower Oiler Filled -as needed

-

Clean and Inspect Electric Slip Ring / Commutator - weekly

-

As per ride manual section 20.11.6

-

-

Ventilation Grills (clean) - weekly

-

Gearbox Oil (check) - monthly

-

Add media

-

Add signature