Title Page

-

Conducted on

-

Prepared by

-

Location

Work Areas

-

Is safety signage, labelling in good condition and not missing? (Examples: Pinch Point, Electrical Hazard, Fire Extinguishers, Eye Wash Stations, etc.)

-

add detailed notes and create action item

-

Are communication postings current or in date? (Example: OSHA Log, Safety Communication Boards, etc.)

-

add detailed notes and create action item

-

Are pallets, packing materials, waste stored safely in the right place? (Example: No higher than 25 pallets in a stack, pallets not overhanging racking, pallets not leaning against the wall)

-

add detailed notes and create action item

-

Is lighting adequate (Ask two employees)

-

Who did you ask?

-

Who did you ask?

-

Are racks, storage shelves in good condition

-

add detailed notes and create action item

-

Is the area clear of slip, trip, and fall hazards?

-

add detailed notes and create action item

-

Is there adequate space, aisles, work space (36-42 inch aisles maintained clear)?

-

add detailed notes and create action item

First Aid Facilities

-

Is there at least one fully equipped first aid box available nearby?

-

add detailed notes and create action item

-

Are first aid supplies within their expiration date drugs, eyewash bottles)?

-

add detailed notes and create action item

-

Are eyewash stations within expiration date and not leaking?

-

add detailed notes and create action item

-

Do workers know who is qualified persons to render first aid (ask one employee)

-

Who did you ask?

Machine, Equipment, Ladders

-

Are employees using machines safely?

-

add detailed notes and create action item

-

Does equipment/ machinery appear safe and in good condition?

-

add detailed notes and create action item

-

Are safeguards provided for all hazardous moving parts? (i.e., catch points, snag points protected?) Take a picture of all safeguards provided

-

add detailed notes and create action item

-

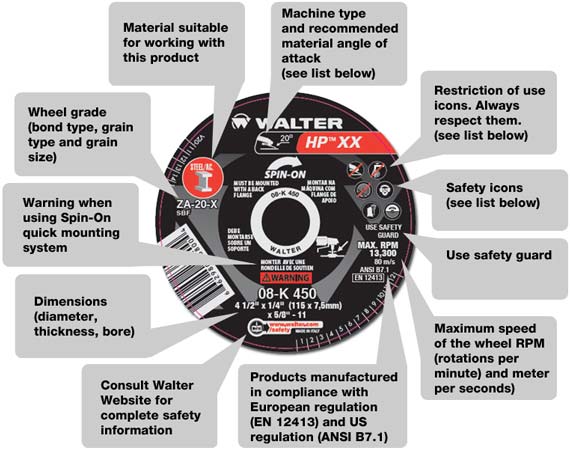

Abrasive wheel grinder guide

-

Abrasive wheel grinders - is tongue guard at 1/4” & tool rest at 1/8” (use guide)?

-

add detailed notes and create action item

-

Are portable/fixed ladders/stairs in good condition, labeled, properly stowed? (secured to support in an upright position, rubber feet attached, tightly constructed)

-

add detailed notes and create action item

Electrical Safety

-

Are wires or wire connections free of damage and in good condition?

-

add detailed notes and create action item

-

Do all electrical panels have at least 36" unobstructed clearance?

-

add detailed notes and create action item

-

All power strips & extension cords free of “Daisy Chaining”?

-

add detailed notes and create action item

-

No more than one power strip plugged into the outlet?

-

add detailed notes and create action item

-

Are all switchboxes, panels and sockets provided with suitable cover (knockouts)

-

add detailed notes and create action item

-

No flexible drop cords running through unprotected holes or lacking strain relief?

-

add detailed notes and create action item

-

Are extension cords free of damage and being used properly? (temp. Only 90 days max, ask someone

-

Is LOTO being used when working on equipment? (Observe or ask an employee)

-

add detailed notes and create action item

Personal Ergonomics, training and PPE

-

Are the employees practicing good ergonomics? (Observe)

-

add detailed notes and create action item

-

If lifting aides are available are they being used? (Observe, ask)?

