Title Page

-

Type of report?

-

Conducted by

-

Conducted on

-

Project Number:

-

Project Location

-

Employee Name:

-

Employee Union:

Orientation

Topics Discussed

-

Allied Painting Inc. is dedicated to providing the highest quality of work available while at the same time providing for the protection of the surrounding environment and natural resources, and the safety and well-being of the community, its residents, the traveling public, as well as all employees of Allied Painting and the facility owner, or any of its subcontractors or consultants and visitors on this or any job sites and projects in which the Company endeavors to do business.

In all cases Allied will meet or exceed all government regulations, industry standards and job specifications, including those of OSHA, EPA, AMPP, the facility owner, as well as all State and Local regulations. Resources will be committed as necessary to ensure that all health, safety, and environmental issues are adequately covered. Anyone knowingly found to violate this policy or any of these requirements will be subjected to the company's disciplinary program, which includes warning followed by temporary then permanent dismissal from employment. This commitment will be communicated to all employees through continual management support of the program.

Allied Painting Inc. is committed 100% to safety. -

Please check all topics discussed.

-

Personal Protective Equipment

-

Personal protective equipment (PPE) plays a vital role in maintaining personal safety. <br> API will issue PPE to you with the expectation that you will inspect, clean and maintain it in accordance with manufacturer’s instructions throughout the duration of the project. It is important to keep your PPE in your duffle bag to minimize its loss and/or damage. Should your PPE become damaged, immediately notify your foreman or the Safety Officer for replacement.<br>When disposing of contaminated PPE, place it only in drums labeled Hazardous Waste. Do not dispose contaminated PPE in the regular trash or containers labeled Non-Hazardous Waste. <br>Contaminated coveralls will be stored separately in designated recepticles. Turn coverall pockets inside out or remove the pocket in order to prevent accumulations of contaminated blast media.

-

Fall Protection

-

Falls are the number one cause of fatalities in the workplace. API has a Zero Tolerance policy regarding fall protection use. If you are working at heights greater than six (6) feet or are working within twenty (20) feet of a leading edge, you MUST establish and properly use fall protection 100% of the time. No exceptions. <br> <br>API will issue fall protection equipment consisting of a full-body harness and double lanyard to you with the expectation that you will inspect, don and maintain the equipment in accordance with manufacturer’s instructions throughout the duration of the project. <br> <br>Work area assessments may also require API to issue other fall protection devices such as beam clamps and self-retracting lifelines (SRL) to ensure your safety when working at heights. It is important to keep your fall protection equipment in your duffle bag to minimize loss and damage. <br>Should your fall protection equipment become damaged or not function properly, immediately stop work and notify your foreman or the Safety Officer for replacement.

-

Leading Edge

-

LEADING EDGE<br>Leading edge work is among the most hazardous of tasks required in bridge painting. API has developed a plan to address the fall hazards associated with leading edge work. <br> It is imperative that you understand and adhere to the provisions of this plan in order to remain safe when participating in this activity. Although decking installation is a hazardous job, ironworkers have long been reluctant to use personal fall-arrest systems for fear that such systems could cause their own safety problems. <br> Today fall prevention systems should serve to dissipate any reluctance on the part of the worker to comply with the provisions of this plan. That said, failure to comply with the provisions of the plan will result in your immediate removal from the project under API’s ZERO tolerance program regarding fall protection and prevention. <br> During this task, metal sheets (decking) are applied and fastened over a series of wire rope (5/8) to form a work platform, constantly creating a new working surface is called “leading edge”. When constructing the platform there are typically three leading edges. <br> These leading edges shall be defined as:<br>- Advancing edge<br>- Right flanking edge<br>- Left flanking edge<br> IMPORTANT NOTE: The deck foreman shall not extend the advancing edge beyond fifty feet until guardrail and toe board systems are fully installed along right and left flanking edges.<br><br>When installing deck around piers and other fixed structural support members, gaps that exceed one inch (1") must be sealed to minimize the chances of objects falling to a lower level. The deck foreman shall ensure that no opening greater than one inch (1") exist before advancing. <br> Gaps less than 12" may be covered with wood panels secure to the surrounding steel decking. Gaps greater than 12"shall be covered with overlapping steel decking that is secured to the surrounding steel decking. <br> IMPORTANT NOTE: Closing gaps is the responsibility of the deck crew it is NOT the responsibility of the containment crew. Failure to close deck gaps initially upon installation places all personnel, including the containment crew at risk. <br>

-

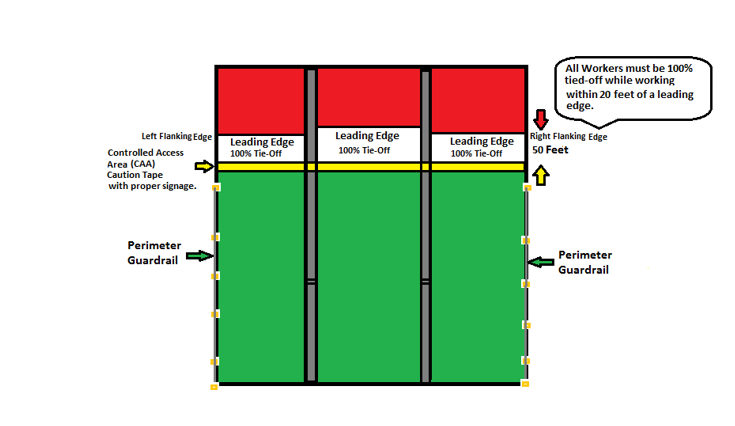

The illustration below provides the layout plan for a typical Controlled Access Area (CAA).

-

The CAA will be delineated using reinforced yellow caution tape with the following signage affixed along its perimeter. A minimum of four (4) signs shall be affixed to the caution tape adequately spaced across the delineated area.

-

The deck foreman will be responsible for establishing and properly maintaining a safe CAA throughout the entire deck installation process. Individuals assigned to this activity shall temporarily STOP work and immediately report any unsafe condition or act observed while working to the deck foreman or the HSO.

-

Workers observed within the CAA who are not 100% tied-off within twenty feet of a leading edge will be subject to immediate termination for breach of the API ZERO tolerance policy regarding use of fall protection. <br> Workers within the CAA will utilize self-retracting lifelines anchored to beam straps or clamps fastened to structural members of the bridge. The maximum length of self-retracting lifelines will be thirty (30) feet. Lifelines that exceed 30 feet will require prior approval from Allied Painting's EH&S Manager. <br> Installation of the beam clamp or beam strap may require the use of a portable ladder. Portable ladders shall be properly inspected, staged and secured when used. <br> Leading edge workers shall be equipped with deployable stirrups in the event of a fall. Use of the stirrups will minimize vascular damage during the period of suspension. <br> <br>IMPORTANT NOTICE: Platform installers must advance the perimeter guardrails and toe board in a manner that continually and consistently preserves the established and delineated CAA. Failure to maintain the consistency of the CAA can result in serious injury or death as its sole purpose is to properly delineate the leading edge. <br><br>A safety boat will be deployed when work is being conducted near or over water. The operator will remain in the vicinity of the work and will have the ability to communicate with the deck crew foreman. <br>

