Information

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

Subpart D - Walking Working Surfaces

1910.22 - General requirements

(a) "Housekeeping."

-

(1)<br>All places of employment, passageways, storerooms, and service rooms shall be kept clean and orderly and in a sanitary condition

-

(2)<br>The floor of every workroom shall be maintained in a clean and, so far as possible, a dry condition. Where wet processes are used, drainage shall be maintained, and false floors, platforms, mats, or other dry standing places should be provided where practicable

-

(3) To facilitate cleaning, every floor, working place, and passageway shall be kept free from protruding nails, splinters, holes, or loose boards

(b) "Aisles and passageways"

-

(2) Permanent aisles and passageways shall be appropriately marked

-

(1)<br>Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made. Aisles and passageways shall be kept clear and in good repairs, with no obstruction across or in aisles that could create a hazard

(c) "Covers and guardrails."

-

(c) "Covers and guardrails." Covers and/or guardrails shall be provided to protect personnel from the hazards of open pits, tanks, vats, ditches, etc

(d) "Floor loading protection."

-

(1) In every building or other structure, or part thereof, used for mercantile, business, industrial, or storage purposes, the loads approved by the building official shall be marked on plates of approved design which shall be supplied and securely affixed by the owner of the building, or his duly authorized agent, in a conspicuous place in each space to which they relate. Such plates shall not be removed or defaced but, if lost, removed, or defaced, shall be replaced by the owner or his agen

-

(2) It shall be unlawful to place, or cause, or permit to be placed, on any floor or roof of a building or other structure a load greater than that for which such floor or roof is approved by the building official

1910.23 - Guarding floor and wall openings and holes

(a) "Protection for floor openings."

-

(1) Every stairway floor opening shall be guarded by a standard railing constructed in accordance with paragraph (e) of this section. The railing shall be provided on all exposed sides (except at entrance to stairway). For infrequently used stairways where traffic across the opening prevents the use of fixed standard railing (as when located in aisle spaces, etc.), the guard shall consist of a hinged floor opening cover of standard strength and construction and removable standard railings on all exposed sides (except at entrance to stairway)

-

(2) Every ladderway floor opening or platform shall be guarded by a standard railing with standard toeboard on all exposed sides (except at entrance to opening), with the passage through the railing either provided with a swinging gate or so offset that a person cannot walk directly into the opening

-

(3) Every hatchway and chute floor opening shall be guarded

-

(4) Every skylight floor opening and hole shall be guarded by a standard skylight screen or a fixed standard railing on all exposed sides

-

(5) Every pit and trapdoor floor opening, infrequently used, shall be guarded by a floor opening cover of standard strength and construction. While the cover is not in place, the pit or trap opening shall be constantly attended by someone or shall be protected on all exposed sides by removable standard railings

-

(6) Every manhole floor opening shall be guarded by a standard manhole cover which need not be hinged in place. While the cover is not in place, the manhole opening shall be constantly attended by someone or shall be protected by removable standard railings

-

(7) Every temporary floor opening shall have standard railings, or shall be constantly attended by someone

-

(8) Every floor hole into which persons can accidentally walk shall be guarded

-

(9) Every floor hole into which persons cannot accidentally walk (on account of fixed machinery, equipment, or walls) shall be protected by a cover that leaves no openings more than 1 inch wide. The cover shall be securely held in place to prevent tools or materials from falling through

-

(10) Where doors or gates open directly on a stairway, a platform shall be provided, and the swing of the door shall not reduce the effective width to less than 20 inches.

-

23(c) Open sided floors shall have a standard guard rail which consists of Top rail (42"), mid-rail, and a toe board (if small items are stored overhead and persons are working below).

-

23(d) All stairs w/ 4 or more risers, have to have a handrail at least on right hand descending side. If both sides are open, then have on both sides

-

23(e)(1) All stairs w/ 4 or more risers, have to have a handrail at least on right hand descending side. If both sides are open, then have on both sides

(b) "Protection for wall openings and holes."

-

(1) Every wall opening from which there is a drop of more than 4 feet shall be guarded

-

(2) Every chute wall opening from which there is a drop of more than 4 feet shall be guarded

-

(3) Every window wall opening at a stairway landing, floor, platform, or balcony, from which there is a drop of more than 4 feet, and where the bottom of the opening is less than 3 feet above the platform or landing, shall be guarded by standard slats, standard grill work (as specified in paragraph (e)(11) of this section), or standard railing

-

(4) Every temporary wall opening shall have adequate guards but these need not be of standard construction

(c) "Protection of open-sided floors, platforms, and runways."

-

(1) Every open-sided floor or platform 4 feet or more above adjacent floor or ground level shall be guarded by a standard railing (or the equivalent as specified in paragraph (e)(3) of this section) on all open sides except where there is entrance to a ramp, stairway, or fixed ladder. The railing shall be provided with a toeboard wherever, beneath the open sides,<br><br>Persons can pass,<br>There is moving machinery, or<br>There is equipment with which falling materials could create a hazard

-

(2) Every runway shall be guarded by a standard railing (or the equivalent as specified in paragraph (e)(3) of this section) on all open sides 4 feet or more above floor or ground level. Wherever tools, machine parts, or materials are likely to be used on the runway, a toeboard shall also be provided on each exposed side

-

(3) Regardless of height, open-sided floors, walkways, platforms, or runways above or adjacent to dangerous equipment, pickling or galvanizing tanks, degreasing units, and similar hazards shall be guarded with a standard railing and toe board

(d) "Stairway railings and guards."

-

(1) Every flight of stairs having four or more risers shall be equipped with standard stair railings or standard handrails as specified in paragraphs (d)(1)(i) through (v) of this section, the width of the stair to be measured clear of all obstructions except handrails:<br>(i) On stairways less than 44 inches wide having both sides enclosed, at least one handrail, preferably on the right side descending.<br>(ii) On stairways less than 44 inches wide having one side open, at least one stair railing on open side.<br>(iii) On stairways less than 44 inches wide having both sides open, one stair railing on each side.<br>(iv) On stairways more than 44 inches wide but less than 88 inches wide, one handrail on each enclosed side and one stair railing on each open side<br>(v) On stairways 88 or more inches wide, one handrail on each enclosed side, one stair railing on each open side, and one intermediate stair railing located approximately midway of the width

-

(2) Winding stairs shall be equipped with a handrail offset to prevent walking on all portions of the treads having width less than 6 inches

(e) "Railing, toe boards, and cover specifications."

-

(1) A standard railing shall consist of top rail, intermediate rail, and posts, and shall have a vertical height of 42 inches nominal from upper surface of top rail to floor, platform, runway, or ramp level. The top rail shall be smooth-surfaced throughout the length of the railing. The intermediate rail shall be approximately halfway between the top rail and the floor, platform, runway, or ramp. The ends of the rails shall not overhang the terminal posts except where such overhang does not constitute a projection hazard

-

(2) A stair railing shall be of construction similar to a standard railing but the vertical height shall be not more than 34 inches nor less than 30 inches from upper surface of top rail to surface of tread in line with face of riser at forward edge of tread

-

(4) A standard toeboard shall be 4 inches nominal in vertical height from its top edge to the level of the floor, platform, runway, or ramp. It shall be securely fastened in place and with not more than 1/4-inch clearance above floor level. It may be made of any substantial material either solid or with openings not over 1 inch in greatest dimension.<br>Where material is piled to such height that a standard toeboard does not provide protection, paneling from floor to intermediate rail, or to top rail shall be provided

-

(3) reserved

-

(i) For wood railings, the posts shall be of at least 2-inch by 4-inch stock spaced not to exceed 6 feet; the top and intermediate rails shall be of at least 2-inch by 4-inch stock. If top rail is made of two right-angle pieces of 1-inch by 4-inch stock, posts may be spaced on 8-foot centers, with 2-inch by 4-inch intermediate rail

