Title Page

TKNT Pty Ltd SLATER ELECTRICAL - ABN: 94 322 922 169

-

Date Document Completed

Technicians Full Name: Terrence Slater

Electrical Contractor Number: EC009778

Electrical Worker Number: EW164983

-

HWA Works Order Number #

-

Address

Safe Work Method Statement (SWMS) Install or Replace and Test Electrical Safety Devices - All sections must be completed in full ahead of works commencing.

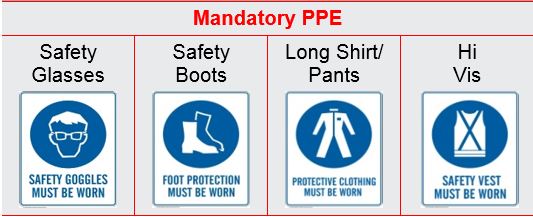

Personal Protective Equipment

-

Mandatory Personal Protective Equipment

-

Hand Protection

-

Dusk Mask

-

Other

-

* After completing this section, please proceed to the next section.

SWMS Tasks & Details

-

Install or Replace and Test Electrical Safety Devices

STEP 1 |Attend site and advise of interruption to supply on circuits under test

-

HAZARD(S): Tenant objects to works being performed

-

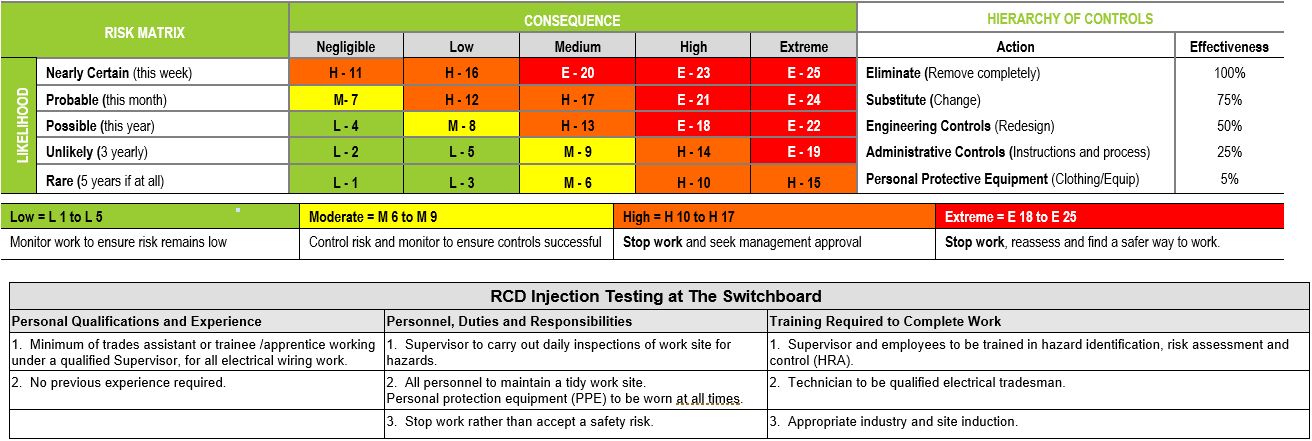

Risk Rating

-

CONTROL: Communicate & coordinate with Tenant. Service Center & Supervisor to prevent downtime

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 2 | Perform Take 5 Site Risk Assessment

-

HAZARD(S): Risks as identified

-

Risk Rating

-

CONTROL: Apply risk management processes to additional identified risks using the Hierarchy of Control

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 3 | Assess Switchboard for condition and age

-

HAZARD(S): Door falling off, Falling Debris into Switchboard, Electrocution, Identification of Asbestos & safe handling requirements

-

Risk Rating

-

CONTROL: If Switchboard in Poor Condition isolate main switch before removing covers

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 4 | Isolate, test, tag and lock out main supply

-

HAZARD(S): Electrocution

-

Risk Rating

-

CONTROL: Ensure use of calibrated electrical test equipment (if Live, conduct work in accordance with AS/NZS 4836 Safe Work Live Practices and AS/NZS 3017 Testing & Inspecting guidelines, ensure voltage disconnected)

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 5 | Remove switchboard covers

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Manual Handling injuries (Sprains, Strains); Trip hazard, cuts and pinch points

-

Risk Rating

-

CONTROL: Ensure workers are trained in correct Manual Handling techniques, Ensure SWB cover is away from traffic areas, wear gloves where appropriate

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 6 | Assess behind switchboard covers for condition and age

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Electrocution, Falling Debris into, Switchboard, Breakdown of insulation on bus-bars, UN-terminated cables

-

Risk Rating

-

CONTROL: Test all exposed terminals for dead, if switchboard is deemed unsafe reinstate covers, Take Photos and Report issue and seek direction on how best to proceed.

