Title Page

-

Prepared by

-

Conducted on

-

Site conducted

-

Solarvista Job Number

-

Verisae WON

Maintenance Tasks

-

Erect signage of work area to warn of work in progress

Pack

Details

-

System Number

- HT1

- HT2

- HT3

- HT4

- HT5

- HT6

- HT7

- HT8

- HT9

- HT10

- LT1

- LT2

- LT3

- LT4

- LT5

- LT6

- LT7

- LT8

- LT9

- LT10

- DT1

- DT2

- DT3

- DT4

- DT5

- DT6

- DT7

- DT8

- DT9

- DT10

- HT/LT1

- HT/LT2

- HT/LT3

- HT/LT4

- HT/LT5

- HT/LT6

- HT/LT7

-

Make

-

Model

-

Serial Number

-

Date Of Manufacturer

-

Confirm PRV's Are In Date and Tagged

Safety Checks

-

Ensure the work area is clear from any obstruction

-

Check the general condition of asset

-

Perform test run to confirm asset is operational

Visual Inspections

-

Confirm asset tag is in place & not damaged

-

Manually test operation of plant ventilation override

-

Confirm correct warning labels are displayed on plant housing and control panels

-

Ensure panel keys are in place

-

Ensure all electrical drawings & manuals are on site, up to date & available to access

-

Confirm electrical components are not overheating or arcing

-

Ensure all pressure relief valves are connected to blow off lines

-

Confirm pack housing has no internal/ external damage

Electrical Tasks

-

Confirm isolator engineer interlock is functioning correctly

-

Confirm earthing and continuity to all metal work and sub circuit components

-

Ensure electrical panel and interior of pack casing is clean and free from debris.<br>Confirming trunking covers and electrical cables are tidy

-

Confirm UPS does not have any warning lights lit.

-

Using an infra red thermometer record the temperatures. Should not exceed 40 degrees

-

Confirm control voltage is 24vdc

-

Confirm PLC/Controller is operational & staging compressor in/out

-

Examine overloads and confirm they are set for 10 % above operational amps. Refer to<br>compressor/motor data plate

-

Confirm crankcase heaters are operational<br>

-

Confirm operation of housing extract fan, isolate and clean if required using a soft brush<br>(where Fitted)

-

Confirm Inverters are operational

Refrigeration Tasks

-

Confirm all compressor mounts and fixings are in place and secure

-

Confirm service valve connections are secure and leak free. corroding valves should be<br>cleaned and protected

-

Check for pressure drop across the Oil filters

-

Confirm oil management system is working correctly

-

Confirm oil level is adequate and visually inspect oil for any sign of burn out or acidity

-

Confirm liquid level is correct **at least 20% for G&C and Bottom Level Glass for Space & Teko**

-

Confirm transducers are reading correctly in correlation with gauges

-

Confirm all Temp probes are in the correct place and secure and reading correctly

-

Confirm liquid line filter (where present) and change where necessary, or remove if manufacturers spec is to remove.

-

Confirm main safety switch is fitted and operational with no signs of damage and<br>operation is at correct pressure **Label with set pressure and date tested**

-

Confirm pressure vessels are clear of corrosion or damage

-

Confirm there are no signs of damage to insulation to Pressure vessel and heat exchanger

-

Confirm components and pipework are clear of rubbing or damage

-

Carry out a pressure differential test and confirm no Suction filter is present

-

Confirm all components and pipework are clear of any signs of accumulation of ice

-

Confirm pipe work is free from any signs of damage, or leaks

-

Confirm pipe brackets and clips are tight and secure

-

Leak Test all components & pipework for any leaks. Confirm there are no leaks with an<br>electronic leak detector

Gas Cooler

-

The cleaning of the gas cooler may not be required for this section if the gas cooler has been cleaned by our gas cooler cleaning engineer.

-

Confirm that the rotation of gas cooler fans and the operation of the controllers is correct

-

Confirm all condenser fan fixings, blades and fan guards are in place and secure

-

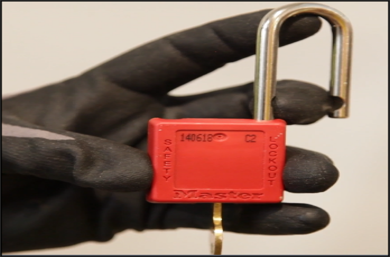

Lock out Tag out Gas cooler fan (only carry out clean of one fan at a time )

-

Brush off debris from underneath the gas cooler prior to jet washing.

-

Jet wash all fins until water runs clear

-

Confirm Gas Cooler is Clean with photos

-

Confirm Gas cooler fins are clear from any damage or corrosion. If fins are damaged<br>straighten using correct size fin comb

-

Remove any debris from underneath Gas cooler

Completion

-

Confirm all electrical panel doors are closed and pack housing has no internal damage

-

Confirm isolators are engaged with the interlocks<br>

-

Leave work area in a Clean & tidy condition

-

Close and lock Plant Doors ensuring they are secure

-

Remove any signage used. Return any Keys used to store

Shop Floor

Shop Floor Cabinets

-

Leak test all shop floor cabinets and pipe components with an electronic leak detector

-

Confirm all system dividers are in place and undamaged

-

Clean all shop floor integral condensers

-

Record any fabric issues with shop floor cabinets

Monitoring Panel

-

Confirm on Alarm Panel all fixtures are running to Tesco Specification and are<br>communicating

-

Confirm Battery Status is not in alarm indicated at the top of the screen Replace if<br>required

-

Confirm with area desk engineer that there are no active alarms on IMS

Signature

-

I confirm that this PPM has been completed with any issues recorded.