-

(ii)<br>For pipe railings, posts and top and intermediate railings shall be at least 1 1/2 inches nominal diameter with posts spaced not more than 8 feet on centers

-

(iii) For structural steel railings, posts and top and intermediate rails shall be of 2-inch by 2-inch by 3/8-inch angles or other metal shapes of equivalent bending strength with posts spaced not more than 8 feet on centers

-

(iv) The anchoring of posts and framing of members for railings of all types shall be of such construction that the completed structure shall be capable of withstanding a load of at least 200 pounds applied in any direction at any point on the top rai

-

(v) Other types, sizes, and arrangements of railing construction are acceptable provided they meet the following conditions:<br> (a) A smooth-surfaced top rail at a height above floor, platform, runway, or ramp level of 42 inches nominal<br> (b) A strength to withstand at least the minimum requirement of 200 pounds top rail pressure<br> (c) Protection between top rail and floor, platform, runway, ramp, or stair treads, equivalent at least to that afforded by a standard intermediate rail;<br> <br>

(5) handrail construction practices

-

(i) A handrail shall consist of a lengthwise member mounted directly on a wall or partition by means of brackets attached to the lower side of the handrail so as to offer no obstruction to a smooth surface along the top and both sides of the handrail. The handrail shall be of rounded or other section that will furnish an adequate handhold for anyone grasping it to avoid falling. The ends of the handrail should be turned in to the supporting wall or otherwise arranged so as not to constitute a projection hazard

-

(ii) The height of handrails shall be not more than 34 inches nor less than 30 inches from upper surface of handrail to surface of tread in line with face of riser or to surface of ramp

-

(iii) The size of handrails shall be: When of hardwood, at least 2 inches in diameter; when of metal pipe, at least 1 1/2 inches in diameter. The length of brackets shall be such as will give a clearance between handrail and wall or any projection thereon of at least 3 inches. The spacing of brackets shall not exceed 8 feet

-

(iv) The mounting of handrails shall be such that the completed structure is capable of withstanding a load of at least 200 pounds applied in any direction at any point on the rail

-

(6) All handrails and railings shall be provided with a clearance of not less than 3 inches between the handrail or railing and any other object

-

(7) Floor opening covers may be of any material that meets the following strength requirements:<br> (i)Trench or conduit covers and their supports, when located in plant roadways, shall be designed to carry a truck rear-axle load of at least 20,000 pounds<br> (ii) Manhole covers and their supports, when located in plant roadways, shall comply with local standard highway requirements if any; otherwise, they shall be designed to carry a truck rear-axle load of at least 20,000 pounds<br> (iii) The construction of floor opening covers may be of any material that meets the strength requirements. Covers projecting not more than 1 inch above the floor level may be used providing all edges are chamfered to an angle with the horizontal of not over 30 degrees. All hinges, handles, bolts, or other parts shall set flush with the floor or cover surface<br>

-

(8) Skylight screens shall be of such construction and mounting that they are capable of withstanding a load of at least 200 pounds applied perpendicularly at any one area on the screen. They shall also be of such construction and mounting that under ordinary loads or impacts, they will not deflect downward sufficiently to break the glass below them. The construction shall be of grillwork with openings not more than 4 inches long or of slatwork with openings not more than 2 inches wide with length unrestricted

-

(9) Wall opening barriers (rails, rollers, picket fences, and half doors) shall be of such construction and mounting that, when in place at the opening, the barrier is capable of withstanding a load of at least 200 pounds applied in any direction (except upward) at any point on the top rail or corresponding member

-

(10) Wall opening grab handles shall be not less than 12 inches in length and shall be so mounted as to give 3 inches clearance from the side framing of the wall opening. The size, material, and anchoring of the grab handle shall be such that the completed structure is capable of withstanding a load of at least 200 pounds applied in any direction at any point of the handle

-

(11) Wall opening screens shall be of such construction and mounting that they are capable of withstanding a load of at least 200 pounds applied horizontally at any point on the near side of the screen. They may be of solid construction, of grillwork with openings not more than 8 inches long, or of slatwork with openings not more than 4 inches wide with length unrestricted

1910.24 - Fixed industrial stairs

(a) "Application of requirements." This section contains specifications for the safe design and construction of fixed general industrial stairs. This classification includes interior and exterior stairs around machinery, tanks, and other equipment, and stairs leading to or from floors, platforms, or pits. This section does not apply to stairs used for fire exit purposes, to construction operations to private residences, or to articulated stairs, such as may be installed on floating roof tanks or on dock facilities, the angle of which changes with the rise and fall of the base support.

(b) "Where fixed stairs are required."

-

Fixed stairs shall be provided for access from one structure level to another where operations necessitate regular travel between levels, and for access to operating platforms at any equipment which requires attention routinely during operations. Fixed stairs shall also be provided where access to elevations is daily or at each shift for such purposes as gauging, inspection, regular maintenance, etc., where such work may expose employees to acids, caustics, gases, or other harmful substances, or for which purposes the carrying of tools or equipment by hand is normally required

(c) "Stair strength."

-

Fixed stairways shall be designed and constructed to carry a load of five times the normal live load anticipated but never of less strength than to carry safely a moving concentrated load of 1,000 pounds

(d) "Stair width."

-

Fixed stairways shall have a minimum width of 22 inches

(e) "Angle of stairway rise."

-

Fixed stairs shall be installed at angles to the horizontal of between 30 deg. and 50 deg.

(f) "Stair treads."

-

All treads shall be reasonably slip-resistant and the nosings shall be of nonslip finish. Welded bar grating treads without nosings are acceptable providing the leading edge can be readily identified by personnel descending the stairway and provided the tread is serrated or is of definite nonslip design. Rise height and tread width shall be uniform throughout any flight of stairs including any foundation structure used as one or more treads of the stairs

(g) "Stairway platforms."

-

Stairway platforms shall be no less than the width of a stairway and a minimum of 30 inches in length measured in the direction of travel

(h) "Railings and handrails."

-

Standard railings shall be provided on the open sides of all exposed stairways and stair platforms. Handrails shall be provided on at least one side of closed stairways preferably on the right side descending

(i) "Vertical clearance."

-

Vertical clearance above any stair tread to an overhead obstruction shall be at least 7 feet measured from the leading edge of the tread

1910.25 - Portable wood ladders

(b) "Materials"

-

(1)(i) "Requirements applicable to all wood parts." All wood parts shall be free from sharp edges and splinters; sound and free from accepted visual inspection from shake, wane, compression failures, decay, or other irregularities. Low density wood shall not be used

(c) "Construction requirements."

-

(2) "Portable stepladders." Stepladders longer than 20 feet shall not be supplied

-

(i) "General requirements."

-

(b) A uniform step spacing shall be employed which shall be not more than 12 inches. Steps shall be parallel and level when the ladder is in position for use.

-

(c) The minimum width between side rails at the top, inside to inside, shall be not less than 11 1/2 inches. From top to bottom, the side rails shall spread at least 1 inch for each foot of length of stepladder

-

(f) A metal spreader or locking device of sufficient size and strength to securely hold the front and back sections in open positions shall be a component of each stepladder. The spreader shall have all sharp points covered or removed to protect the user

-

(3) "Portable rung ladders."

-

(ii) Single ladders longer than 30 feet shall not be supplied

-

(iii) Two-section extension ladders longer than 60 feet shall not be supplied

(d) "Care and use of ladders"

(1) "Care."