-

Respiratory Protection

-

RESPIRATORY PROTECTION<br>Proper use of respiratory equipment plays a critical role toward protecting your personal health. Improper use, care and storage of respiratory protection can result in adverse impacts to your health. Therefore proper use, care and storage of your respiratory equipment is required to minimize health impacts. <br> API will issue you two types of respiratory protective equipment. <br> <br>They shall include:<br>- Air purifying respirator (APR); and<br>- Type CE* continuous flow respirator for abrasive blasting operations. <br> <br>*Type CE denotes respirator equipped with head and neck protection. <br> <br>Regulatory requirements governing the use respiratory equipment include initial use authorization by a licensed occupation physician that may involve additional medical testing procedures. Another requirement is annual fit testing.<br> <br>Respiratory equipment inspection is required before each use. <br> <br>Inspection includes:<br>- Inhalation and exhalation valves;<br>- Cartridge seals;<br>- Head band; and <br>- Face piece (tears, cracks, deformity) <br> <br>Cleaning your respirator face piece should be performed daily at minimum preferably prior to initial use. API will supply disposable wipes for cleaning and disinfecting your respirator. The entire respirator face piece should be cleaned and disinfected on a daily basis.<br> <br>Proper storage of your respirator will minimize cross contamination. Cross contamination can contribute to health impacts therefore leaving your respirator unprotected will be considered a substandard safety practice subject to disciplinary action. <br> <br>API will issue a properly sized zip-lock bag to store your respirator while not in use. You’ll be responsible to place your respirator face piece into the bag when not in use. Remove the filters, clean the respirator face piece then place it into the bag then seal the bag. The respirator should be placed into your duffle bag in a manner that does not crush or distort the face piece. <br> <br>Filters must be placed in a separate bag and sealed to prevent cross contamination. <br> <br>Personal grooming is another important aspect of respirator use. Workers must not possess facial hair that would interfere with the face to seal fit of the respirator face piece. <br> It is recommended that workers shave daily in order to maintain the integrity of this seal. <br> <br>There have been documented cases of increased blood lead levels for workers who have been disciplined for improper respirator use including facial hair. <br> <br>Workers who possess facial hair that are participating in work activities that do require or potentially require the use of respiratory protection will be immediately from the removed work area and subject to disciplinary action. <br> <br>Should your respiratory equipment become damaged, immediately notify your foreman or the Safety Officer for replacement.<br> <br>When disposing of contaminated filters, place the filters in receptors labeled Hazardous Waste. Do not dispose contaminated filters in the regular trash or receptors labeled Non-Hazardous Waste. <br> For blasting activities, continuous flow respirators are issued. Inspection of the unit shall be in performed in accordance with manufacturer’s instructions. <br> Components requiring inspection include:<br>- Cape;<br>- Headband and chinstrap;<br>- Helmet;<br>- Lens and window frame gasket;<br>- Breathing tube assembly; and<br>- Air supply hose<br> <br>Inspect for items that include but are not limited to wear, abrasions, holes, cracks, tears, etc. <br> Do not doff (remove) the respirator inside containment where it will be subject to cross contamination. Once outside containment remove the respirator, remove filters, clean it, then place it in a clear bag with your name written on it. Place filters in a separate bag.<br>

-

Scaffolding

-

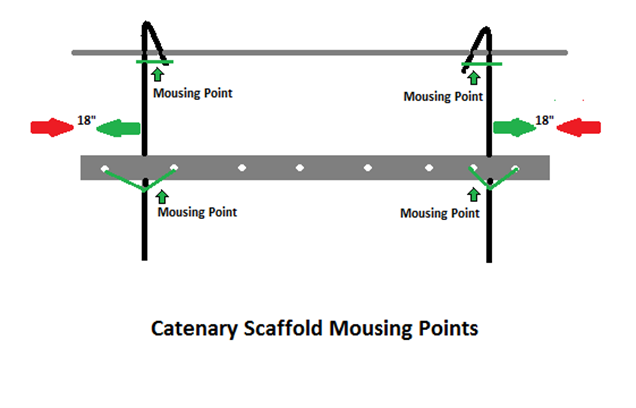

SUSPENDED SCAFFOLD SAFETY<br>Completion of work tasks will require working at heights on suspended scaffold (catenary). A daily pre-work inspection of the catenary scaffold being manned is required prior to use. 100% tie-off is required at all times when entering, exiting and working on catenary scaffold. <br> A double lanyard MUST be utilized while working on suspended scaffold as a means to ensure 100% tie-off at all times. <br> <br>Workers will initially ensure a proper overhang of approximately 18" and the mousing of both sides of the pick and saddles (when used). It is recommended you visually inspect your scaffold to ensure it is properly moused as illustrated below. If it is not properly moused, take a section of flat rope with you to secure it Violation of API’s 100% tie-off requirement may result in immediate termination. <br>

-

-

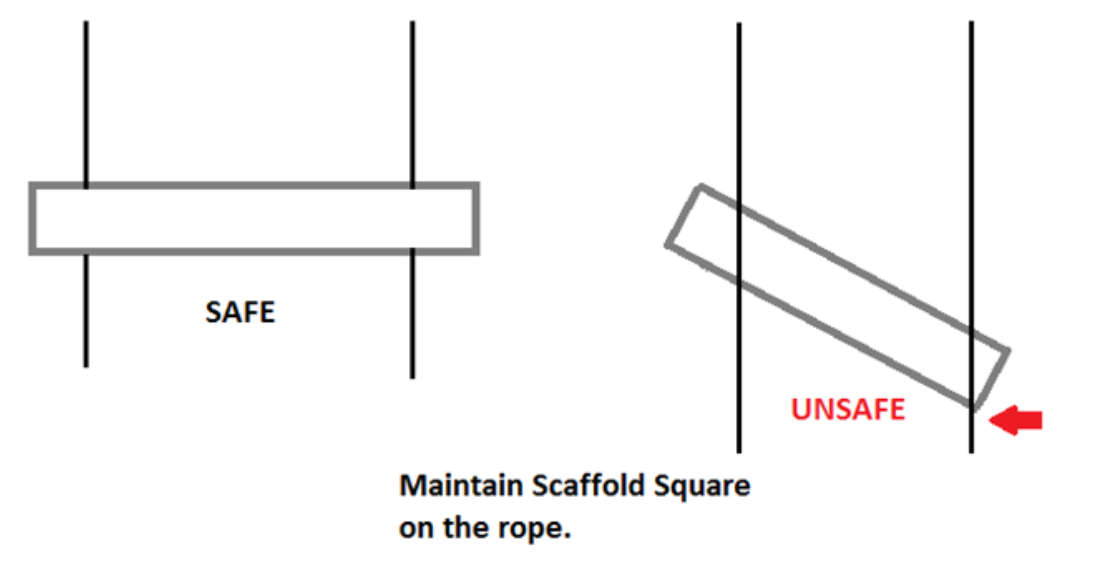

A catenary system is considered an independent stand-alone system. Any other use (e.g. attaching containment curtain clips to the catenary wire ropes) to any system component is strictly prohibited. <br> <br>Important Notes: 1. when entering and exiting your catenary scaffold with a ladder your scaffold MUST be firmly secured against a fixed location (i.e., steel girder). 2. When moving your scaffold along the rope always square the scaffold ends parallel with the ropes. Do NOT leave scaffold in a diagonal position on the rope (see below).<br>

-

-

A catenary scaffold is a scaffold consisting of a platform supported by two essentially horizontal and parallel ropes attached to structural members of a building or other structure.

-

- Catenary scaffolds may not have: <br> <br> More than one platform between consecutive vertical pickups, and<br> <br> More than two platforms altogether. [1926.452(r)(1)]<br> <br>Platforms supported by wire rope must have hook-shaped stops on each of the platform to prevent them from slipping off the wire ropes. <br> These hooks must be positioned so that they prevent the platform from falling if one of the horizontal wire ropes breaks. [1926.452(r)(2)] <br>- Wire ropes must not be over-tightened to the point that a scaffold load will overstress them. [1926.452(r)(3)]<br>- Wire ropes must be continuous and without splices between anchors. [1926.452(r)(4)]<br>- Each employee on a catenary scaffold must be protected by a personal fall-arrest system. [1926.451(g)(1)(i)]<br><br>

-

Cell Phones

-

Your personal safety demands your full attention. The use of cell phones while working puts your personal safety at risk therefore cell phone use is prohibited with exception to break and lunch. Photos taken with phones is also prohibited during working hours.

