Information

-

Warehouse Name

-

Address

-

How large is the warehouse? (describe, sq ft, made up of # buildings etc.)

-

How many entrances into the warehouse are there?

-

About how many coworkers work at this location?

-

Conducted on

-

Prepared by

References

-

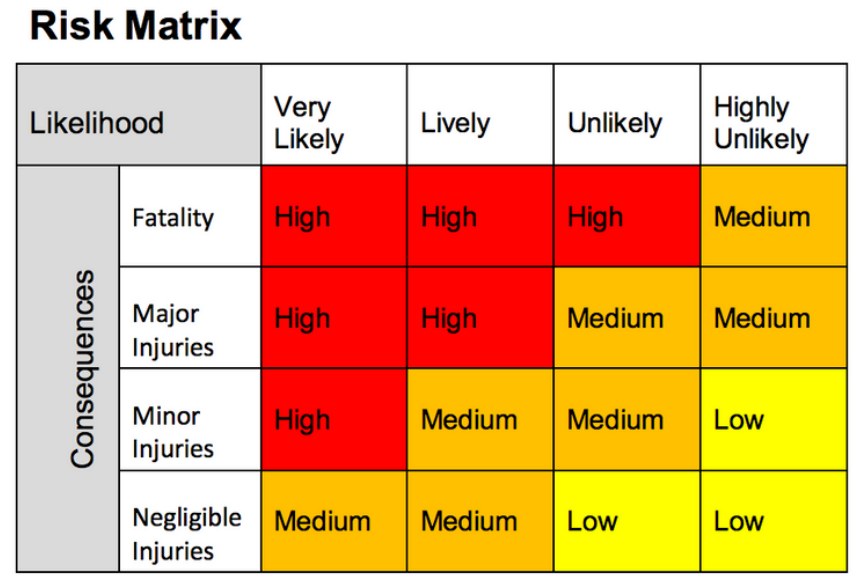

Risk Matrix Reference

-

Risk - An estimate of the probability of a hazard-related incident or exposure occurring and the severity of harm or damage that could result. (ANSI/ASSE Z590.3-2011)

Level of Risk - Magnitude of a risk or combination of risks, expressed in terms of the combination of consequences and their likelihood. (ISO Guide 73/ANSI/ASSE Z690.1- 2011)

Likelihood - Chance of something happening. (ISO Guide 73/ANSI/ASSE Z690.1- 2011)

Risk Matrix - Tool for ranking and displaying risks by defining ranges for consequence and likelihood. (ISO Guide 73/ANSI/ASSE Z690.1-2011)

Hierarchy of Controls - A systematic approach to avoiding, eliminating, controlling, and reducing risks, considering steps in a ranked and sequential order, beginning with avoidance -

Hierarchy of Controls Reference

General Safety

General Safety

-

Dress code being followed (No open toed shoes, no rings, no watches, necklaces tucked in, etc.)

-

Adequate periodic rest breaks to avoid fatigue levels that could result in greater risk of accidents and reduced quality of work.

-

Hearing protection being worn where required.

Housekeeping

Housekeeping

-

Areas are free of tripping hazards.

-

Aisles free from obstructions such as skids, equipment, shelves.

-

Floors are clean and free from slippery substances such as water, oil, etc.

-

Scrap metal, pallet banding straps, plastic wrap, wood, box cutter blades, etc. deposited in the proper containers.

Walking Working Surfaces/Fall Protection

FALLS OR FALLING OBJECTS

-

All staircases secure and fitted with suitable handrails.

-

Exposed or open loading dock doors and other areas that employees could fall 4 feet or more or walk off are chained off, roped off or otherwise blocked.

-

Ladders, platforms, step stools and other equipment for working at heights in good repair and suitable for the task.

-

Materials and objects adequately stored or stacked to prevent them from falling and causing injury.

-

Fall protection equipment (harnesses, lanyards, etc.) inspected by a competent person once a year.