-

(i) Ladders shall be maintained in good condition at all times, the joint between the steps and side rails shall be tight, all hardware and fittings securely attached, and the movable parts shall operate freely without binding or undue play

-

(ii) Metal bearings of locks, wheels, pulleys, etc., shall be frequently lubricated

-

(iii) Frayed or badly worn rope shall be replaced

-

(iv) Safety feet and other auxiliary equipment shall be kept in good condition to insure proper performance

-

(x) Ladders shall be inspected frequently and those which have developed defects shall be withdrawn from service for repair or destruction and tagged or marked as "Dangerous, Do Not Use."

-

(xi) Rungs should be kept free of grease and oil

(2) "Use."

-

(i) Portable rung and cleat ladders shall, where possible, be used at such a pitch that the horizontal distance from the top support to the foot of the ladder is one-quarter of the working length of the ladder (the length along the ladder between the foot and the top support). The ladder shall be so placed as to prevent slipping, or it shall be lashed, or held in position. Ladders shall not be used in a horizontal position as platforms, runways, or scaffolds

-

(iii) Portable ladders shall be so placed that the side rails have a secure footing

-

(iv) Ladders shall not be placed in front of doors opening toward the ladder unless the door is blocked upon, locked, or guarded

-

(v) Ladders shall not be placed on boxes, barrels, or other unstable bases to obtain additional height

-

(viii) Ladders with broken or missing steps, rungs, or cleats, broken side rails, or other faulty equipment shall not be used; improvised repairs shall not be made

-

(xv) No ladder should be used to gain access to a roof unless the top of the ladder shall extend at least 3 feet above the point of support, at eave, gutter, or roofline;

-

(xx) The bracing on the back legs of step ladders is designed solely for increasing stability and not for climbing

1910.26 - Portable metal ladders

(a) "Requirements"

(1) "General."

-

(iii) The spacing of rungs or steps shall be on 12-inch centers.

-

(v) Rungs and steps shall be corrugated, knurled, dimpled, coated with skid-resistant material, or otherwise treated to minimize the possibility of slipping.

(2) "General specifications - straight and extension ladders."

-

-

(i) The minimum width between side rails of a straight ladder or any section of an extension ladder shall be 12 inches

-

(ii) The length of single ladders or individual sections of ladders shall not exceed 30 feet. Two-section ladders shall not exceed 48 feet in length and over two-section ladders shall not exceed 60 feet in length

(3) "General specifications - step ladders."

-

(vii) The bottoms of the four rails are to be supplied with insulating non-slip material for the safety of the user.

-

viii) A metal spreader or locking device of sufficient size and strength to securely hold the front and back sections in the open position shall be a component of each stepladder. The spreader shall have all sharp points or edges covered or removed to protect the user

(c) "Care and maintenance of ladders"

(2) "Care of ladders."

-

(iv) Ladders must be maintained in good usable condition at all times

-

(vii) Ladders having defects are to be marked and taken out of service until repaired by either maintenance department or the manufacturer

(3) "Use of ladders.

-

(i) A simple rule for setting up a ladder at the proper angle is to place the base a distance from the vertical wall equal to one-fourth the working length of the ladder

-

(ii) Portable ladders are designed as a one-man working ladder based on a 200-pound load

-

(iii) The ladder base section must be placed with a secure footing

-

(iv) The top of the ladder must be placed with the two rails supported, unless equipped with a single support attachment

1910.27 - Fixed ladders.

(b) "Specific features"

(1) "Rungs and cleats."

-

(i) All rungs shall have a minimum diameter of three-fourths inch for metal ladders, except as covered in paragraph (b)(7)(i) of this section and a minimum diameter of 1 1/8 inches for wood ladders

-

(ii) The distance between rungs, cleats, and steps shall not exceed 12 inches and shall be uniform throughout the length of the ladder

-

(iii) The minimum clear length of rungs or cleats shall be 16 inches

-

(iv) Rungs, cleats, and steps shall be free of splinters, sharp edges, burrs, or projections which may be a hazard

(7) "Protection from deterioration."

-

(i) Metal ladders and appurtenances shall be painted or otherwise treated to resist corrosion and rusting when location demands. Ladders formed by individual metal rungs imbedded in concrete, which serve as access to pits and to other areas under floors, individual metal rungs shall have a minimum diameter of 1 inch or shall be painted or otherwise treated to resist corrosion and rusting

(c) "Clearance"

-

(1) "Climbing side." On fixed ladders, the perpendicular distance from the centerline of the rungs to the nearest permanent object on the climbing side of the ladder shall be 36 inches for a pitch of 76 degrees, and 30 inches for a pitch of 90 degrees

-

(2) "Ladders without cages or wells." A clear width of at least 15 inches shall be provided each way from the centerline of the ladder in the climbing space, except when cages or wells are necessary

-

(3) "Ladders with cages or baskets." Ladders equipped with cage or basket are excepted from the provisions of subparagraphs (1) and (2) of this paragraph

-

(4) "Clearance in back of ladder." The distance from the centerline of rungs, cleats, or steps to the nearest permanent object in back of the ladder shall be not less than 7 inches, except that when unavoidable obstructions are encountered

(d) "Special requirements"

(1) "Cages or wells."

-

(ii) Cages or wells (except as provided in subparagraph (5) of this paragraph) shall be provided on ladders of more than 20 feet to a maximum unbroken length of 30 feet

-

(iii) Cages shall extend a minimum of 42 inches above the top of landing,unless other acceptable protection is provided

-

(iv) Cages shall extend down the ladder to a point not less than 7 feet nor more than 8 feet above the base of the ladder, with bottom flared not less than 4 inches, or portion of cage opposite ladder shall be carried to the base

-

(v) Cages shall not extend less than 27 nor more than 28 inches from the centerline of the rungs of the ladder. Cage shall not be less than 27 inches in width. The inside shall be clear of projections. Vertical bars shall be located at a maximum spacing of 40 degrees around the circumference of the cage; this will give a maximum spacing of approximately 9 1/2 inches, center to center

(2) "Landing platforms."

-

When ladders are used to ascend to heights exceeding 20 feet (except on chimneys), landing platforms shall be provided for each 30 feet of height or fraction thereof, except that, where no cage, well, or ladder safety device is provided, landing platforms shall be provided for each 20 feet of height or fraction thereof. Each ladder section shall be offset from adjacent sections. Where installation conditions (even for a short, unbroken length) require that adjacent sections be offset, landing platforms shall be provided at each offset.

-

(i) Where a man has to step a distance greater than 12 inches from the centerline of the rung of a ladder to the nearest edge of structure or equipment, a landing platform shall be provided. The minimum step-across distance shall be 2 1/2 inches

-

(ii) All landing platforms shall be equipped with standard railings and toeboards, so arranged as to give safe access to the ladder. Platforms shall be not less than 24 inches in width and 30 inches in length

(5) "Ladder safety devices." Ladder safety devices may be used on tower, water tank, and chimney ladders over 20 feet in unbroken length in lieu of cage protection. No landing platform is required in these cases. All ladder safety devices such as those that incorporate lifebelts, friction brakes, and sliding attachments shall meet the design requirements of the ladders which they serve

(f) "Maintenance."

-

All ladders shall be maintained in a safe condition. All ladders shall be inspected regularly, with the intervals between inspections being determined by use and exposure

1910.28 - Safety requirements for scaffolding.

(a) "General requirements for all scaffolds."