-

Rigging

-

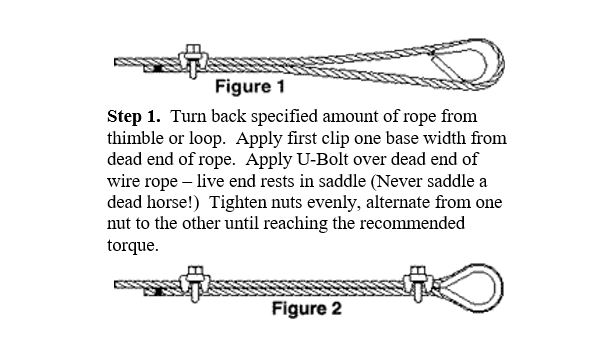

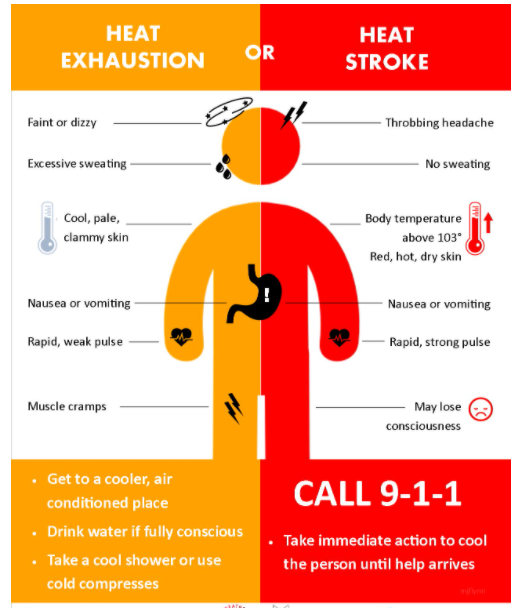

Safe rigging is critical in every application. The rigging foreman is responsible for safe and compliant rigging performed in accordance with acceptable rigging practices and to ensure the proper type and size of wire rope is being utilized. The rigging foreman will brief his team daily concerning the specific expectations involved with the rigging task to be performed in addition to the proper safety equipment and tools required to perform the task. Once work begins the rigging foreman will periodically observe individual team members to ensure those specific expectations are being met from both safety and quality perspectives.<br>When deck and catenary scaffold rigging is being performed, wire rope is generally required to be looped. <br> When looping wire rope follow the illustrations provided in Figures 1 through 3 below. Failure to do so can result in serious injury or death. <br> When applying wire rope clips, they must be tightened and torqued in accordance with the manufacturer’s published rating chart. Wire rope clips must be made of forged non-malleable steel. Once the hardware is torqued to specification the installer will apply a bead of paint along the nut and the protruding thread. This bead of paint will be used as part of a daily pre-use visual inspection of the scaffold to be manned in order to determine that the clip assembly remains intact. A broken bead indicates that the hardware has loosened. Loose hardware requires immediate re-torqueing.

-

-

-

Stairway & Ladders

-

STAIRWAYS<br>As a means for safe access to the work deck, the installation of a stair tower may be used. Generally, a stair tower will utilize system scaffold commonly called tube and coupler or system scaffold. The stair tower shall be erected by a competent person and inspected daily and inspection tag initialed as a means to verify the inspection. Access to the stair tower must be secured by lock and key during back-shift hours. Persons using stair towers should always utilize the handrail while ascending and descending. Immediately report any deficiencies noted to your foreman or the project safety officer. <br><br><br>LADDERS<br>Portable ladders on the project must have a minimum industrial rating of Type1 - 250 pounds or Type 1A- 300 pounds. Ladders must be inspected prior to use and immediately taken Out-of-Service and tagged if any damage is observed. <br> All ladder safety labels must be legible. Ladders must be properly stored in a safe and secure manner to prevent loss. Always face the ladder when ascending and descending and always maintain use three points of contact. Do not carry tools, supplies or materials when ascending and descending ladders. Work areas may have to be cautioned off when ladders are in use as a means to protect workers and the work area. <br> Extension Ladders - When using an extension ladder the Ladder must be properly inspected by the user prior to use and immediately taken Out-of-Service and tagged if any damage is observed. Aluminum extension ladders will not be used within 50 feet of an energized power line when line voltage is unknown. The ladder will be positioned on a level surface then the top section extended three (3) feet above the designated landing. The ladder base will then be repositioned to a 75 degree angle, roughly one foot out at the base for every four feet of height. Initially, a worker will climb the ladder with another person securing the base to tie-off the top section to the landing. Always maintain three points of contact when climbing the ladder and keep your body close to the rails. Avoid over extending your body beyond the confines of the rails. Two people should always handle extension ladders to minimize loss during transport and setup. Barricade the overhead work area when required (i.e., people passing under, close to a doorway, etc.) to avoid loss.<br> <br>IMPORTANT NOTE: Extension ladders shall NOT be separated and used individually as they are not designed for this purpose. Warning and Danger labels must be preserved on all ladders. Clear plastic tape can be applied over the label to preserve the label. <br><br>Step Ladders - When using a Step ladder the Ladder must be inspected by the user prior to use and immediately taken Out-of-Service and tagged if any damage is observed. The ladder must be placed upon a level surface. The front and rear rails must be fully opened with the spreader assembly fully engaged. Step ladders should only be used for light work such as inspection and light touch-up. When working on a step ladder, keep your body between the rails and your knees below the top of the ladder to maximize balance. Select the proper size ladder for the task. Use of a closed step ladder is prohibited. Store ladders where they will not be subject to damage or loss. Barricade areas subject to traffic. <br><br>Straight Ladders – Straight ladder must be inspected by the user prior to use and immediately taken Out-of-Service and tagged if any damage is observed. A straight ladder can be used in place of an extension ladder. Straight ladders are lighter and easier to manage. Aluminum straight ladders will not be used within 50 feet of an energized power line when line voltage is unknown. Straight ladders must also be of sufficient length to extend a minimum of three feet above the landing. The ladder base will then be repositioned to a 75 degree angle, roughly one foot out at the base for every four feet of height. Initially, a worker will climb the ladder with another person securing the base to tie-off the top section to the landing. Always maintain three points of contact when climbing the ladder and keep your body close to the rails. Avoid over extending your body beyond the confines of the rails. Barricade the overhead work area when required (i.e., people passing under, close to a doorway, etc.) to avoid loss.<br>

-

Hearing Protection

-

HEARING PROTECTION<br> Hearing protection is required when continually exposed to a noise level that is at or exceeds 90 decibels. A general Rule-of-Thumb to determine if field noise is excessive is when normal conservation cannot be understood when standing three feet apart. You will be issued disposable hearing protection. The technique for proper installation of hearing protection is to roll the protector until it becomes very compressed. Using you left hand reach back behind your head and pull the top of your right ear upward to open the ear canal then insert the compressed protector partially into your ear canal then release your ear. As the foam protector opens you will notice a change in background noise. Repeat the process. Make sure your hands are clean before inserting the protectors into your ears. When properly inserted the protection will serve to reduce noise in accordance with the plug’s noise rate reduction (NRR). Proper use of hearing protection preserves your ability to hear. Hearing loss is so gradual a process that you don’t realize it’s happening so wear the protection correctly to avoid any loss. <br>

-

Electrical Hazards

-

ELECTRICAL HAZARDS<br>On this project there are two types of electrical hazards present, high voltage and low voltage. Electrical hazards associated with this project can result in serious injury or death if improperly assessed or when established safety precautions are ignored. Therefore it is essential that all workers understand that personal safety in their hands. Don’t ignore the signs. <br>