-

Records kept?

Material Handling and Equipment

Material Handling Equipment

-

Are all containers, skids, pallets, materials, and equipment arranged neatly and orderly in assigned areas.

-

Only certified personnel operating fork lifts

-

How are certified drivers tracked? (infolink, badge, etc.)

-

Approved Safety cutters

-

Only approved safety knives are being used.

-

Pallets properly banded or secured for shipment.

-

Forklifts and pallet jacks in good condition.

-

Material stored so it does not block sprinkler heads, alarm systems, electrical panels, or access to fire extinguishers? (A minimum clearance of 3 feet )

-

There is adequate clearance from overhead light fixtures when placing material overhead.

-

Pallet jacks are stored in a manner that would minimize the possibility of tripping (under load and handle turned sideways).

-

Nameplates and markings are in place and maintained in a legible condition.

-

Battery charging is conducted only in designated areas.

-

Precautions are taken to prevent smoking, open flames, sparks or electric arcs in battery charging areas (signage).

- Safe

- At Risk

- N/A

-

Refresher training and evaluation is conducted whenever an operator has been observed operating the vehicle in an unsafe manner or has been involved in an accident or a near-miss incident.

-

Evaluations of each operator’s performance are conducted at least once every three years.

-

Load engaging means are fully lowered, with controls neutralized, power shut off and brakes set when a forklift is left unattended.

-

There is sufficient headroom for the forklift and operator under overhead installations, lights, pipes, sprinkler systems, etc.

-

Operators observe all traffic regulations, including authorized speed limits.

-

Dock plates are properly secured when loading or unloading.

LIFTING AND HANDLING

-

Mechanical equipment, such as conveyors, fork lifts, lifts, etc. are used to avoid manual handling.

-

Coworkers are properly trained in lifting and other manual handling techniques.

Electrical Safety

-

No electrical cords with frayed wired, loose ends, broken insulation, etc.

-

Fans have protective covering with no damage.

-

Outlets are not damaged and do not show signs of burning.

-

The facility has lockout/tagout procedures.

Environmental

Air Quality

-

Temperature, ventilation, and lighting are adequate.

-

Ventilation systems regularly inspected, tested and maintained.

-

Air inlets and exhaust free of accumulation of dust and mold.

Waste

-

Universal Waste locations set up and maintained (accurate signage).

-

Recycles: Bottles/Cans, Paper, Batteries, Toner.

-

Who is responsible for the Universal Waste in the building:

-

Coworkers know what to do with old/used batteries and equipment.

Hazard Communication

Hazard Communication Safety

-

All hazardous materials containers are properly labeled, indicating the chemical’s identity, the manufacturer’s name and address, and appropriate hazard warnings.

-

There is an updated list of hazardous chemicals.

-

The facility has a written program that covers hazard determination, including Safety Data Sheets (SDSs), labeling and training.

-

There is a system to check that each incoming chemical is accompanied by a SDS.

-

All employees are trained in the requirements of the hazard communication standard, the chemical hazards to which they are exposed, how to read and understand a SDS and chemical labels, and on what precautions to take to prevent exposure.

-

All employee training is documented.

-

Employees use proper personal protective equipment when handling chemicals.

-

All chemicals are stored according to the manufacturer’s recommendations and local or national fire codes.

Fire Safety

Fire Safety

-

Fire extinguishers are all accounted for and have been inspected as per NFPA 10.

-

Check the inspection Tag.

-

Exits, aisles, evacuation routes, and fire alarm pull stations are unblocked.

-

Pull stations are properly housed/ in tact.

-

All exit signs and evacuation lights are fully operational.

-

Debris, discarded packing materials, trash, and flammable items are in proper waste bins (nothing is accumulating where it shouldn’t).

-

Extension cords and electrical equipment are being used properly; no extension cords are being used long-term or connected to each other.

-

Nothing is hanging from fire sprinkler/suppression systems lines, heads, nozzles.

