Title Page

-

Conducted on

-

Prepared by

-

Location

General Information

Prior To Arrival On Site

-

Prior to starting work please ensure you have received authorisation from Sanford Ltd to perform the work.

Auckland Engineering Coordinator: 02108129196

Auckland Fleet Engineer: 0272790940.

Auckland Operations Manager: 0276291088.

Inform your contact & agree on: arrival, site access requirements & work arrangements prior to arrival.

Inform Sanford Ltd prior to arrival if:

Sub contractors are to be used.

Staff need a site induction.

Worksafe NZ or Port notifications are required (contractors responsibility to complete these)

Check the work order for the scope of work.

*****NO WORK ORDER, NO WORK****

Do staff have required competency for the work required:

Work at heights

Confined space entry

Do you have the right PPE for the job

Respirators

Hearing protection

Safety glasses

Cold Protection (hat coat, gloves)

PPE to be approved to NZ standards.

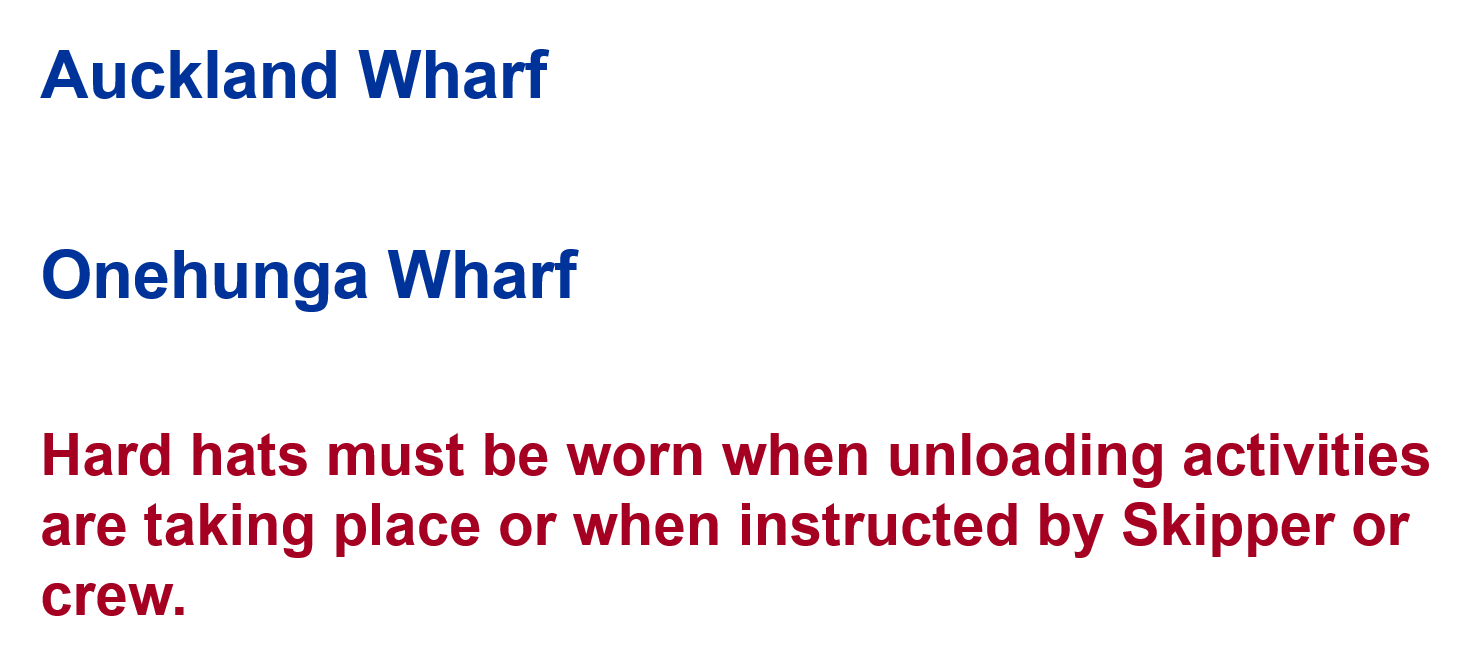

Wharf Entry

-

Auckland Viaduct Wharf: this is a public wharf. Extra care must be taken when accessing this wharf.