-

-

High voltage aspects focus on utility and rail catenary lines which pass under the structure. Low voltage aspects focus on portable powered electrical equipment (i.e., generators and power tools) and other accessories such as extension cords and portable GFCI. <br> <br>High voltage utilities shall be safely addressed by their owners who will be in communication with API supervision. <br> Personnel shall maintain a minimum safe distance of fifty feet in instances when line voltage is unknown. Once live voltage is known, workers will be informed and placards will denote voltage. Workers will maintain the minimum safe distance from the utility. De-energizing the utility will be required in instances where working in close proximity is required. Such work activities will be carefully planned in advance, communicated and executed with all safety precautions <br> <br> Low voltage is defined as voltage below 600 volts. Contact with low voltage can result in serious injury or death. The risk is actually higher since worker exposure is higher. Higher in light of the fact that workers are handling on a regular basis equipment such as portable generators, power tools and extensions cords. <br> Use of an inline portable Ground Fault Circuit Interrupter (GFCI) greatly reduces risk of electrical shock but does not eliminate the risk all together. A portable GFCI must be installed at the source of the power supply such as wall outlet. There are also GFCI breakers that supply energy to outdoor outlets or outlets proximal to kitchen or bathroom facilities. The GFCI outlet must be tested prior to use to ensure proper function. Portable generators equipped with a GFCI outlet or breaker must also be tested to ensure proper function.<br> Extension cords used on API projects must be 3 prong, Heavy Duty rated number 12 or 10 gauge. The cord should have the following letters visible on the outer jacket; SJEW or SJEOW. <br> <br>These letters represent the following: <br>S Service (600V)<br>J Junior (300V)<br>E Thermoplastic Elastomer (TPE)<br>O Oil-Resistant<br>W Weather Approved (water-, moisture-, damp-, sunlight-resistant)<br> Extension cords shall be visually inspected daily to ensure the following conditions do not exist;<br> <br>- Damage to the outer jacket (gouges, tears, holes, cracks)that expose the inner conductors<br>- Exposed conductors at stress ends at either end of the cord;<br>- Missing ground prong on the male end of the cord.<br> Other safety considerations include:<br> <br>- Route extension cords in a manner that minimizes tripping hazards.<br>- Do not route extension cords through areas prone to water accumulation or exposure to vehicle or equipment traffic.<br>- Do not hang extension cords over nails or lay over sharp edges.<br>- Do not “daisy-chain” cords.<br>- Store extension cords in a manner that does not cause damage.<br>- OSHA prohibits repairs to extension cords (taping outer jacket or replacing cord ends). <br> Allied Painting Inc has a strict “no live-work policy” that conforms to OSHA standards and requires the shutdown of live electrical circuits that may be contacted by workers during the execution of the project. Electrical work shall proceed only after the evaluation of potential live work areas and a review of a schedule of live work shutdowns has been completed.

-

Power Tools / Hand Tools

-

POWER TOOLS<br>Use of power tools on this project may be required for various tasks. All power tools must be inspected prior to use. For electrical power tools, inspection shall include but is not limited to: <br> - Power cord – inspect for cracks in outer insulation, exposed conductors at both ends of the cord, strain relief is intact, and plug condition.<br>- Inspect the ON – OFF switch<br><br>Select power tools such as portable grinders are equipped with guards. GUARDS SHALL NOT BE REMOVED from any power tool under ANY circumstances. Personnel removing guards or using a power tool without the required guard will be subject to disciplinary action. <br><br>Working with power tools may require additional personal protective equipment for the face such as a face-shield or goggles. Hand and hearing protection will also be required. <br> <br>Hand tools shall be inspected prior to use and shall be used for their intended purpose. Hand tools found to be defective shall be immediately repaired, dressed, or taken out of service. <br>

-

Aerial Work Platforms

-

AERIAL WORK PLATFORMS (High Reach)<br>The use of an Aerial Work Platform (AWP) allows elevated work to be performed safety and more efficiently than other conventional means such as scaffold. AWP operators must be trained on AWP general safety and qualified on the AWP unit(s) delivered to and used on the project. <br> Do not operate an AWP if you are not properly trained.<br> Documented inspection of an AWP must be performed prior to use. Deficiencies noted shall be addressed prior to authorizing or resuming operations. Should a deficiency involve the audible travel alarm, a service call will be made initially and the AWP may be used with an assigned spotter until repaired. <br> The operator and occupant must don fall protection and clip off to the anchor point, (not the basket handrails) before elevating or moving the AWP. Operators will operate the AWP in SLOW mode and completely retract the AWP’s immediate boom when advancing long distances. Operating in SLOW mode also reduces jolting motions when positioning the basket. <br> Areas of AWP operation must be demarcated to prevent access by unauthorized personnel. <br> Operators shall not exceed the weight load capacity for the lift. <br> AWPs shall not be used for lifting or lowering materials in a manner that would:<br>- Exceed the rated load capacity for the lift (500 pounds- personnel + material)<br>- Be attached to the sides of the basket<br> AWPs should always be operated on stable level surfaces to avoid risk to the machine and its occupants. When work close to overhead power lines is required, the operator shall initially verify line voltage and maintain the minimum safe distances required for safe operation. <br>

-

Types of MEWPS's

-

Track Safety

-

TRACK SAFETY<br>Sometimes a section of the structure is located within the limits of state and federal railroad authorities. Working proximal to these locations including the staging of personnel and equipment within the boundaries requires advanced planning and notification. Representatives of these authorities to ensure the safety of operations within the boundaries of these locations is required. Additional training may also be required for personnel as a means of ensuring they understand the safety requirements for working within these boundaries. Personnel shall remain within the safety boundaries established for these locations to minimize risk. <br>

-

Hazard Communication / SDS

-

HAZARDOUS COMMUNICATION (RIGHT-TO-KNOW) SAFETY DATA SHEETS (SDS)<br>The objective of this section is to communicate the hazards associated with safe use, storage and disposal of hazardous materials used on the project. <br> The hazardous materials used are similar to those used on other structural steel painting projects and include but are not limited oils, grease, paints, primers, reducers and fuels (gasoline and diesel). <br> Safety Material Data (SMS) sheets shall be obtained for each product used and be maintained in a virtual drive in which the project HSO has immediate access to in the event you would like to review any of them. <br> Hard copies of any SDS will be made available to you at your request. <br> In an emergency involving hazardous materials, the SDS for the product will be reviewed for proper instructions regarding emergencies such as spills, fires and over exposure. <br> If transferring hazardous materials (i.e., MEK) from one container to another (55 gal. drum to 5 gal. can) a HAZMAT label must be completed and affixed to the container. <br> CONTAINER LABELING<br><br>• Container labels must be clearly legible and accurately identify contents.<br>• Appropriate primary hazard warnings and secondary hazards are noted.<br>• The name and address of the manufacturer or distributor is listed.<br>

-

See informational document below.

-

Hexavalent Chromium

-

Hexavalent Chromium may be present in the existing coatings that are located on our projects, as these coatings are disturbed you could be exposed to this toxic metal. <br> All forms of hexavalent chromium are regarded as carcinogenic (cancer causing) to workers. Workers who breathe hexavalent chromium compounds at their jobs for many years may be at increased risk of developing lung cancer. The risk of developing lung cancer increases with the amount of hexavalent chromium inhaled and the length of time the worker is exposed. Breathing high levels of hexavalent chromium can irritate or damage the nose, throat, and lungs. Repeated or prolonged exposure can damage the mucous membranes of the nasal passages and result in ulcers. In severe cases, exposure causes perforation of the septum (the wall separating the nasal passages). Breathing small amounts of hexavalent chromium even for long periods does not cause respiratory tract irritation in most people. Some employees become allergic to hexavalent chromium, so that inhaling the chromate compounds can cause asthma symptoms such as wheezing and shortness of breath.<br><br>Irritation or damage to the eyes and skin can occur if hexavalent chromium contacts these organs in high concentrations or for a prolonged period. Direct eye contact with chromate dusts can cause permanent eye damage. Prolonged skin contact can result in dermatitis and skin ulcers. Some workers develop an allergic sensitization to chromium. In sensitized workers, contact with even small amounts can cause a serious skin rash.<br><br>Occupational exposures occur mainly among workers who handle pigments containing dry chromate, spray paints and coatings containing chromate, operate chrome plating baths, and weld or cut metals containing chromium, such as stainless steel.<br><br>The current (effective 5/30/2006) Permissible Exposure Limit (PEL) is 5 micrograms of Cr (VI) per cubic meter of air (5 µg/m³) as an 8-hour time-weighted average for all Cr (VI) compounds. The Action Level (AL) is 2.5 micrograms of Cr (VI) per cubic meter of air (2.5 µg/m³) calculated as an 8-hour time-weighted average (TWA). The action level triggers requirements for exposure monitoring and medical surveillance.<br>

