Information

-

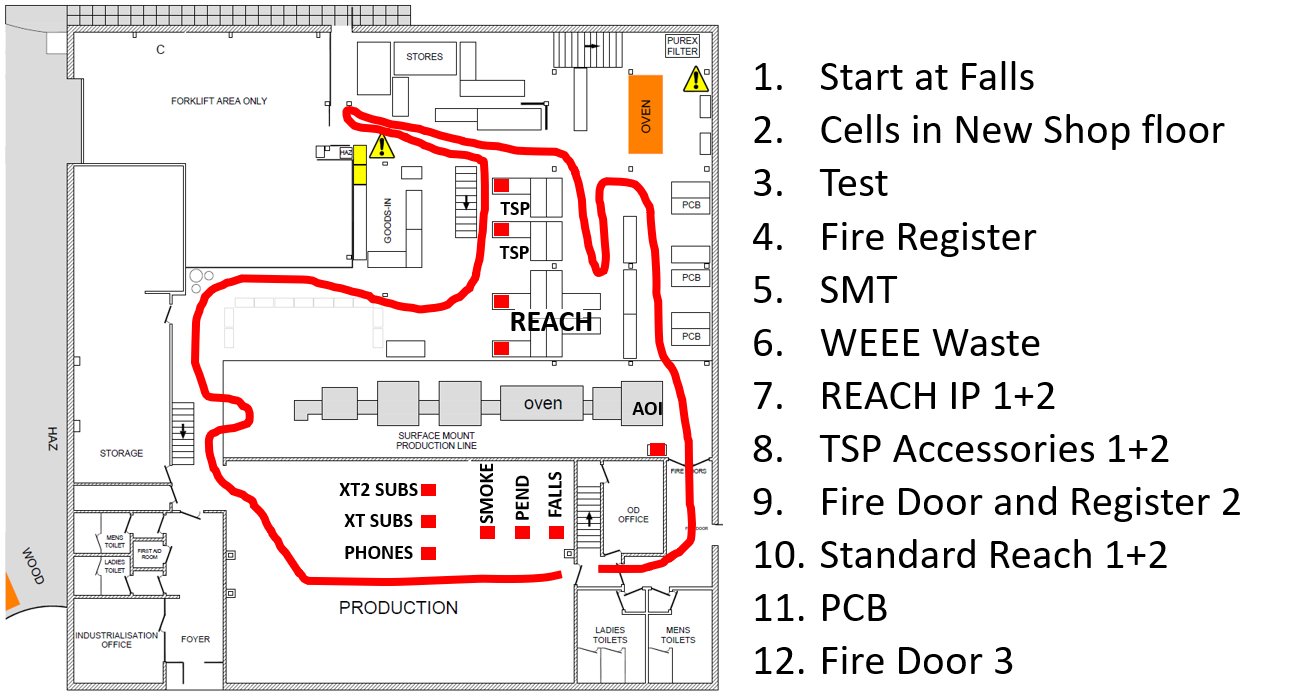

Date and Time of Field Tour

Tynetec Field Tour

-

Use this audit to assess the following aspects of this site as Safe, At Risk or Not Applicable. Unsafe response indicate that attention is required to bring items to a satisfactory standard. Notes and photos should be attached where appropriate, particularly to At Risk items. You will also be auditing 5S and PTA compliance.

Inspection Areas

-

New Shop Floor

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Cell Storage (stock is stored safely) across whole of the new shop floor

-

Plan to Actual - FALLS

-

Plan to Actual - PENDANTS

-

Plan to Actual - SMOKES

-

Plan to Actual - PHONES

-

Plan to Actual - INTERCOMS

-

Required PPE in use?

-

Test Cell In Use

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Cell Storage (stock is stored safely)

-

Test rigs and equipment stored away if not in use

-

Fire Register 1 - Up To Date?

-

SMT in Use

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Walkways are clear of trolleys/trip hazards

-

Machine Safety Checklist is Up To Date

-

Efficiency spreadsheet is up to date (fail +/- 20%)

-

Shopfloor Waste Area Requires Attention

-

Which bins?

- Lithium

- Alkaline

- Lead Acid

- WEEE Waste Bins

- Face Masks

-

Drilling Area Safety

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Floor and bench area is clear of stock/work pieces

-

Machine Safety Checklist is Up To Date

-

Electrics are switched off if not in use (including drill)

-

Reach IP Cells In Use

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Cell Storage (neat, tidy, safe)

-

Plan to Actual - Cell 1

-

Plan to Actual - Cell 2

-

TSP Accessory Cells In Use

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Cell Storage (neat, tidy, safe)

-

Plan to Actual - Cell 1

-

Plan to Actual - Cell 2

-

Fire Door and Register 2 - Clear and Up to Date?

-

Stores (Ground Floor)

-

Walkways clear of tripping hazards

-

Machine safety check is completed

-

Forklift daily check sheet completed

-

Forklift area is clear of obstructions

-

Chemical cabinets locked

-

Pallet trucks safely located if not in use

-

Correct PPE is being worn

-

Stores (First Floor)

-

Walkways clear of tripping hazards

-

Pallet trucks safely located if not in use

-

Correct PPE is being worn

-

Customer Repairs

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Storage (repairs are stored safely)

-

Test rigs and equipment stored away if not in use

-

Walkways clear of tripping hazards

-

Correct PPE is being worn

-

Standard Reach Cells In Use

-

General Housekeeping (neat, tidy, dust free) - 5S

- Good

- Fair

- Poor

- N/A

-

Cell Storage (neat, tidy, safe)

-

Plan to Actual - Cell 1

-

Plan to Actual - Cell 2

-

PCB in Use

-

General Housekeeping (neat, tidy, dust free) - 5S

-

Walkways are clear of trolleys/trip hazards

-

Machine Safety Checklist is Up To Date

-

Efficiency spreadsheet is up to date (fail +/- 20%)

-

Fire Door 3 - Clear

General Comments

-

Any further comments or recommendations arising from this inspection?

-

Add any additional relevant photos

-

Have all required corrective actions been added as Actions to this inspection?

-

Please add any corrective actions to the appropriate questions above before completing this report

Sign Off

-

Name & Signature of Inspector