-

add detailed notes and create action item

-

Are the employees using proper PPE?

-

add detailed notes and create action item

-

Have employees been properly trained on the use of PPE? (Ask an employee)

-

add detailed notes and create action item

-

Is all PPE in good condition and maintained? (Example: are respirators stored properly)

-

add detailed notes and create action item

-

Is the proper PPE available when needed?

-

add detailed notes and create action item

-

Are respirator cartridges within the effective use dates?

-

add detailed notes and create action item

-

Are employees trained in lifting and other manual handling techniques (ask employee)?

-

add detailed notes and create action item

-

Are office staff trained on proper computer workstation design (VDT’s) (ask one employee)?

-

add detailed notes and create action item

-

Do the employees seem sufficiently focused on their job?

-

add detailed notes and create action item

Emergency Exits, Fire and Safety Equipment

-

Are all emergency exits free from obstructions?

-

add detailed notes and create action item

-

Are all emergency exits clearly marked with illuminated or self-illuminated signs?

-

add detailed notes and create action item

-

Are fire extinguishers accessible within 75 feet and locations marked (on floor and above)?

-

add detailed notes and create action item

-

Have employees been instructed in the evacuation procedures (Ask employee)?

-

add detailed notes and create action item

-

Is the proper fire and safety equipment available and inspected?

-

add detailed notes and create action item

-

Are fire pull stations free of obstructions?

Handling Hazardous/Non-Hazardous Materials

-

Are all containers including secondary containers properly labeled and stored? (i.e., closed) - Provide photos

-

add detailed notes and create action item

-

Are all containers free of damage such as bulging and rusting, crusting, evident leakage?

-

add detailed notes and create action item

-

Are containers stored away from incompatible materials/ chemicals by means of a separate spill pallet or another form of containment?

-

add detailed notes and create action item

-

Is there a spill kit available in the area where hazardous/non-hazardous material stored?

-

add detailed notes and create action item

-

Are SAA (Satellite Accumulation Area) & HWSA (Hazardous Waste Storage Area) being inspected? (Wiscasset only)

-

add detailed notes and create action item

-

Is suitable PPE available for handling hazardous/non-hazardous materials?

-

add detailed notes and create action item

-

Do employees know what to do if there is a spill (ask an employee)?

-

add detailed notes and create action item

-

Have employees been trained on the hazards of the materials (ask an employee)?

-

add detailed notes and create action item

-

Are Safety Data Sheet (SDS) readily available for reference if needed (ask an employee for the location)?

-

add detailed notes and create action item

-

Are all materials/chemicals within their expiration dates?

-

add detailed notes and create action item

Building exterior

-

Is night time lighting adequate?

-

add detailed notes and create action item

-

Are loading dock areas free of trash and debris?

-

add detailed notes and create action item

-

Are all hydraulic lines on compactor in good condition?

-

add detailed notes and create action item

-

Are all emergency exits free of obstacles?

-

add detailed notes and create action item

-

Are walkways, entrances and stairways clear of snow/ice in winter months?

-

add detailed notes and create action item

-

Are all areas salted or sanded during winter months?

-

add detailed notes and create action item

-

Are there no visible dangers present during winter months? (ice build- up overhead slip hazards, etc.)

-

add detailed notes and create action item

-

No unsecured/unlocked “attractive nuisances” that others can access, i.e., ladders, hazardous or flammable materials, etc.<br>

-

add detailed notes and create action item

Quality (Speak to area employees to answer quality questions)

-

Is there a cross-training plan in place?

-

add detailed notes and create action item

-

Are product specifications known?

-

add detailed notes and create action item

-

Are proper non-conformance handling procedures being practiced?

-

add detailed notes and create action item

-

Are procedures periodically reviewed?

-

add detailed notes and create action item

-

Is A3 problem solving taking place?

-

add detailed notes and create action item

-

Is non-conforming material being segregated from conforming material?

-

add detailed notes and create action item

-

Are materials identified and is the location accurate on the label?

-

add detailed notes and create action item