-

Cadmium

-

Cadmium may be present in the existing coatings located on our projects, as these coatings are disturbed you could be exposed to this toxic metal. <br> Cadmium and its compounds are highly toxic and exposure to this metal is known to cause cancer and targets the body's cardiovascular, renal, gastrointestinal, neurological, reproductive, and respiratory systems. <br> <br>Occupational exposure to cadmium can lead to a variety of adverse health effects including cancer. Acute inhalation exposure (high levels over a short period of time) to cadmium can result in flu-like symptoms (chills, fever, and muscle pain) and can damage the lungs. Chronic exposure (low level over an extended period of time) can result in kidney, bone and lung disease.

-

Beryllium

-

Beryllium may be present in the existing coatings located on our projects, as these coatings are disturbed you could be exposed to this toxic metal. <br> Beryllium is a light weight but extremely strong metal. Its compounds are important materials used in the construction, aerospace, electronics, energy, telecommunications, medical and defense industries. In the construction industry they are encountered while removing paint from metal surfaces made of beryllium alloys. However, beryllium is a highly toxic metal and workers who inhale beryllium are at an increased risk of developing chronic beryllium disease (CBD) or lung cancer. <br> Lung cancer is associated with occupational exposure to beryllium by inhaling beryllium containing dust, fumes or mist. The International Agency for Research on Cancer (IARC) lists beryllium as a Group 1 carcinogen and the National Toxicology Program (NTP) lists beryllium as a human carcinogen.

-

Arsenic

-

Arsenic may be present in the existing coatings located on our projects, as these coatings are disturbed you could be exposed to this toxic metal. <br> Health effects<br>Inorganic arsenic is a confirmed carcinogen and is the most significant chemical contaminant in drinking-water globally. Arsenic can also occur in an organic form. Inorganic arsenic compounds (such as those found in water) are highly toxic while organic arsenic compounds (such as those found in seafood) are less harmful to health.<br><br>Acute effects<br>The immediate symptoms of acute arsenic poisoning include vomiting, abdominal pain and diarrhoea. These are followed by numbness and tingling of the extremities, muscle cramping and death, in extreme cases.<br><br>Long-term effects<br>The first symptoms of long-term exposure to high levels of inorganic arsenic (for example, through drinking-water and food) are usually observed in the skin, and include pigmentation changes, skin lesions and hard patches on the palms and soles of the feet (hyperkeratosis). These occur after a minimum exposure of approximately five years and may be a precursor to skin cancer.<br><br>In addition to skin cancer, long-term exposure to arsenic may also cause cancers of the bladder and lungs. The International Agency for Research on Cancer (IARC) has classified arsenic and arsenic compounds as carcinogenic to humans, and has also stated that arsenic in drinking-water is carcinogenic to humans.<br><br>Other adverse health effects that may be associated with long-term ingestion of inorganic arsenic include developmental effects, diabetes, pulmonary disease, and cardiovascular disease. Arsenic-induced myocardial infarction, in particular, can be a significant cause of excess mortality. In China (Province of Taiwan), arsenic exposure has been linked to “Blackfoot disease”, which is a severe disease of blood vessels leading to gangrene.<br><br>Arsenic is also associated with adverse pregnancy outcomes and infant mortality, with impacts on child health (1), and exposure in utero and in early childhood has been linked to increases in mortality in young adults due to multiple cancers, lung disease, heart attacks, and kidney failure (2). Numerous studies have demonstrated negative impacts of arsenic exposure on cognitive development, intelligence, and memory (3). <br> (1) Association of arsenic with adverse pregnancy outcomes/infant mortality: a systematic review and meta-analysis.<br>Quansah R, Armah FA, Essumang DK, Luginaah I, Clarke E, Marfoh K, et al. Environ Health Perspect. 2015;123(5):412-21.<br><br>(2) In utero and early life arsenic exposure in relation to long-term health and disease.<br>Toxicol Appl Pharmacol. Farzan SF, Karagas MR, Chen Y. 2013;272(2):384-90.<br><br>(3) The developmental neurotoxicity of arsenic: cognitive and behavioral consequences of early life exposure.<br>Tolins M, Ruchirawat M, Landrigan P. Ann Glob Health. 2014;80(4):303-14.

-

Lead

-

Lead may be present in the existing coatings located on our projects, as these coatings are disturbed you could be exposed to this toxic metal. <br> Epidemiological and experimental studies indicate that chronic exposure resulting in blood lead levels (BLL) as low as 10 µg/dL in adults are associated with impaired kidney function, high blood pressure, nervous system and neurobehavioral effects, cognitive dysfunction later in life, and subtle cognitive effects attributed to prenatal exposure. Pregnant women need to be especially concerned with reducing BLL since this can have serious impact on the developing fetus.<br><br>Chronic exposures leading to BLLs above 20 µg/dL can cause subclinical effects on cognitive functions as well as adverse effects on sperm/semen quality and delayed conception. BLLs between 20 to 40 µg/dL are associated with effects such as cognitive aging as well as deficits in visuomotor dexterity, lower reaction times and attention deficit. At BBLs above 40 µg/dL, workers begin to experience symptoms such as headache, fatigue, sleep disturbance, joint pain, myalgia, anorexia, and constipation.<br><br>While much less common today, workers can be exposed to high lead levels resulting in BLL over 60 µg/dL. Health effects at these very high BLLs can range from acute effects such as convulsions, coma, and in some cases, death, to more chronic conditions such as anemia, peripheral neuropathy, interstitial kidney fibrosis, and severe abdominal cramping. <br> Based on limited evidence of human carcinogenic effects, workers may develop stomach cancer and lung cancer following inhalation exposure to lead, but more studies are needed to demonstrate the cancer risks compared to the levels and durations of lead exposure, and possibly confounding factors such as smoking, diet, and other carcinogens in the workplace. Experimental research indicates that rats and mice develop renal tumors following exposure to lead.

-

Traffic Safety

-

TRAFFIC SAFETY<br>Another dangerous activity in our daily work is exposure to vehicular traffic. Employees being struck by vehicles or mobile equipment on a construction job site lead to many work zone fatalities or injuries. <br> <br>Allied Painting will have traffic controls identified by signs, cones, barrels and barriers. <br> <br>Above and beyond your training, you MUST maintain a high level of self-discipline not to become complacent around live traffic. A few key safe practices to maintain are as follows:<br><br>- Initially observe traffic BEFORE you act.<br>- Avoid walking along barrels or cones that are immediately close to a live lane. If required to walk along a live lane, wait until the lane is clear of traffic then walk.<br>- If a large vehicle is approaching, wait until the vehicle has passed before acting.<br> <br> REMEMBER<br><br>ALERT AWARE ALIVE<br><br>Drivers, employees on foot, and pedestrians must be able to see and understand the proper routes. Project traffic control plans are pre-determine, reviewed and approved. API has designated a Traffic Control Coordinator (TCC) to establish and maintain traffic control patterns for each job. <br> <br>If assigned to road operations, make sure your safety vest is not soiled to a point where its color and reflective properties are ineffective. If such conditions exist, see the HSO for immediate replacement.<br> <br>IMPORTANT NOTE: make sure your operations on the roadway are conducted in a safe manner that minimizes risk to the motoring public. <br> Of significant importance is the installation and removal of containment tarps. <br> Materials, debris, and equipment must be secured within a lane closure to ensure nothing enters live traffic. Tarps MUST be rolled and installed in a manner that prevents them from being caught by the prevailing wind and potentially entering a live lane of traffic.<br>

-

Disciplinary Action

-

DISCIPLINARY ACTION<br>Disciplinary action is part of any structured business. <br> API has a disciplinary policy that involves four tiers:<br> 1. Verbal Warning<br>2. Written Warning<br>3. Suspension <br>4. Termination<br> <br>API possesses a Zero Tolerance policy for severe breaches of company policy. In the area of safety, any unsafe act or unsafe condition that would present an immediate threat to life and health. <br> Such examples include but are not limited to:<br> <br>- Failure to tie-off when working at elevated height;<br>- Failure to tie-off when working on a leading edge;<br> <br>Other breaches that would give cause to enact the policy would include but are not limited to:<br> - Positive post-accident drug test;<br>- Company theft <br>

-

Accident Reporting

-

Employees have the first and primary responsibility in accident reporting. If you or anyone else is involved in an incident that causes injury, you must report it to the project HSO immediately. This will help expedite treatment for your injuries as well as document the incident.