-

Entry to Onehunga Wharf: All warning signs to be adhered to

Vessel Entry & Exit

-

Tongariro & Rakaia

Before entry onto the vessel, place your identification card (i.e. business card, drivers licence) in the pockets on the vessel boarding board.

Entry & Exit ONLY via the gang way

On leaving (and evacuation) remove card from board.

You must contact Sanford Auckland engineering. before boarding & after exiting the vessel.

Personal Protective Equipment

-

PPE

Working Alone & After Hours

-

Working alone on any Sanford vessel is prohibited.

Site Induction

-

All contractors entering the work site shall be inducted.

This induction covers Sanford Vessels. You will need a separate induction for land based premises.

All sub contractors you hire must receive this induction and records of this induction must be passed onto Sanford when completed.

Ongoing inductions to be completed by your employer.

This induction is to be repeated every year.

Emergency Evacuation Vessels

-

In An Emergency:

Raise the alarm.

Remove your card from the Vessel Entry Board

Leave the vessel via the gangway.

Assemble at the bottom of the gangway.

DO NOT leave the muster point Until the All Clear is given.

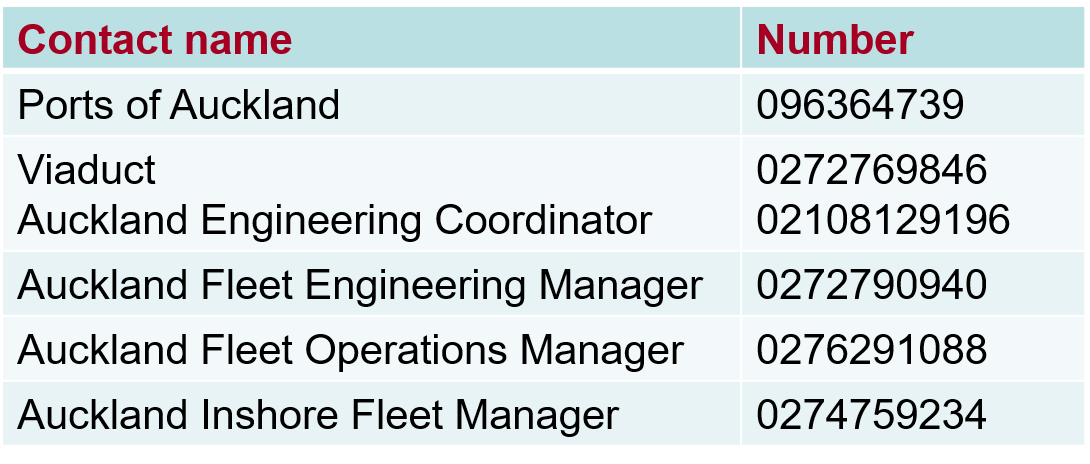

Emergency Contacts

-

Contact Numbers

Spills to water

-

Spills into waterways are unacceptable environmental events to which vessels must take extreme care to prevent.

Spills include: Oil, fuel, hydraulic fluid, sewerage, cleaning chemicals & garbage.

None of these can go into the water.

When any material enters the water the level of an incident escalates & we must notify the Port & Regional Council regardless of the amount spilled.

Preventing Spills To Water

-

Remove all materials & chemicals before working on equipment.

Isolate all service connections (oil, chemical, sewerage etc)

Know who to report to in an emergency & where to find them.

Know where the nearest spill kit is on the vessel.

Close all scuppers & drains.

If material may be spilled during work lay an oil absorbent boom around the equipment prior to starting work.

Erect curtains to contain solid materials or dust particles from entering the waterway during work.