-

Fire pump riser rooms are empty – nothing should be stored in these.

-

Flammable/combustible liquids are in safety cabinets and stored per OSHA1926, NFPA30, and your local Authorities Having Jurisdiction (AHJ) guidelines.

Emergency Management & Response

-

Designated Severe Weather Shelter Areas exist (Away from windows, external walls, clearly marked).

-

There are designated Emergency Response Team (ERT) members.

-

ERT up to date and accurate with who is on site.

-

All emergency exits visible and properly marked.

-

Coworkers know and are trained on the evacuation procedures.

-

Emergency Maps posted and up to date.

-

Designated Evacuation Assembly area(s) visible and located at safe distance(s).

-

Emergency contact list up to date.

-

Date of the last time the facility had a drill:

First Aid

-

First aid kit(s) available and in good condition.

-

Total number of First Aid Kits on site:

-

Who checks the First Aid Kit(s):

-

How often is the First Aid Kit checked:

-

Sufficient supplies<br>*See OSHA Link below for First Aid Kit Requirements*

-

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.266AppA

-

First aid kits don't contain prescription or over-the-counter medications such as aspirin, Ibuprofen, decongestants, sinus relief, etc. (due to not being first aid/ liability risk there should not be any of these in the first aid kit)

-

No defective item(s).

-

Nothing out-of-date/expired.

AEDs

-

Total number of AEDs on site:

-

Make/Model of AEDs utilized:

-

AEDs inspected by:

-

AEDs inspected monthly and in good condition (pads not expired, no missing supplies)

Coworker Awareness (Ask 3 Coworkers)

-

Provide Coworker with answer if they do not know.

-

Coworker 1

-

Do you know what the ERT is?

-

Do you know where an AED is located?

-

Do you know where a First Aid Kit is located?

-

Do you know what to do in an emergency? (Fire, tornado)

-

Person 1 signature

-

Coworker 2

-

Do you know what the ERT is?

-

Do you know where an AED is located?

-

Do you know where the first Aid Kit is located?

-

Do you know what to do in an emergency? (Fire, tornado)

-

Person 2 signature

-

Coworker 3

-

Do you know what the ERT is?

-

Do you know where an AED is located?

-

Do you know where the First Aid Kit is located?

-

Do you know what to do in an emergency? (Fire, tornado)

-

Person 3 signature

Trailer Yard

-

Yard is clear of major obstructions and has clear passageways for vehicle traffic.

-

Yard is free of debris (Pallets, trash, etc.)

-

Trailer yard access is restricted.

Parking Lot

-

Parking lot is clear of debris.

-

Sidewalks, ramps and walking surfaces in good repair.

-

Mirrors or STOP signs posted at blind spots.

-

Directional signs posted and are legible.

-

Lot paved, lines & directional arrows visible.

-

Vegetation is trimmed away from walkways & entrances.

-

No tripping hazards, Curbs, Holes, Debris.

-

Designated pedestrian walkways.

-

Designated handicapped parking spots (ADA compliant: 8 foot wide with 5 foot access aisle between parking spaces? Signage?)

- Safe

- At Risk

- N/A

-

Are ramp slopes to entrance provided.

-

Lot bumpers secured. Easily identified.

Required Postings

-

State, Federal law and OSHA “Job Safety and Health - It’s the Law” Poster posted in easily accessible location where coworkers will see them.

-

OSHA 300A (injury and illness summary data) Log signed and posted from 02/01 until 04/01 each year, in a common area where any coworker can easily see it.

Visitor Safety/Security

-

Is there building security on site?

-

What is the name of the security company?

-

Metal detectors working as intended.

-

Visitors Safety Guide Brochure/ Visitor Guidance available at entrance and current/up to date.

-

There are cameras that cover this warehouse.

-

Ask GSOC if all cameras are operational (add note of what cameras are not)

Completion

-

Any other observations or recommendations

-

Full Name and Signature of the Inspector