-

(2) The footing or anchorage for scaffolds shall be sound, rigid, and capable of carrying the maximum intended load without settling or displacement

-

(4) Scaffolds and their components shall be capable of supporting without failure at least four times the maximum intended load

-

(5) Scaffolds and other devices mentioned or described in this section shall be maintained in safe condition. Scaffolds shall not be altered or moved horizontally while they are in use or occupied

-

(6) Any scaffold damaged or weakened from any cause shall be immediately repaired and shall not be used until repairs have been completed

-

(11) All planking or platforms shall be overlapped (minimum 12 inches) or secured from movement

-

(12) An access ladder or equivalent safe access shall be provided

-

(13) Scaffold planks shall extend over their end supports not less than 6 inches nor more than 18 inches

-

(17) Scaffolds shall be provided with a screen between the toeboard and the guardrail, extending along the entire opening, consisting of No. 18 gauge U.S. Standard Wire one-half-inch mesh or the equivalent, where persons are required to work or pass under the scaffolds

-

(20)Tools, materials, and debris shall not be allowed to accumulate in quantities to cause a hazard

-

(26) Scaffolds shall be secured to permanent structures, through use of anchor bolts, reveal bolts, or other equivalent means

(c) "Tube and coupler scaffolds."

-

(6) All tube and coupler scaffolds shall be erected by competent and experienced personne

(d) "Tubular welded frame scaffolds."

-

(12) All tubular welded frame scaffolds shall be erected by competent and experienced personnel

1910.30 - Other working surfaces.

(a) "Dockboards (bridge plates)."

-

(1) Portable and powered dockboards shall be strong enough to carry the load imposed on them

-

(2) Portable dockboards shall be secured in position, either by being anchored or equipped with devices which will prevent their slipping

1910 Subpart E - Means of Egress

1910.36 - Design and construction requirements for exit routes.

(b) The number of exit routes must be adequate.

-

(1) Two exit routes. At least two exit routes must be available in a workplace to permit prompt evacuation of employees and other building occupants during an emergency, except as allowed in paragraph (b)(3) of this section

-

(3) A single exit route. A single exit route is permitted where the number of employees, the size of the building, its occupancy, or the arrangement of the workplace is such that all employees would be able to evacuate safely during an emergency

(d) An exit door must be unlocked.

-

(1) Employees must be able to open an exit route door from the inside at all times without keys, tools, or special knowledge. A device such as a panic bar that locks only from the outside is permitted on exit discharge doors

(a) Basic requirements

-

(1) An exit route must be permanent

-

(2) An exit must be separated by fire resistant materials

-

(3) Openings into an exit must be limited. An exit is permitted to have only those openings necessary to allow access to the exit from occupied areas of the workplace, or to the exit discharge. An opening into an exit must be protected by a self-closing fire door that remains closed or automatically closes in an emergency upon the sounding of a fire alarm or employee alarm system

1910.37 - Maintenance, safeguards, and operational features for exit routes.

(a) The danger to employees must be minimized

-

(1) Exit routes must be kept free of explosive or highly flammable furnishings or other decorations

-

(3) Exit routes must be free and unobstructed

(b) Lighting and marking must be adequate and appropriate

-

(1) Each exit route must be adequately lighted so that an employee with normal vision can see along the exit route

-

(2) Each exit must be clearly visible and marked by a sign reading "Exit."

-

(3) Each exit route door must be free of decorations or signs that obscure the visibility of the exit route door

-

(4) If the direction of travel to the exit or exit discharge is not immediately apparent, signs must be posted along the exit access indicating the direction of travel to the nearest exit and exit discharge. Additionally, the line-of-sight to an exit sign must clearly be visible at all times

-

(5) Each doorway or passage along an exit access that could be mistaken for an exit must be marked "Not an Exit" or similar designation, or be identified by a sign indicating its actual use (e.g., closet)

-

(6) Each exit sign must be illuminated to a surface value of at least five foot-candles (54 lux) by a reliable light source and be distinctive in color. Self-luminous or electroluminescent signs that have a minimum luminance surface value of at least .06 footlamberts (0.21 cd/m2) are permitted

-

(7) Each exit sign must have the word "Exit" in plainly legible letters not less than six inches (15.2 cm) high, with the principal strokes of the letters in the word "Exit" not less than three-fourths of an inch (1.9 cm) wide

(e) An employee alarm system must be operable

-

Employers must install and maintain an operable employee alarm system that has a distinctive signal to warn employees of fire or other emergencies, unless employees can promptly see or smell a fire or other hazard in time to provide adequate warning to them

Subpart F - Powered Platforms, Manlifts, and Vehicle-Mounted Work Platforms

1910.67 - Vehicle-mounted elevating and rotating work platforms.

(c) "Specific requirements"

(2) "Extensible and articulating boom platforms."

-

(i) Lift controls shall be tested each day prior to use to determine that such controls are in safe working condition

-

(ii) Only trained persons shall operate an aerial lift

-

(iii) Belting off to an adjacent pole, structure, or equipment while working from an aerial lift shall not be permitted

-

(iv) Employees shall always stand firmly on the floor of the basket, and shall not sit or climb on the edge of the basket or use planks, ladders, or other devices for a work position

-

(v) A body belt shall be worn and a lanyard attached to the boom or basket when working from an aerial lift

-

(vii) The brakes shall be set and outriggers, when used, shall be positioned on pads or a solid surface. Wheel chocks shall be installed before using an aerial lift on an incline

(b) "General requirements."

-

67(b)(2) Aerial lifts may be "field modified" for uses other than those intended by the manufacturer, provided the modification has been certified in writing by the manufacturer or by any other equivalent entit

Subpart G - Occupational Health and Environmental Control

1910.95 - Occupational noise exposure.

-

(b)(1) When employees are subjected to sound exceeding those listed in Table G-16, feasible administrative or engineering controls shall be utilized

(c) "Hearing conservation program."

-

(1) The employer shall administer a continuing, effective hearing conservation program, as described in paragraphs (c) through (o) of this section, whenever employee noise exposures equal or exceed an 8-hour time-weighted average sound level (TWA) of 85 decibels measured on the A scale (slow response) or, equivalently, a dose of fifty percen

(d)"Monitoring."

-

(1) When information indicates that any employee's exposure may equal or exceed an 8-hour time-weighted average of 85 decibels, the employer shall develop and implement a monitoring program

(i) "Hearing protectors."

-

(1) Employers shall make hearing protectors available to all employees exposed to an 8-hour time-weighted average of 85 decibels or greater at no cost to the employee

-

(2) Employers shall ensure that hearing protectors are worn

-

(3) Employees shall be given the opportunity to select their hearing protectors from a variety of suitable hearing protectors provided by the employer

(k) "Training program."

-

(2) The training program shall be repeated annually for each employee included in the hearing conservation program

-

(1) The employer shall train each employee who is exposed to noise at or above an 8-hour time weighted average of 85 decibels in accordance with the requirements of this section. The employer shall institute a training program and ensure employee participation in the program

(l) "Access to information and training materials."

-

(1) The employer shall make available to affected employees or their representatives copies of this standard and shall also post a copy in the workplace

(m) "Recordkeeping"

-

(1) "Exposure measurements." The employer shall maintain an accurate record of all employee exposure measurements required by paragraph (d)

(3) "Record retention

-

(i) Noise exposure measurement records shall be retained for two years

-

(ii) Audiometric test records shall be retained for the duration of the affected employee's employment

1910.94 - Ventilation.

(a) Abrasive blasting

(c) Spray finishing operations

(b) Grinding, polishing, and buffing operations

Subpart H - Hazardous Materials

1910.106 - Flammable liquids.

