Title Page

-

Customer

-

Site address

-

Post code

-

Conducted on

-

Inspected By

-

Location

-

Risk assessments and method statements must be carried on all sites to ensure that the risk of injury or fatality is eliminated to users or members of the general public as a result of the system design.

Gates

-

Gate Location

-

Gate Direction

-

Users who may encounter the gate

-

Ensure the gate complies with BS EN 12453 and the current machinery directive. If the gate does not comply the system must be isolated and left open

-

Please provide photographs

-

Take a photo from the front and back of the gate

-

Height of gate

-

Width of gate

-

Approximate age of gate

-

Approximate number of cycles per day

-

Make and model of motor

-

Take a picture if unsure

-

Voltage of motor unit

-

Model of control unit

-

Photocells fitted?

-

Brief description of how photocells can be installed E.g. wireless, cabled etc

-

Safety edges fitted?

-

Brief description of number, sizes, wireless etc...

-

Manual override key available?

-

Put the gates into manual operation. Do the gates move effortlessly and freely

-

Investigate and report.

-

Take photographs if applicable

-

Are there stops front and back of the gate to prevent overrun?

-

Report.

-

Take photographs if applicable.

-

Lubricate all moving parts ensuring drive gear is well greased

Checklist

-

Inspect the condition of motor track and pinion

-

Check all electrical connections are tight and correct

-

Ensure all access control systems are working correctly

-

Loops in good condition? test with Megger.

-

Adjust and secure limits and strike plates

-

Check all buttons are working on keypad, all relays working? code change?

-

Ensure all safety systems are working correctly

Safety assesment

-

Check safety systems are compliant, shared pedestrian use, internal key pad, Push to exit buttons, Break glass, Gaps and External Beams.

-

Report on items that may make the system unsafe

-

System complies with EN SAFETY regulations

-

Supply details

-

All tests carried out to manufacturers guidelines

-

Supply Details

Electrical checks

-

Electrical certificate available in barrier and in date?

-

Does the electrical installation appear sound and correct

-

Is the wiring tidy and free from bad connections?

-

Provide photographs

-

Any signs of water ingress

-

Supply details

-

Additional information?

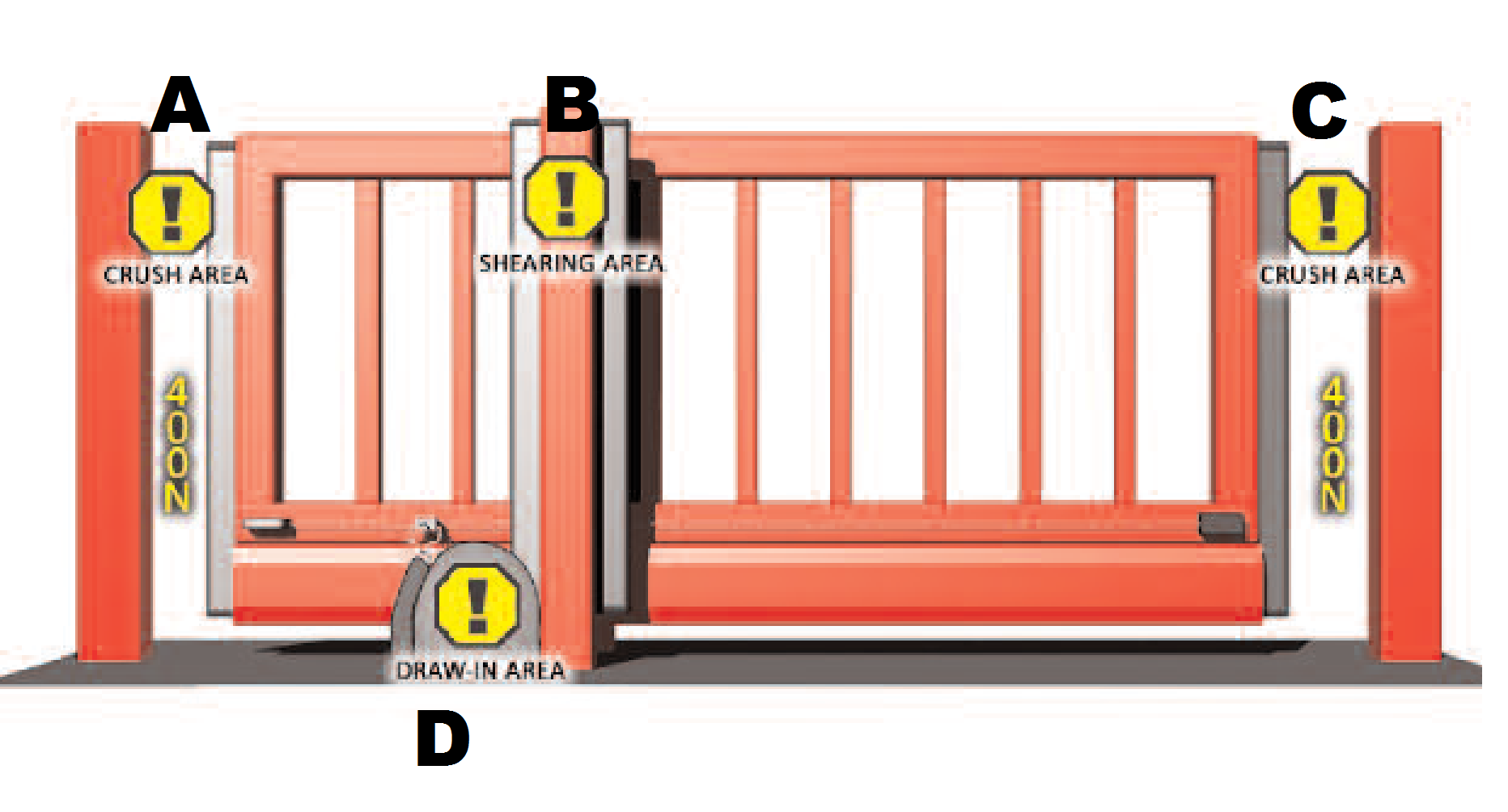

Installation diagram and assessment

-

Identify (if relevant) potential hazards at points labelled on diagram, and comment below

-

Include diagram from library

-

A - Crushing on rear opening edge

-

B - Shearing around any of the fixed portal posts or fence lines

-

C - Crushing on the main closing edge

-

D - Drawing in around any part of the moving motor parts of bearing wheels

-

Any additional photos

-

Reccomendations

Overall condition / Performance of system / additional information

-

Defects (list defects that need attention)

-

Recommendations (list items that you would recommend)

-

Engineer

-

Client representative