-

Emergency Procedures

-

There are several types of emergency situations that could arise on the project. These are classified under the following terms:<br>- Personal Injury<br>- Fire<br>- Chemical Spill <br>- Inclement Weather<br>- Vehicle Accident<br>Personal Injury – personal injury is divided into two primary categories:<br>- Critical<br>- Non-Critical<br>Critical is defined as any life threatening conditions expressed by the injured or observed by others. Conditions include but are limited to: <br>- Shortness of breath or difficulty breathing<br>- Chest pain<br>- Allergic reaction (bee sting)<br>- Arterial bleeding<br>- Fall from height<br>- High pressure injection<br>- Compound fracture<br>- Heat stroke (Review Handout)<br>- Second or third degree burn<br>- Electric shock<br><br>Workers should immediately contact 911 or transport the worker to the hospital (when safe to do so) DO NOT MOVE INDIVIDUALS WHO HAVE BEEN INVOLVED IN A FALL FROM HEIGHT. KEEP THEM STABLE AND CALL 911.<br><br><br><br>Non-Critical injuries are injuries that require first-aid or professional medical assessment and diagnostics (i.e., x-ray). Conditions include but are not limited to:<br>- Minor cuts and laceration<br>- Sprains and strains<br>- Fractures (minor)<br>- Eye injury<br>- Minor burns<br> In the event of an emergency, please evacuate the working platforms and structures and meet at the pre-determined muster area designated by the project HSO. DO NOT LEAVE THE JOB! This is very important, if you leave the site and we dont know, we have to assume that you are still on the structure. in the event of a fire this could needlessly put first responders in harms way trying to locate an employee who has already left.

-

Bloodborne Pathogens

-

Blood and other bodily fluids may contain infectious diseases. <br><br>The three most common bloodborne pathogens (BBPs) are human immunodeficiency virus (HIV), hepatitis B virus (HBV), and hepatitis C virus (HCV).<br><br>Although, in our industry we are not regularly exposed to blood and/or other bodily fluids, it is possible to be exposed to these hazards in the event that another employee sustains serious injury resulting in the release of blood or other bodily fluids.<br><br>Each project will have a full time Health & Safety Officer (HSO) on site.<br><br>Allied Painting’s HSO’s shall be formally trained in CPR as well as First Aid. <br><br>Only those specifically trained in first aid shall administer care to any injured party.<br><br>In the event of blood or other bodily fluids released, all will be considered infectious and treated as such.<br><br>The following protocol must be adhered to.<br><br>Purpose<br>This policy pertains to spills of blood or other body fluids. It is not a first aid/emergency response procedure. This policy is specific to clean-up of such fluids.<br> Procedure<br>1. In the event of a serious injury resulting in release of blood or other body fluids which could contain pathogens (e.g., HIV or HBV), the first step is to treat the injured party. <br>2. Spilled body fluids should not be cleaned up without the appropriate protective equipment and materials specifically designated for such fluids. In the case where spilled body fluids need clean-up, this procedure must be followed by all personnel:<br><br>I. Advise the Supervisor on duty. The supervisor should be aware of the individual(s) doing the actual clean-up and the purpose of the cleanup.<br><br>II. Clean up the spilled fluids as follows:<br> a. Put on protective gloves, located in first aid kit on site.<br>b. Spread the absorbent material on the spilled body fluids, (e.g., paper towels) or use the materials in a First Aid kit located on site.<br>c. Neutralize the potential pathogens with a 10% bleach-with-water solution. Cover the spill for 15 minutes.<br>d. Use paper towels to pick up material as best possible. Place all potentially contaminated materials in a leak-proof plastic bag.<br>e. Sweep/mop-up any additional neutralized/absorbed fluids and place in the leak-proof bag.<br>f. Clean sweep/mop materials with hot, soapy water. Lastly, remove gloves from inside-out and place in the bag.<br>g. Secure the bag and discard it as other trash.<br>h. Wash hands thoroughly, using soapy water. Soap and water are available at hand wash stations located on site.<br><br>3. After all activity is completed and checked by the supervisor; the supervisor should complete an accident/near miss investigation form or incident report, whichever is appropriate.<br>

-

Fire prevention

-

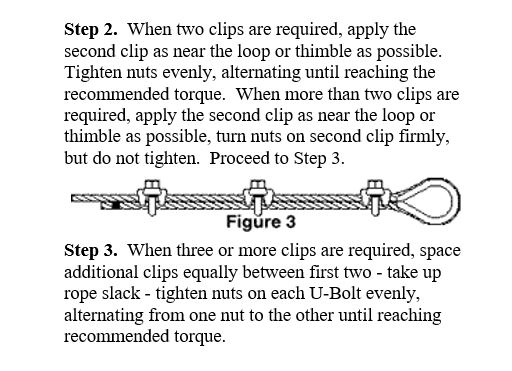

Fire prevention is critical to our operations since we store and handle flammable and combustible materials. Prevention methods include but ae not limited to:<br>- Designated smoking areas<br>- Staging of portable fire extinguishers<br>- Properly storing flammable and conmbustible liquids<br>- Properly dispensing flammable and combustible liquids<br>- Proper use of extension cords<br>- Keep parking areas mowed to prevent grass fires from exhaust systems.<br>These and other prevention methods are key in miniming loss from fire.<br>Portable fire extinguishers (PFEs) are stages in various storage and work areas. PFEs should be stages in areas where they are clearly visible and not subject to physical damage. The HSO or a designated alternate will inspect the PFE monthly to endsure its charged and not damaged. The inspector must then date the back of the inspection card as record of inspection. <br>Should a fire occur you should warn others and contact 911. If safe to do so, you can firght incipient stage fires with a PFE. Use the PASS method illustrated below:<br>

-

-

Confined Space

-

We often encounter Permit-Required confined spaces on our projects. <br> To qualify as a true confined space, an area must meet three requirements. It must:<br><br>- Be large enough for an employee to enter and perform assigned work in<br>- Not be designed for continuous occupancy by the employee<br>- Have limited or restricted means of entry or exit <br> Hazardous atmospheres are the biggest dangers that workers will face in permit-required confined spaces. A hazardous atmosphere is any atmosphere that may expose workers to the risk of death, injury, acute illness or incapacitation, or reduce their ability to escape unaided from a permit-required confined space. <br> Hazardous atmospheres can be caused by flammable or combustible materials in the air, too much or too little oxygen in the air, or chemical substances in the air. <br> Dangerous conditions can be heightened in confined spaces due to their atmospheric conditions and limited means of escape. Small entrances, lack of adequate ventilation, and hazardous atmospheres can pose serious and potentially fatal risks to workers. <br> <br>Never enter a Permit-Required confined space before its atmosphere is tested and has been deemed safe by the site HSO. <br> It is very important that when working in a permit required confined space, that communication with the entry attendant is established and maintained at all times while working in a confined space. If the entry supervisor instructs you to leave the space you must do so immediately.