Have enough absorbent material in place to contain any spills that occur when the equipment is opened up.

After spill has been cleaned up, ensure it is disposed of as per SDS.

Ensure you understand the spill risk when performing your risk assessment prior to starting work.

If a spill occurs stop the flow, contain the material & report it immediately.

Business Security & Communications

-

All information obtained during your visit is to be used only in accordance with the purpose of your visit.

The following are not permitted without prior authorization:

No removal of Sanford business information in any format.

No photographs, videos or sound recordings.

No disclosure of information to third parties.

No response to requests for information from third parties.

No visitors, guests or family on site.

Enquires regarding the above shall be directed to the relevant Vessel Manager in advance.

Bunkering

-

No smoking or hot work on the vessel or wharf when the vessel is bunkering.

Fueling is when RED (bravo) flag is raised.

No smoking inside the vessel.

Hazards On Vessels

-

Overhead loads and cranes / booms.

Work on fuel systems.

Limited ventilation.

Presence of refrigerant.

Limited exits.

Limited means of access.

Congestion during work periods.

Vessel Movements at berth.

Wires, winches & net work.

Falls into water & onto Wharf

Being Crushed by vessel

Hazards On Wharves

-

Overhead loads & Cranes.

Forklifts & other vehicle traffic.

Wet & slippery wharves.

Fueling operations.

Vessel mooring lines parting

Falls into water potential for crushing by vessels

Public

If working on wharf, area MUST be coned off and appropriate signage put up.

Accident & Hazard Reporting

-

Accidents: shall be reported to your contact person immediately.

Do not leave the site until given the OK, we have to log & investigate the accident.

If your contact person is not available reporting can be done at the bridge.

Near misses: shall be reported in the same way as accidents.

Accidents & near misses should also be reported to your employer on return to your workplace.

Hazards: Shall be reported immediately to the your Sanford contact.

Hazards can include those created by:

Sanford personnel

Other contractors working in the area

Equipment that you are working with or in close proximity to

Hazards on the Wharf.

First Aid

-

Vessels

First aid kits are on the bridge of all vessels.

Each vessel has a number of qualified first aid staff.

Port facilities

As first aid kits are not available at port locations please ensure you have these in your vehicles.

Drug & Alcohol

-

No drugs or alcohol to be brought onto Sanford sites.

No drugs or alcohol to be consumed on Sanford sites.

No persons may enter a Sanford work site when impaired by drugs or alcohol.

Sanford Ltd have a zero tolerance policy to drug & alcohol use.

Sanford Ltd have a zero tolerance policy to drug & alcohol use.

Safety Plans

-

A safety plan must be completed before job commences.

It is prepared by the contractor & accepted by Sanford Ltd before the contract is awarded.

The safety plan outlines:

How the work is to be completed.

Who is doing the work.

Sub contractors used

Regulatory notifications.

Engineering certificates.

Staff competency.

Risk Assessment

-

A risk assessment shall be completed prior to the start of work.

This shall be completed by Sanford with the contractor at the place the work is done.

The risk assessment shall specify hazards for performing the work & the controls required for those hazards.

These controls are considered mandatory.

The risk assessment shall be signed off when the job is complete. Give us the completed document prior to leaving the vessel.

Monitoring

-

Contractor work will be routinely monitored by Sanford Ltd.

This is to ensure:

The risk assessment identified the hazards for the work.

The control of hazards is being implemented as specified.

If issues are identified during the monitoring they will logged as corrective actions in our H&S database.

Permit To Work

-

A permit to work shall be issued by Sanford to the contractor outlining the safety requirements for high hazard work.

Sanford may revoke the permit at any time.

Permits are required for:

Confined space entry

Hot work

Work At height

Diving under vessels

Gas free Certificates

UHP Water blasting

Work on open Refrigeration Systems

Any other work considered high hazard.

A permit to work is completed after the risk assessment is completed.

The permit is completed in conjunction with the permit receiver.

The permit is issued by Sanford.