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 7 | Reinstate power supply if isolated in step 3

-

HAZARD(S): Electrocution

-

Risk Rating

-

CONTROL: All employees to be aware of live services, Use of Insulation Mats where applicable

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 8 | Impose fault current on circuit and record trip time - trip time is required to be 40ms or less.

-

Is this work task required? If Yes proceed with risk assessment

-

Hazard: Arcing of contacts projecting foreign matter into eye

-

Risk Rating

-

CONTROL: Safety glasses or face shield to be worn and be aware of live services, Use of Insulation Mats where applicable and use calibrated electrical test equipment, insulated gloves

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 9 | Reset circuit and conduct push button test, confirm operation

-

Is this work task required? If Yes proceed with risk assessment

-

Hazard: Arcing of contacts projecting foreign matter into eye

-

Risk Rating

-

CONTROL: Safety glasses or face shield to be worn and be aware of live services, Use of Insulation Mats where applicable and use calibrated electrical test equipment, insulated gloves

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 10 | If RCD fails either push button or trip time tests then replace RCD and repeat tests

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Electrocution

-

Risk Rating

-

CONTROL: Isolate circuit, wear safety glasses

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 11 | Reinstate Switchboard covers

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Manual Handling injuries (Sprains, Strains); Trip hazard, cuts and pinch points

-

Risk Rating

-

CONTROL: Ensure workers are trained in correct Manual Handling techniques, Ensure SWB cover is away from traffic areas, wear gloves where appropriate and before leaving ensure cover is secure

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 12: Perform Smoke Alarm visual check and push button test.

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Manual Handling injuries (Sprains, Strains); Noise, Trip hazard, Fall from Ladder

-

Risk Rating

-

CONTROL: Ensure workers are trained in correct Manual Handling techniques, Ensure ladder is fit for use, secure and on flat surface and all trip hazards removed from work area and hearing protection worn.

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 13: If Smoke Alarm tests fail, then replace smoke alarm with approved brand and label, reconnect supply, test and commission

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Manual Handling injuries (Sprains, Strains); Noise, Falling debris, Trip hazard, Fall from Ladder

-

Risk Rating

-

CONTROL: Ensure workers are trained in correct Manual Handling techniques, Ensure ladder is fit for use, secure and on flat surface and all trip hazards removed from work area and hearing & eye protection worn.

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 14: Perform visual inspection of main earth wire and electrode, where damaged repair or replace (isolate supply if replacing) refer to Step 4.

-

Is this work task required? If Yes proceed with risk assessment

-

HAZARD(S): Manual Handling injuries (Sprains, Strains); Trip hazard

-

Risk Rating

-

CONTROL: Ensure workers are trained in correct Manual Handling techniques and all trip hazards removed from work area.

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

STEP 15: Once all Tasks have been completed and before leaving site, Reinstate power supply

-

HAZARD(S): Electrocution

-

Risk Rating

-

CONTROL: All employees to be aware of live services, Use of Insulation Mats where applicable

-

Residual Risk after Control Implemented (NOTE: Where High or Extreme risks have been identified - Stop Work and report to Supervisor)

-

RESPONSIBLE PERSONS: Supervisors, Workers

TOOLS AND EQUIPMENT MAINTENANCE INSPECTIONS | Checked Ladders for compliance, Checked all electrical leads are tested with current compliance tag, Checked all tools and all testing equipment is calibrated and fit for use.

REFERENCES| Legislation/ regulations/ standards/ codes of practices/ guidelines that are relevant to this activity/ task: AS/NZS 4836 Safe Work Live Practices, AS/NZS 3017 Electrical Installations, testing and inspections guidelines, Electricity (Licensing) Regulations, Programmed Policies, Programmed Life Saving Rules and Procedures, Manufactures Product Instructions

VERIFICATION & INDUCTION SIGN-OFF

SWMS Prepared, Reviewed and Approved By: Terrence Slater Director 4/10/2018

I have reviewed this Safe Work Method Statement (SWMS) and agree with this safe work procedure. I am aware of all the job steps, hazards and control measures that will be implemented and will work to this safe work procedure. I will complete a daily JSEA as required. I have also reviewed all the Safety Data Sheets (SDS) and have assessed all the plant and equipment that is to be used by myself for this task. I will work within the recommended safe procedures for SDS, plant and equipment for this period.

-

SWMS Agreed and understood.