Unit details

-

Machine type and Unit No

-

Conducted on

-

Location

-

Engine hour meter reading

Prepared by

-

Name

-

SAP No

Washing prior to inspection / repair

-

Has the machine been thoroughly cleaned?

-

If no machine must be thoroughly cleaned first before entering workshop.

-

Open all covers

-

Remove spiral wrap

-

Spread degreaser over the boom(s) / feed

-

If the machine is thoroughly cleaned then drive the machine to the workshop

-

Ensure machine and work area are compliant with all safety requirements

Booms

-

Check all bushings and pins for play

Boom swing / lift cylinders

-

Check for leaks

-

Check for any visible play in taper pins

Boom swing / lift shafts

-

Check main boom swing shafts for damage

-

Check main boom swing shafts for play in pins and bushings

Feed swing / tilt cylinders

-

Check for leaks

-

Check for visible play in taper pins

Bolting cylinder

-

Check for leaks

Feed extension

-

Check for leaks

-

Check for visible play in taper pins

Feed

-

TFX

-

Functions

-

Valves working

-

Set feed vertical and check that the drifter doesn't fall down

Feed cylinder

-

Check for leaks

-

Check bushes and pins for wear

Feed wire ropes conditions

Sliding pads condition

-

Mounting bolts tightness

Drifter bolts

-

Check tightness of cradle bolts

-

Check tightness of body bolts

-

Check accumulator pressures

Cable reel

-

Check the condition of the steel strand mechanism drive wheels

-

Check condition

Cement system

-

Check the condition of the cement pump non return valve by removing the non-return valve housing.

-

Check there is no hardened cement in it

-

Check the condition of the cement mixer blades

-

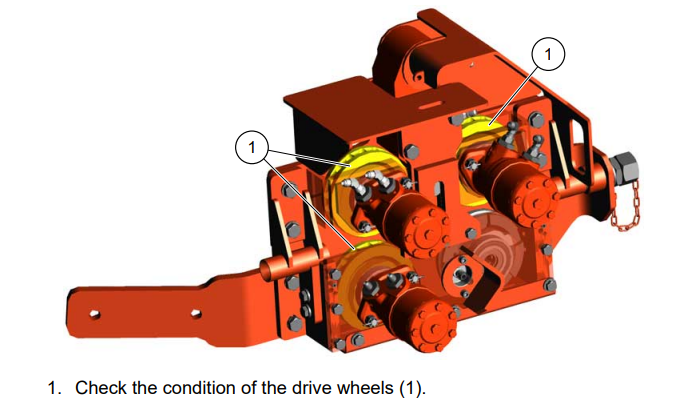

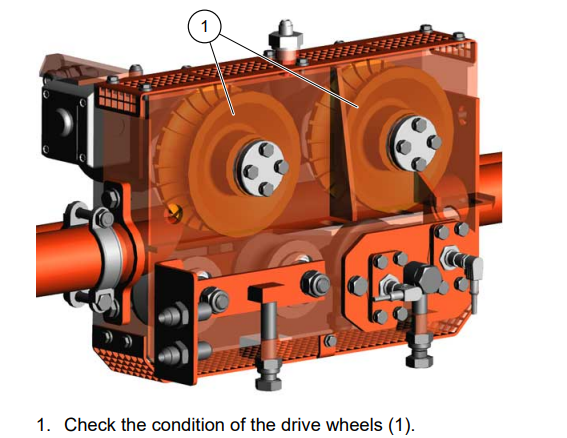

Check the condition of the cement hose feed drive wheels

-

Replace if necessary

-

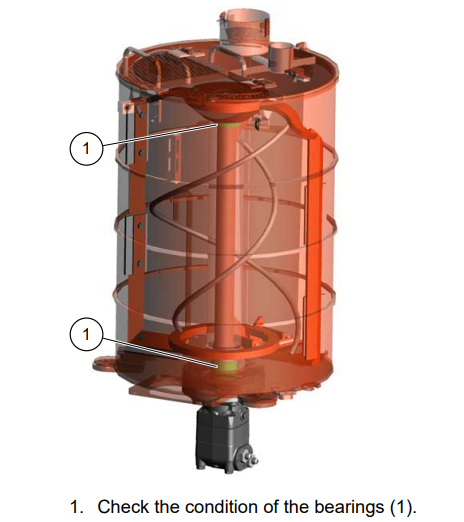

Check the condition of the cement mixer bearings

-

Replace if necessary

-

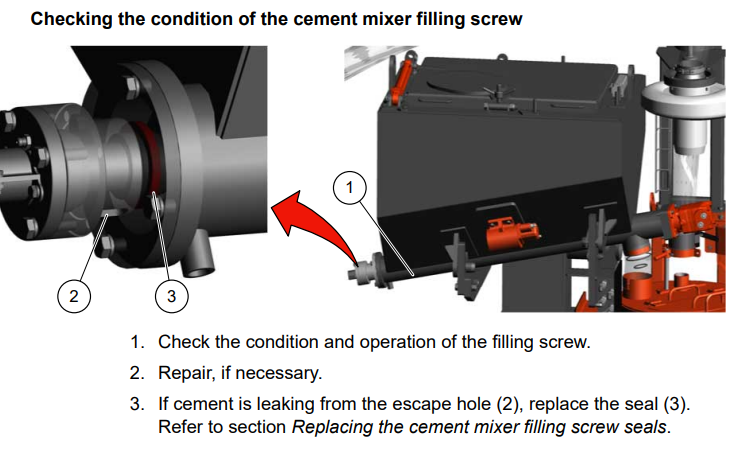

Check the condition of the cement mixer filling screw

-

Replace if necessary

Rod changer

-

Check the condition, position and fastening of the cassette's dividing plate

-

Check the tightness of the jaws

-

Check the adjustment of the gripper pads

-

Check the condition of the gripper jaws

Carrier

-

Lights

-

Emergency buttons operation

Compressor

-

Hour meter reading

-

Check for oil leaks

-

Check oil level

-

Check belts condition

-

Check control valve function

-

Compressor ON

Steering

-

Check for oil leaks

-

Check cylinder pins and bushes for wear

Brakes

-

Complete brake test

-

Check accumulator conditions

-

Check brake pressure gauge function

Engine

-

Check engine oil level

-

Check coolant level

-

Check and record all alarms if present

-

Check belts condition

Sign off sheet

-

Have all faults been rectified or had notifications generated

-

Signature

-

SAP No

-

Date