The permit accepted by the permit receiver

The work must be completed per the conditions of the permit.

The permit is cancelled after checking work is completed per the permit conditions.

Permits shall be displayed at all times in the place of work.

Permits are valid for 24 hours maximum

Hot Work

-

Hot work is any process that can be a source of ignition when a flammable material may be present.

Includes:

Welding

Gas Cutting

Abrasive cutting causing sparks

Grinding

Brazing

Soldering

Gas Free Certificate

-

Gas Free certificates are required for any hot work in & on equipment that may have contained flammable substances.

The gas free cert is to be posted close to the equipment worked on.

The gas free cert is valid for a maximum of 24 hours.

Work At Height

-

Unit standard required & (< 2 years old).

Permit required where fall hazard > 1.8m.

PPE must break the fall before you hit the ground.

Rescue plan required.

Diving Under Vessels

-

Permit required.

Isolation of ship systems completed & verified before diving.

Confined Space Entry

-

Permit Required.

You are expected to provide:

Evidence Of Competency (< 2years old)

Safety Person At Entry

Gas Meter

Ventilation

Rescue Plan Required.

Hot work & Gas free certs required for hot work.

Lock Out Tag Out (LOTO)

-

Your lockout prevents harm to you.

Our lockout prevent harm to others & damage to vessel systems.

LOTO process:

On the Tongario and Rakaia vessels the Chief Engineer locks out.

Apply YOUR locks & tags with your NAME & CONTACT Phone.

Remove your lock when the work is completed OR when there will be delays before work can be completed.

Report to the Chief Engineer or Sanford representative & advise work is completed or current status of completion.

The Chief Engineer or Sanford representative removes the final lockout device when the system can be reactivated.

Sanford DO NOT supply Lockout Devices for contractor use.

Cold

-

Ice Holds & product may be cold.

Make sure you have warm clothing when in fish holds

Hazardous Substances

-

Include details & controls in the

Risk Assessment:

General Requirements:

Contractors must supply MSDS for any chemical they bring on to the vessel

Substances must be correctly labeled

MSDS must be on hand with the substance.

Must be used ,as specified in the MSDS.

PPE specified on MSDS must be worn.

Your substances must not create a hazard

for others working on the vessel.

Bring additional ventilation if required.

Do you need a hot work exclusion zone?

Contractor Equipment

-

Bad

-

Bad

-

Good

-

Good

-

Failure of equipment could cause

Electrocution.

Explosion (gas lines).

Trips & Falls.

Contractor Equipment

-

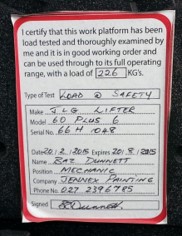

Machine Inspections

-

Electrical Equipment

Potable electrical equipment to have current tag attached.

Testing is required as per Industry requirements.

RCD or isolating transformers to be used.

Other Equipment

All certificates & licenses for equipment shall be available for inspection.

Equipment shall only be used by appropriately qualified or trained personnel, wear the correct PPE.

Do not use Sanford equipment without authorisation.

Ladders & Stairs

-

Serious accidents have happened on vessel stairs & ladders.

Take care when descending ladders & Stairs.

Go down backwards on steep stairs or use the trailing hand technique.

Use the handrails with both hands.

SiteWise

-

Already registered?

Check that you have submitted your first assessment (or carried out an annual re-submission)

Check you have paid your annual membership fee.

Check your contact details and business profile is up to date.

Check that your are taking steps to improve your grade in subsequent assessments – our goal is to have all contractors with a score of 75% or higher. -

-

Steps from here:

It is a requirement of the Sanford Board of Directors that all contractors comply with the above criteria, and where non-compliance prevails, consideration will be given as to our on-going business relationship.

Acknowledgement & Signatures

-

I hereby give notice that I have fully read, understood and will abide with the terms and conditions of this Sanford Induction Form whilst working on Sanford sites

-

Signed

-

Date