-

106(e)(2)(iv)(a) Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), shall be kept in covered containers when not actually in use

(7)(i)(a) At least one portable fire extinguisher having a rating of not less than 12-B units shall be located outside of, but not more than 10 feet from, the door opening into any room used for storage

-

106(e)(9)(iii) "Waste and residue." Combustible waste material and residues in a building or unit operating area shall be kept to a minimum, stored in covered metal receptacles and disposed of dail

(e) "Industrial plants"

-

106(e)(6)(ii) Grounding. Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), shall not be dispensed into containers unless the nozzle and container are electrically interconnected

-

106(e)(9)(i) "General." Maintenance and operating practices shall be in accordance with established procedures which will tend to control leakage and prevent the accidental escape of flammable liquids. Spills shall be cleaned up promptl

(d) "Container and portable tank storage"

(3) "Design, construction, and capacity of storage cabinets"

-

(i) Maximum capacity. Not more than 60 gallons of Category 1, 2, or 3 flammable liquids, nor more than 120 gallons of Category 4 flammable liquids may be stored in a storage cabinet

-

(ii) "Fire resistance." Storage cabinets shall be designed and constructed to limit the internal temperature to not more than 325 deg. F. Metal cabinets constructed in the following manner shall be deemed to be in compliance. The bottom, top, door, and sides of cabinet shall be at least No. 18 gage sheet iron and double walled with 1 1/2 - inch air space. Joints shall be riveted, welded or made tight by some equally effective means. The door shall be provided with a three-point lock, and the door sill shall be raised at least 2 inches above the bottom of the cabinet.

(2) "Design, construction, and capacity of containers"

-

(i) "General." Only approved containers and portable tanks shall be used

1910.107 - Spray finishing using flammable and combustible materials.

1910.110 - Storage and handling of liquefied petroleum gases.

-

110(f)(4)(i) The quantity of LP-Gas stored shall not exceed 300 pound

1910.119 - Process safety management of highly hazardous chemicals.

1910 Subpart H - Hazardous Materials

1910.132 - General requirements.

(d) Hazard assessment and equipment selection

-

(1) The employer shall assess the workplace to determine if hazards are present, or are likely to be present, which necessitate the use of personal protective equipment (PPE).

-

(i) Select, and have each affected employee use, the types of PPE that will protect the affected employee from the hazards identified in the hazard assessment

-

(ii) Communicate selection decisions to each affected employee

-

(iii) Select PPE that properly fits each affected employee

-

(2) The employer shall verify that the required workplace hazard assessment has been performed through a written certification that identifies the workplace evaluated; the person certifying that the evaluation has been performed; the date(s) of the hazard assessment; and, which identifies the document as a certification of hazard assessment

(e) Defective and damaged equipment

-

Defective or damaged personal protective equipment shall not be used

(f) Training.

-

(1) The employer shall provide training to each employee who is required by this section to use PPE; when,what, how, limitations, proper care, maintenance use and disposal

-

(2) Each affected employee shall demonstrate an understanding of the training specified in paragraph (f)(1) of this section, and the ability to use PPE properly, before being allowed to perform work requiring the use of PPE

Employer Pay for PPE See Minnesota Statute 182.655 10(a)

1910.133 - Eye and face protection.

(a) General requirements

-

(1) The employer shall ensure that each affected employee uses appropriate eye or face protection when exposed to eye or face hazards

-

(2) The employer shall ensure that each affected employee uses eye protection that provides side protection

(b) Criteria for protective eye and face protection

-

(1) Protective eye and face protection devices must comply with any of the following consensus standards: ANSI Z87.1-2003 ANSI Z87.1-1989

1910.134 - Respiratory Protection.

(a) Permissible practice

-

(1)......Primary objective shall be to prevent atmospheric contamination,...as far as feasible by accepted engineering control measures. When effective engineering controls are not feasible, or while they are being instituted, appropriate respirators shall be used pursuant to this section

-

(2) The employer shall be responsible for the establishment and maintenance of a respiratory protection program....

(c) Respiratory protection program

(2) Where respirator use is not required

-

(i) An employer may provide respirators at the request of employees or permit employees to use their own respirators, if the employer determines that such respirator use will not in itself create a hazard. The employer shall provide the respirator users with the information contained in Appendix D

-

(ii)<br>In addition, the employer must establish and implement those elements of a written respiratory protection program necessary.. Employers are not required to include in a written respiratory protection program those employees whose only use of respirators involves the voluntary use of filtering facepieces (dust masks).

-

(3) The employer shall designate a program administrator who is qualified by appropriate training or experience

-

(1) In any workplace where respirators are necessary to protect the health of the employee or whenever respirators are required by the employer, the employer shall establish and implement a written respiratory protection program with worksite-specific procedures; administered by a suitably trained program administrator

-

(viii) Training of employees in the proper use of respirators, including putting on and removing them, any limitations on their use, and their maintenance

-

(ix) Procedures for regularly evaluating the effectiveness of the program.

(k) Training and information

-

The training must be comprehensive, understandable, and recur annually, and more often if necessary

(l) Program evaluation

-

(1) The employer shall conduct evaluations of the workplace as necessary to ensure that the provisions of the current written program are being effectively implemented and that it continues to be effective

-

(2) The employer shall regularly consult employees required to use respirators to assess the employees' views on program effectiveness and to identify any problems

(m) Recordkeeping

-

(4) Written materials required to be retained under this paragraph shall be made available upon request to affected employees and to the Assistant Secretary or designee for examination and copying

-

(1) Medical evaluation. Records of medical evaluations required by this section must be retained and made available

-

(2) Fit testing.The employer shall establish a record of the qualitative and quantitative fit tests administered to an employee;

1910.135 - Head protection.

(a) General requirements

-

(1) The employer shall ensure that each affected employee wears a protective helmet when working in areas where there is a potential for injury to the head from falling objects

-

(2) The employer shall ensure that a protective helmet designed to reduce electrical shock hazard is worn by each such affected employee when near exposed electrical conductors which could contact the head

(b) Criteria for head protection

-

(1) Criteria for head protection. (1) Head protection must comply with any of the following consensus standards: (ANSI) Z89.1-2009, (ANSI) Z89.1-2003, (ANSI) Z89.1-1997

1910.136 - Foot protection.

-

(a) The employer shall ensure that each affected employee uses protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects, or objects piercing the sole, and where such employee's feet are exposed to electrical hazards

1910.137 - Electrical protective devices.

(b) "In-service care and use

(2) The following specific requirements apply to insulating blankets, covers, line hose, gloves, and sleeves made of rubber

-

(ii) Insulating equipment shall be inspected for damage before each day's use and immediately following any incident that can reasonably be suspected of having caused damage. Insulating gloves shall be given an air test, along with the inspection

-

(iv) Insulating equipment found to have other defects that might affect its insulating properties shall be removed from service and returned for testing

-

(vii) Protector gloves shall be worn over insulating gloves, except as follows: Protector gloves need not be used with Class 0 gloves, under limited-use conditions, where small equipment and parts manipulation necessitate unusually high finger dexterity; Any other class of glove may be used for similar work without protector gloves if the employer can demonstrate that the possibility of physical damage to the gloves is small and if the class of glove is one class higher than that required for the voltage involved

-

(xii) The employer shall certify that equipment has been tested in accordance with the requirements of paragraphs (b)(2)(viii), (b)(2)(ix), and (b)(2)(xi) of this section. The certification shall identify the equipment that passed the test and the date it was tested.<br>Note: Marking of equipment and entering the results of the tests and the dates of testing onto logs are two acceptable means of meeting this requirement. Rubber insulating gloves - Before first issue and every 6 months thereafter.

1910.138 - Hand Protection.

-

(a) Employers shall select and require employees to use appropriate hand protection when employees' hands are exposed to hazards such as those from skin absorption of harmful substances; severe cuts or lacerations; severe abrasions; punctures; chemical burns; thermal burns; and harmful temperature extremes

1910 Subpart J - General Environmental Controls

1910.146 - Permit Required Confined Spaces

(c) General requirements

-

146(c)(1) The employer shall evaluate the workplace to determine if any spaces are permit-required confined spaces

-

146(c)(2) If the workplace contains permit spaces, the employer shall inform exposed employees, by posting danger signs or by any other equally effective means, of the existence and location of and the danger posed by the permit spaces.

