Title Page

-

Prepared by

-

Conducted on

-

Site conducted

-

Solarvista Job Number

-

Verisae WON

Maintenance Tasks

-

The purpose of this document is to guide you through all tasks to be completed on a Major PPM on Tesco Larger Stores (All Stores with the exception of Express Stores) and to document all PPM's that we complete on our clients sites.

Pack

Details

-

System Number

- HT1

- HT2

- HT3

- HT4

- HT5

- HT6

- HT7

- HT8

- HT9

- HT10

- HT11

- HT12

- HT13

- LT1

- LT2

- LT3

- LT4

- LT5

- LT6

- LT7

- LT8

- LT9

- LT10

- LT11

- LT12

- LT13

- DT1

- DT2

- DT3

- DT4

- DT5

- DT6

- DT7

- DT8

- DT9

- DT10

- DT11

- DT12

- DT13

-

Asset Number

-

Make

-

Model

-

Serial

-

Year of Manufacture

-

Are PRV's in Date and Tagged

-

Expiry Date

-

Are PRV's Tagged

-

If PRV's are Out Of Date, Details of PRV's Required

Safety Checks

-

Erect Signage Close to Work Area to Warn of Any Work in Progress

-

Ensure Work Area is Clear From Any Obstruction

-

Check General Condition of Asset

-

Perform Test Run To Confirm Asset is Operational

Visual Inspections

-

Confirm Asset Tag is In Place and Not Damaged

-

Confirm Correct Warning Labels are Displayed on Control Panel Door

-

Confirm Mains Incoming Isolator Terminal Shields are in Place

-

Confirm Panel Wiring and Components Have No Signs of Over Heating Damage

-

Confirm Pack Has no Liquid Flood Back

-

Confirm Oil Level is Achieved in All Compressors & Oil Separators

-

Confirm Liquid Reciever is Free From Corrosion & Damage

-

Confirm All PRV's are Connected To Vent Lines

-

Confirm There is a Visible Level in The Bottom Indicator of the Liquid Line Sight Glass

Electrical Tasks

-

Confirm Isolator Engineer Interlock is Functioning Correctly. **This Allows Access to Control**

-

Using an Infrared Thermometer, Record Mains Terminal Temperatures **Should Not Exceed 40°c**

-

Confirm All Ventilation Panel Fans are Working and Filters are Clear of Debris

-

Confirm All Overloads and Trips are Operational

-

Confirm All Compressors Run When Required by Pack Controller

-

Check All Compressor Run Currents From The Overload

-

Confirm Against Compressor Data Plates That All Overloads Are Set No Higher Than 10% Above The Full Load Amps

-

Confirm All Crankcase Heaters are Operational

Refrigeration Tasks

-

Confirm Operation of Housing Extract Fan, Isolate and Clean Using A Soft Brush

-

Confirm All Compressor Mounts and Fixings Are Present and Secure

-

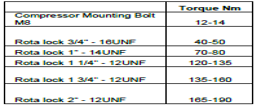

Rota Lock Torque Chart

-

Confirm All Compressor Rota Lock Valves are Tightened To Correct Torque Setting

-

Confirm Compressor Vapour/Liquid Injection is Operational with Compressor Running (LT ONLY)

-

Visually Inspect Oil in Compressors and Oil Separators/Reservoir Sight Glasses for Any Signs of Burnout or Acidity.

-

Confirm Oil Separator for Excessive Pressure Drop Across the Internal Filter. **If Pressure Drop is More Than 20PSI Filter Requires To Be Replaced**

-

Test All Override and Safety Switches, Confirm Safety Switches Operate at The Correct Pressure. **Label Switches With Test Date and Set Pressure**

-

Trip Main Pack Controller to Confirm the Plant Runs in Backup Mode, Reset The Main Controller After Task. **Label Back up controller with High Suction Set Point and Time**

-

Confirm With Service Gauges That Pressure Transducers are Reading Correctly for the Main Pack Controller and Backup Controller

-

Replace Liquid Line Drier Core. **Label Plant or Drier Housing With Date of Replacement**

-

Leak Test All Refrigeration Pipework & Components

Condenser

-

Test For Non Condensable in Condenser

-

Confirm All Condenser Fan Fixings, Blades and Fan Guards are In Place and Secure

-

Confirm That The Rotation of Condenser Fans and The Operation of The Controllers is Correct

-

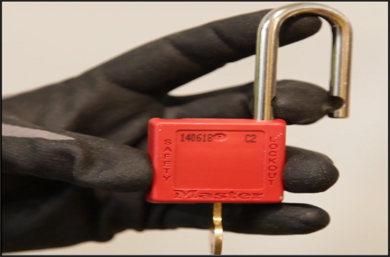

Brush Off Debris from Underneath the Condenser Prior to Jet Washing. Lock Off and Tag off Each Fan When Jet Washing the Condenser.

-

Remove One Fan At A Time and Jet Wash Condenser Down Through From Above, Ensure Water is running Clear When Completed. **upload Photo of Condenser After Clean**

-

Confirm Condenser Fins Are Clear From Any Damage Or Corrosion. If Fines are Damaged, Straighten Using Correct Size Fin Comb

Completion

-

Ensure Electrical Panel and Interior of Pack Housing is Clean and Free From Debris

-

Ensure Electrical Panel Door Fully Closes and Locks are Engaged

-

Ensure All Drawings are Left in Designated Folder

-

Leave Work Area In a Clean & Tidy Condition

-

Close and Lock Plant Doors, Ensuring Canopy Locks are in Place

Shop Floor

-

Leak Test All Shop Floor Refrigeration Cabinets, Pipework and Components

Monitoring Panel

-

Confirm on Alarm Panel All Cases are Running to Set Point & Communicating

-

Confirm Battery Status, Replace if Required

-

Confirm All Alarms are Clear and Healthy On Ims. **Area Desk Engineer Will Confirm**

Signature

-

All Tasks On This PPM Are Complete