Information

-

Customer

-

Site Address

-

Post Code

-

Conducted on

-

Inspected By

-

Item Location

Preventative Maintenance and Safety Check

-

Control Type

- Controlled Entry, Free Exit

- Controlled entry and exit

Standard Preventative Maintenance

Gates

-

Gate Location

-

Gate Direction

-

Users and others who may encounter gate

-

Ensure the gates comply with BS EN 12453 and the current machinery directive. If not then the equipment must be isolated until further works are carried out

-

Please provide photographs

-

Take a photo from this side of the gate system

-

Height of gate (mm)

-

Width of each leaf (mm)

-

Motor Type

-

Number of motors

-

Motor voltage

-

Manufacturer of automation system

-

Model of Motors

-

Model of control unit

-

Photocells fitted?

-

Brief description of how photocells can be added E.G wireless, cabled etc

-

Take a picture

-

Safety edges fitted?

-

Brief description of number, sizes and type of edges required including wireless systems, end or through edges. If entrapment risk switch off system

-

Take a picture

-

manual override key available?

-

Type of override key required? key box required?

-

Do the gates move easily without great effort

-

Investigate and report

-

Take a photo

-

Inspect the condition of the motor spline and collar

-

Collar type

-

Add media

-

Lubricate hinges and inspect for wear

-

More info

-

Add media

-

Loops fitted

-

Mega test loops if applicable

Wherever Possible safe design has been used over application of safety devices to eliminate hazards:

-

Safe design hinge area?

-

Fixed guards and fences?

-

Anti-climb precautions taken with fences and guards?

Structural integrity (EHSR 1.3.1, 1.3.2, 1.3.6) The following are adequate to support at least 2 x the forces applied by the automation and expected wind loading's without permanent distortion:

-

Foundations?

-

Fixings

-

Brackets

-

Support Structures

-

Posts

-

Supporting masonry

-

Gate leaf structure

The following are adequate to support the gate and the forces applied by the automation and expected wind loading's and protect it from singe component failure hazards:

-

Hinges

-

Travel stops

Equipment on gate?

-

Loops?

-

Number? free exit? safety?

-

Keypad?

-

Make/Model

-

Add media

-

Intercom?

-

Make/Model

-

Add media

-

Remote Receiver

-

Make /Model

-

Add media

-

Warning Lights Fitted?

Safety Assessment

-

Check safety systems are compliant, shared pedestrian use, internal key pad, Push to exit buttons, Break glass, Gaps and External Beams.

-

System complies with EN SAFETY regulations

-

Supply details

-

All checks carried out to manufacturers instructions?<br>

-

Supply Details

Electrical Checks

-

Electrical certificate available in barrier and in date?

-

Does the electrical installation appear sound and correct

-

Is the wiring free from any poor connections<br>

-

Any signs of water ingress?

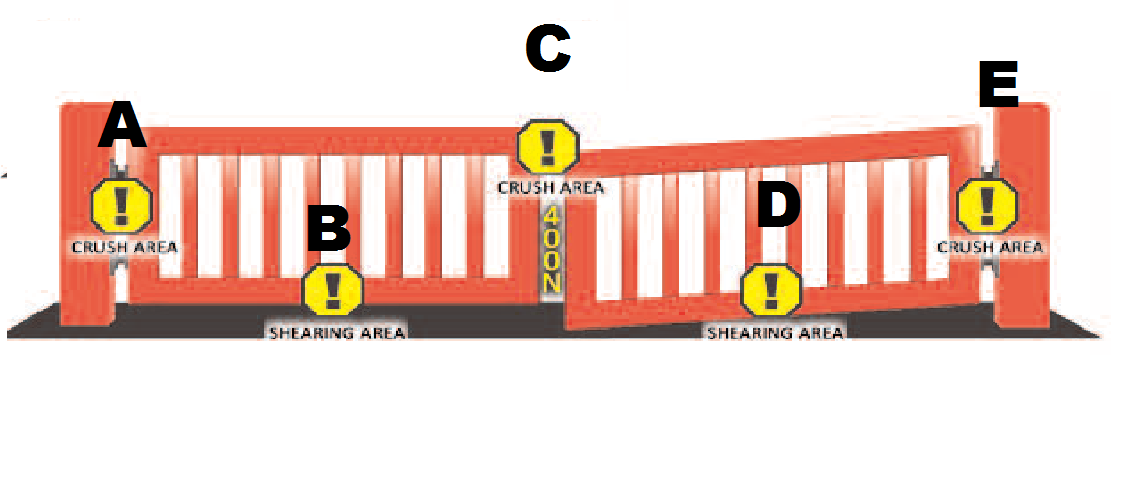

Installation diagram and assessment

-

Identify (if relevant) potential hazards at points labelled on diagram, and comment below

-

Include diagram from library

-

A - Crushing area at leading leaf hinge point

-

B - Shearing & crushing area at rear of leading leaf

-

C - Crushing area in between closing edge on gate leaves

-

D - Shearing & crushing area at rear of leading leaf

-

E - Crushing area at leading leaf hinge point

-

Recommendations

-

Additional photographs

Overall condition / Performance of system / additional information.

-

Defects? (list any defects that need attention)

-

Recommendations (list items that you would recommend

-

Engineer

-

Client representative