-

-

Inclement Weather

-

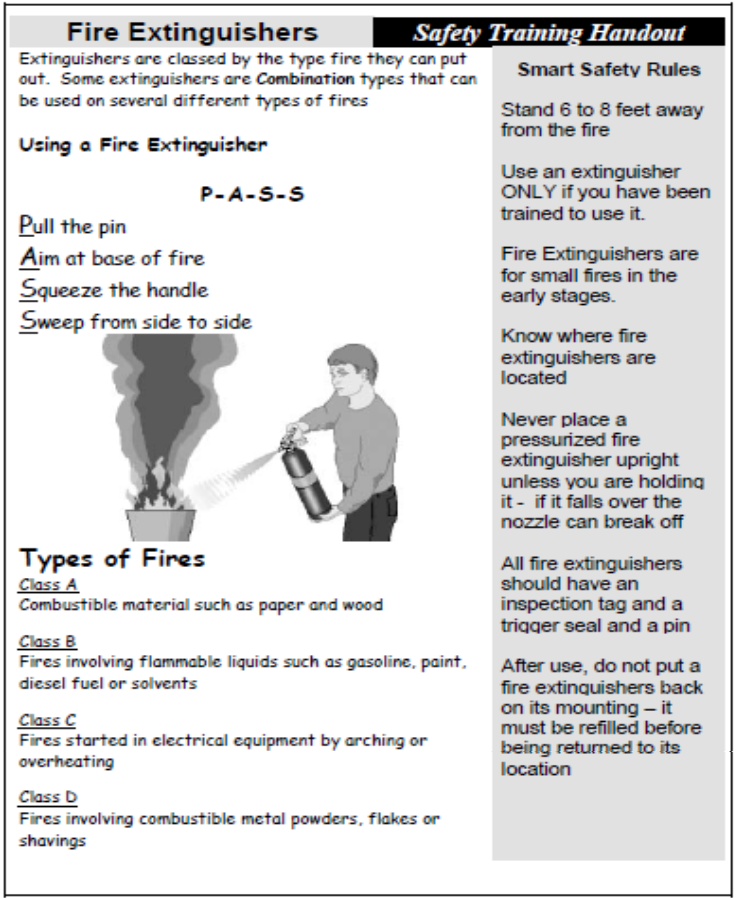

In our industry, weather affects all aspects of the job. Its important to take proper measures to remain safe and minimize risk. There are many weather hazards that we could encounter on our projects, below is a list of weather conditions that could make a job difficult and/or dangerous. <br> Rain showers: Can cause poor visibility and slippery surfaces.<br> Thunderstorms & Lightning: Risk of electrocution by lightning. If lightning is present, immediately leave the structure and seek shelter.<br> Flooding: Flooded areas increase risk of drowning, as well as electrocution due to live circuits in close proximity to water.<br><br>High winds: Strong winds can displace materials and/or equipment creating struck-by hazards, or even potentially cause collapse of structures.<br> Snow & Ice: Frozen conditions can cause materials to become brittle and fail, causing injury. Icy conditions create slippery surfaces.<br> Excessive Heat. Heat Stroke is the number one hazard related to hot environments, below is a photo to differentiate Heat Exhaustion and Heat Stroke.

-

-

Industrial Vacuum Safety

-

When cleaning up spent or recycleable abrasive we use an industrial vacuum to collect it. <br> Anyone who has handled the vacuum hose on our jobs can tell you they are very dangerous.<br>If you are not careful you could be seriously injured or even killed.<br> You should always have a guard installed on the end of the hose while in use to ensure your limbs cannot fit inside.<br><br>A vacuum hose under suction can produce an air velocity of up to 624 miles per hour.<br> In the event that a body part comes in contact with a hose end, you will be unable to pull yourself free. Keep vacuum hoses away from face and body.<br> <br>Concentrated vacuum on the body, such as through a hose end in full contact can result in pulling of<br>organs outside of the body!<br> Vacuum will pull fluids out of the body causing damage to surrounding tissues.<br> These are life threatening injuries. Please be careful while operating the vacuum hose.<br> Also, when PVC pipe is in use as a vacuum line it is important to remember to stay clear of the pipe as it<br>generates static electricity while grit passes through the pipe and can deliver a serious shock.

-

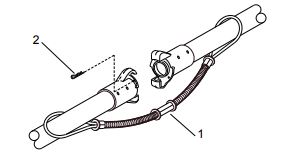

Typical guard installed on hose end.

-

Compressed Air Safety

-

Compressed air is used for many tasks on our projects. It is important to remain aware of all locations that have pressurized vessels and/or hoses around site to minimize risk of injury of death. Minimize the time you are in close proximity to compressed air by avoiding walking or lingering near pressurized equipment. Always de-pressurize equipment before servicing. Whip-Checks must be installed on EVERY connection of air line. (Please See Image Below of a Whip Check Installed). When using compressed air to blow down, the pressure must be turned down to a maximum of 30 PSI.

-

Typical whip check Installed on a hose

-

Installation instruction of whip check

-

COVID-19

-

COVID-19 spreads very easily from person to person<br>How easily a virus spreads from person to person can vary. The virus that causes COVID-19 appears to spread more efficiently than influenza but not as efficiently as measles, which is among the most contagious viruses known to affect people.<br><br>COVID-19 most commonly spreads during close contact<br>People who are physically near (within 6 feet) a person with COVID-19 or have direct contact with that person are at greatest risk of infection.<br>When people with COVID-19 cough, sneeze, sing, talk, or breathe they produce respiratory droplets. These droplets can range in size from larger droplets (some of which are visible) to smaller droplets. Small droplets can also form particles when they dry very quickly in the airstream.<br>Infections occur mainly through exposure to respiratory droplets when a person is in close contact with someone who has COVID-19.<br>Respiratory droplets cause infection when they are inhaled or deposited on mucous membranes, such as those that line the inside of the nose and mouth.<br>As the respiratory droplets travel further from the person with COVID-19, the concentration of these droplets decreases. Larger droplets fall out of the air due to gravity. Smaller droplets and particles spread apart in the air.<br>With passing time, the amount of infectious virus in respiratory droplets also decreases.<br>COVID-19 can sometimes be spread by airborne transmission<br>Some infections can be spread by exposure to virus in small droplets and particles that can linger in the air for minutes to hours. These viruses may be able to infect people who are further than 6 feet away from the person who is infected or after that person has left the space.<br>This kind of spread is referred to as airborne transmission and is an important way that infections like tuberculosis, measles, and chicken pox are spread.<br>There is evidence that under certain conditions, people with COVID-19 seem to have infected others who were more than 6 feet away. These transmissions occurred within enclosed spaces that had inadequate ventilation. Sometimes the infected person was breathing heavily, for example while singing or exercising.<br>Under these circumstances, scientists believe that the amount of infectious smaller droplet and particles produced by the people with COVID-19 became concentrated enough to spread the virus to other people. The people who were infected were in the same space during the same time or shortly after the person with COVID-19 had left.<br>Available data indicate that it is much more common for the virus that causes COVID-19 to spread through close contact with a person who has COVID-19 than through airborne transmission. [1]<br>COVID-19 spreads less commonly through contact with contaminated surfaces<br>Respiratory droplets can also land on surfaces and objects. It is possible that a person could get COVID-19 by touching a surface or object that has the virus on it and then touching their own mouth, nose, or eyes.<br>Spread from touching surfaces is not thought to be a common way that COVID-19 spreads<br>COVID-19 rarely spreads between people and animals<br>It appears that the virus that causes COVID-19 can spread from people to animals in some situations. CDC is aware of a small number of pets worldwide, including cats and dogs, reported to be infected with the virus that causes COVID-19, mostly after close contact with people with COVID-19. Learn what you should do if you have pets.<br>At this time, the risk of COVID-19 spreading from animals to people is considered to be low. Learn about COVID-19 and pets and other animals.<br>Protect yourself and others<br>The best way to prevent illness is to avoid being exposed to this virus. You can take steps to slow the spread.<br><br>Stay at least 6 feet away from others, whenever possible. This is very important in preventing the spread of COVID-19.<br>Cover your mouth and nose with a mask when around others. This helps reduce the risk of spread both by close contact and by airborne transmission.<br>Wash your hands often with soap and water. If soap and water are not available, use a hand sanitizer that contains at least 60% alcohol.<br>Avoid crowded indoor spaces and ensure indoor spaces are properly ventilated by bringing in outdoor air as much as possible. In general, being outdoors and in spaces with good ventilation reduces the risk of exposure to infectious respiratory droplets.<br>Stay home and isolate from others when sick.<br>Routinely clean and disinfect frequently touched surfaces and take other steps to stop the spread at home.<br>Pandemics can be stressful, especially when you are staying away from others. During this time, it’s important to maintain social connections and care for your mental health.<br><br><br>