-

146(c)(3) If the employer decides that its employees will not enter permit spaces, the employer shall take effective measures to prevent its employees from entering the permit spaces

-

146(c)(4) If the employer decides that its employees will enter permit spaces, the employer shall develop and implement a written permit space program that complies with this section

(d) Permit-required confined space program

-

146(d)(3) Develop and implement the means, procedures, and practices necessary for safe permit space entry operations

-

146(d)(9) Develop and implement procedures for summoning rescue and emergency services, for rescuing entrants from permit spaces, for providing necessary emergency services to rescued employees, and for preventing unauthorized personnel from attempting a rescu

-

146(d)(10) Develop and implement a system for the preparation, issuance, use, and cancellation of entry permits as required by this section

-

146(d)(11) Develop and implement procedures to coordinate entry operations when employees of more than one employer are working simultaneously as authorized entrants in a permit space

-

146(d)(14) Review the permit space program, using the canceled permits retained under paragraph (e)(6) of this section within 1 year after each entry and revise the program as necessary, to ensure that employees participating in entry operations are protected from permit space hazards

(k) Rescue and emergency services

-

146(k)(2) An employer whose employees have been designated to provide permit space rescue and emergency services shall take the following measures: Provide affected employees with the personal protective equipment (PPE) needed to conduct permit space rescues safely and train affected employees so they are proficient in the use of that PPE and Train affected employees to perform assigned rescue duties

-

146(k)(2)(iii) Train affected employees in basic first-aid and cardiopulmonary resuscitation (CPR). The employer shall ensure that at least one member of the rescue team or service holding a current certification in first aid and CPR is available

-

146(k)(2)(iv) Ensure that affected employees practice making permit space rescues at least once every 12 months, by means of simulated rescue operations in which they remove dummies, manikins, or actual persons from the actual permit spaces or from representative permit spaces

-

(3) To facilitate non-entry rescue, retrieval systems or methods shall be used whenever an authorized entrant enters a permit space

-

146(k)(3)(ii) The other end of the retrieval line shall be attached to a mechanical device or fixed point outside the permit space in such a manner that rescue can begin as soon as the rescuer becomes aware that rescue is necessary. A mechanical device shall be available to retrieve personnel from vertical type permit spaces more than 5 feet (1.52 m) deep

(g) Training

-

(3) The training shall establish employee proficiency in the duties required by this section and shall introduce new or revised procedures, as necessary, for compliance with this section

-

(4) The employer shall certify that the training required ... has been accomplished. The certification shall contain each employee's name, the signatures or initials of the trainers, and the dates of training. The certification shall be available for inspection by employees and their authorized representatives

-

146(g)(1) The employer shall provide training so that all employees whose work is regulated by this section acquire the understanding, knowledge, and skills necessary for the safe performance of the duties assigned under this section

1910.147 - The control of hazardous energy (lockout/tagout)

(c) General

-

147(c)(5)(ii)(B) Lockout and tagout devices shall be standardized within the facility in at least one of the following criteria: Color; shape; or size

-

147(c)(6)(i) The employer shall conduct a periodic inspection of the energy control procedure at least annually to ensure that the procedure and the requirements of this standard are being followed

-

147(c)(7)(iv) The employer shall certify that employee training has been accomplished and is being kept up to date. The certification shall contain each employee's name and dates of training

-

(1) Energy control program. The employer shall establish a program consisting of energy control procedures, employee training and periodic inspections

(f) Additional requirements

-

147(f)(2)(i) Whenever outside servicing personnel are to be engaged in activities covered by the scope and application of this standard, the on-site employer and the outside employer shall inform each other of their respective lockout or tagout procedures

-

147(f)(3)(ii)(D) Each member of group lockout has individual lockout device and remove when completed

-

147(f)(4) Shift change procedures for Lock-out

Subpart K - Medical and First Aid

1910.151 - Medical services and first aid

-

151(b) In the absence of an infirmary, clinic, or hospital in near proximity to the workplace which is used for the treatment of all injured employees, a person or persons shall be adequately trained to render first aid. Adequate first aid supplies shall be readily availabl

-

151(c) Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use

Subpart L - Fire Protection

1910.165 - Employee alarm systems.

(b) General requirements

-

165(b)(4) The employer shall post emergency telephone numbers near telephones, or employee notice boards, and other conspicuous locations when telephones serve as a means of reporting emergencie

-

165(b)(5) The employer shall establish procedures for sounding emergency alarms in the workplace. For those employers with 10 or fewer employees in a particular workplace, direct voice communication is an acceptable procedure for sounding the alarm provided all employees can hear the alarm

1910.157 - Portable fire extinguishers.

(d) Selection and distribution

-

(1) Portable fire extinguishers shall be provided for employee use and selected and distributed based on the classes of anticipated workplace fires and on the size and degree of hazard which would affect their use

-

(2) The employer shall distribute portable fire extinguishers for use by employees on Class A fires so that the travel distance for employees to any extinguisher is 75 feet (22.9 m) or less

-

(4) The employer shall distribute portable fire extinguishers for use by employees on Class B fires so that the travel distance from the Class B hazard area to any extinguisher is 50 feet (15.2 m) or less.

-

(6) The employer shall distribute portable fire extinguishers or other containers of Class D extinguishing agent for use by employees so that the travel distance from the combustible metal working area to any extinguishing agent is 75 fee

(e) Inspection, maintenance and testing

-

(2) Portable extinguishers or hose used in lieu thereof under paragraph (d)(3) of this section shall be visually inspected monthly

-

(3) The employer shall assure that portable fire extinguishers are subjected to an annual maintenance check

(g) Training and education

-

(1) Where the employer has provided portable fire extinguishers for employee use in the workplace..., the employer shall also provide an educational program

-

157(g)(2) The employer shall provide the education required in paragraph (g)(1) of this section upon initial employment and at least annually thereafter

-

(3) The employer shall provide employees who have been designated to use fire fighting equipment as part of an emergency action plan with training in the use of the appropriate equipment.

-

157(g)(4) The employer shall provide the training required in paragraph (g)(3) of this section upon initial assignment to the designated group of employees and at least annually thereafte

Subpart M - Compressed Gas and Compressed Air Equipment

-

253(e)(6)(iii) Gages on oxygen regulators shall be marked "USE NO OIL."

-

253(b)(4)(iii) Oxygen cylinders in storage shall be separated from fuel-gas cylinders or combustible materials (especially oil or grease), a minimum distance of 20 feet

-

253(b)(4)(i) Oxygen cylinders shall not be stored near highly combustible material, especially oil and grease; or near reserve stocks of carbide and acetylene or other fuel-gas cylinders

1910 Subpart N - Materials Handling and Storage

1910.178 - Powered industrial trucks.

(l) Operator training

-

(2)(ii) Training shall consist of a combination of formal instruction (e.g., lecture, discussion, interactive computer learning, video tape, written material), practical training (demonstrations performed by the trainer and practical exercises performed by the trainee), and evaluation of the operator's performance in the workplace

-

(4)(i)Refresher training, including an evaluation of the effectiveness of that training, shall be conducted as required. An evaluation of each powered industrial truck operator's performance shall be conducted at least once every three years

-

(6) The employer shall certify that each operator has been trained and evaluated as required .... The certification shall include the name of the operator, the date of the training, the date of the evaluation, and the identity of the person(s) performing the training or evaluation.

-

(1)(i) The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by the successful completion of the training and evaluation

(m) Truck operations

-

(5)(i) When a powered industrial truck is left unattended, load engaging means shall be fully lowered, controls shall be neutralized, power shall be shut off, and brakes set. Wheels shall be blocked if the truck is parked on an incline

(q) Maintenance of industrial trucks

-

(7) Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily. Where industrial trucks are used on a round-the-clock basis, they shall be examined after each shift. Defects when found shall be immediately reported and corrected

(a) General requirements.

-

(4) Modifications and additions which affect capacity and safe operation shall not be performed by the customer or user without manufacturers prior written approval

-

(6) The user shall see that all nameplates and markings are in place and are maintained in a legible condition

(g) Changing and charging storage batteries

-

(1) Battery charging installations shall be located in areas designated for that purpose

-

(2) Facilities shall be provided for flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation for dispersal of fumes from gassing batteries

-

(10) Smoking shall be prohibited in the charging area

(k) Trucks and railroad cars.

-

(1) The brakes of highway trucks shall be set and wheel chocks placed under the rear wheels to prevent the trucks from rolling while they are boarded with powered industrial trucks.

1910.179 - Overhead and gantry cranes.

(b) General requirements

-

(5) Rated load marking. The rated load of the crane shall be plainly marked on each side of the crane, and if the crane has more than one hoisting unit, each hoist shall have its rated load marked on it or its load block and this marking shall be clearly legible from the ground or floor

(j) Inspection

-

(2)(iv) Hoist chains, including end connections, for excessive wear, twist, distorted links interfering with proper function, or stretch beyond manufacturer's recommendations. Visual inspection daily; monthly inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier of the chain which was inspected

-

(3) Periodic inspection. Complete inspections of the crane shall be performed at intervals as generally defined in paragraph (j)(1)(ii)(b) of this section, depending upon its activity, severity of service, and environment (1-12 months)

-

(2)(i) All functional operating mechanisms for maladjustment interfering with proper operation. Daily

-

2)(iii) Hooks with deformation or cracks. Visual inspection daily; monthly inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial number, or other identifier, of the hook inspected

1910.184 - Slings.

(c) Safe operating practices.

-

(1) Slings that are damaged or defective shall not be used

-

(2) Slings shall not be shortened with knots or bolts or other makeshift devices

-

(7) Slings shall be padded or protected from the sharp edges of their loads

-

(14) Employers must not use slings without affixed and legible identification markings

(e) Alloy steel chain slings

-

(1) Sling identification. Alloy steel chain slings shall have permanently affixed durable identification stating size, grade, rated capacity, and reach

-

184(e)(2)(ii) Makeshift links or fasteners formed from bolts or rods, or other such attachments, shall not be used

-

184(e)(3)(i) a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis. Such inspections shall in no event be at intervals greater than once every 12 months

-

184(e)(3)(ii) The employer shall make and maintain a record of the most recent month in which each alloy steel chain sling was thoroughly inspected, and shall make such record available for examination

-

184(e)(9)(i) Alloy steel chain slings with cracked or deformed master links, coupling links or other components shall be removed from service

(f) Wire-rope sling

-

184(f)(1) Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one

-

184(f)(5) Removal from service. Wire rope slings shall be immediately removed from service if any of the following conditions are present:Ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay;Wear or scraping of one-third the original diameter of outside individual wires; Kinking, crushing, bird caging or any other damage resulting in distortion of the wire rope structure; Evidence of heat damage; End attachments that are cracked, deformed or worn; Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook; Corrosion of the rope or end attachments

(i) Synthetic web slings

-

184(i)(9) Removal from service. Synthetic web slings shall be immediately removed from service if any damage present

-

(1) Sling identification. Each sling shall be marked or coded to show the rated capacities for each type of hitch and type of synthetic web material

Subpart O - Machinery and Machine Guarding

1910.212 - General requirements for all machines.

-

212(a)(2) General requirements for machine guards. Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself

-

212(a)(3)(ii) The point of operation of machines whose operation exposes an employee to injury, shall be guarded

-

212(b) Anchoring fixed machinery. Machines designed for a fixed location shall be securely anchored to prevent walking or moving

-

5205.0890 Hydraulic Presses: A barrier guard shall be maintained on all hydraulic presses, whether hand or power operated, where there is a possibility of materials being ejected from the press

1910 Subpart Q - Welding, Cutting, and Brazing

1910.253 - Oxygen-fuel gas welding and cutting.

-

(b)(2)(ii) Inside of buildings, cylinders shall be stored in a well-protected, well-ventilated, dry location, at least 20 (6.1 m) feet from highly combustible materials

-

(b)(4)(i) Oxygen cylinders shall not be stored near highly combustible material, especially oil and grease; or near reserve stocks of carbide and acetylene or other fuel-gas cylinders, or near any other substance likely to cause or accelerate fire; or in an acetylene generator compartment

-

(b)(4)(iii) Oxygen cylinders in storage shall be separated from fuel-gas cylinders or combustible materials (especially oil or grease), a minimum distance of 20 feet (6.1 m) or by a noncombustible barrier at least 5 feet (1.5 m) high having a fire-resistance rating of at least one-half hour

1910.254 - Arc welding and cutting.

-

(d)(9)(iii) Cables with damaged insulation or exposed bare conductors shall be replaced

Subpart P - Hand and Portable Powered Tools and Other Hand-Held Equipment

1910.242 - Hand and portable powered tools and equipment, general.

-

(a) General requirements. Each employer shall be responsible for the safe condition of tools and equipment used by employees, including tools and equipment which may be furnished by employees

-

(b) Compressed air used for cleaning. Compressed air shall not be used for cleaning purposes except where reduced to less than 30 p.s.i. and then only with effective chip guarding and personal protective equipment

1910.243 - Guarding of portable powered tools.

-

(c)(1) General requirements. Abrasive wheels shall be used only on machine provided with safety guards

-

(c)(3) Vertical portable grinders. Safety guards used on machines known as right angle head or vertical portable grinders shall have a maximum exposure angle of 180 deg., and the guard shall be so located so as to be between the operator and the wheel during use. Adjustment of guard shall be such that pieces of an accidentally broken wheel will be deflected away from the operator

1910.244 - Other portable tools and equipment.

(a) Jacks

-

(1)(ii) The rated load shall be legibly and permanently marked in a prominent location on the jack by casting, stamping, or other suitable means

-

(2)(iii) After the load has been raised, it shall be cribbed, blocked, or otherwise secured at once

-

(2)(vi) Each jack shall be thoroughly inspected at times which depend upon the service conditions. Inspections shall be not less frequent than the following: For constant or intermittent use at one locality, once every 6 months

Subpart R - Special Industries

1910.266 - Logging operations.

Subpart S - Electrical

-

303(b)(7) Mechanical execution of work. Electric equipment shall be installed in a neat and workmanlike manner

-

303(b)(7)(i) Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment

-

335(b)(2) Barricades. Barricades shall be used in conjunction with safety signs where it is necessary to prevent or limit employee access to work areas exposing employees to uninsulated energized conductors or circuit parts. Conductive barricades may not be used where they might cause an electrical contact hazard

-

335(a)(1)(ii) Protective equipment shall be maintained in a safe, reliable condition and shall be periodically inspected or tested, as required by 1910.13

-

335(a)(1)(v) Employees shall wear protective equipment for the eyes or face wherever there is danger of injury to the eyes or face from electric arcs or flashes or from flying objects resulting from electrical explosion

-

335(b)(1) Safety signs and tags. Safety signs, safety symbols, or accident prevention tags shall be used where necessary to warn employees about electrical hazards which may endanger them, as required by 1910.145

1910.303 - General.

(b) Examination, installation, and use of equipment

-

(1) Examination. Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees

-

(7)(i) Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment

-

(8)(i)<br>Electric equipment shall be firmly secured to the surface on which it is mounted

(c) Electrical connections

-

(3)(i) Splices: Conductors shall be spliced or joined with splicing devices identified for the use or by brazing, welding, or soldering with a fusible metal or alloy. Soldered splices shall first be spliced or joined to be mechanically and electrically secure without solder and then soldered. All splices and joints and the free ends of conductors shall be covered with an insulation equivalent to that of the conductors or with an insulating device identified for the purpose.

(f) Disconnecting means and circuits

-

(1) Motors and appliances. Each disconnecting means required by this subpart for motors and appliances shall be legibly marked to indicate its purpose, unless located and arranged so the purpose is evident

-

(2) Services, feeders, and branch circuits. Each service, feeder, and branch circuit, at its disconnecting means or overcurrent device, shall be legibly marked to indicate its purpose, unless located and arranged so the purpose is evident

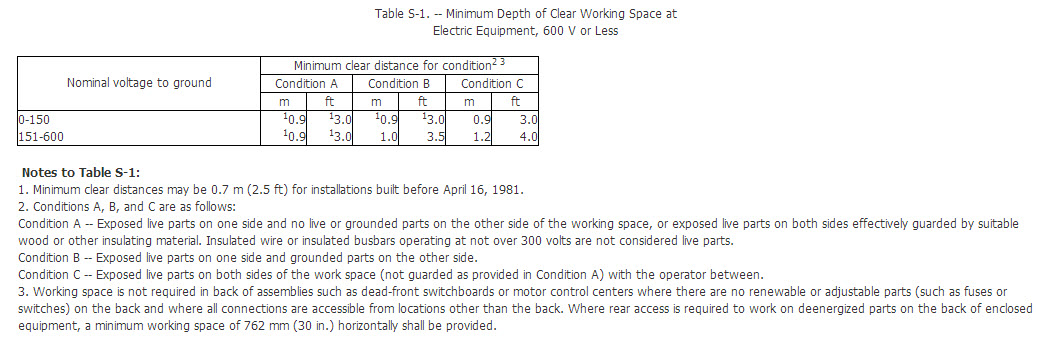

(g) 600 Volts, nominal, or less

-

(1) Space about electric equipment. Sufficient access and working space shall be provided and maintained about all electric equipment to permit ready and safe operation and maintenance of such equipment

-

-

(1)(i)(B) The width of working space in front of the electric equipment shall be the width of the equipment or 762 mm (30 in.), whichever is greater. In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels

-

(1)(ii) Working space required by this standard may not be used for storage. When normally enclosed live parts are exposed for inspection or servicing, the working space, if in a passageway or general open space, shall be suitably guarded

-

(1)(vii) Switchboards, panelboards, and distribution boards installed for the control of light and power circuits, and motor control centers shall be located in dedicated spaces and protected from damage

1910.304 - Wiring design and protection.

-

304(b)(3)(ii)(A) All 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of the permanent wiring of the building or structure and that are in use by personnel shall have ground-fault circuit-interrupter protection for personnel.

-

304(b)(3)(ii)(B) Receptacles other than 125 volt, single-phase, 15-, 20-, and 30-ampere receptacles that are not part of the permanent wiring of the building or structure and that are in use by personnel shall have ground-fault circuit-interrupter protection for personnel

-

304(b)(3)(ii)(C) Where the ground-fault circuit-interrupter protection required by paragraph (b)(3)(ii)(B) of this section is not available for receptacles other than 125-volt, single-phase, 15-, 20-, and 30-ampere, the employer shall establish and implement an assured equipment grounding conductor program covering cord sets

-

304(b)(3)(ii)(C)(6) Tests performed as required in paragraph (b)(3)(ii)(C) of this section shall be recorded. This test record shall identify each receptacle, cord set, and cord- and plug-connected equipment that passed the test and shall indicate the last date it was tested or the interval for which it was tested

-

304(f)(1)(viii) Circuit breakers used as switches in 120-volt and 277-volt, fluorescent lighting circuits shall be listed and marked "SWD."

1910.305 - Wiring methods, components, and equipment for general use.

-

1910.305(a)(2)(i)<br>Temporary electrical power and lighting installations of 600 volts, nominal, or less may be used only as follows:<br>1910.305(a)(2)(i)(A)<br>During and for remodeling, maintenance, or repair of buildings, structures, or equipment, and similar activities;<br>1910.305(a)(2)(i)(B)<br>For a period not to exceed 90 days for Christmas decorative lighting, carnivals, and similar purposes; or<br>1910.305(a)(2)(i)(C)<br>For experimental or development work, and during emergencies.<br>1910.305(a)(2)(ii)<br>Temporary wiring shall be removed immediately upon completion of the project or purpose for which the wiring was installed.<br>

-

305(a)(2)(ix) All lamps for general illumination shall be protected from accidental contact or breakage by a suitable fixture or lampholder with a guard

-

305(a)(2)(x) Flexible cords and cables shall be protected from accidental damage, as might be caused, for example, by sharp corners, projections, and doorways or other pinch points

-

305(b)(1)(i) Conductors entering cutout boxes, cabinets, or fittings shall be protected from abrasion, and openings through which conductors enter shall be effectively closed

-

305(b)(1)(ii) Unused openings in cabinets, boxes, and fittings shall be effectively closed.

-

305(g)(2)(iii) Flexible cords and cables shall be connected to devices and fittings so that strain relief is provided that will prevent pull from being directly transmitted to joints or terminal screws

-

305(g)(2)(ii) Flexible cords may be used only in continuous lengths without splice or tap. Hard-service cord and junior hard-service cord No. 14 and larger may be repaired if spliced so that the splice retains the insulation, outer sheath properties, and usage characteristics of the cord being spliced

1910.332 - Training

-

332(b)(3) Additional requirements for qualified persons. Qualified persons (i.e. those permitted to work on or near exposed energized parts) shall, at a minimum, be trained in and familiar with the appropriate subject matter

1910.333 - Selection and use of work practices

-

333(c)(2) "Work on energized equipment." Only qualified persons may work on electric circuit parts or equipment that have not been deenergized under the procedures of paragraph (b) of this section

-

333(c)(3)(iii)(A) Any vehicle or mechanical equipment capable of having parts of its structure elevated near energized overhead lines shall be operated so that a clearance of 10 ft. (305 cm) is maintained

1910.334 - Use of equipment.

-

334(c)(2) Visual inspection. Test instruments and equipment and all associated test leads, cables, power cords, probes, and connectors shall be visually inspected for external defects and damage before the equipment is used

1910.335 - Safeguards for personnel protection.

Subpart Z - Toxic and Hazardous Substances

Minnesota Rules Not otherwise classified

-

182.655, subd. 10(a), requires the <br>employer to provide suitable personal protective equipment "...by and at the cost of the <br>employer." Current interpretation of this requirement is that the employer is responsible <br>for providing at least the minimum cost of PPE that is of a type necessary for the job <br>being performed

-

5205.0116 (sub 1) CARBON MONOXIDE MONITORING: The employer shall monitor environmental exposure of employees to carbon monoxide whenever internal combustion engine powered industrial trucks are operated indoors. The air monitoring shall be done at least quarterly

-

5205.0116 (sub 2) CARBON MONOXIDE MONITORING: The employer shall ensure that powered industrial truck engine exhaust gases do not contain more than one percent carbon monoxide for propane fueled trucks or two percent carbon monoxide for gasoline fueled trucks measured at idle and at three-fourths throttle during final engine tuning in a regular maintenance program

-

5205.0020 HEAD PROTECTION: Employees working in areas where there is danger of scalp injury if the employee's hair should become entangled in moving machinery parts shall be protected by having their hair contained or secured in a shop cap, snood, or similar device

-

5205.0030 HIGH VIS. PPE: Each employee…..exposed to or working adjacent to moving motor vehicle traffic ….shall be provided with and required to wear a high visibility warning vest or other high visibility garment.

-

5205.0675 OVERHEAD DOORS Sub. 2 All overhead or sliding doors with sufficient weight or closing force to cause crushing injury to employees shall be provided with a constant pressure closing switch, safety edge, pressure relief mechanism, or three button control station

-