-

Electromagnetic Frequencies

-

When performing work on towers you may be exposed to EMF's, it is important to note that EMF's may be harmful to your health. Cell towers (or cell sites) that hold antennas and other communications equipment flood the area for miles around with powerful high frequency radio waves (known as microwaves) to support the use of cellphones as well as Wi-Fi, WiMax, Wireless LANs, 802.11 networks, Bluetooth supported devices and more. Cell tower microwaves might travel for as few as two miles in hilly areas, and up to 45 miles where there are fewer obstructions; and of course, they easily penetrate brick and metal Radio masts - Smaller versions of cell towers, often seen on rooftops and billboards, typically installed 800-1300 feet apart. Mobile towers - Sometimes installed on the tops of buildings. Mobile towers are especially dangerous because they emit microwaves at a frequency of 1900 MHz. Recent studies have shown that the intense radioactivity from mobile phone towers adversely impacts every biological organism within one square kilometer. Cellphone tower microwaves have a significantly higher frequency than even radio waves. The higher the frequency, the more powerful the wave—and the more powerful effect on biological organisms (recall that a mobile tower emit microwaves at 1900 MHz). Microwave radiation can also interfere with the natural processes involved in DNA replication and repair, by subtly altering molecular conformation (architecture). Another possibility of DNA damage is via free radical formation inside cells. Free radicals kill cells by damaging macromolecules, such as DNA, protein and membrane and are shown to be carcinogenic. Several reports have indicated that electromagnetic fields (EMF) enhance free radical activity in cells. The Fenton reaction is a catalytic process of iron to convert hydrogen peroxides, a product of oxidative respiration in the mitochondria, into hydroxyl free radical, which is a very potent and toxic free radical. Thus EMF affects the DNA via an indirect secondary process. Damage to DNA is a central mechanism for developing tumors and cancer. When the rate of damage to DNA exceeds the rate at which DNA can be repaired, there is the possibility of retaining mutations and initiating cancer. DNA damage in brain cells can affect neurological functions and also possibly lead to neurodegenerative diseases. Please review the following RF Safety PDF to learn more about antenna types and risks involved in working around EMF.

- I understand and have read the RF Safety PDF

-

Please read the PDF below.

-

Chemical Spills

-

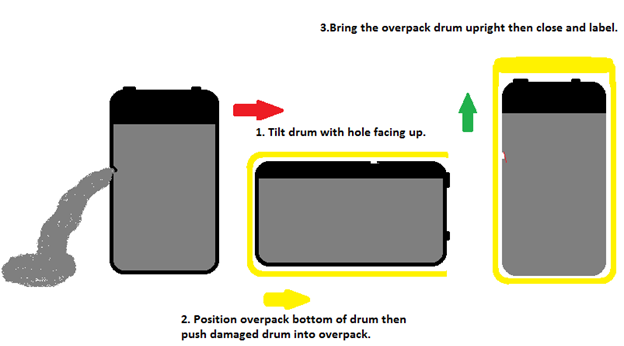

Chemical Spill <br>Designated chemical storage areas shall be established upon the start of work. Separate lockable storage area will be capable of housing a limited quantity of hazardous material and hazardous waste in liquid and solid physical states.<br> Each designated storage area will be equipped with passive venting, a portable fire extinguisher and a spill kit. Spill kits will contain a sufficient number and type of supplies compatible with twenty-five percent (25%) of the total volume of hazardous material contained within the storage unit. The type of spill control material can be derived from the hazardous material’s Safety Data Sheet (SDS) section, ”Accidental Release Measures” .<br>Bulk storage of hazardous materials shall always be maintained under the material’s Reportable Quantity (RQ) limit established by the Department of Transportation (DOT). For example Methyl Ethyl Ketone (MEK) has a reportable quantity of 5000 pounds. 1 gallon = 6.68 pounds x 55 gallons = 367 pounds/55 gallon drum. Therefore 367/5000 = 13 gallons. <br> IMPORTANT NOTE: As the project progresses, storage of hazardous material and waste can and should be minimized through Just in Time (JIT) management. JIT management stores the minimum quantity of hazardous material onsite with replenishment upon one or two days of notification to the hazardous material’s supplier.<br>In order to minimize spills and releases, workers shall properly and compliantly handle and dispense hazardous materials. <br>Proper safe handling practices include but are not limited to:<br> Staging drums on a containment cell.<br> Safely position and secure drum(s) that require movement on a sturdy pallet in good condition. <br> Ensure container bungs and lids are firmly in place before moving and when not in use.<br> Establish a safe path of travel prior to moving.<br> Drive slowly and gently brake. <br> Proper dispensing practices include but are not limited to:<br> Safe removal of the hazardous material from the container.<br> Safe dispensing of waste materials into a designated storage drum.<br> Bonding of the container whenever dispensing flammable materials.<br> Proper drainage of pump hoses.<br> <br>Every effort should be made to minimize spills and releases when handling hazardous materials and waste. All containers must be properly labeled with the correct information which will serves to promote an efficient and effective response should it become required. <br>In the event of spill the following guidelines should be observed:<br> Notify affected personnel in the immediate area;<br> Extinguish all nearby ignition sources regardless of material; <br> Protect sensitive environmental receptors;<br> If drum with side puncture that has all bungs in place follow the illustration below:<br>

-

-

Other

-

Please explain what other topics were discussed.

Employee Acknowledgement and Signature

-

I have received training in the requirements of Allied Painting Inc's Lead Health and Safety Plan (LHASP) and understand that it is my responsibility to comply with these requirements as a condition of employment on this project, including all Safety, Health, Environmental, and Hazardous Waste handling procedures. I agree to these conditions.

I have been notified of the hazards involved in this project and understand that I have a right to access records of both my medical evaluations and information, and any exposure information pertaining to work on this project.

I have discussed the topics listed on the above checklist with the project HSO.

I understand it is my responsibility to demonstrate safe working habits on all job assignments. I have been trained in the use and care of the PPE issued to me, and understand it is my responsibility to inspect my equipment before each use.

Furthermore, I understand that I may be subject to disciplinary action if I violate company policy. -

By signing this form you agree to the above statement.

PPE Issuance

-

Was any PPE issued?

-

Please check all items that were issued to employee.

-

Hard Hat

-

Ear Plugs

-

Safety Vest

-

Harness

-

Lanyard

-

Life Vest

-

Safety Glasses

-

Retractable Lanyard

-

Protective Work Clothing

-

Respirator

-

What type of respirator was issued?

-

What size?

-

What size?

-

What brand and model of Blast Hood was issued?

PPE Acknowledgement

-

By signing you acknowledge that Allied Painting Inc issued the PPE selected above, and that it is your responsibility to protect and maintain the equipment that is issued to you. In the event that your PPE becomes damaged you will be issued a replacement.

-

Employee Signature: